Chapter 4. Chips, Ahoy!

Before I get into the fascinating topic of integrated circuit chips (often referred to as ICs or simply chips), I have to make a confession. Some of the things I asked you to do in previous experiments could have been done a bit more simply, if we had used chips.

Does this mean you have been wasting your time? Absolutely not! I firmly believe that by building circuits with individual components such as transistors and diodes, you acquire the best possible understanding of the principles of electronics. Still, you are going to find that chips containing dozens, hundreds, or thousands of transistor junctions will enable some shortcuts.

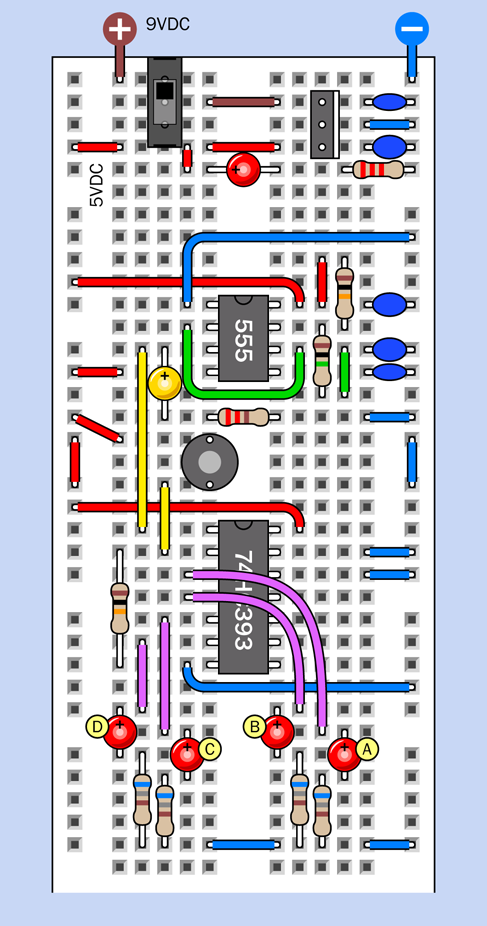

You may also find chips curiously addictive to play with—although you may not become quite as excited as the character in Figure 4-1.

The tools, equipment, components, and supplies described below will be useful in Experiments 16 through 24, in addition to items that have been recommended previously.

Figure 4-1. My role model.

Necessary Items for Chapter Four

The only new tool that you might consider using in conjunction with chips is a logic probe. This tells you whether a single pin on a chip has a high or low voltage, which can be helpful in figuring out what your circuit is doing. The probe has a memory function so that it will light its LED, and keep it lit, in response to a pulse that may have been too quick for the eye to see.

Some of my readers disagree with me, but I regard the logic probe as optional, not essential. Search online and buy the cheapest one you can find. I don’t have any specific brand recommendations.

Components

As before, if you want kits containing components, see “Kits”. If you prefer to buy your own components from online sources, see “Components”. For supplies, see “Supplies”.

Fundamentals: Choosing Chips

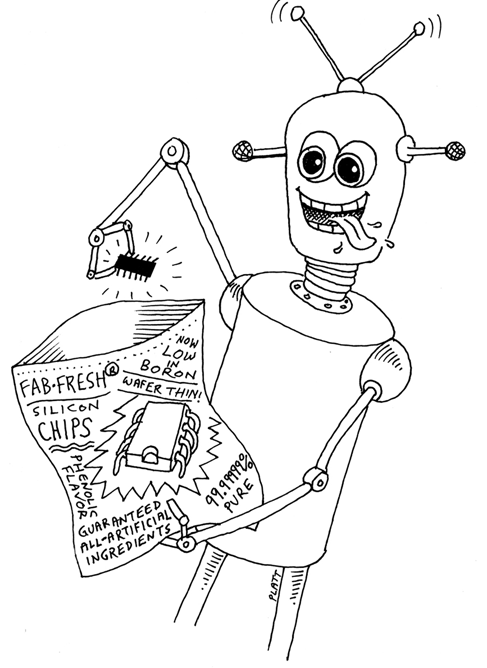

Figure 4-2 shows two integrated circuit chips. The one at the top is of the old-school, through-hole design, with pins spaced at 1/10” so that they will fit through the holes in your breadboard or perforated board. These are the chips I will be using exclusively, because they’re easy to handle. The smaller chip is a surface-mount design, which I will not be using, because they don’t fit breadboards or perforated boards and are difficult to handle.

Many through-hole and surface-mount chips are functionally identical. The only difference is the size (although some surface-mount versions use a lower voltage).

The body of a chip is usually made of plastic or resin and is often referred to as the package. The traditional chip is usually sold in a dual-inline package, meaning that it has two (i.e., dual) rows of pins. The acronym for this package is DIP or (when it is made of plastic) PDIP.

Figure 4-2. A through-hole chip (top) and surface-mount chip (bottom).

Surface-mount packages often are identified with acronyms beginning with letter S, as in SOIC, meaning small-outline integrated circuit. Numerous surface-mount variants exist, with different pin spacing and other specifications. They are all outside the scope of this book, and if you buy your own components, you should be careful not to select them by mistake.

Inside the package, the circuit is etched on a tiny wafer of silicon, which is where the term “chip” comes from, although the whole component is now usually referred to as a chip, and I will follow that convention here. Tiny wires inside the package link the circuit with the rows of pins that protrude on either side.

The PDIP chip in Figure 4-2 has seven pins in each row, making a total of 14. Other chips may have 4, 6, 8, 16, or more pins.

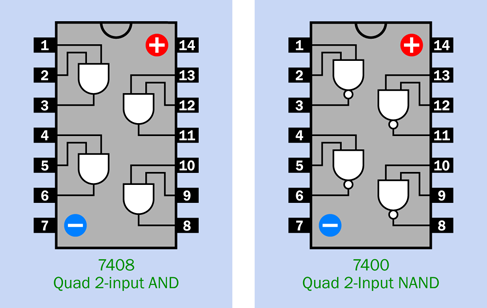

Just about every chip has a part number printed on it. Notice in the photograph that even though the chips look quite different from each other, they both have “74” in their part numbers. This is because both of them are members of the family of logic chips that were assigned part numbers from 7400 and upward when they were introduced several decades ago. This is often referred to as the 74xx family, and I’ll be using these chips a lot.

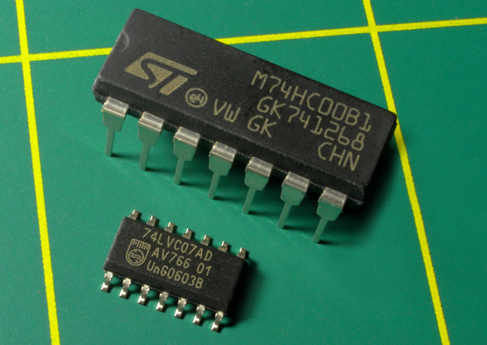

Take a look at Figure 4-3. The initial letters identify the manufacturer, which you can ignore, as it really makes no difference for our purposes. (If you are wondering why “SN” identifies Texas Instruments, it’s because the company used to call their chips “semiconductor networks” in the early days.)

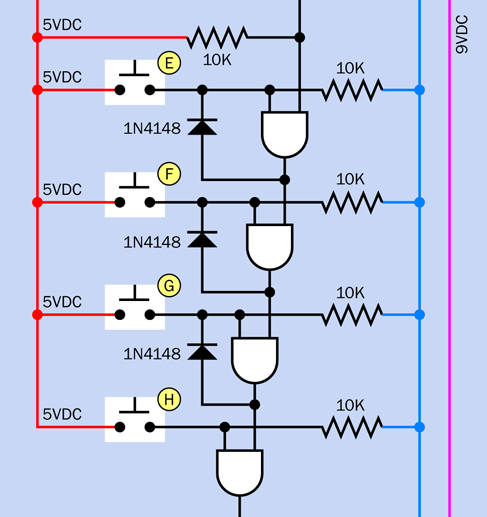

Skip the letters until you get to the “74.” After that, you find two more letters, which are important. The 7400 family has evolved through many generations, and the letter(s) inserted after the “74” tell you which generation you’re dealing with. Generations have included: 74L, 74LS, 74C, 74HC, and 74AHC. There are many more.

Figure 4-3. How to decode the part number of a chip in the 74xx family.

Generally speaking, later generations tend to be faster or more versatile than earlier generations. In this book, I am using the HC generation of the 7400 family exclusively, because almost all 7400 chips are available in it, the cost is moderate, and the chips don’t use a lot of power. For our purposes, the extra speed offered by later generations is not relevant—although you can certainly use the HCT generation if you prefer.

Following the letters identifying the generation, you’ll find a sequence of two, three, four, or (sometimes) five digits. These identify the specific function of the chip. Following the digits is another letter, or two letters, or more. For our purposes, those terminating letters are not important.

Looking back at Figure 4-2, the DIP chip part number, M74HC00B1, tells you that it is a chip made by STMicroelectronics, in the 74xx family, HC generation, with its function identified by numerals 00.

The purpose of this long explanation is to enable you to interpret catalog listings if you go chip shopping. You can search for “74HC00” and the search engines at online vendors are usually smart enough to show you appropriate chips from multiple manufacturers, even though there are letters preceding and following the term that you’re searched for.

Just be sure that they will fit your breadboard. Limit your search results to DIP, PDIP, or through-hole packages. If the part number begins with SS, SO, or TSS, it’s absolutely definitely surface-mount, and you don’t want it. For a lot more information on searching and shopping, see “Searching and Shopping Online”.

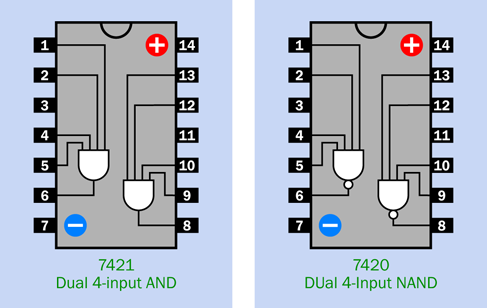

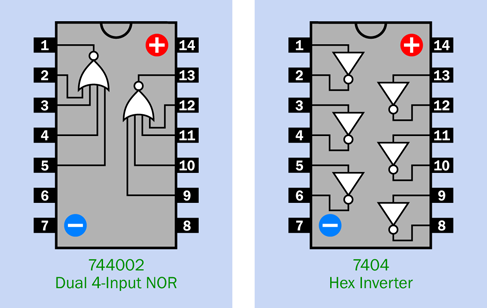

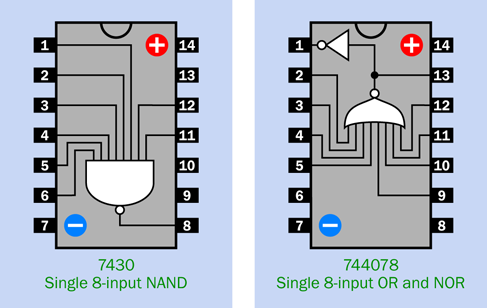

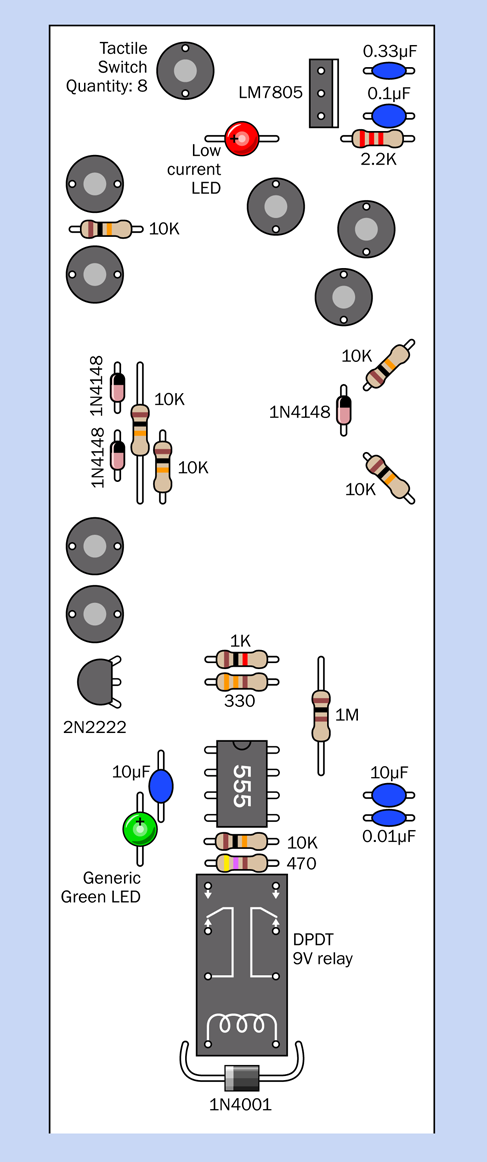

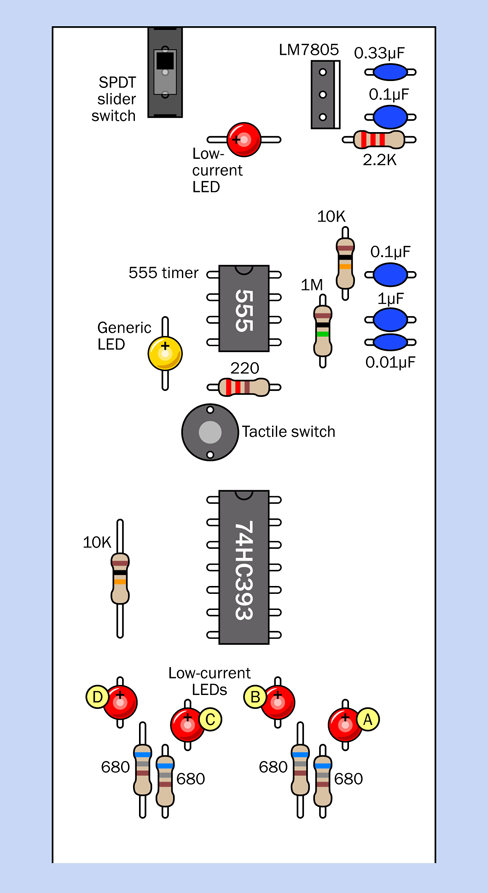

All the chips needed for the experiments in this chapter of the book are listed in Figure 6-7. You will need a few other types of components, which I will list here.

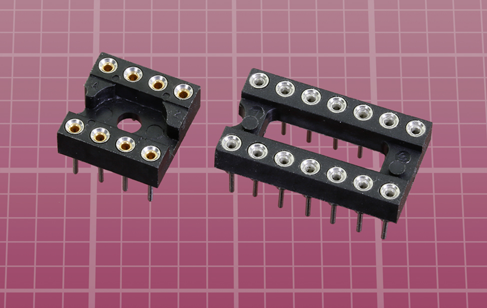

Optional: IC Sockets

If you plan to immortalize any of your circuits in solder, I suggest you avoid soldering chips directly, because if you make a wiring error or damage the chip, you have to desolder multiple pins in order to remove it. This is very difficult. To avoid the problem, buy some DIP sockets, solder the sockets onto the board, and then plug the chips into the sockets. You can use the cheapest sockets you can find (you don’t need gold-plated contacts for our purposes). You will need 8-pin, 14-pin, and 16-pin sockets. Quantity of each: 5 minimum. Two sockets are shown in Figure 4-4.

Figure 4-4. To avoid the risk of damaging a chip by soldering it directly, it can be mounted in an IC socket after the socket has been soldered into a circuit board.

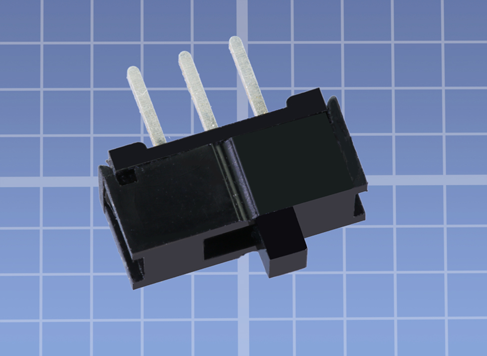

Essential: Subminiature Slide Switch

A slide switch has a tiny lever that you slide to and fro with the tip of your finger, making and breaking an electrical contact inside the switch, as shown in Figure 4-5. It has three pins spaced 0.1” apart (2.54mm in metric). If you buy your own components, see “Other Components” and go down to the subhead “Components for Chapter Four” for more information about switches.

Figure 4-5. The subminiature slide switch recommended for projects in this book.

Caution: Switching Overload

A very small slide switch is not designed to switch significant currents or voltages. It is designed for low-powered circuits. A limit may be as low as 100mA at 12VDC. This is sufficient for our purposes. Check the manufacturer’s datasheet if you want a slide switch to do more than this.

Essential: Low-Current LEDs

HC series logic chips are not designed to deliver current much beyond 5mA. You can take as much as 20mA from them to drive an LED, but this will pull down the output voltage, making it unsuitable as an input to other logic chips. I am suggesting low-current LEDs for all your experiments with logic chips.

Remember that low-current LEDs require higher-value series resistors, because they don’t tolerate as much current as generic LEDs. I will mention this wherever it is important.

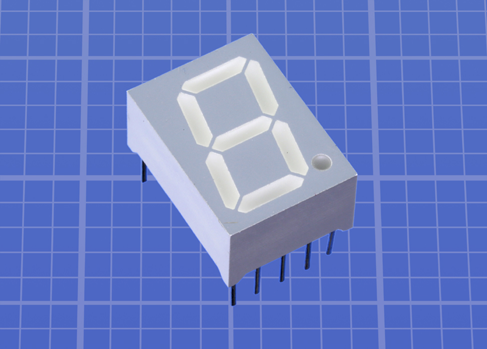

Essential: Numeric Displays

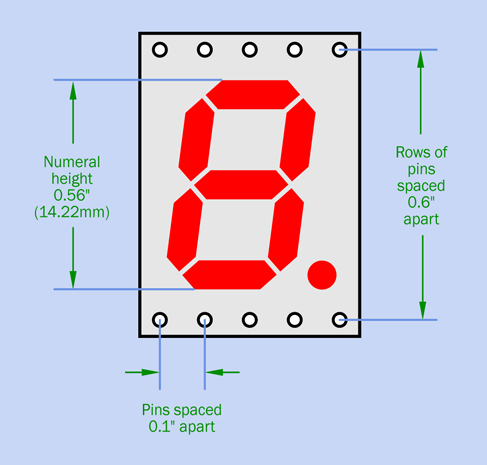

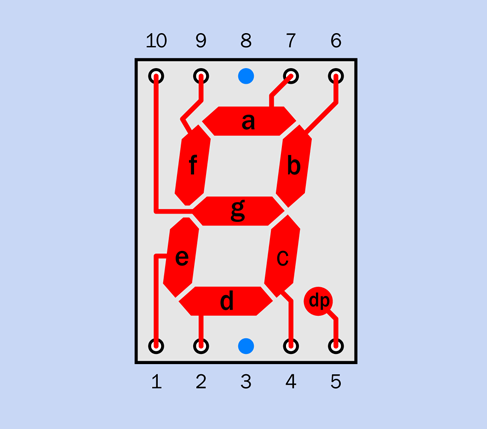

One of the chip projects will display its output using seven-segment numeric displays—the simple kind of digits that you still find on digital clocks and microwave ovens. See Figure 4-6. For purchasing information, see “Other Components” and go down to the subhead “Components for Chapter Four.”

