Treehouse Projects

If you’ve stuck with us from the beginning of the book you’ve learned how to design and build each part of a treehouse. Now you can see all those parts come together in two start-to-finish treehouse projects completed in real backyards. The designs of the houses are intentionally quite different: One is a lot like a terrestrial house and is built in a single tree; the other is an open-sided affair supported by a large tree and two posts. Of course, these projects just scratch the surface of options and features that you might incorporate into your own design. For a few more ideas, check out the treehouse plans on pages 196–219.

In this chapter:

▪ Gable Roof with Auxiliary Posts

Open-air Treehouse

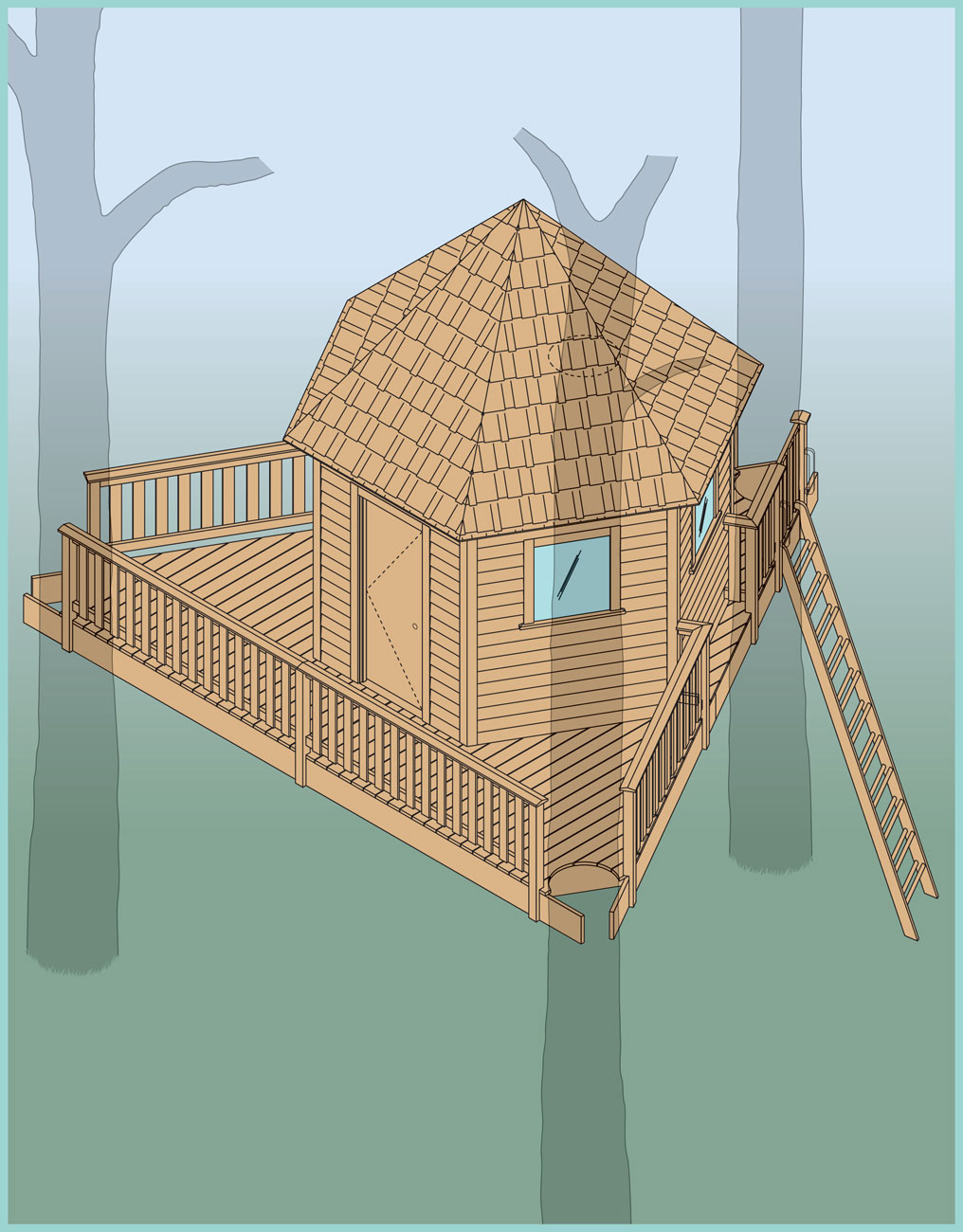

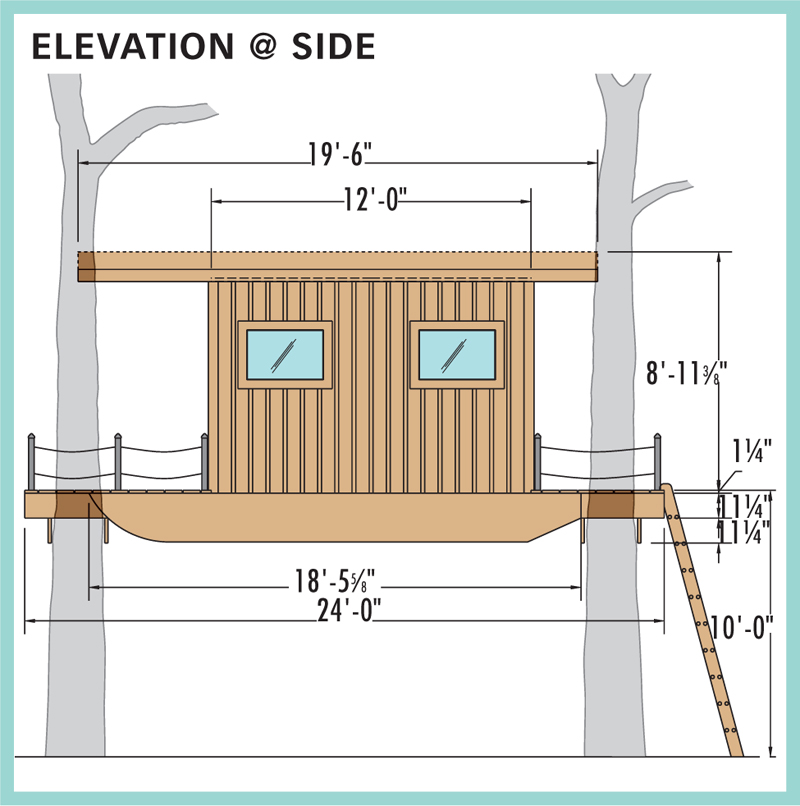

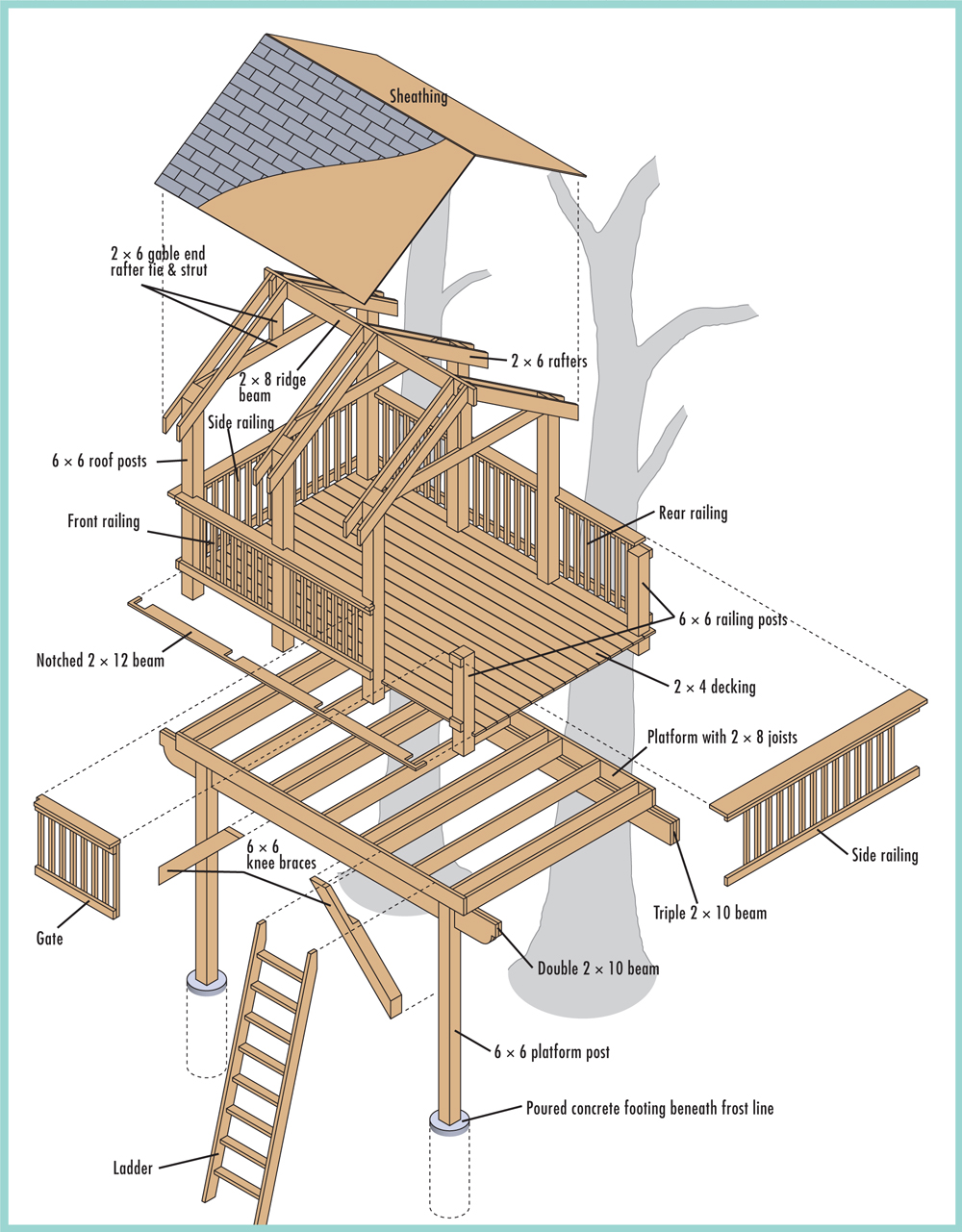

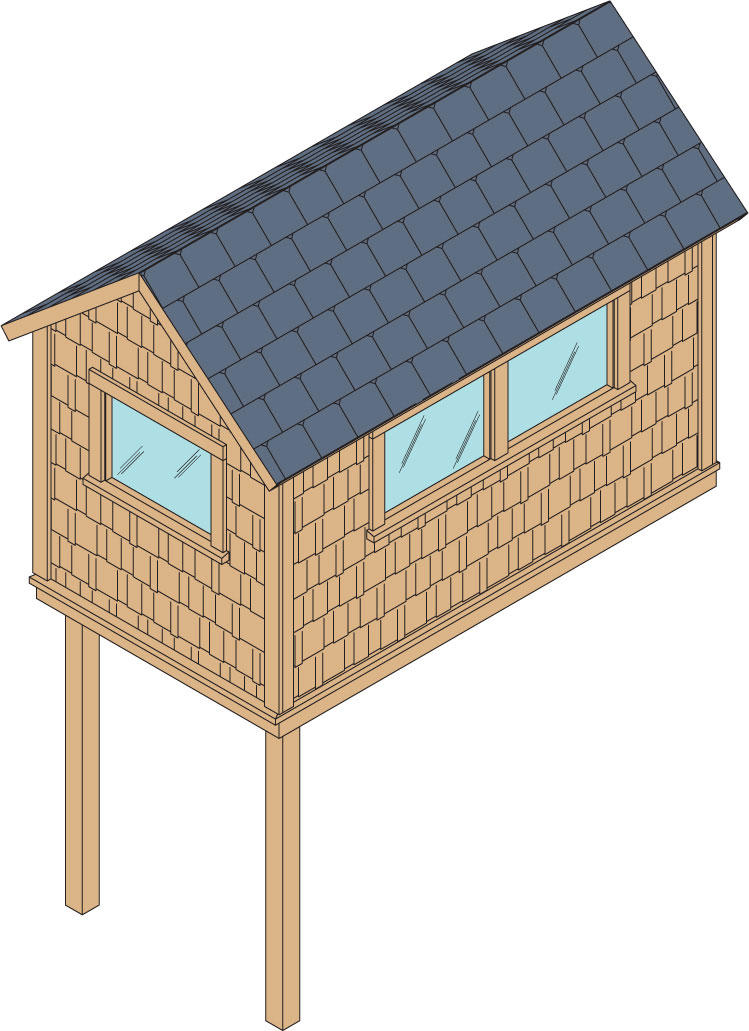

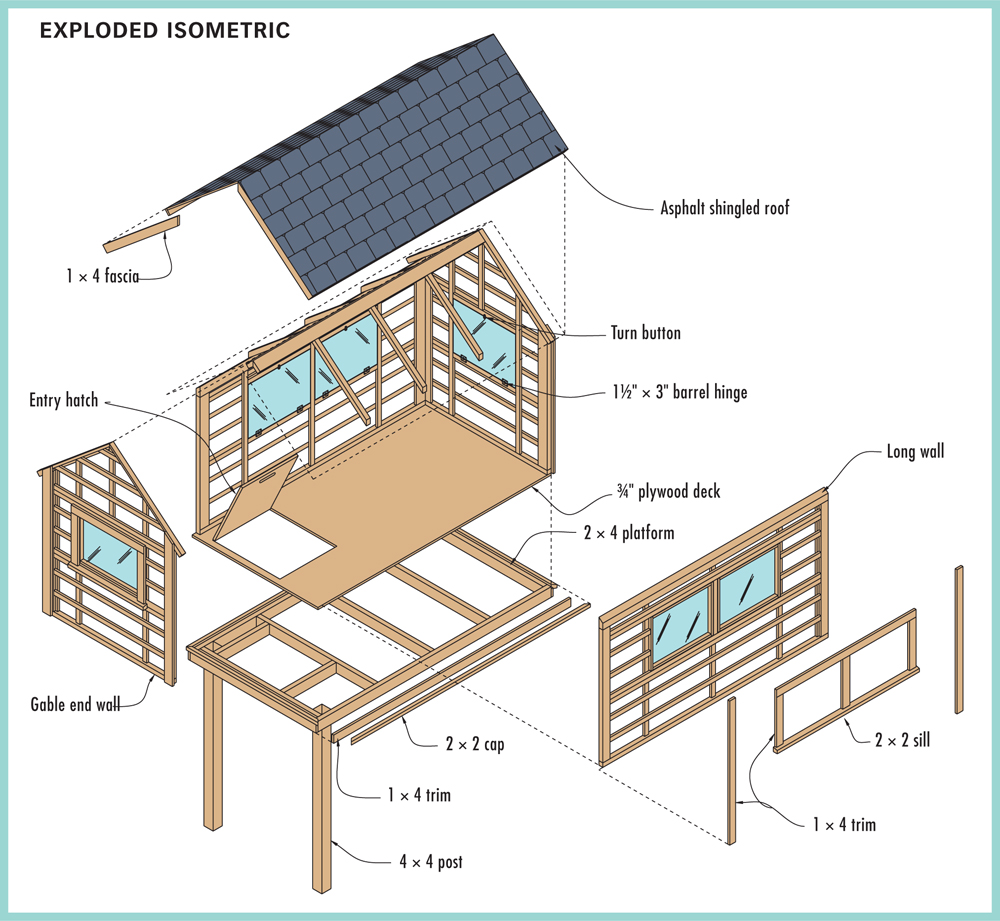

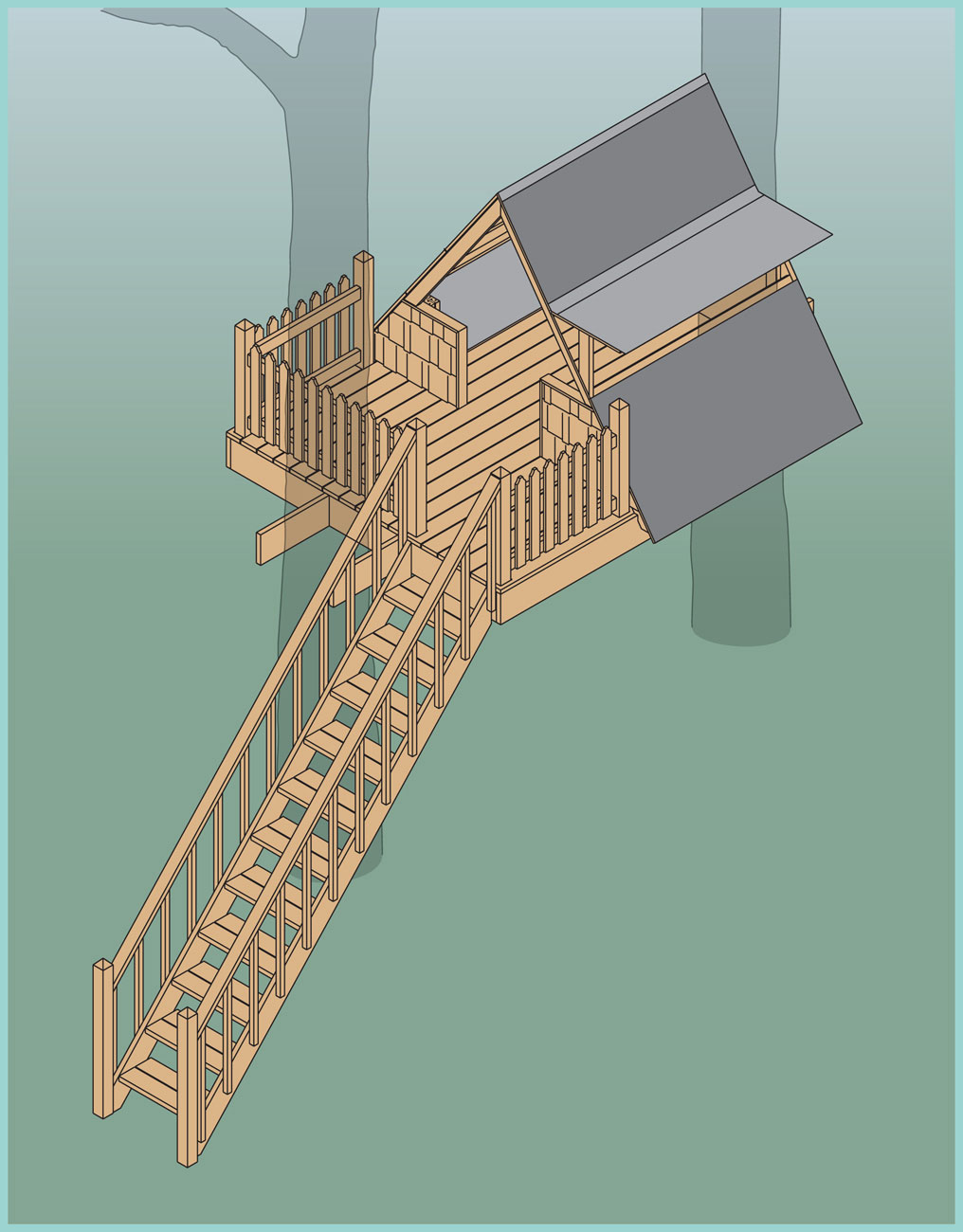

Open-air TreehouseThis house design could just as easily be called the All-ages Treehouse. Adults will like it because they can move around in the house without having to see their chiropractor the next day and because the broad deck surface and ample headroom make it a great venue for outdoor entertaining and everyday cocktails at sundown. Kids will love it because, well, because it’s a treehouse, but also because it’s large enough to fit loads of them. The open sides are ideal for backyard games, and the deck makes the perfect stage for picnics and campouts. Best of all, everyone can use the treehouse at once, although this may require a willingness to dodge water balloons or act as a captive on a pirate ship.