Figure 4-6. Seven-segment displays are the cheapest way to show a numeric output and can be driven directly by some CMOS chips.

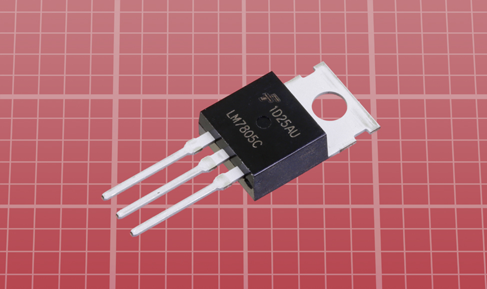

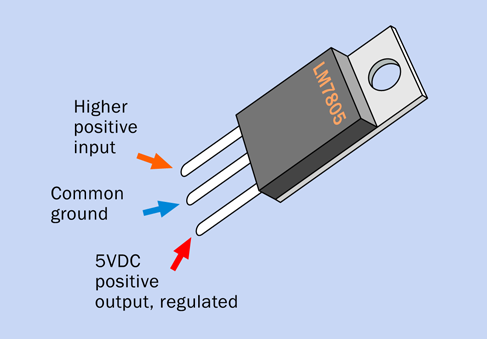

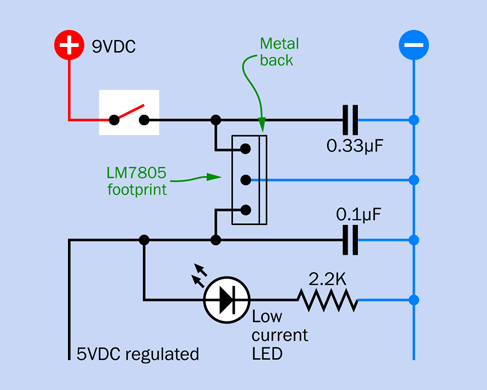

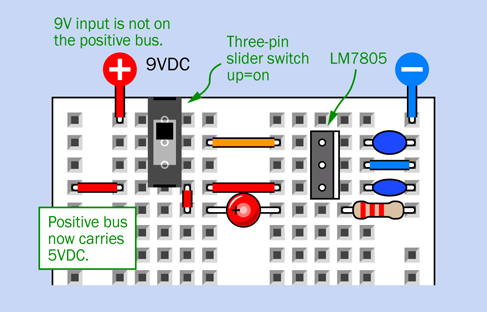

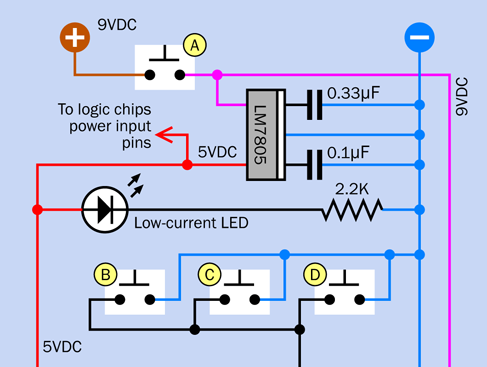

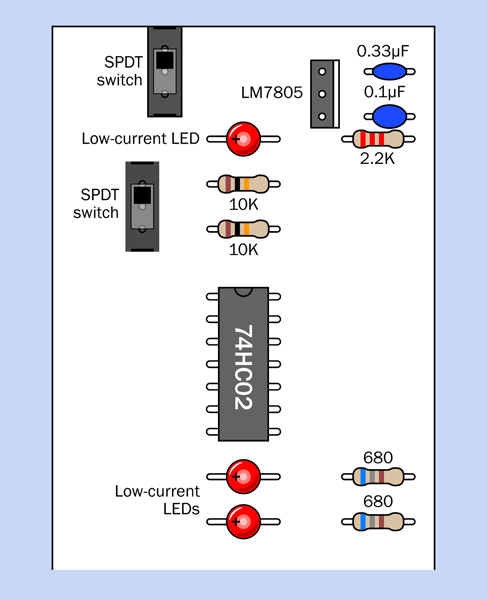

Essential: Voltage Regulator

Because many logic chips require precisely 5 volts DC, you need a voltage regulator to guarantee this. The LM7805 does the job. The chip number will be preceded or followed with an abbreviation identifying the manufacturer and package style, as in the LM7805CT from Fairchild. Any manufacturer will do, but the regulator should look like the one in Figure 4-7. (This is known as the TO220 package style.) You need them in any logic circuit, so five would be a good number to have available.

Optional Extras

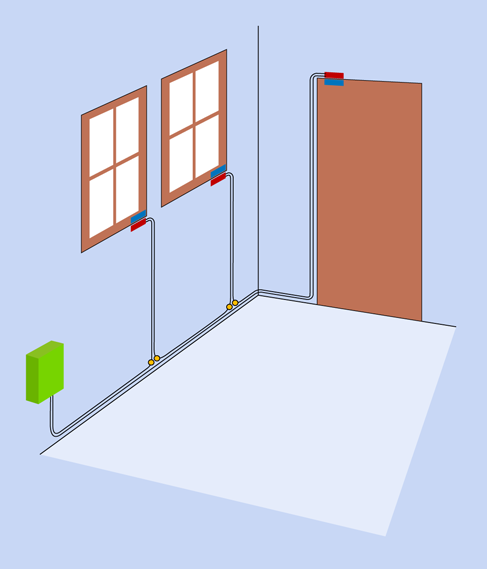

To complete the alarm system in Experiment 18, you will require magnetic sensors that you can apply to doors or windows, such as the Directed model 8601, available from dozens of sources online.

If you expect to move a project from a breadboard to a permanent enclosure, the tactile switches that you have been using will be insufficiently sturdy or accessible. For Experiment 18, you will need a full-size DPDT pushbutton switch, ON-(ON) type, with solder terminals. If you search eBay for “DPDT pushbutton” there will be no shortage of options.

Figure 4-7. Many integrated circuit chips require a controlled power supply of 5 volts, which can be delivered by this regulator from a supply of 7.5 to 12 volts.

Background: How Chips Came to Be

The concept of integrating solid-state components into one little package originated with British radar scientist Geoffrey W. A. Dummer, who talked about it for years before he attempted, unsuccessfully, to build one in 1956. The first true integrated circuit wasn’t fabricated until 1958 by Jack Kilby, working at Texas Instruments. Kilby’s version used germanium, as this element was already in use as a semiconductor. (You’ll encounter a germanium diode when I deal with crystal radios in Experiment 31.) But Robert Noyce, pictured in Figure 4-8, had a better idea.

Figure 4-8. Robert Noyce, who patented the integrated circuit chip and cofounded Intel.

Born in 1927 in Iowa, Noyce moved to California in the 1950s, where he found a job working for William Shockley. This was shortly after Shockley had set up a business based around the transistor, which he had coinvented at Bell Labs.

Noyce was one of eight employees who became frustrated with Shockley’s management and left to establish Fairchild Semiconductor. While he was the general manager of Fairchild, Noyce invented a silicon-based integrated circuit that avoided the manufacturing problems associated with germanium. He is generally credited as the man who made integrated circuits possible.

Early applications were for military use, as Minuteman missiles required small, light components in their guidance systems. These applications consumed almost all chips produced from 1960 through 1963, during which time the unit price fell from around $1,000 to $25 each, in 1963 dollars.

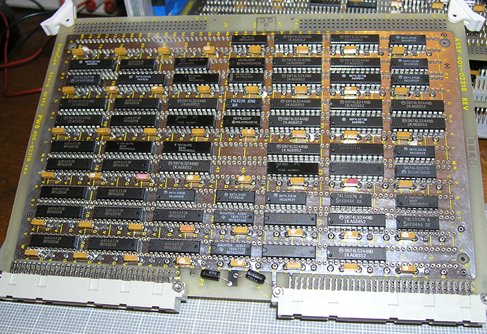

In the late 1960s, MSI (medium-scale integration) chips emerged, each containing hundreds of transistors. LSI (large-scale integration) enabled tens of thousands of transistors on one chip by the mid-1970s, and today’s computer chips can contain several billion transistors.

Robert Noyce eventually cofounded Intel with Gordon Moore, but died unexpectedly of a heart attack in 1990. You can learn more about the fascinating early history of chip design and fabrication at the Silicon Valley Historical Association.

Experiment 16: Emitting a Pulse

I’m going to begin our experiments with chips by introducting you to the most successful one ever made: the 555 timer. You can find numerous guides to it online, so why do I need to discuss it here? I have three reasons for doing so:

It’s unavoidable. You simply have to know about this chip. Some sources estimate that more than 1 billion are still being manufactured annually. It will be used in one way or another in most of the remaining circuits in this book.

It’s useful. The 555 is probably the most versatile chip that exists, with endless applications. Its relatively powerful output (rated at up to 200mA) is extremely useful, and the chip itself is hard to damage.

It’s misunderstood. After reading literally dozens of guides, beginning with an early Signetics datasheet and making my way through various hobby texts, I concluded that the inner workings of the chip are seldom explained on an introductory level. I want to give you a graphic understanding of what’s happening inside it, because if you don’t have this, you won’t be in a good position to use the chip creatively.

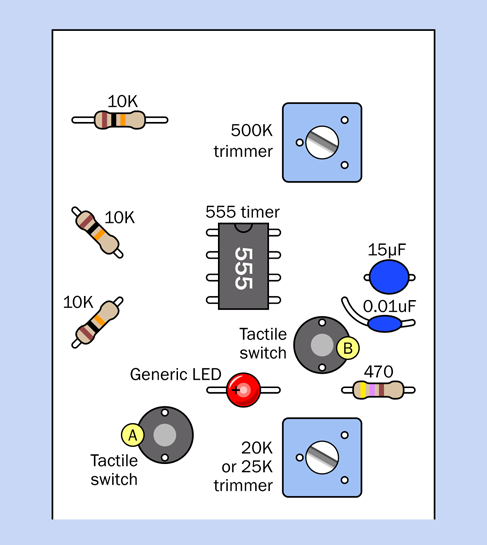

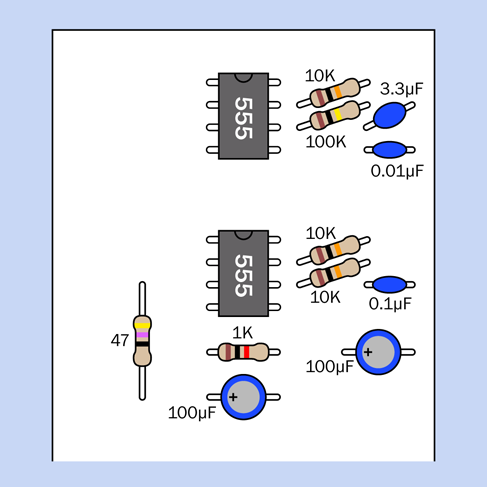

What You Will Need

-

Breadboard, hookup wire, wire cutters, wire strippers, multimeter

-

9VDC power supply (battery or AC adapter)

-

Resistors: 470 ohms (1), 10K (3)

-

Capacitors: 0.01µF (1), 15µF (1)

-

Trimmer potentiometers: 20K or 25K (1), 500K (1)

-

555 timer chip (1)

-

Tactile switches (2)

-

Generic LED (1)

Know Your Chips

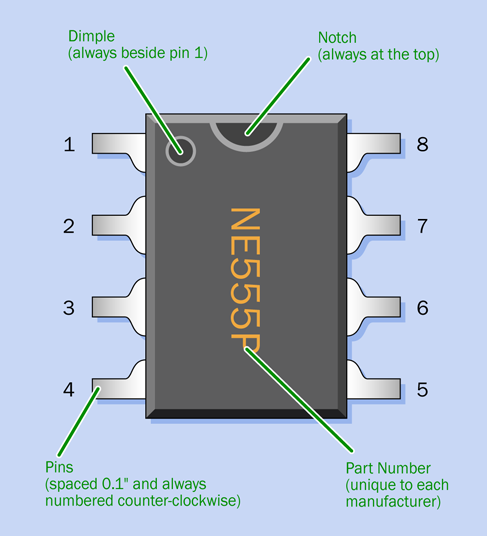

The pins of a 555 timer are numbered counterclockwise (seen from above), as shown in Figure 4-9. The package has a notch, or a dimple, or both, at the end which is considered the top. The pin spacing is 1/10”.

All other through-hole chips have the same specification, although they may have more pins. Usually (not always) the horizontal spacing between the two rows of pins is 3/10”, which means that the chip neatly straddles the channel down the middle of a breadboard, and the conductors inside the breadboard allow you to have access to each pin of the chip. Yes, that’s why the breadboard is designed that way.

Figure 4-9. The package design of an eight-pin chip. While virtually all chips have a semicircular notch at the top, some do not have a dimple beside pin 1.

Monostable Test

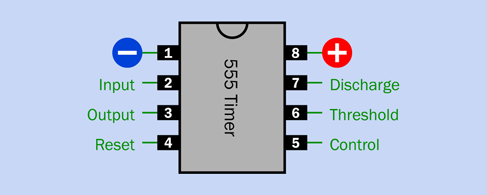

The pins on a 555 timer also have names, as shown in Figure 4-10. A diagram like this tells you the pinouts of the chip. I’ll be explaining the function of each pin—but as usual, I prefer you to make a preliminary investigation of your own.

Figure 4-10. The pinouts of the 555 timer chip.

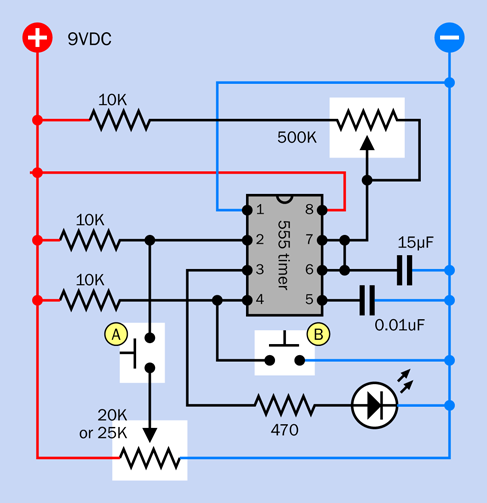

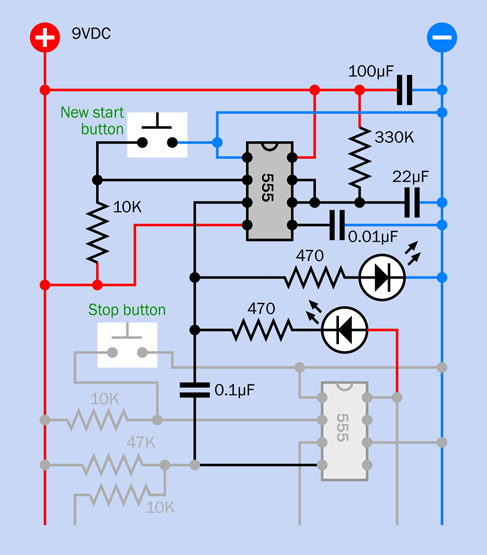

The schematic of a test circuit for the timer is shown in Figure 4-11.

Figure 4-11. A circuit to assist in your investigation of the 555 timer chip.

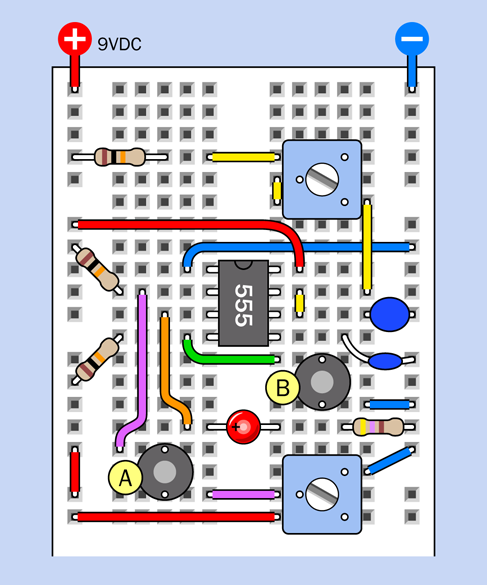

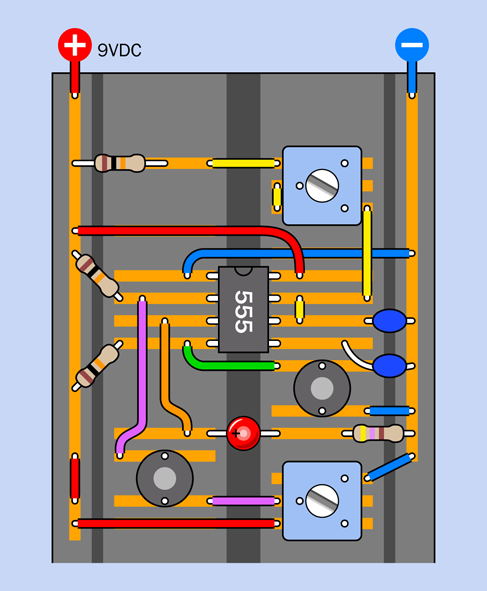

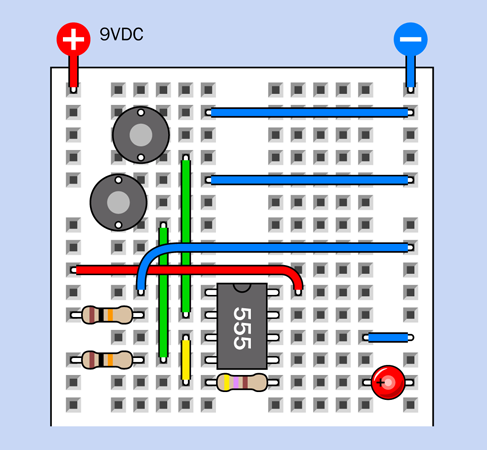

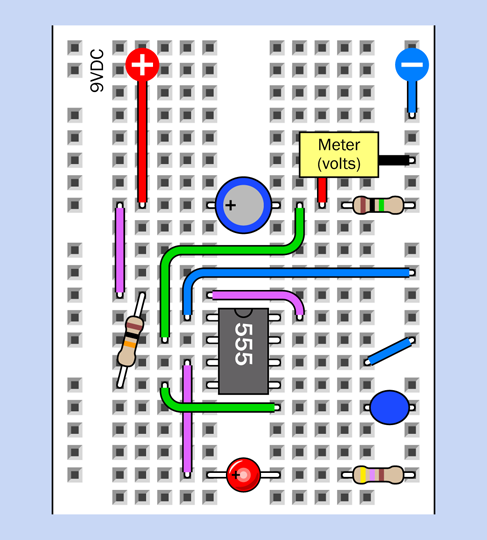

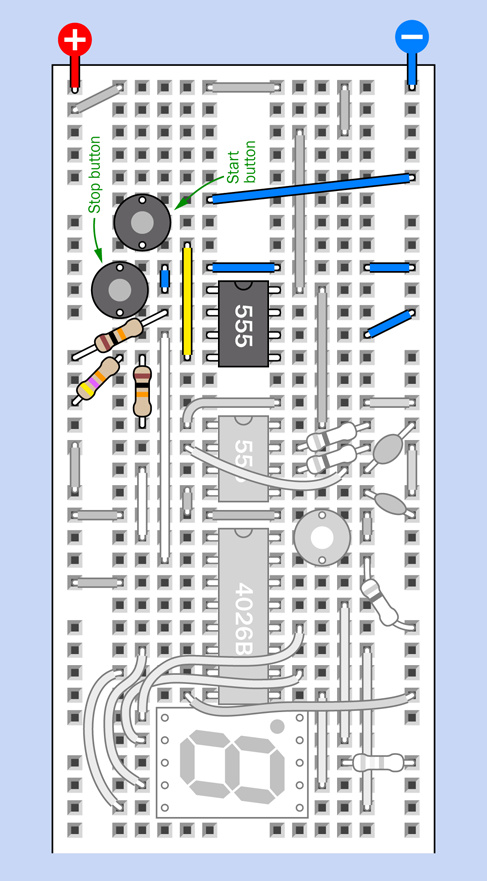

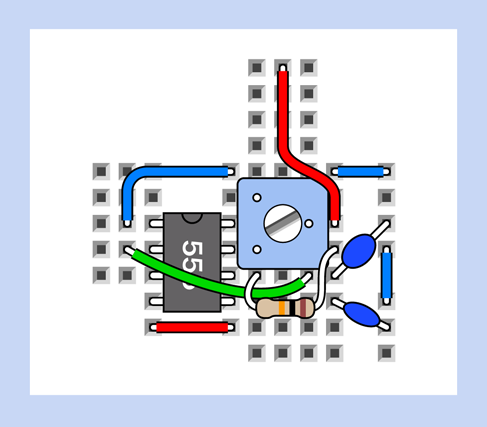

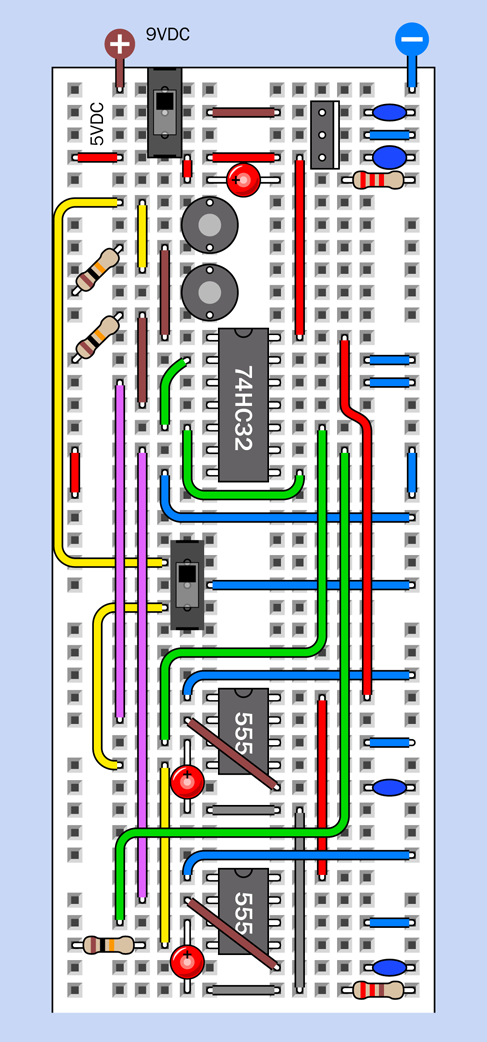

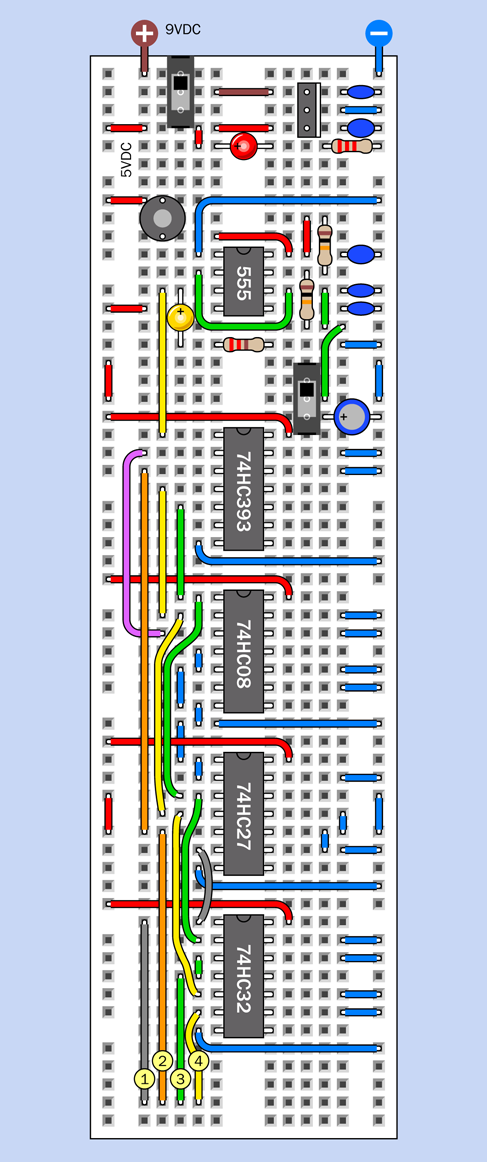

You can set up this circuit on a breadboard as shown in Figure 4-12. Note that near the bottom-left corner there is a short red jumper connecting the top section of the positive bus to the section immediately below it. The jumper is there in case your breadboard is the type that has a break in its bus.

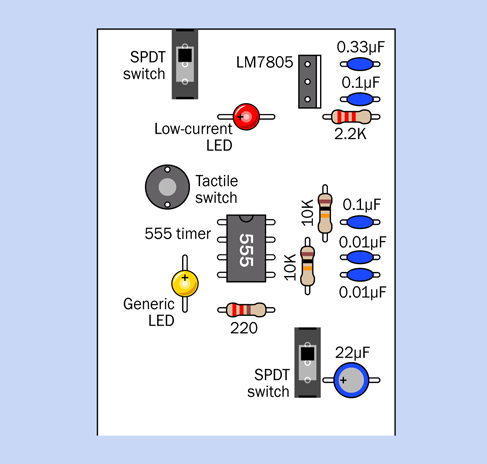

The component values are shown in Figure 4-13. To assist you in visualizing the connections, an x-ray version is shown in Figure 4-14.

Apply some power, and nothing happens. The timer is waiting for you to trigger it. Set it up by turning the 500K trimmer to the middle of its range.

Now rotate the 20K trimmer all the way counterclockwise, and press button A. If still nothing happens, rotate the 20K trimmer all the way clockwise, and try again. One of these settings or the other should create a pulse from the LED, depending on which way around you plugged in your trimmer. If you don’t get anything, there is an error in your circuit.

Check the schematic, and you see that pin 2 of the timer—the trigger pin—is hardwired through a 10K resistor to the positive side of the power supply. But a purple wire also connects with the trigger pin, and runs down, through a tactile switch, to the trimmer. If the trimmer is rotated so that the wiper connects directly to the negative ground side of the power supply, this will allow the tactile switch to overwhelm the 10K resistor and apply low voltage to pin 2. This triggers the timer.

Figure 4-12. Breadboarded version of the timer test circuit.

If the 20K trimmer is turned all the way in the opposite direction, button A will apply positive voltage directly to pin 2, and because pin 2 already has positive voltage through the 10K resistor, an additional positive voltage through button A makes no difference.

-

Positive voltage on the trigger pin is ignored by the chip.

-

A drop in voltage on the trigger pin will trigger the chip.

But, how positive is positive, and how much of a drop will be low enough to act as a trigger? Let’s find out.

Figure 4-13. Component values for the timer test circuit.

Get out your meter, set it to measure DC volts, and measure the voltage between pin 2 and negative ground while you adjust the 20K trimmer to various settings and press button A. I’m betting that when you press the button to apply a voltage below 3 volts to pin 2, the timer will flash the LED. Above 3 volts, I doubt that anything will happen.

-

The timer is triggered by a voltage on its trigger pin that is one-third of the supply voltage (or less).

-

The LED will continue to glow after you release the button.

-

You can press the button for any length of time that is less than the timer’s cycle time, and the LED always emits the same length of pulse.

Figure 4-14. Connections inside the breadboard wired for the timer test.

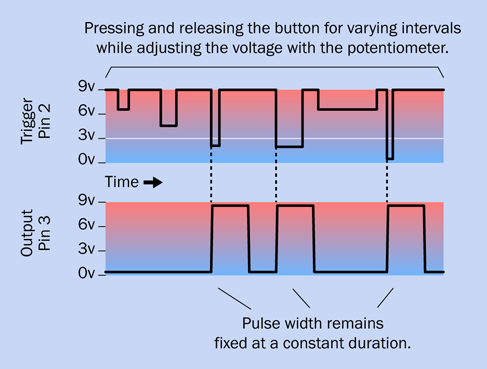

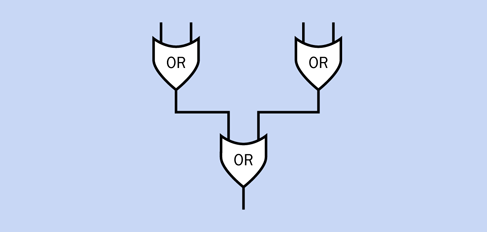

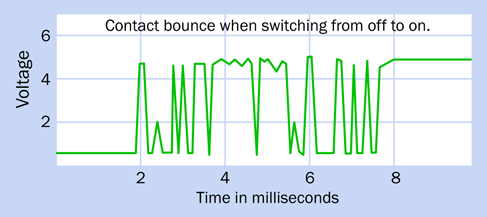

Figure 4-15 shows how the timer is behaving, in graphical format. The 555 converts the imperfect world around it into a precise and dependable output. It doesn’t switch on and off absolutely instantly, but is fast enough to appear instant.

Now try triggering the timer while you turn the 500K trimmer to different positions. You will find that this adjusts the length of the pulse.

-

The resistance between pin 7 and the positive side of the power supply determines how long the pulse from the timer will last (in conjunction with the capacitor on pin 6).

Figure 4-15. How a 555 timer responds to different durations and voltages on its trigger pin.

Here’s another thing to try. Set the 500K trimmer to give a long pulse. Press button A, and then quickly press button B, which will stop the pulse before it completes. Hold down button B while you try to trigger the timer again with button A, and nothing happens.

-

Pin 4 is the reset pin. When you ground it, you force the timer to interrupt whatever it is doing, and it is immobilized until you release pin 4 from its connection with negative ground.

Lastly, let go of button B, hold down button A, and continue to hold it down. This prolongs the pulse from the timer, until you let go of button A.

Regarding the 10K resistors attached to pins 2 and 4—these are known as pullup resistors, because they hold the pins at a positive level. A more direct connection to negative ground will overwhelm the pullup resistor.

The concept of a pullup resistor is important when you are dealing with chips, because you must never allow an input pin to remain unconnected. An unconnected pin is said to be floating, and can cause trouble, as it may pick up stray electromagnetic fields, and we won’t know what voltage is on it from one moment to the next.

Is there such a thing as a pulldown resistor? Absolutely. But the 555 timer needs pullup resistors, because pin 2 or pin 4 is kept in a normal state by positive voltage, and is activated by a low voltage.

-

The 555 timer is triggered or reset by negative voltages on pins 2 and 4 respectively.

Timing the Pulse

If you study the schematic in Figure 4-11, you can see that positive current reaches pin 7 (the discharge pin) by passing through a 10K resistor and a 500K trimmer. (The 10K resistor is there because pin 7 should not be connected directly to the positive side of the power supply.)

You can also see that after passing through the 500K trimmer, the current can reach a 15µF capacitor. Hmmmm, a resistor followed by a capacitor—does this look like an RC network? Is the timer using the combination of the resistance and the 15µF capacitor to determine the length of the output pulse?

Yes, that’s exactly what is going on. Inside the timer chip, some clever electronics are sensing the voltage on the 15µF capacitor, and the timer uses this to terminate its output pulse.

You can measure this yourself. Set the 500K trimmer to create a long pulse, and use your meter to measure the voltage on the left side of the 15µF capacitor. You should see it climbing up—until it reaches about 6 volts. The timer uses this as a signal to stop its output pulse, and the voltage quickly goes down again, because the timer is grounding it internally. This is why pin 7 is known as the discharge pin: the timer discharges the capacitor through it.

-

When the voltage on the timing capacitor reaches two-thirds of the supply voltage, the timer ends its output pulse.

But why are the discharge pin and the threshold pin tied together? You’ll learn about that in the next experiment, when the timer is rewired to deliver a series of pulses, instead of just one. At that time, the timer will be running in astable mode. Currently, you are using it in monostable mode.

-

In monostable mode, the timer delivers only one pulse in response to a triggering event.

-

In astable mode, the timer delivers a continuing series of pulses.

Finally, you may be wondering about the purpose of the 0.01µF capacitor attached to pin 5. This pin is the “control” pin, which means that if you apply a voltage to it, you can control the sensitivity of the timer. Because we are not using this function yet, it’s good practice to put a capacitor on pin 5 to protect it from voltage fluctuations and prevent it from interfering with normal functioning.

Caution: Beware of Pin-Shuffling!

In all of the schematics in this book, chips are shown exactly as you would see them on a breadboard, with the pins in numerical sequence.

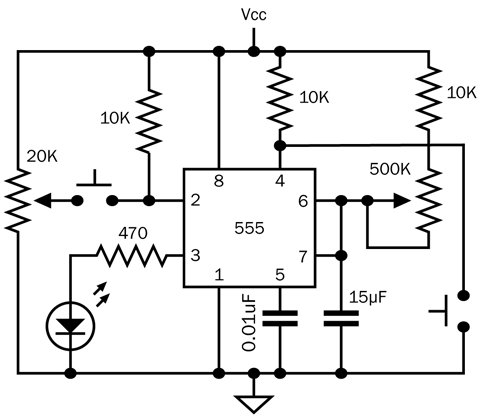

Other schematics that you may find, on websites or in books, do things differently. For convenience in drawing circuits, people often resequence the pin numbers. Also, there is no attempt to replicate a breadboard layout with a positive bus and a negative bus at each side. To give you an example, in Figure 4-16 the circuit is identical to that in Figure 4-11, but the pins have been shuffled to simplify connections and minimize wiring crossovers.

Figure 4-16. This circuit is identical in function to the test circuit shown previously, but pins on the chip have been resequenced to simplify the schematic.

Pin shuffling can create a circuit that is easier to understand in some ways (especially if positive power is at the top and ground at the bottom), but you have to convert the layout, often using pen and paper, before you can build it on a breadboard.

Fundamentals: Timer Duration

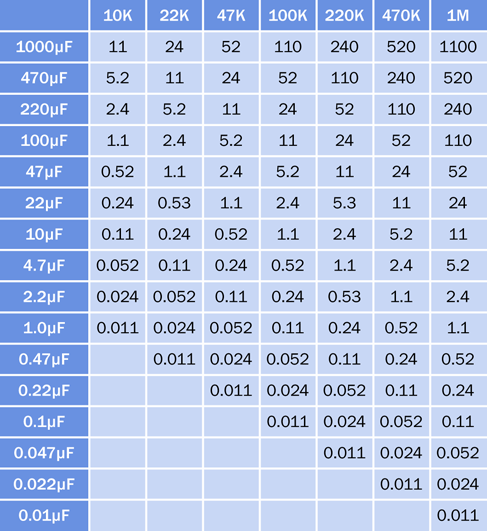

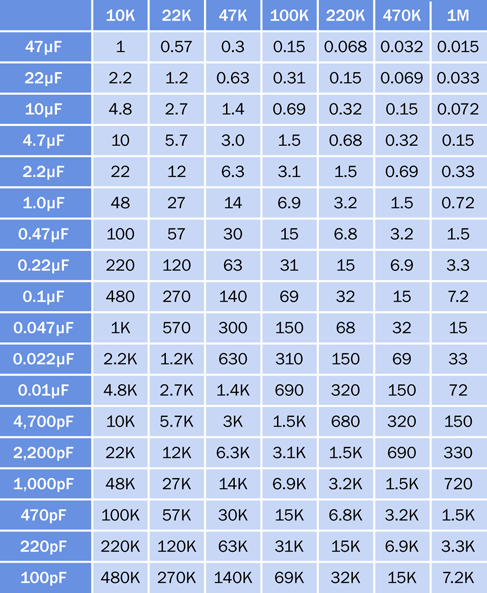

When you made your own RC network in Experiment 9, some annoying calculations were necessary to figure out how long a capacitor would take to reach any particular voltage. Using a 555 timer, everything is much easier. You just look up the duration of its output pulse in a table such as the one in Figure 4-17. The resistance between pin 7 and the positive side of the power supply is shown along the top of the table, the value of the timing capacitor is shown down the left side, and the numbers in the table tell you the approximate pulse duration in seconds.

Figure 4-17. Pulse duration, in seconds, of a 555 timer running in monostable mode, for values of the timing resistor and timing capacitor. Times are rounded to two digits.

-

Resistor values below 1K should not be used.

-

Resistor values below 10K are undesirable, as they increase power consumption.

-

Capacitor values above 100µF may produce inaccurate results because leakage in the capacitor becomes comparable with its charging rate.

What if you want a time longer than 1,100 seconds or shorter then 0.01 seconds? Or what if you want a pulse duration that falls somewhere between the values in the table?

You can use this simple formula, where T is the pulse time in seconds, R is the resistance in kilohms, and C is the capacitance is microfarads.

T = R × C × 0.0011

Bear in mind that the result may not be exact, because resistor and capacitor values can be inaccurate, and because of other factors such as ambient temperature.

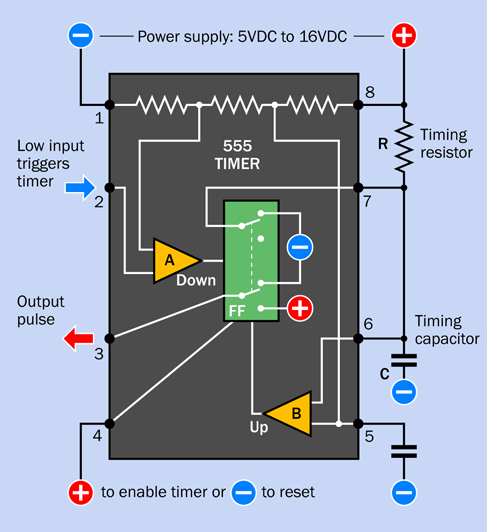

Theory: Inside the 555 in Monostable Mode

The plastic body of the 555 timer contains a wafer of silicon on which are etched dozens of transistor junctions in a pattern that is too complex to be explained here. However, I can summarize their function by dividing them into groups, as shown in Figure 4-18.