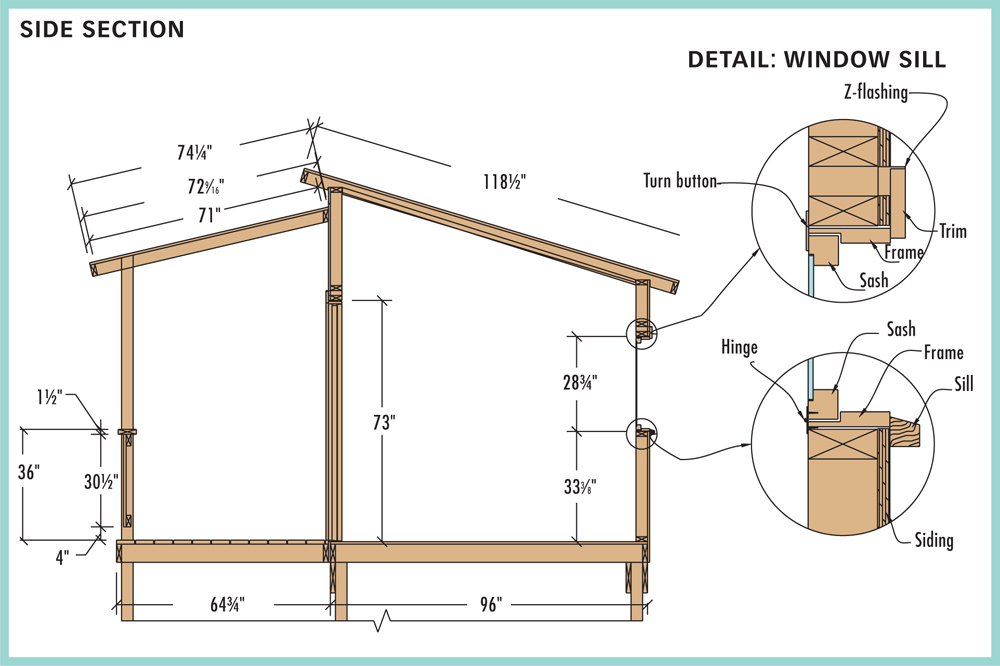

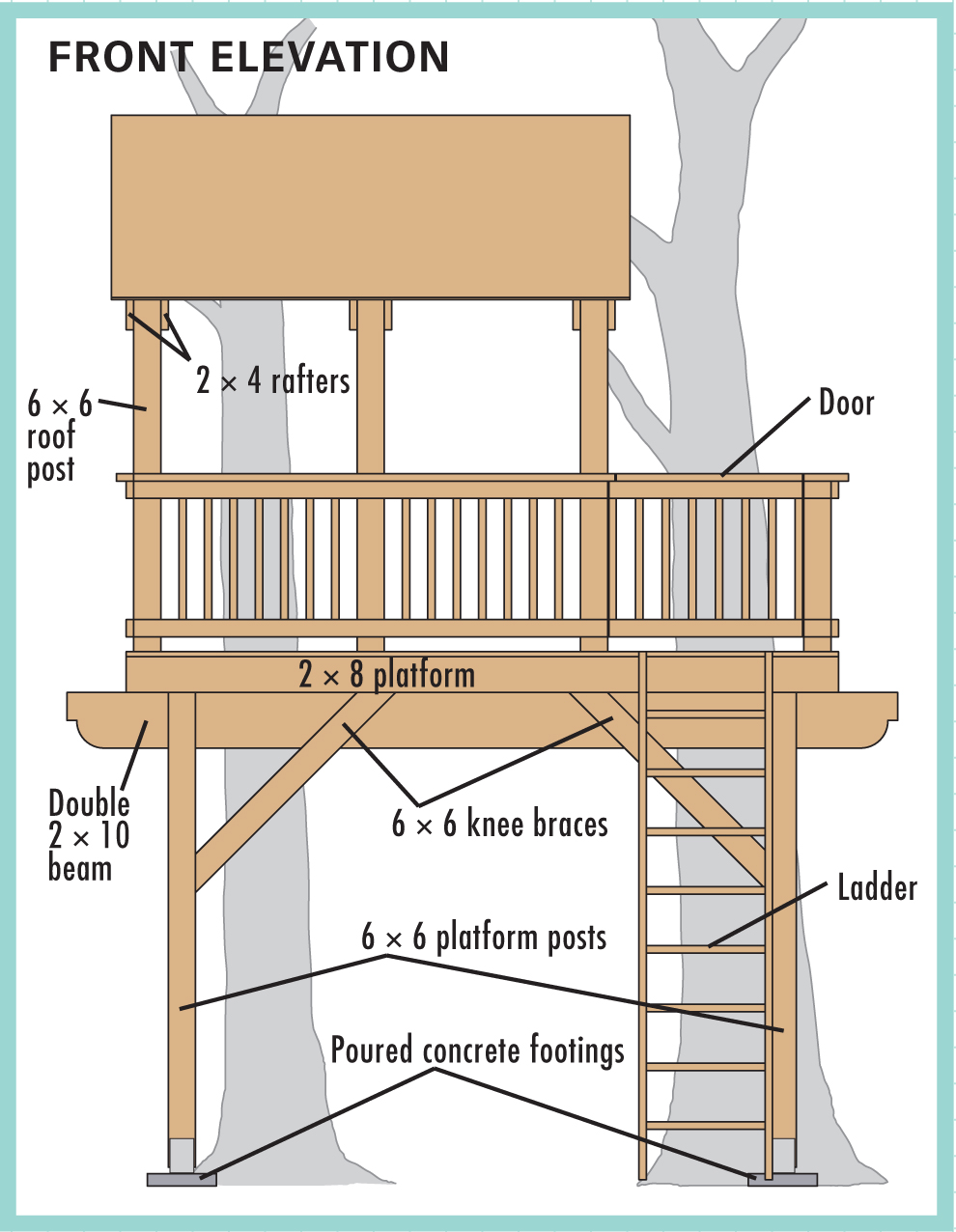

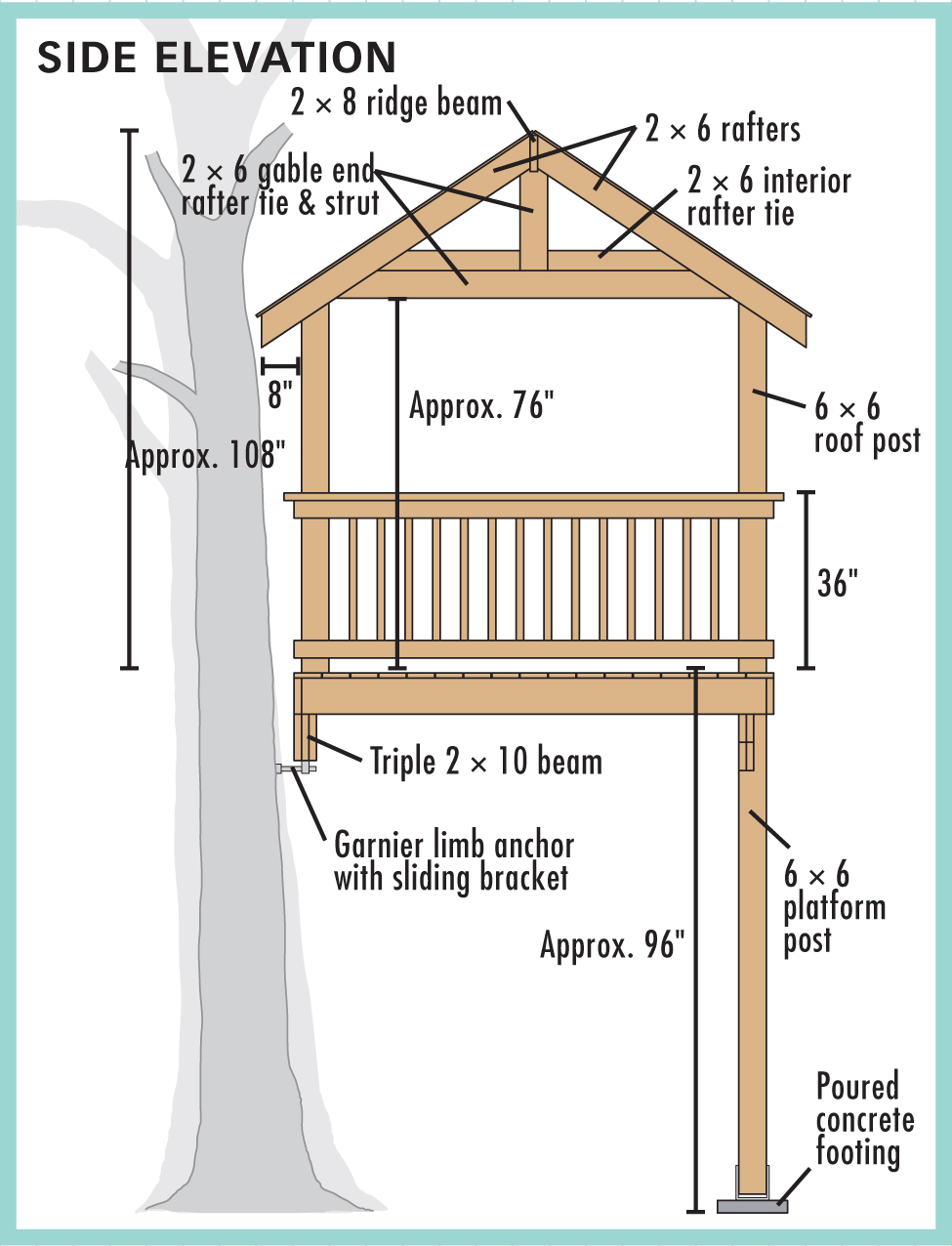

The house shown in this project has an 8 × 12-foot floor plan and measures about 9 feet from the deck to the roof peak. It’s supported along the front side by two posts and along the rear side by two trees (see page 171), using special anchors designed specifically for treehouses. The treehouse deck stands about 8 feet off the ground.