Figure 4-18. Simplified representation of internal functions of a 555 timer, wired in monostable mode.

The negative and positive symbols inside the chip are power sources that actually come from pins 1 and 8, respectively. I omitted the internal connections to those pins for the sake of clarity.

The two yellow triangles are comparators. Each comparator compares two inputs (at the base of the triangle) and delivers an output (from the apex of the triangle) depending on whether the inputs are similar or different. FF is a flip-flop, a logic component that can rest in one state or the other. I have depicted it as a double-throw switch, although in reality it is solid-state.

Initially when you power up the chip, the flip-flop is in its “up” position, which delivers low voltage through the output, pin 3. If the flip-flop receives a signal from comparator A, it flips to its “down” state, and flops there. When it receives a signal from comparator B, it flips back to its “up” state, and flops there. The “Up” and “Down” labels on the comparators will remind you how each one changes the switch when it is activated. Some people feel that the term “flip-flop” is derived from it having two states named “flip” and “flop.” But I prefer to think of it flipping and flopping.

Notice the external wire that connects pin 7 with capacitor C. As long as the flip-flop is “up,” it sinks the positive voltage coming through resistor R to pin 7, and prevents the capacitor from charging positively.

If the voltage on pin 2 drops to 1/3 of the supply, comparator A notices this, and flips the flip-flop to its “down” position. This sends a positive pulse from pin 3, the output pin, and also disconnects the negative power from pin 7. Now the capacitor can start charging through the resistor. While this is happening, the positive output from the timer continues.

As the voltage increases on the capacitor, comparator B monitors it through pin 6. When the capacitor accumulates 2/3 of the supply voltage, comparator B sends a pulse to the flip-flop, flipping it back into its original “up” state. This discharges the capacitor through pin 7. Also, the flip-flop ends the positive output through pin 3 and replaces it with a negative voltage. This way, the 555 returns to its original state.

I’ll sum up this sequence of events:

-

Initially, the flip-flop grounds the capacitor and grounds the output (pin 3).

-

A drop in voltage on pin 2 to 1/3 of the supply voltage or less makes the output (pin 3) positive and allows capacitor C to start charging through resistor R.

-

When the capacitor reaches 2/3 of the supply voltage, the chip discharges the capacitor, and the output at pin 3 goes low again.

Fundamentals: Pulse Suppression

When power is first applied to a timer that is configured in monostable mode, the timer tends to emit one pulse spontaneously before going dormant and waiting to be triggered again. This can be annoying in many circuits.

One way to prevent it is by putting a 1µF capacitor between the Reset pin and negative ground. The capacitor sinks current from the Reset pin when the power is first turned on, and holds the pin low for a fraction of a second—just long enough to stop the timer from emitting its waking-up pulse. After the capacitor is charged, it doesn’t do anything more, and a 10K resistor holds the reset pin positive, so it won’t interfere with the running of the timer.

I’ll be using the pulse-suppression concept in subsequent experiments.

Fundamentals: Why the 555 Is Useful

In its monostable mode, the 555 will emit a single pulse of fixed (but programmable) length. Can you imagine some applications? Think in terms of the pulse from the 555 controlling some other component. A motion sensor on an outdoor light, perhaps. When an infrared detector “sees” something moving, the light comes on, but only for a specific period—which can be controlled by a 555.

Another application could be a toaster. When someone lowers a slice of bread, a switch will close, triggering the toasting cycle. To change the length of the cycle, you could use a potentiometer and attach it to the external lever that determines how dark you want your toast. At the end of the toasting cycle, the output from the 555 would pass through a power transistor, to activate a solenoid (which is like a relay, except that it has no switch contacts) to release the toast.

Intermittent windshield wipers could be controlled by a 555 timer—and on earlier models of cars, they were. The repeat rate of keys on a rather basic computer keyboard could be controlled by a 555 timer—and on the Apple II, it was.

What about the intrusion alarm in Experiment 15? One of the features on my wish list was that it should wait long enough for you to shut it off, before it starts to make a noise. The output from a 555 timer can take care of that.

The experiment that you just performed seemed trivial, but it implies a huge range of possibilities.

Fundamentals: Bistable Mode

There’s another way to use the timer, known as bistable mode. This entails disabling its fundamental features. Why would you want to do this? I will explain.

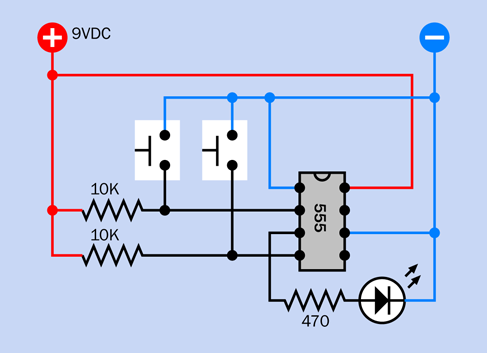

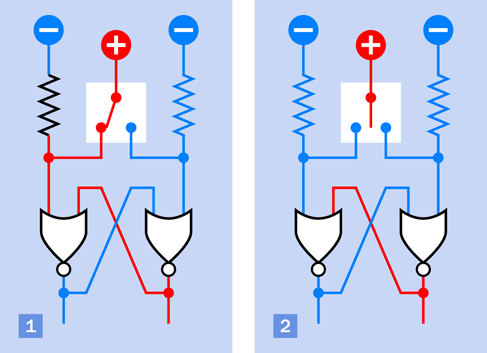

Figure 4-19 shows a circuit that you can build in just a few minutes. Give it a try. The two resistors on the left are pullup resistors, 10K each. The resistor at the bottom is 470 ohms, to protect the LED. Add two tactile switches, and the timer chip itself, and you’re done.

Figure 4-19. Breadboard circuit to make the 555 timer function as a flip-flop.

Once you have it on your breadboard, press and release the top button, and the LED lights up. For how long? For as long as you supply power to the circuit. The output from the timer continues indefinitely.

Now press and release the bottom button, and the LED goes off. For how long? For as long as you like. It won’t come back on until you press the top button again.

I mentioned that there is a flip-flop inside the timer. This circuit makes the timer into one big flip-flop. It flips into its “on” state when you ground pin 2—and it flops there. It flips into its “off” state when you ground pin 4—and it flops there. Flip-flops are very important in digital circuits, as I will explain a bit later, but right now, how does this work, and why would you need it?

Take a look at the schematic in Figure 4-20. You may notice that there is no resistor or capacitor on the righthand side. The RC network is missing. So—this timer circuit has no timing components! Normally, when you trigger the timer, its output pulse ends when the timing capacitor on pin 6 accumulates 2/3 of supply voltage. But pin 6 is grounded, so it can never reach the 2/3 value. Consequently, when you trigger the timer, the output pulse will never end.

Figure 4-20. A test circuit for the 555 timer in bistable mode.

Of course, you can stop the output by applying a low voltage to the reset pin. But once the output stops, it will remain stopped, so long as you don’t trigger the timer again.

This configuration is called bistable because it is stable when the output is high, and it is stable when the output is low. A simple flip-flop like this can also be called a latch.

-

A negative pulse to pin 2 turns the output positive, and latches it.

-

A negative pulse to pin 4 turns the output negative, and latches it.

You do have to keep pins 2 and 4 high when you are not triggering them. That’s what the pullup resistors in the schematic are for.

It’s OK to leave pin 5 of the timer unconnected, because we’re pushing it into extreme states where any random signals from those pins will be ignored.

As for why you would need to use a timer in this way—you’ll be surprised how useful it can be. I’m going to use it in three experiments in the remainder of this book. The 555 was not really designed to function in bistable mode, but it can be convenient.

Background: How the Timer Was Born

Back in 1970, when barely a half-dozen corporate seedlings had taken root in the fertile ground of Silicon Valley, a company named Signetics bought an idea from an engineer named Hans Camenzind (pictured in Figure 4-21). It wasn’t a huge breakthrough concept—just 23 transistors and a bunch of resistors that would function as a programmable timer. The circuit would be versatile, stable, and simple, but these virtues paled in comparison with its primary selling point. Using the emerging technology of integrated circuits, Signetics could reproduce the whole thing on a silicon chip.

Figure 4-21. Hans Camenzind, inventor, designer, and developer of the 555 timer chip for Signetics.

This entailed some trial and error. Camenzind worked alone, building the whole thing initially on a large scale, using off-the-shelf transistors, resistors, and diodes on a breadboard. It worked, so then he started substituting slightly different values for the various components to see whether the circuit would tolerate variations during production, and other factors such as changes in temperature when the chip was in use. He made at least 10 different versions of the circuit. This took months.

Next came the crafts work. Camenzind sat at a drafting table and used a specially mounted X-Acto knife to scribe his circuit into a large sheet of plastic. Signetics then reduced this image photographically by a ratio of about 300:1. They etched it into tiny wafers, and embedded each of them in a half-inch rectangle of black plastic with the product number printed on top. Thus, the 555 timer was born.

It turned out to be the most successful chip in history, both in the number of units sold (tens of billions and counting) and the longevity of its design (not significantly changed in almost 40 years). The 555 has been used in everything from toys to spacecraft. It can make lights flash, activate alarm systems, put spaces between beeps, and create the beeps themselves.

Today, chips are designed by large teams and tested by simulating their behavior using computer software. Thus, the chips inside a computer enable the design of new chips. The heyday of solo designers such as Hans Camenzind is long gone, but his genius lives inside every 555 timer that emerges from a fabrication facility. If you’d like to know more about chip history, visit the Transistor Museum.

A personal note: in 2010, when I was writing Make: Electronics, I looked up Hans Camenzind online and found that he maintained his own website, which included a phone number. On impulse, I called him. This was a strange moment, to be talking to the man whose chip design I had used for more than 30 years. He was friendly (although he didn’t waste words), and readily agreed to review the text of my book. Even more kindly, after he read it, he gave it a strong endorsement.

Subsequently I bought his own short history of electronics, Much Ado About Almost Nothing, which is still available online, and which I highly recommend. I felt honored to have had the opportunity to talk to one of the pioneers in integrated circuit design. I was sad when I heard of his death in 2012.

Fundamentals: 555 Timer Specifications

-

The 555 can run from a reasonably stable voltage source ranging from 5VDC to 16VDC. The absolute maximum is 18VDC. Many datasheet specifications are measured at 15VDC. The voltage does not have to be controlled by a voltage regulator.

-

Most manufacturers recommend a range from 1K to 1M for the resistor attached to pin 7, but values below 10K draw a more significant amount of current. It’s a better idea to reduce the value of the capacitor than to reduce the value of the resistor.

-

The capacitor value can go as high as you like, if you want to time really long intervals, but the accuracy of the timer will diminish because leakage in the capacitor becomes comparable with its charge rate.

-

The timer imposes a voltage drop that is greater than the drop created by a transistor or a diode. The difference between supply voltage and output voltage will be 1V or more.

-

The output is rated to source or sink 200mA, but an output current above 100mA will pull down the voltage and can affect the timing accuracy.

Caution: Not All Timers Are Equal

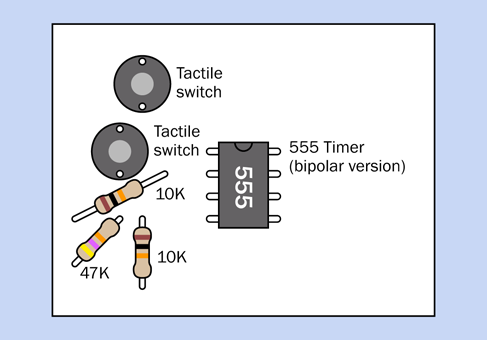

Everything I have said so far applies to the old original “TTL” version of the 555 timer. TTL is an acronym for transistor–transistor logic, which preceded modern CMOS chips that use much less power. The TTL version of the timer is also referred to as the bipolar version, as it contains bipolar transistors.

The advantage of the original 555 is that it is cheap and robust. You can’t damage it easily, and its output is powerful enough to connect directly with a relay coil or a small loudspeaker. However, the 555 is not efficient, and tends to generate voltage spikes that sometimes interfere with the operation of other chips.

To address these disadvantages, a newer version of the 555 timer was developed using CMOS transistors, which draw less power. This chip also doesn’t create voltage spikes. But its output is more limited. How much more? That depends on the particular manufacturer.

Unfortunately, there is a lack of standardization among CMOS versions of the 555 timer. Some claim to deliver 100mA while others are limited to 10mA.

Confusingly, the CMOS versions have a variety of part numbers. The 7555 is clearly identified as a CMOS chip, but others merely precede the 555 number with a different group of letters, and it’s up to you to notice, and to understand what they mean.

In this book, to avoid confusion and keep things simple, I am only using the TTL version of the 555 timer, also known as the bipolar version. If you are buying your own, see “Other Components” and go down to the subhead “Components for Chapter Four” where you will find timer buying advice.

Experiment 17: Set Your Tone

Now that you’re familiar with the 555 timer in monostable mode and bistable mode, I want you to get acquainted with it in astable mode—so called because the output fluctuates constantly between high and low, and does not remain stable in either of those states.

This resembles the output of the transistor oscillator that you built in Experiment 11, except that it is much more versatile and easier to control, and instead of requiring two transistors, four resistors, and two capacitors to create the oscillation, you only need one chip, two resistors, and one capacitor.

What You Will Need

-

Breadboard, hookup wire, wire cutters, wire strippers, multimeter

-

9-volt power supply (battery or AC adapter)

-

555 timer chips (4)

-

Miniature loudspeaker (1)

-

Resistors: 47 ohms (1), 470 ohms (4), 1K (2), 10K (12), 100K (1)

-

Capacitors: 0.01µF (8), 0.022µF (1), 0.1µF (1), 1µF (3), 3.3µF (1), 10µF (4), 100µF (2)

-

1N4148 diode (1)

-

Trimmer potentiometer, 100K (1)

-

Tactile switch (1)

-

Generic LEDs (4)

Astable Test

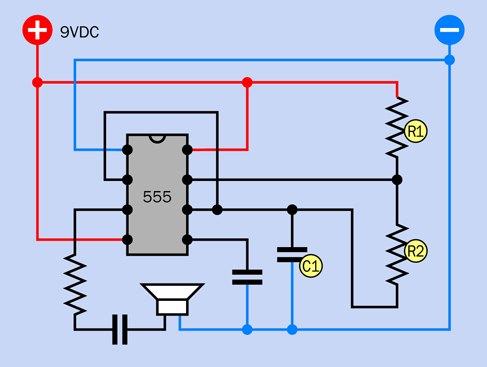

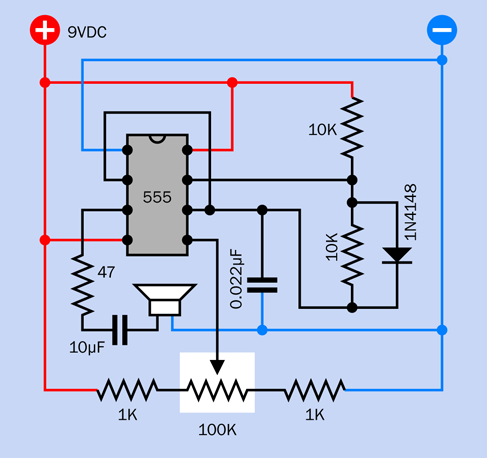

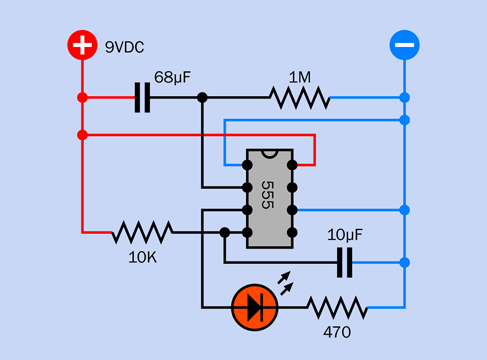

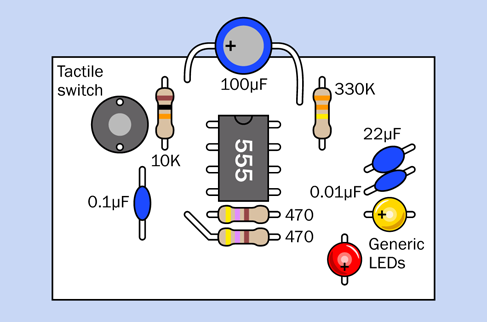

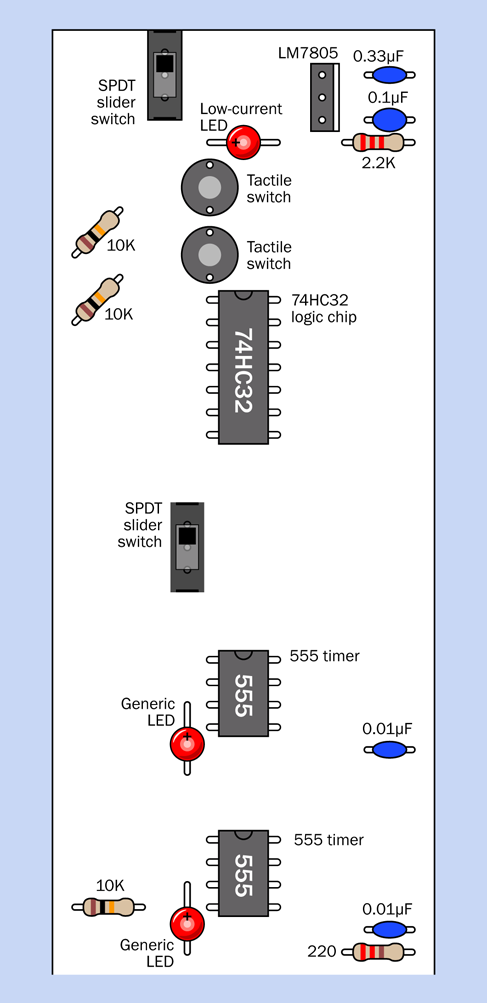

A generic astable circuit is shown in Figure 4-22. I’ve put a loudspeaker on the output, because the timer will be running at an audio frequency. The loudspeaker is driven through a resistor, to limit the current, and a coupling capacitor, which passes audio frequencies while blocking DC. You’ll see the values for these components in the next schematic. Right now I just want you to see the general layout.

Figure 4-22. A basic, generic circuit that runs a 555 timer in astable mode.

The components labeled R1, R2, and C1 control the speed of the timer. These labels are always used in manufacturers’ datasheets and other sources, so I’m following the same convention.

C1 does the same thing as the timing capacitor in the monostable circuit in Figure 4-11. The need for two resistors, instead of one, will be explained below.

See if you can get a sense of how this circuit may work, using the knowledge that you gained in Experiment 16. The first thing you may notice is that there’s no input. Pin 2 (the trigger pin) is connected back to pin 6 (the threshold pin). Can you see how that’s going to work? C1 will accumulate a charge, as it did when the timer was in monostable mode, until it reaches 2/3 of the power supply, at which point it will discharge through R2 into pin 7, and its voltage will drop. Its connection with pin 2 will mean that the trigger pin senses the drop in voltage on C1. And what does the trigger pin do when the voltage on it drops suddenly? It triggers the timer. So, in this configuration, the timer will retrigger itself.

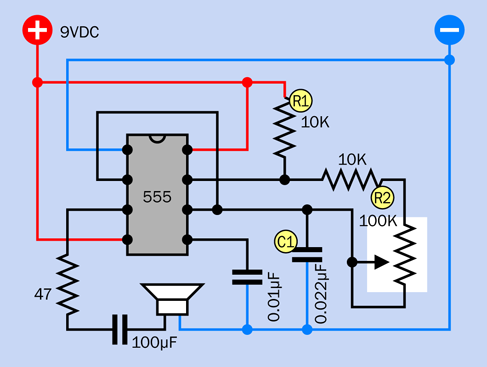

How fast will that happen? I think you should build a test version of the circuit to find out. In Figure 4-23 I have suggested values for the components and have redrawn the schematic to include a trimmer potentiometer, so that you’ll see (or, rather, hear) the effect of varying this resistance. The trimmer, plus the 10K resistor that precedes it, add up to R2. The timing capacitor, C1, is 0.022µF, and R1 is 10K.

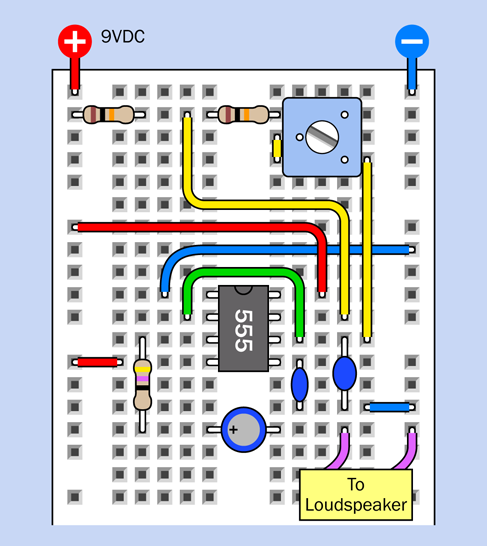

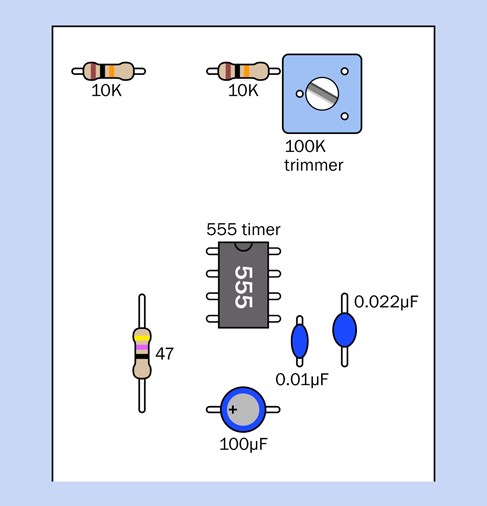

Figure 4-24 shows the breadboard layout, while Figure 4-25 shows the component values.

Figure 4-23. This test circuit allows you to adjust the performance of the timer in astable mode.

Now what happens when you apply power? Immediately, you should hear noise through the loudspeaker. If you don’t hear anything, you almost certainly made a wiring error.

Notice that you don’t have to activate the chip with a pushbutton anymore. The 555 timer is triggering itself, as predicted.

Figure 4-24. Breadboard layout for the astable timer test.

Figure 4-25. Component values for the astable timer test.

Rotate the screw on the trimmer potentiometer, and the pitch of the sound varies. The trimmer adjusts how quickly C1 charges and discharges, and this determines the length of one “on” cycle relative to the next “off” cycle in the audio signal. With these component values, the stream varies between approximately 300 and 1,200 pulses each second. These pulses are sent by the timer to the loudspeaker. They move its cone up and down, creating pressure waves in the air, and your ear responds to those waves, hearing them as sound.

Theory: Output Frequency

The frequency of a sound is its number of full cycles per second, including the high-pressure pulse and the low-pressure pulse that follows.

The term hertz is a unit of frequency, meaning the same thing as “cycles per second.” It was introduced in Europe, named after yet another electrical pioneer, Heinrich Hertz. The abbreviation for hertz is Hz, so the output of your 555 timer in its test circuit will range approximately between 300Hz and 1,200Hz.

As in most standard units, a k can be inserted to mean “kilo,” so 1,200Hz is normally written as 1.2kHz.

How do the values for the timing capacitor and the resistors determine the frequency of the timer? If R1 and R2 are measured in kilohms, and C1 is measured in microfarads, the frequency f, in hertz, is given by:

f = 1,440 / ( ( ( 2 × R2 ) + R1 ) × C1 )

Doing this calculation is a hassle, so I have provided you with a lookup table in Figure 4-26. In this table, I am assuming that the value for the resistor labeled R1 in the schematic is fixed at 10K. The values across the top of the table are for R2. The values on the left side of the table are for the timing capacitor, C1.

You may remember than the abbreviation pF means “picofarad,” which is one-millionth of a microfarad. Nanofarads are halfway between microfarads and picofards, but the term is not used so frequently in the US, so I didn’t use it in the table.

Figure 4-26. For a 555 timer running in astable mode, values across the top refer to R2 in a standard circuit, so long as R1 has a fixed value of 10K. Numbers in the table show the frequency of the timer in Hz (cycles per second).

Theory: Inside the 555 in Astable Mode

To gain a better understanding of what happens when the timer runs in astable mode, take a look at Figure 4-27. The internal configuration is exactly the same as in monostable mode, but the external connections are different.

Figure 4-27. Internal view of the 555 timer with external connections running it in astable mode.

Initially, the flip-flop grounds C1, the timing capacitor, as before. But now the low voltage on the capacitor is connected from pin 6 to pin 2 through an external wire. The low voltage tells the chip to trigger itself. The flip-flop obediently flips to its “on” position and sends a positive pulse to the loudspeaker, while removing the negative voltage from pin 6.

Now C1 starts charging, as it did when the timer was in monostable mode, except that it is being charged through R1 + R2 in series. Because C1 has a low value, it charges quickly. When it reaches two-thirds of full voltage, comparator B takes action as before, discharging the capacitor and ending the output pulse from pin 3.

The capacitor discharges through R2 to pin 7, the discharge pin. While the capacitor is discharging, its voltage diminishes. The voltage is still linked to pin 2. When it drops to one-third of full power or less, comparator A kicks in and sends another pulse to the flip-flop, starting the process all over again.

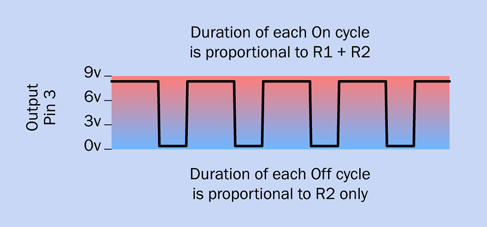

Fundamentals: Unequal On-Off Cycles

When the timer is running in astable mode, C1 charges through R1 and R2 in series. But when C1 discharges, it dumps its voltage into the chip through R2 only. Because the capacitor charges through two resistors but discharges through only one of them, it charges more slowly than it discharges. While it is charging, the output on pin 3 is high; while it is discharging, the output on pin 3 is low. Consequently the “on” cycle is always longer than the “off” cycle. Figure 4-28 shows this as a simple graph.

Figure 4-28. High pulses are always longer than gaps between them in the output from a 555 timer chip, when the chip is wired in the standard way for astable operation.

If you want the on and off cycles to be equal, or if you want to adjust the on and off cycles independently (for example, because you want to send a very brief pulse to another chip, followed by a longer gap until the next pulse), all you need to do is add a diode, as shown in Figure 4-29. (Because a diode deducts some voltage, this circuit works best with a supply voltage greater than 5VDC.)

Figure 4-29. Adding a diode to bypass R2 allows the high and low output cycles of a timer to be adjusted independently.

Now when C1 charges, the electricity flows through R1 as before but takes a shortcut around R2, through the diode. When C1 discharges, the diode blocks the flow of electricity in that direction, and so the discharge goes back through R2.

R1 now controls the charge time on its own, while R2 controls the discharge time. The formula for calculating the frequency is now approximately:

Frequency = 1,440 / ( ( R1 + R2 ) × C1 )

where R1 and R2 are in kilohms and C1 is in microfarads. (I use the word “approximately” because the diode adds a small amount of effective resistance to the circuit, which is not factored into the formula.)

If you set R1 = R2, you should get almost equal on/off cycles.

Astable Modifications

Instead of using a potentiometer to vary the value of R2, the frequency of the timer can be changed to a limited extent by using pin 5, the control pin. This is shown in Figure 4-30.

Figure 4-30. A circuit that demonstrates the function of pin 5, the control pin, on the 555 timer.

Disconnect the capacitor that was attached to that pin and substitute the series of resistors shown. They ensure that pin 5 always has at least 1K between it and the positive side or the negative side of the power supply. Connecting it directly to the power supply won’t damage the timer, but will prevent it from generating audible tones. As you turn the potentiometer, the frequency will vary. This happens because you are changing the reference voltage on comparator B inside the chip.

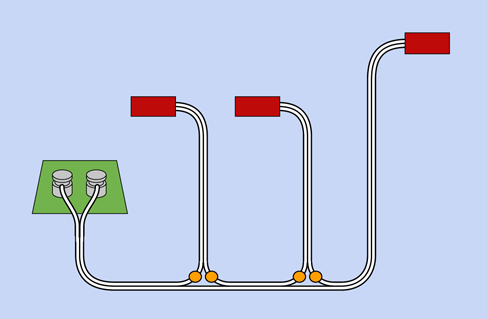

Chaining Chips

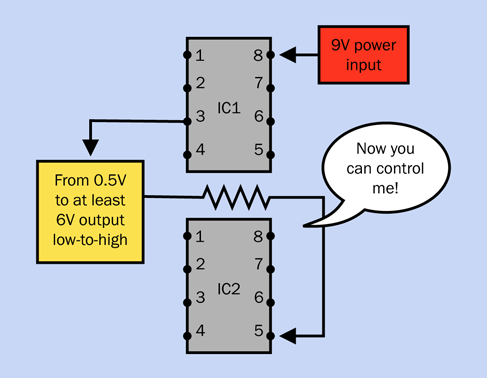

Timer chips can be chained together in four possible ways. Note that these configurations are workable regardless of whether each timer is running in monostable or astable mode, except where noted.

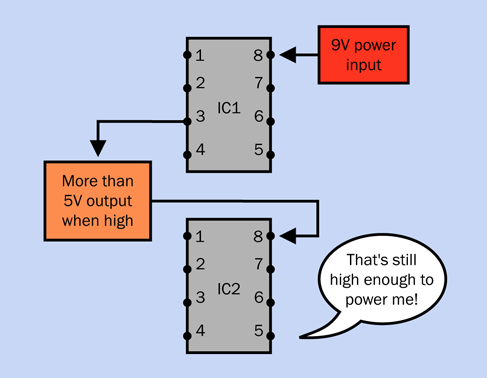

-

If you are using 9V to power a 555 timer, the output from that timer can be sufficient to power another 555 timer.

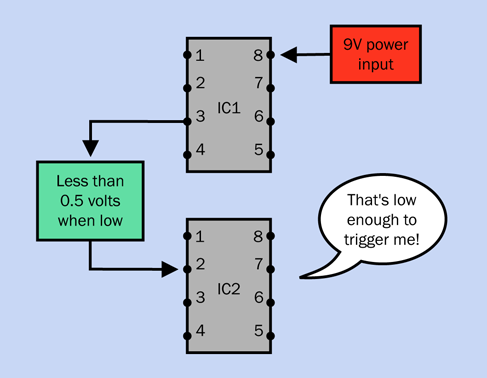

-

The output from one timer can trigger the input of another timer. This only works if the second timer is running in monostable mode. In astable mode, it would be self-triggering.

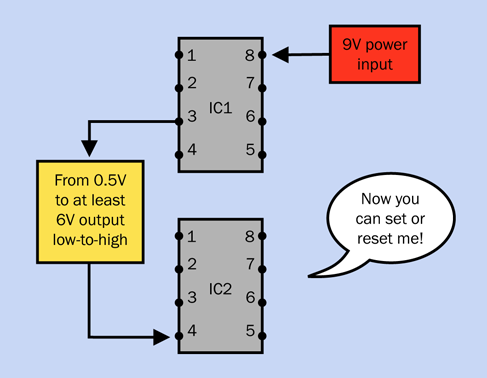

-

The output from one timer can unlock the reset pin of another timer.

-

The output from one timer can be connected through a suitable resistor to the control pin of another timer.

These options are illustrated in Figure 4-31, Figure 4-32, Figure 4-33, and Figure 4-34.

Figure 4-31. One timer powering another.

Figure 4-32. One timer triggering another.

Figure 4-33. One timer setting or resetting another.

Figure 4-34. One timer controlling the frequency of another.

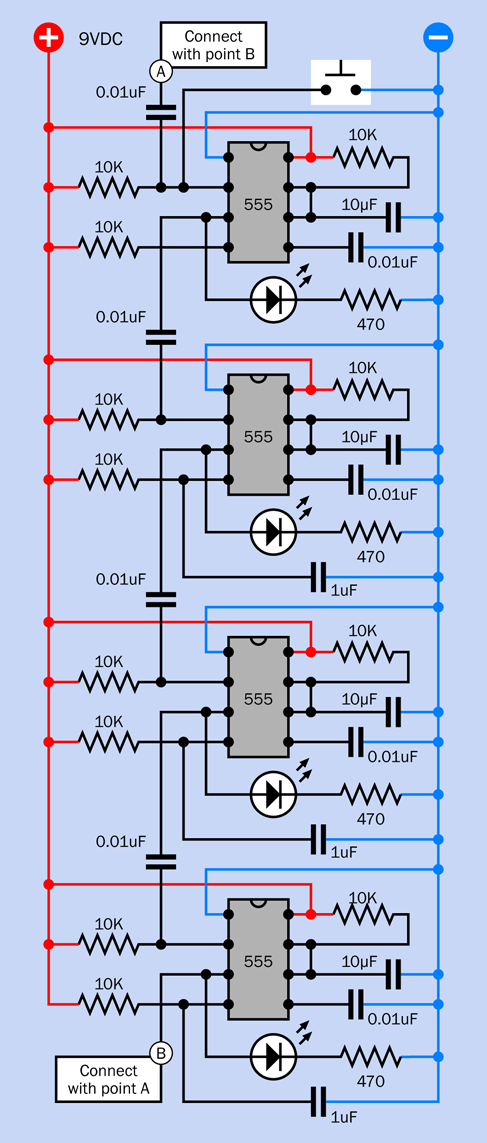

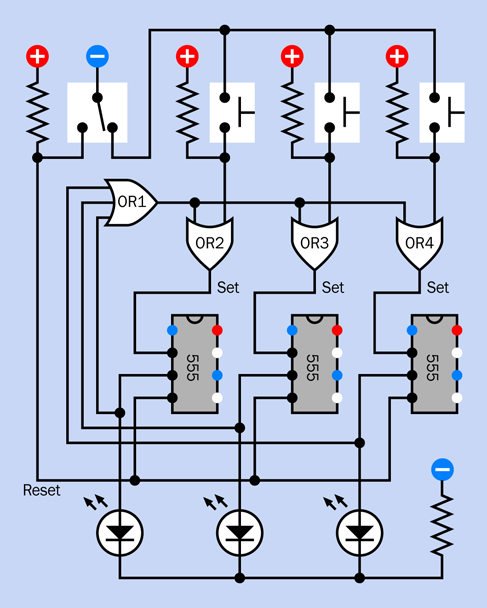

Why would you want to chain timers together? Well, you might want to have a couple of them running in monostable mode, so that the end of a high pulse from the first one triggers the start of a high pulse in the second one, and vice versa. In fact, you could chain together as many timers as you like, with the last one feeding back and triggering the first one, and they could flash a series of LEDs in sequence, like Christmas lights.

Figure 4-35 shows four timers chained in this way. They are linked through coupling capacitors, because we only want a brief pulse from one to trigger the next. Without the capacitors, the end of the pulse from the first timer in the chain would trigger the second timer, but the output from the first timer would remain in its low state, which would continue triggering the second timer indefinitely.

In addition, each timer must have a 10K pullup resistor on its trigger pin to hold it normally high.

Figure 4-35. Four timers wired to trigger each other in a recirculating sequence.

An interesting question comes to mind when monostable timers are chained together. That is: how do they start? I mentioned in Experiment 16 that a 555 timer in monostable mode will usually emit one spontaneous pulse when it is first powered up. When multiple timers are chained together, they will all try to do this at about the same time, and because of small manufacturing differences, the outcome will be unpredictable. Sometimes they will settle down to a nice orderly sequence, but other times they will end up flashing in pairs.

The way to deal with this is to use the concept of pulse suppression that I mentioned in Experiment 16 (see “Fundamentals: Pulse Suppression”).

A 1µF capacitor between the reset pin and negative ground will hold the reset pin in a low state just long enough to suppress the timer’s initial pulse. A 10K pullup resistor sharing the reset pin will then keep it stable while the timer is running.

In my experience, this works well, although timers from a different manufacturer could conceivably behave differently, as the behavior of the reset pin is not well documented. If you have trouble with pulse suppression, try substituting a larger or smaller capacitor.

In a chain of timers, the only remaining problem is that pulse suppression works too well. You apply power, and—nothing happens, because all the timer outputs have been suppressed.

The way around this is to omit pulse suppression from just one timer. It will almost certainly emit an initial pulse when it receives power, and that will trigger the rest in sequence. This setup is illustrated in Figure 4-35.

But—wait a minute. What is this “almost certainly” phrase? Electronic circuits should always work, all the time, not “almost” all the time.

I agree. But I can’t control the tendency of 555 timers to do unpredictable things when they are powered up. Therefore I also added a button, at the top of the circuit, that can be used to start the cascade if it doesn’t start itself.

There is an alternative, which is for the first timer in the chain to run in astable mode. It sends a series of pulses that ripple down through the others configured in monostable mode, and the last one does not feed back to the first. In electronics terms, we say that the first one is the master and the others are the slaves.

I like this arrangement because it is totally predictable. The trouble is, you have to adjust the speed of the master timer so that it emits its next pulse exactly when the last slave in the chain has just finished emitting its pulse. Otherwise, the first timer will emit another pulse before the last pulse has ended, or there will be a gap between the last pulse and the next first pulse.

Whether this is important will depend on the application. Flashing lights won’t be a problem, but if you increase the speed to drive a stepper motor, getting the timing right will be difficult.

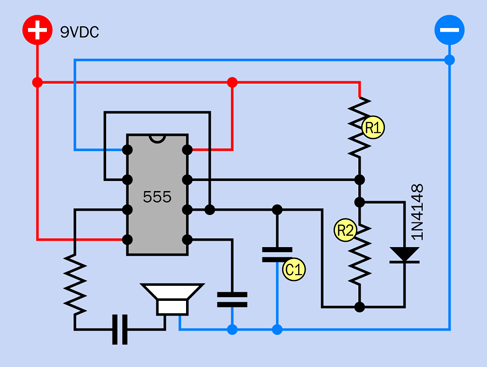

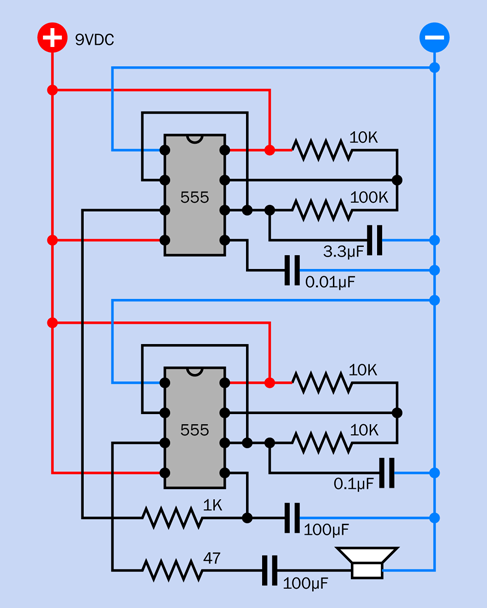

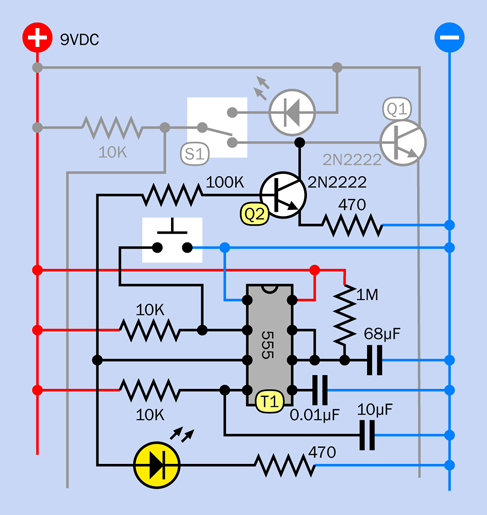

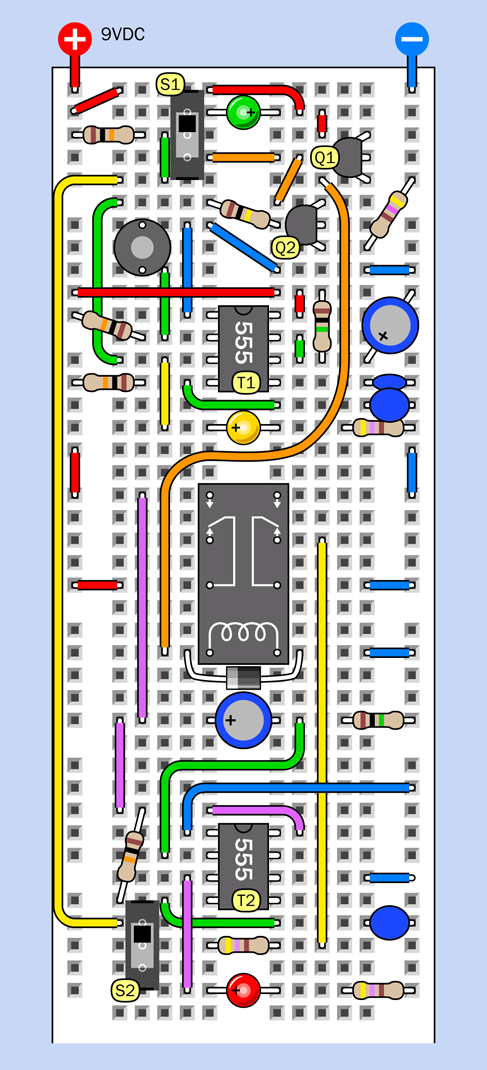

Sounding Like a Siren

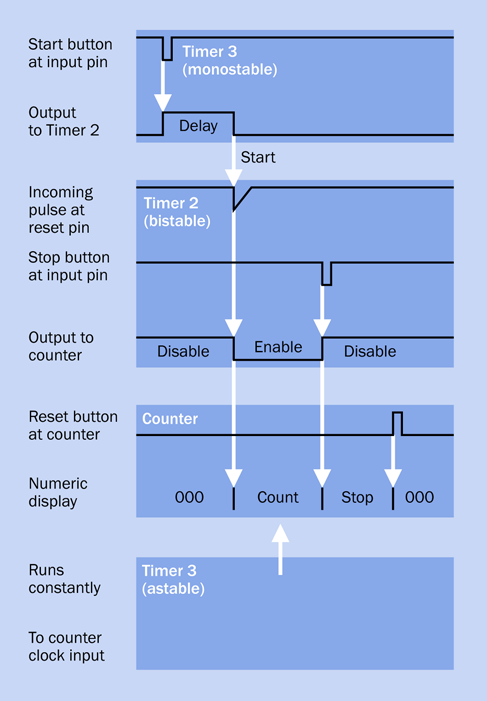

The fourth option that I listed for chaining chips, in Figure 4-34, is of special interest, because it can create a siren sound very like the noise made by a typical burglar alarm. In fact, this could be used for the audio output in the alarm project that I left unfinished in Experiment 15.

The circuit is shown in Figure 4-36. Timer 1 is wired in a basic astable circuit, which you can recognize as being similar to the circuit in Figure 4-22. The component values are larger, so the timer oscillates more slowly, around 1Hz. You can compare this circuit with the one that I suggested in Figure 2-120. The principle is similar.

Timer 2 is also wired in a basic astable circuit, running around 1kHz. The idea is that the slow fluctuations in voltage from Timer 1 are applied to the control pin of Timer 2, forcing it to modulate its sound up and down in that annoying way which we associate with alarm systems.

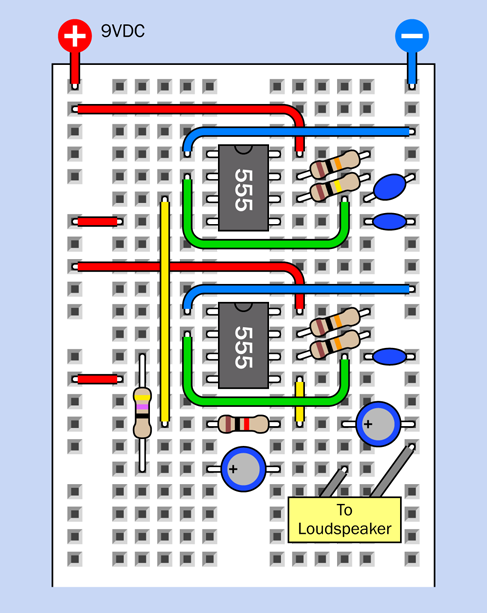

I encourage you to build this circuit, because you may want to use it in the final version of the intrusion alarm coming right up in Experiment 18. The breadboard layout for the siren circuit is in Figure 4-37, and the component values for the layout are shown in Figure 4-38.

Once you get it running, you may find it interesting to remove and then replace the 100µF capacitor connected between pin 6 and ground. The capacitor makes the frequency slide higher and lower instead of switching sharply up and down. I’m using it in the same way that I used a capacitor to make an LED fade smoothly in and out in Experiment 11.

Figure 4-36. When one timer runs relatively slowly, modulating another through its control pin (pin 5), the result is a wavering sound like an alarm siren.

You can modify the sound in other ways. Here are some suggestions:

-

Vary the 0.1µF timing capacitor to raise or lower the pitch of the basic sound.

-

Double the value of the 100µF capacitor on pin 6, or divide it by two.

-

Substitute a 10K potentiometer for the 1K resistor.

-

Change the value of the 3.3µF capacitor.

Part of the pleasure of building things is to customize them, to make them your own. Once your siren sound satisfies you, make a note of the component values for future reference.

Incidentally, you can reduce the chip count (the number of chips) by using a 556 timer instead of two 555 timers. The 556 contains a pair of 555 timers in one package. Because you still have to make the same number of external connections (other than the power supply), I haven’t bothered to use this variant.

Figure 4-37. The siren circuit, breadboarded.

Figure 4-38. Component values for the siren circuit.

Experiment 18: Intrusion Alarm (Almost) Completed

Now that you’ve seen what the 555 timer can do, you can fulfill the remaining requirements on the intrusion-alarm wish list.

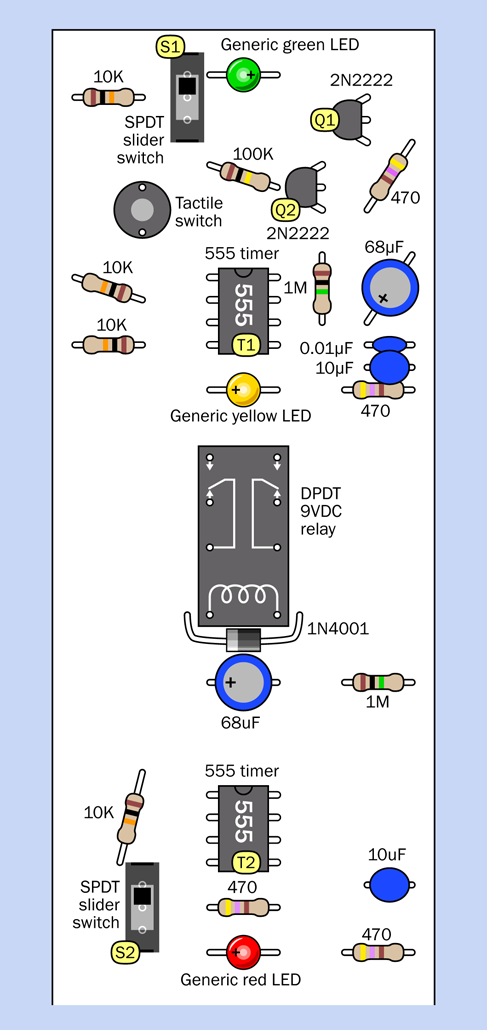

What You Will Need

-

Breadboard, hookup wire, wire cutters, wire strippers, multimeter

-

9-volt power supply (battery or AC adapter).

-

555 timers (2)

-

DPDT 9VDC relay (1)

-

Transistors, 2N2222 (2)

-

LEDs: Red, green, yellow (1 of each)

-

Slide switch, SPDT, for breadboard (2)

-

Tactile switch (1)

-

Capacitors: 0.01µF (1), 10µF (2), 68µF (2)

-

Resistors: 470 ohms (4), 10K (4), 100K (1), 1M (2)

-

Diode, 1N4001 (1)

Optional (for audio output):

-

Components shown in Figure 4-36

Optional (for permanent fabrication of this project):

-

15-watt soldering iron

-

Thin solder

-

Perforated board plated with copper in a breadboard layout

-

SPDT or DPDT toggle switch (1)

-

Pushbutton, SPST (1)

-

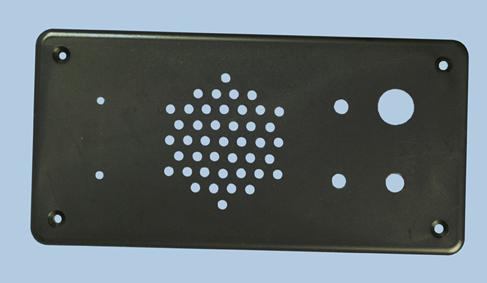

Project box, at least 6” × 3” × 2” (1)

-

Power jack and matching power socket (1 each)

-

Magnetic sensor switches, in pairs, quantity sufficient for your home

-

Alarm network wiring, sufficient for your home

Three Steps to a Functional Device

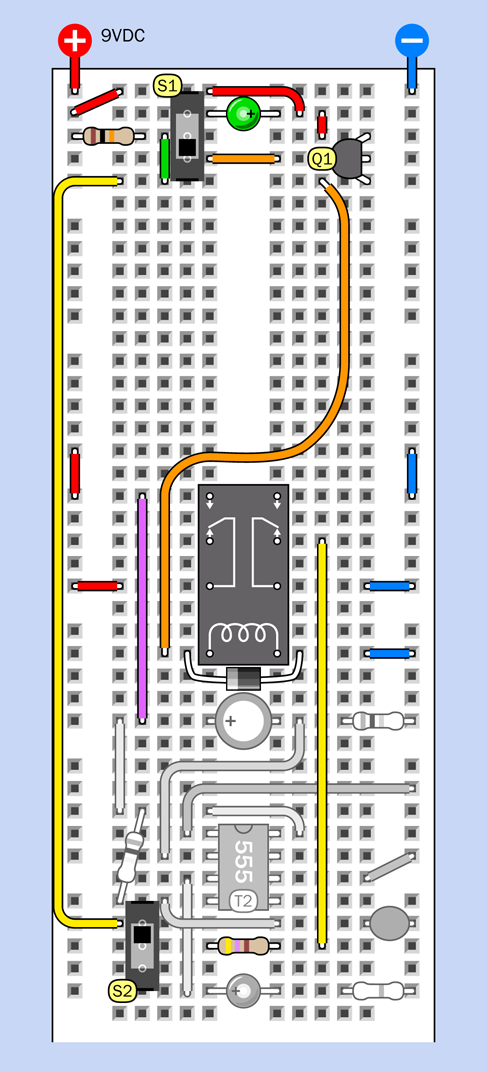

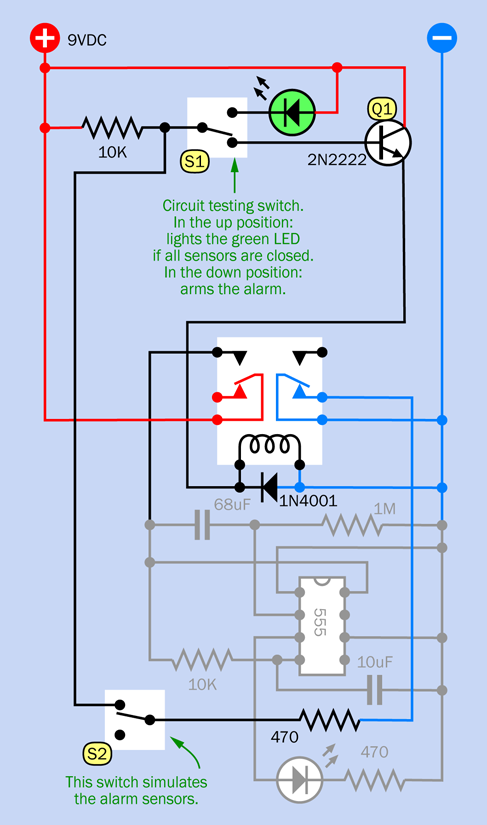

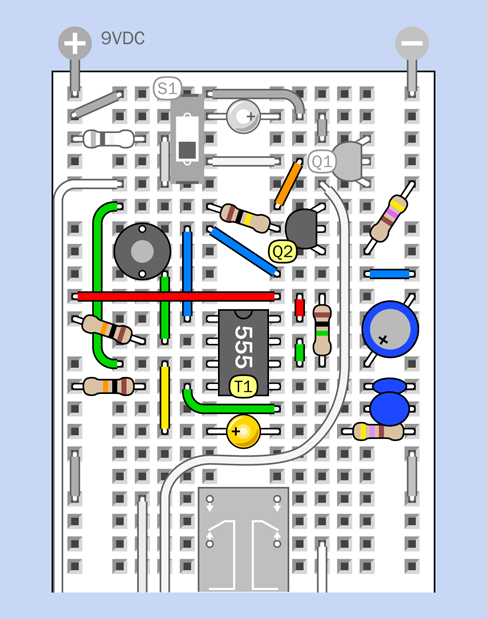

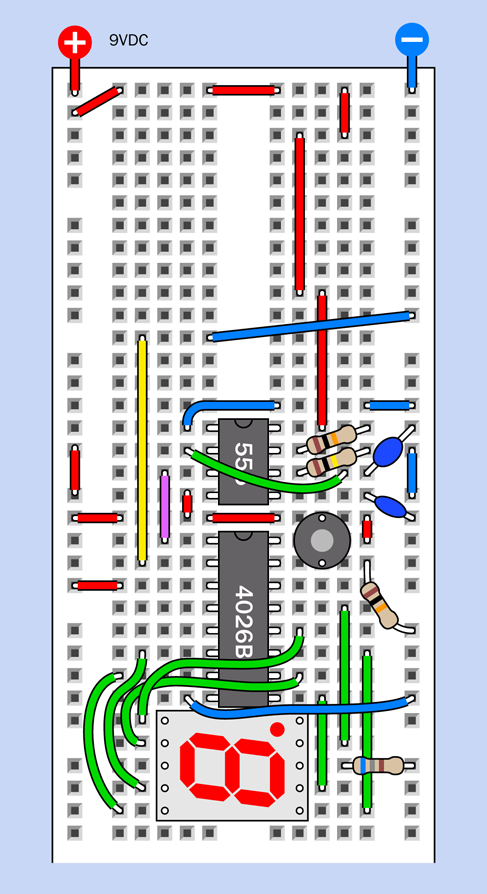

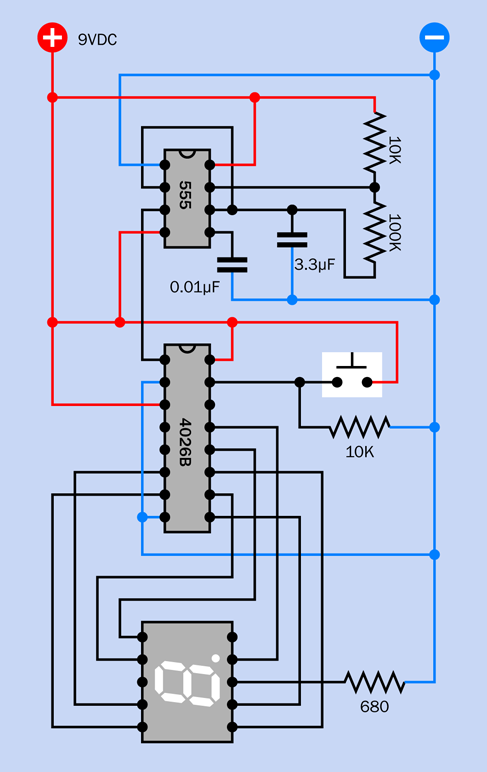

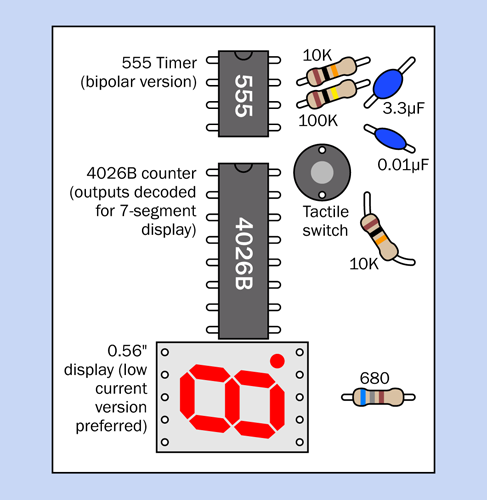

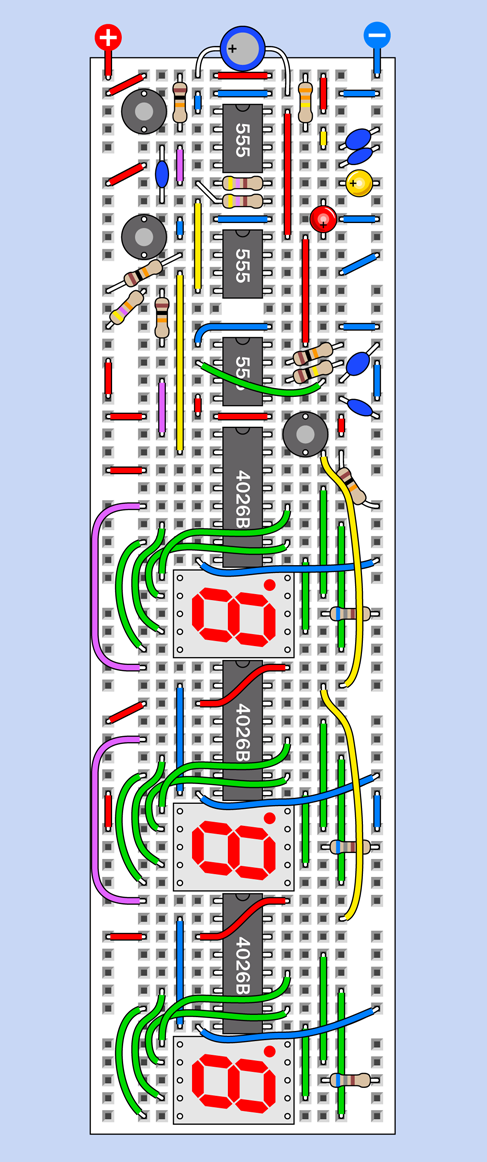

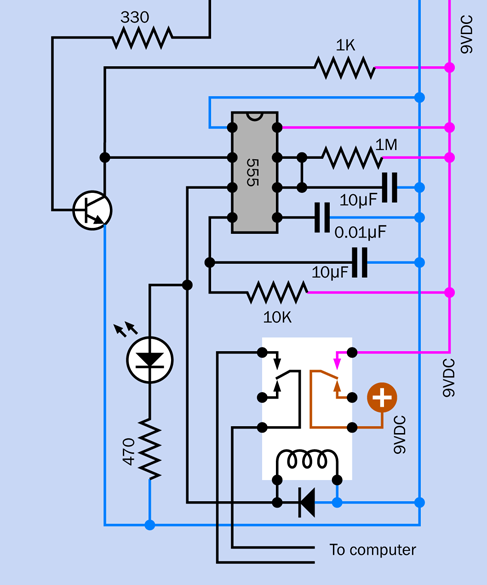

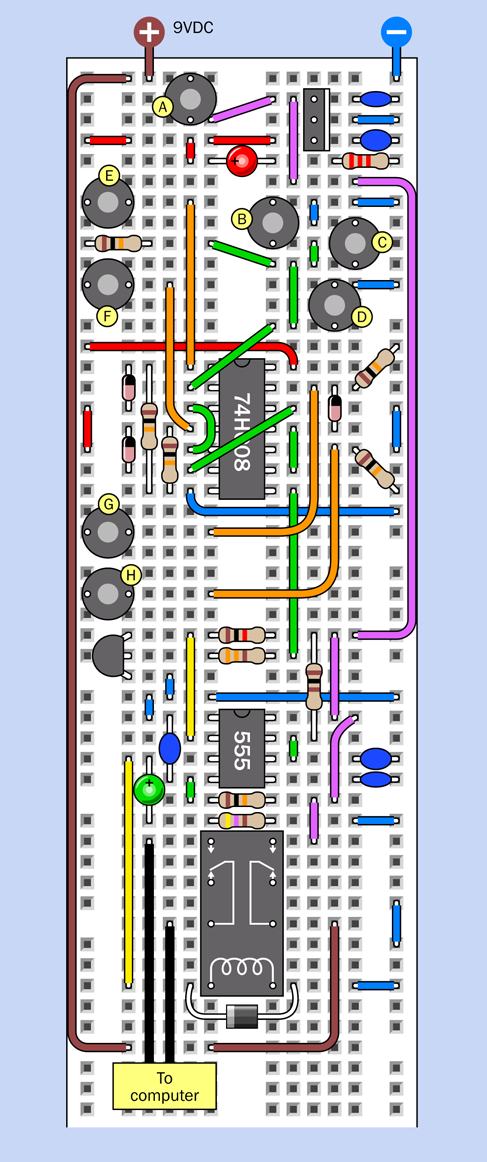

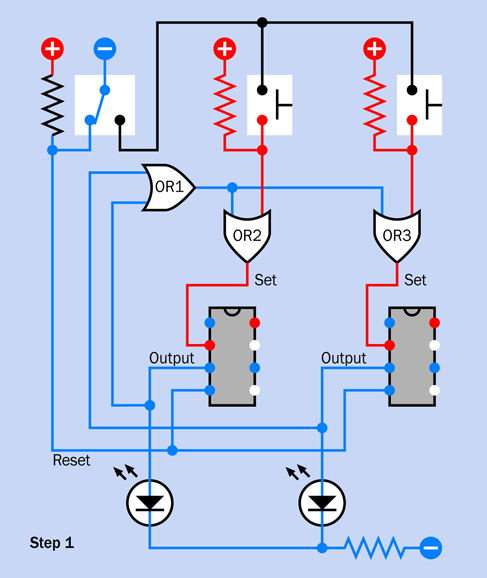

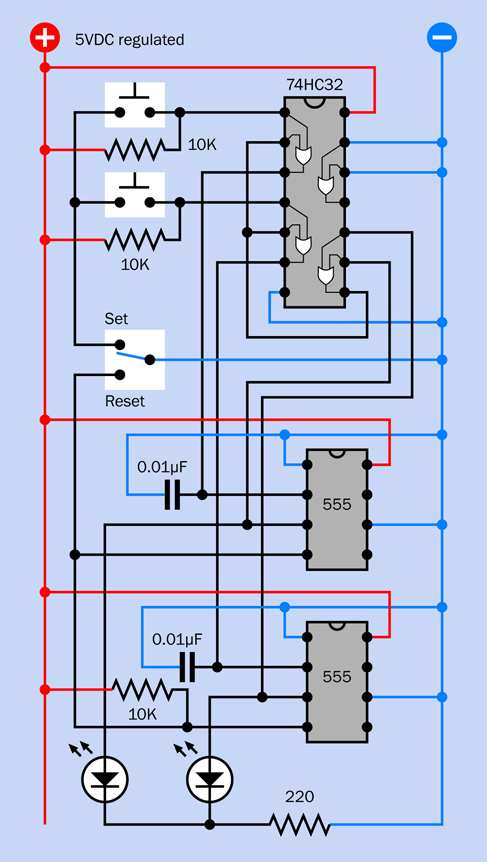

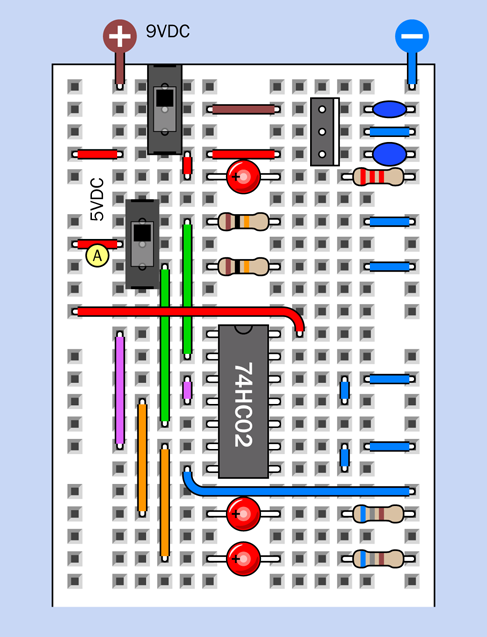

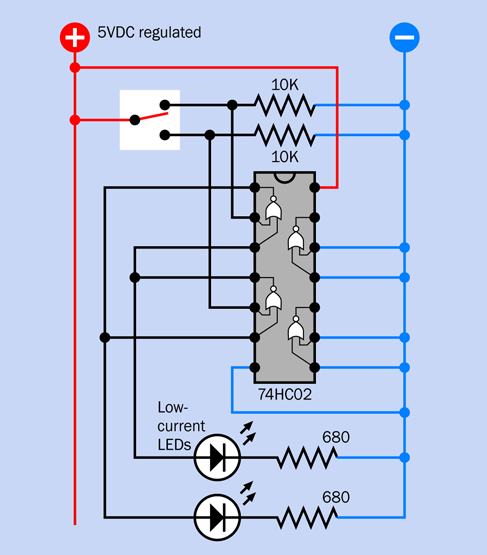

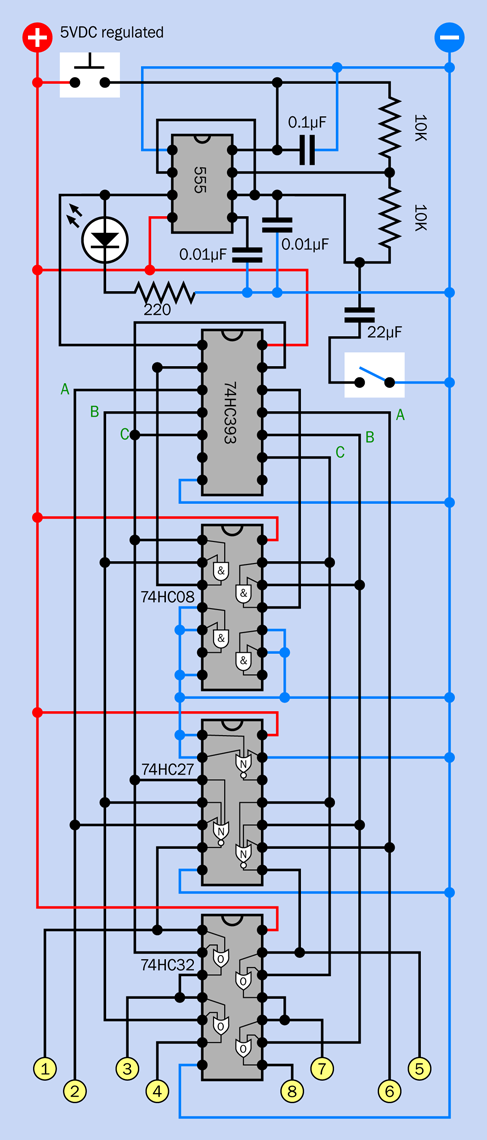

This is a larger and more complicated circuit than anything you have tackled so far, but it’s relatively easy to build, because you can assemble it in three parts that you can test individually. Eventually you’ll end up with a breadboard looking like Figure 4-45, with component values in Figure 4-46. The equivalent schematic is shown in Figure 4-47. But we’ll begin with just a small timer circuit.

Step 1

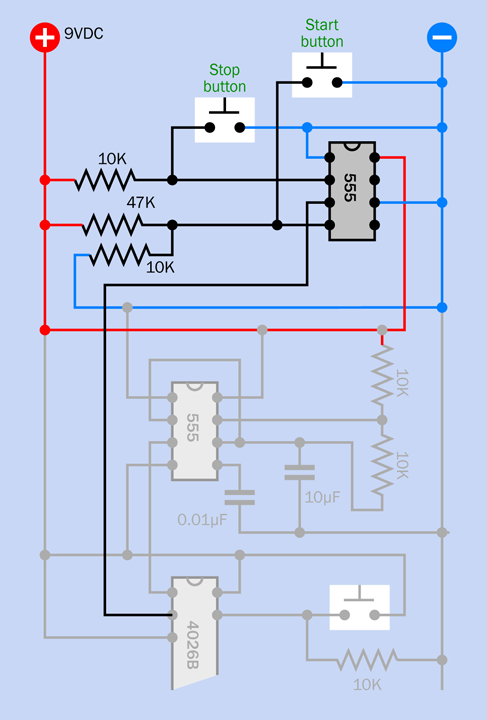

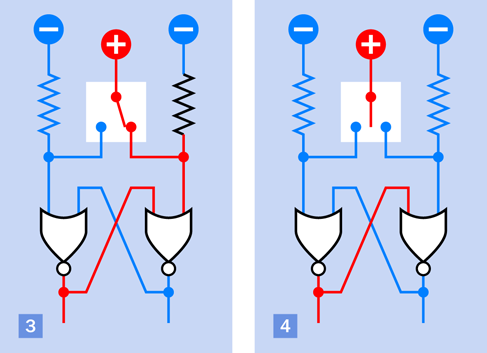

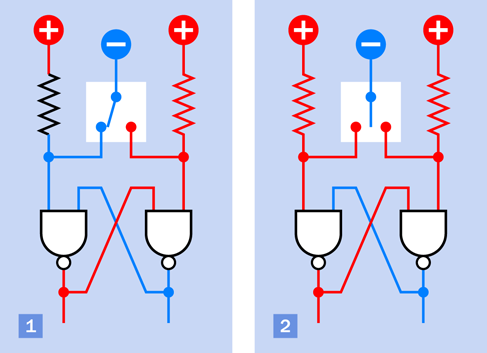

Take a careful look at Figure 4-39. Notice there are no timing components on the righthand side of the 555 timer. You may conclude that this is a version of the bistable circuit that I described in Experiment 16 (see Figure 4-20). When the timer is triggered, its output will go on indefinitely—which seems appropriate for an alarm system.

Figure 4-39. Schematic equivalent of the bottom section of the breadboard layout.

But there’s more to it than that. This circuit also gives you a one-minute grace period in which to disable the alarm before it starts to sound, when you enter the area. (You may remember that this was #9 on the wish list of features that I compiled in Experiment 15.)

To see how it works, you can assemble the components shown in Figure 4-40. Their values are shown in Figure 4-46, and you’ll see their placement at the bottom of the board in Figure 4-45.

The placement is important, because you have to leave room for the additional sections of the circuit that you’ll be adding. One of those sections will be switching on the power to this one.

To make sure that you have everything in the right place, the 1M resistor on the right is on the 29th row in the board, counting down from the top. Also note that power is being applied near the components, not at the top of the board, and the positive bus is not being used, yet.

Don’t power up the circuit just yet. Set your meter to measure at least 10VDC and attach it at the points shown in Figure 4-40, with the negative probe on the negative bus and the positive probe at the left end of the 1M resistor.

Figure 4-40. Placement of components at the bottom of the breadboard for testing.

Now apply power to the circuit, and you should see your meter slowly counting down from 9V. When it gets to one-third of the supply voltage, this triggers the 555 timer, and the red LED comes on. The LED is included for testing purposes; in the final version, you would substitute a noisemaking circuit.

The large 68µF capacitor delays the response of the timer. When you first apply power to the circuit, the capacitor passes the initial pulse to the point between it and the 1M resistor. The green wire runs from this point to the trigger pin of the timer. So, the pin starts off high, and you’ll remember (I hope) that the timer does nothing until the trigger pin goes low.

Voltage on the righthand side of the capacitor leaks out very slowly through the 1M resistor. Eventually, it goes low enough to trigger the timer.

As for the rest of the circuit, in Experiments 16 and 17 I explained how to do “pulse suppression” to stop the timer from emitting a pulse when it is first powered up. This is why I have a 10µF capacitor and a 10K resistor applied to pin 4, the reset pin. I’m using a 10µF capacitor this time, instead of a 1µF capacitor, because this circuit reacts a bit more slowly than the one in Experiment 17.

-

You can use a 555 timer with these components any time you want to delay the timer output in response to a trigger pulse.

-

Use a larger or smaller value for the 68µF capacitor if you want to make the delay longer or shorter.

So far, so good. This part of the circuit will introduce a delay when it is powered up, and after the delay, it will activate the alarm for an indefinite period.

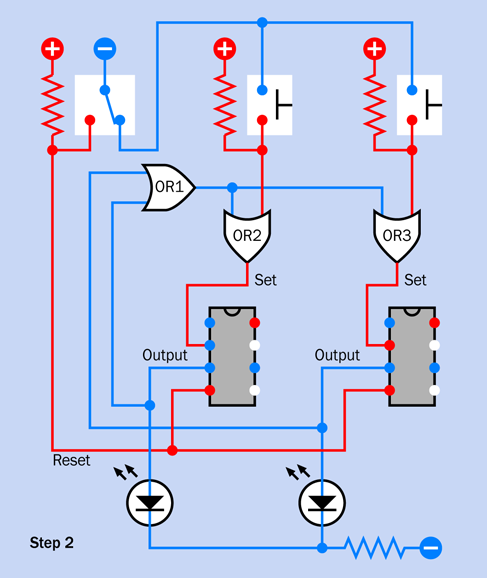

Step 2

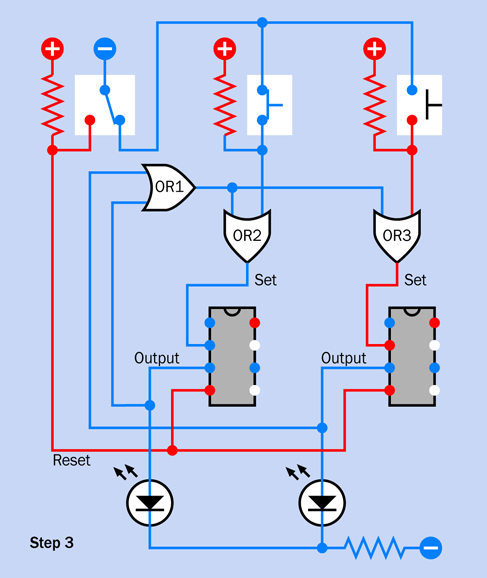

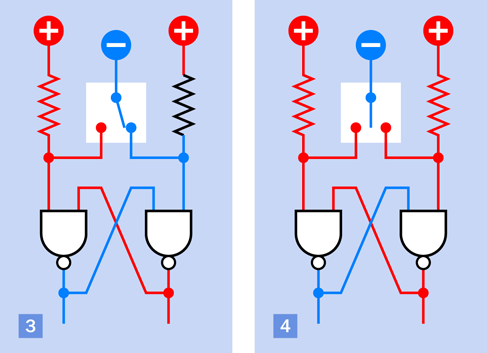

Figure 4-41 and Figure 4-42 show the next step in building the circuit. The components that you placed previously are still there, but they have been grayed out to focus your attention on the new additions.

Don’t forget to install S2, the slide switch at the bottom, and the 470-ohm resistor beside it, and the two long yellow wires. This slide switch is included for testing purposes. It represents the alarm sensors that you would use in an actual application.

The relay has the same function as in Experiment 15. In fact if you trace the connections in the circuit, you’ll find that it works the same way as the one in Figure 3-88, with a couple of minor revisions. The only differences are that a 470-ohm resistor has been substituted for a 1K resistor, and I have added switch S1 at the top, with a green LED. Why? I’ll get to that in a moment.

Place all the components carefully. Don’t overlook the three red wires on the left and the three blue wires on the right. Make sure the pins of the relay are aligned with the wires that serve them.

Double-check that S1 is in the down position, and S2 is in the up position. For testing purposes, remove the 68µF capacitor so that the red LED will respond right away instead of waiting for a minute.

Attach power—and if you made all the connections correctly, nothing should happen. Switch S2 represents the alarm sensors, and in its up position, it simulates them being closed. Slide it down to simulate a sensor being opened, and the test LED at the bottom of the circuit should light up immediately. Slide the switch up, and the LED stays on. The circuit has locked the alarm on, regardless of a sensor being reset.

Figure 4-41. The second step in building this circuit incorporates the relay configuration that was used in Experiment 15.

Figure 4-42. Schematic equivalent of the breadboarded second stage in the circuit.

Disconnect the power, keep S2 in its up position (simulating the sensors being closed), and reapply the power. Now move S1, at the top, to its up position, and the green LED comes on. This is a circuit-testing feature. It checks that all the sensors are closed. When you use the alarm, you will want to conduct this test before you leave the area. This satisfies the first part of item #7 in the wish list from Experiment 15.

Keep S1 in its up position while you move S2 to its down position, to simulate an open sensor. The green LED goes out. Move S2 to its up position, and the green LED comes back on. So, the testing procedure works.

Here’s how you would actually use this circuit. You leave S1 in the up (test) position. When you are ready to leave the area, you apply power to the circuit. If the green LED doesn’t come on, there is a door or window open somewhere. Find the source of the problem, and correct it. When the green LED is on, you know that all the sensors are closed. Now you can arm the alarm. Move S1 down. The green LED goes out, and the alarm is now armed. When you come home, the 555 timer gives you one minute to disable the alarm, to prevent it from going off (so long as you have replaced the 68µF capacitor in the circuit). You can disable the alarm by moving S1 to its up (test) position.

Now, how and why does the circuit work?

The 10K resistor at top-left connects with the base of transistor Q1 through switch S1, when the switch is in its down position. Meanwhile, the righthand pole contact inside the relay is connected to negative ground. This connection runs through the yellow wire on the right, through a 470-ohm resistor, through switch S2 (which simulates the sensors), and back up through the other long yellow wire. It holds the base of the resistor at a low voltage (through the orange wire). So long as the base is low, the transistor doesn’t conduct.

If a sensor opens, the base of the transistor isn’t held low anymore, and the 10K resistor pulls it up so that the transistor starts to conduct. It triggers the relay, through the long curving orange wire. The relay will supply power to the bistable timer, which will eventually activate the alarm. At the same time, the relay breaks the negative-ground connection on the right, so now the transistor is going to continue conducting even if the sensor is closed again.

This is exactly the same circuit concept that I ended up with in Figure 3-88. The significant difference is the green LED. When you move S1 to its “test” position, it cuts off positive power to the transistor (so that the transistor cannot start the alarm). If all the sensors are closed, the LED connects through them, and the 470-ohm resistor, to negative ground, and it lights up to tell you that the system is ready.

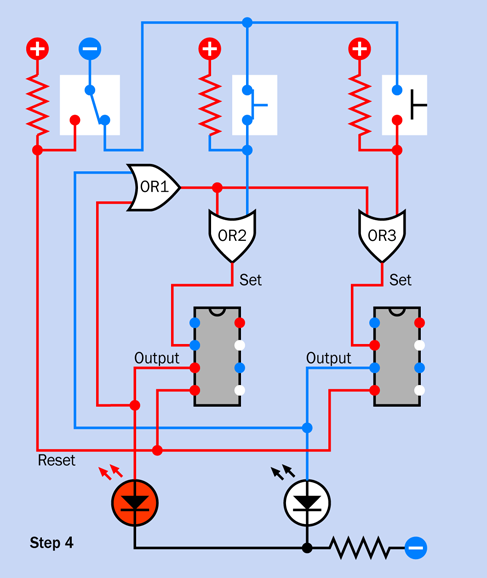

Step 3

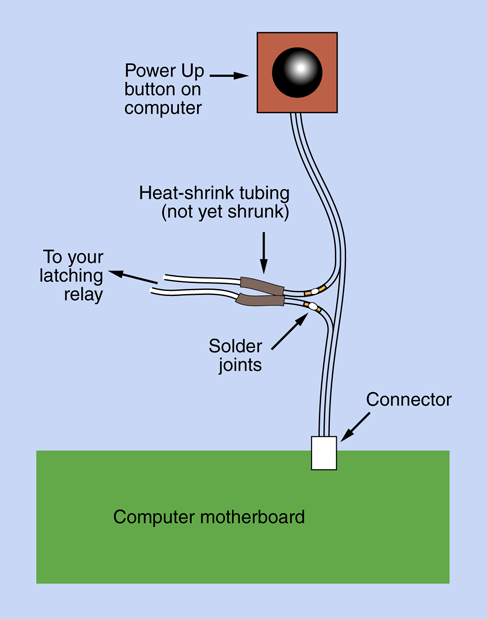

What else could we need in this project? Well, imagine you are using the alarm system. You want to set it before leaving the area. At this point, you suddenly realize that if you set it, and then open a door to leave, you will trigger the alarm.

The bistable timer with its 68µF capacitor added a feature to suppress the alarm for a minute, to give you time to turn it off when you arrive. Now we need another timer to suppress the alarm for a minute when you leave.

This is a little more difficult to arrange. The key is to have the extra timer pull down the voltage on transistor Q1, so that it can’t trigger the relay.

The problem is, a timer output goes high, not low, during its “on” cycle. I’ll have to add another transistor to convert the high output so that it pulls down the voltage on the base of transistor Q1.

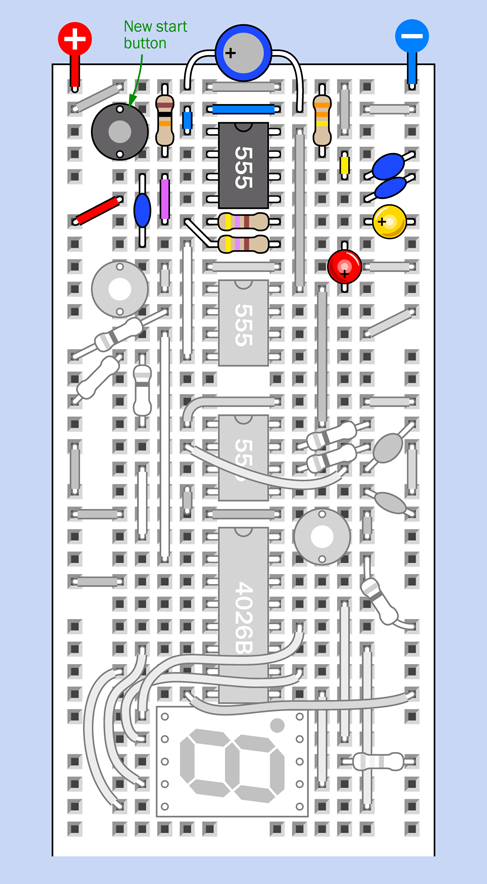

Figure 4-43 and Figure 4-44 show the components that will make it happen. Once again I have grayed out the components that you placed previously.

Figure 4-43. Third and final step in building the alarm circuit.

Figure 4-44. The schematic version of the third step in building the circuit.

The new 555 timer, labeled T1, has a pulse-suppression circuit on pin 4, its reset pin, like the other timer, so that it won’t emit a pulse when you power up the circuit. You press the button to start T1. The button works by grounding the trigger pin of the timer.

While the output of the timer is high, the current flows out of pin 3 (the output pin) and lights up the yellow LED. This tells you that the alarm system is counting down to being armed. So long as you see the LED, the alarm will ignore any activity that opens a sensor switch.

Pin 3 also connects through a green wire, on the left, which is like an elongated letter C. This curls around to a 100K resistor, which is attached to the base of Q2, a second transistor. The output from the timer, through the 100K resistor, is enough to make Q2 conduct. Its emitter is grounded through a 470-ohm resistor, while its collector is attached to the base of Q1. So long as Q2 is conducting, it grounds the base of Q1, and prevents Q1 from triggering the relay and starting the alarm.

In this way, timer T1 stops the alarm from going off. When the one-minute grace period ends, T1 stops conducting, doesn’t pull down the voltage on the first transistor anymore, and the alarm can go off—provided you remembered to move the switch at the top out of “test” mode, of course.

You would now use the circuit like this.

-

First put switch S1 into its “test” position and close all the doors and windows until the green LED comes on.

-

Move S1 into its lower position, so that the alarm is ready.

-

Press the button, and leave, closing the door behind you, while the yellow LED is on.

Does your version do what it is supposed to do? It should, so long as you wired it carefully. Timer T1 should light the yellow LED under any circumstances, making it easy to test. You can also touch your meter probe on the base of Q1, to verify whether the voltage is relatively high or low. So long as the voltage is relatively low, the alarm will not be triggered. When the voltage goes high, the alarm is triggered.

Don’t forget to replace the 68µF capacitor in the circuit, just below the relay, to reactivate the delay timer, when your alarm is ready for prime time.

The complete breadboarded circuit is shown in Figure 4-45, the component values are in Figure 4-46, and the schematic is in Figure 4-47.

Figure 4-45. Breadboard layout for the complete alarm circuit.

Figure 4-46. Component values in the breadboard layout.

Figure 4-47. Schematic equivalent of the breadboarded alarm circuit.

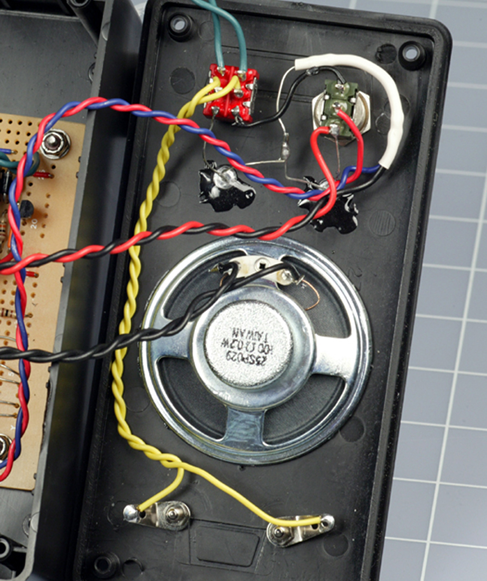

What About the Noise?

When you want the alarm to make noise, you’ll need to substitute an audio circuit or device for the red LED that you have been using for testing purposes.

The easy way to do this is to use an off-the-shelf item. Hundreds of sirens are available cheaply, ready to make an annoying sound if you simply apply power. Many of them require 12VDC, but they deliver almost as much noise at 9VDC. Just remember that timer T2 cannot deliver much more than 150mA.

If you prefer to have a sound that’s all your own, you can use the circuit that I showed in Figure 4-36. Just use the output from your relay to power this circuit, and you have your own sound.

What About On and Off?

You’ve been testing the circuit by applying and removing power. You can add an on-off switch, but a numeric code to switch off the alarm would be more desirable.

Right now, I can’t show you how to implement that, because it requires logic chips that I have not dealt with yet. But Experiment 21 will show you how it can be done.

Finalizing

Meanwhile, since the alarm circuit does actually work in its current form, I want to talk about finalizing it. By this I mean soldering it to a board, mounting the board in a box, and making everything look nice. My main concern in this book is electronics, but still, finalizing a project is an important part of the making experience, so I’ll give you some suggestions.

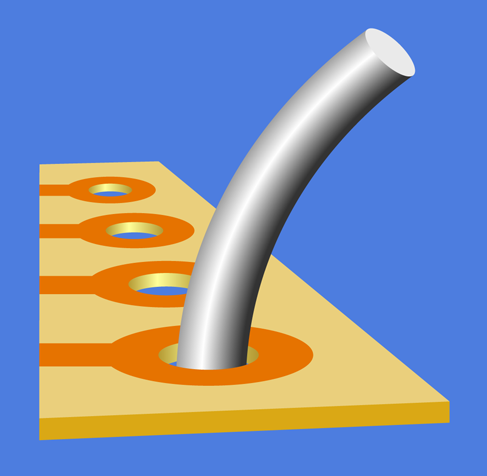

Soldering the circuit can be easier than the procedure in Experiment 14, where I explained point-to-point wiring. You can mount the components on the type of perforated board that has copper traces on the back, in a configuration identical to the connectors inside a breadboard. Simply move each component to its comparable position, and solder it to the copper conductor underneath. No wire-to-wire soldering is necessary.

Guidance for finding and buying this kind of board is in “Supplies” near the end of the book.

Now, how to proceed:

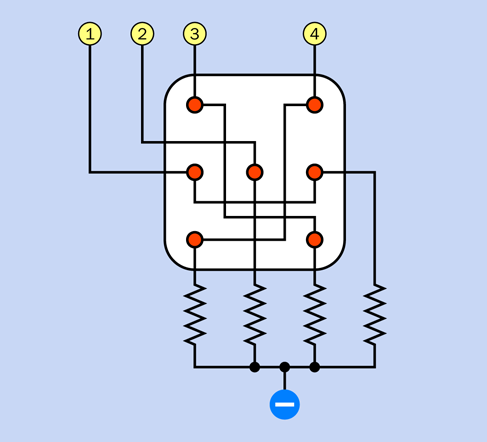

Carefully note the position of a component on your breadboard, then move it to the same relative position on the perforated board, poking its wires through the little holes.

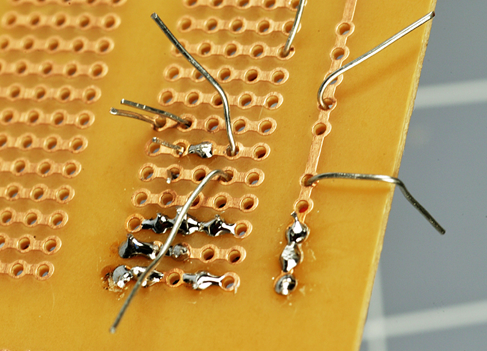

Turn the perforated board upside down, make sure that it’s stable, and examine the hole where the wire is poking through, as shown in Figure 4-48, which shows the underside of the board (the component is on the other side). A copper trace surrounds this hole and links it with others. Your task is to melt solder so that it sticks to the copper and also to the wire, forming a solid, reliable connection between the two of them.

Figure 4-48. The underside of perforated board, with a wire sticking through.

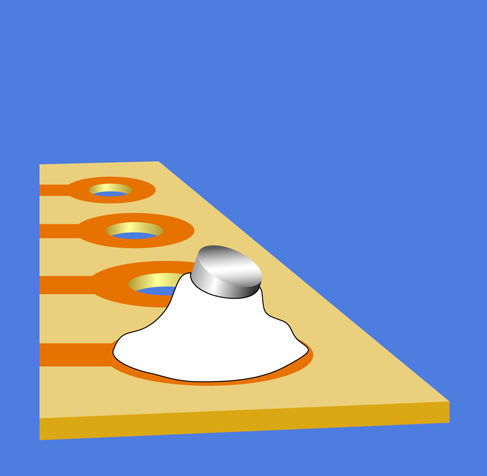

Clamp the perforated board or rest it on a surface where it won’t skid around easily. Take your low-wattage soldering iron in one hand and some solder in your other hand. Hold the tip of the iron against the wire and the copper, and feed some thin solder to their intersection. After two to four seconds, the solder should start flowing.

Allow enough solder to form a rounded bump sealing the wire and the copper, as shown in Figure 4-49. Wait for the solder to harden thoroughly, and then grab the wire with pointed-nosed pliers and wiggle it to make sure you have a strong connection. If all is well, snip the protruding wire with your cutters. See Figure 4-50.

Figure 4-49. Ideally, your solder joint should look something like this.

Figure 4-50. After the solder has cooled and hardened, you snip off the projecting wire.

Because solder joints are difficult to photograph, I’m using drawings to show the wire before and after making a reasonably good joint. The solder is shown in pure white, outlined with a black line.

The process of actually soldering components into perforated board is illustrated in Figure 4-51 and Figure 4-52.

Figure 4-51. This photograph was taken during the process of transferring components from breadboard to perforated board. Two or three components at a time are inserted from the other side of the board, and their leads are bent over to prevent them from falling out.

Figure 4-52. After soldering, the leads are snipped short and the joints are inspected under a magnifying glass. Another two or three components can now be inserted, and the process can be repeated.

Most Common Perfboarding Errors

1. Too much solder. Before you know it, solder creeps across the board, touches the next copper trace, and sticks to it, as depicted in Figure 4-53. When this happens, you can either try to suck it up with a desoldering kit, or carve it away with a knife. Personally I prefer to use a knife, because if you suck it up with a rubber bulb or solder wick, some of it will tend to remain.

Figure 4-53. If you use too much solder, it will tend to end up in places where you don’t want it.

Even a microscopic trace of solder is enough to create a short circuit. Check the wiring with a magnifying glass while turning the perforated board so that the light strikes it from different angles.

2. Not enough solder. If the joint is thin, the wire can break free from the solder as it cools. Even a microscopic crack is sufficient to stop the circuit from working. In extreme cases, the solder sticks to the wire, and sticks to the copper trace around the wire, yet doesn’t make a solid bridge connecting the two, leaving the wire encircled by solder yet untouched by it, as shown in Figure 4-54. You may find this undetectable unless you observe it with magnification.

Figure 4-54. Too little solder (or insufficient heat) can allow a soldered wire to remain separate from the soldered copper on the perforated board. Even a hair-thin gap is sufficient to prevent an electrical connection.

You can add more solder to any joint that may have insufficient solder, but be sure to reheat the joint thoroughly.

3. Components incorrectly placed. It’s very easy to put a component one hole away from the position where it should be. It’s also easy to forget to make a connection.

I suggest that you print a copy of the schematic, and each time you make a connection on the perforated board, you eliminate that wire on your hardcopy, using a highlighter.

4. Debris. When you’re trimming wires, the little fragments that you cut don’t disappear. They start to clutter your work area, and one of them can easily get trapped under your perforated board, creating an electrical connection where you don’t want it.

Clean the underside of your board with an old toothbrush before you apply power to it. Dip the toothbrush in rubbing alcohol to remove flux residues. Keep your work area as neat as possible. The more meticulous you are, the fewer problems you’ll have later.

Once again, be sure to check every joint with a magnifying glass.

Fundamentals: Perforated Board Fault Tracing

If the circuit that worked on your breadboard doesn’t work after you solder it to perforated board, your fault tracing procedure is a little different from that which I outlined previously.

First look at component placement, because this is the easiest thing to verify.

If all the components are placed correctly, flex the board gently while applying power. If you now get an intermittent response from the circuit, you can be virtually certain that solder didn’t stick where it was supposed to stick, or a joint has a tiny crack in it.

Anchor the black lead of your meter to the negative side of the power supply, then switch on the power and go through the circuit point by point, from top to bottom, checking the voltage at each point with the red lead of the meter while you continue to flex the board. In most circuits, almost every part should show at least some voltage. If there is a dead zone, or if your meter responds intermittently, you can zero in on a joint that has something wrong with it, even though it looks good superficially.