The instructions here provide a detailed overview of building the house as shown, for this particular site. They can serve as a general guide to help you design and build a similar house of your own. However, all of the construction specifications for your project must be geared for your specific house design, the intended use of the house, the tree(s), and the building site, as well as any applicable local building codes and zoning restrictions.

Water-resistant cushions are ideal for the open-air treehouse, perfect for extra seat padding or just throwing on the ground—it’s a treehouse, after all.

The open-air treehouse combines the versatility of an elevated deck with the shelter of a covered porch, but of course it’s far better than both because it’s found in the trees.

This treehouse has four anchor points: one 6 × 6 post at each of the front corners of the platform and one tree anchor near each of the rear corners. The anchors used here are the standard GL anchors (see Resources page 220), which screw directly into the tree and support a structural beam for the treehouse platform. If you use GL or other tree anchors, be sure to follow the supplier’s or manufacturer’s recommendations for installation and load-bearing capacity. When installed properly, the anchors used here are rated for a load of 4,000 pounds.

Start by locating the anchor points on the host tree (or trees). Mark the trunk or limb at the approximate height of the treehouse deck minus 18" (the combined depth of the treehouse platform and beam). Inspect the tree in this area carefully to make sure it’s suitable for an anchor. It must be at least 12" in diameter, and it must be solid and healthy: no rot, fungus, cracks, splits, insect damage, or any other indications of existing or potential weakness.

If the first anchor point gets the go-ahead, level over with a long, straight board to the other tree anchor location. You can use straps or tape to hold the board in place for now; there’s no need to put in nails for this procedure. The board also tests how easily you can plane across from one anchor to the next, which you will ultimately do with the beam. Inspect the second anchor point area, then move to the ground. Measure out from the tree, or more accurately, from the board, and mark the ground at the approximate locations of the two posts. It’s best if the ground is relatively level, but most importantly it must be solid and not vulnerable to erosion.

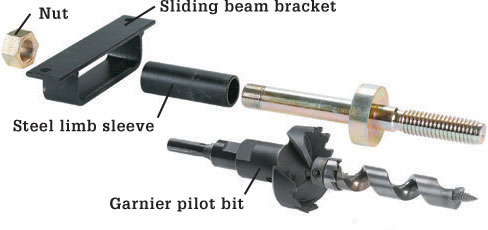

The GL tree anchor requires a precisely made 3-stage pilot hole that accommodates the leading threaded end of the anchor shaft and a short unthreaded portion of the shaft, plus a bore for the collar to bed into the cambium layer of the tree (see page 25 (Treeschool sidebar). If you use this anchor, it’s highly recommended that you drill the pilot hole with the special bit designed for this application (it’s available for purchase or rent from the supplier; see Resources page 220).

Before drilling each pilot hole, double-check the anchor locations, this time using a nail to mark the precise center of each pilot hole. The holes should be centered side-to-side on the tree trunk, pointing toward the trunk’s internal center. They should also be perpendicular to the length of the treehouse beam and perfectly level with each other. Drill each pilot hole as directed, using a heavy-duty 1/2" drill bit. It is critical that the hole is level, so monitor the position of the drill bit throughout the operation.

Use a level board as a visual reference to determine the best height and location for your tree anchors.

Use the drill bit to clear the hole of debris. Carefully hand-thread the anchor into the hole, checking for level with a torpedo level as you go. When it becomes too hard to thread by hand, use a large pipe wrench to drive the anchor the rest of the way, working until the collar is tightly compressed against the wood and you can’t budge the wrench any further. You might want to use a steel pipe slipped over the wrench handle for added leverage. Check again with the long board and level to make sure the anchors will be level with each other, then install the other anchor.

The GL anchor and its specially designed piloting bit. The middle collar section on the anchor compresses into the tree to help prevent rot and disease.

Drill the pilot hole with a heavy-duty 1/2" drill (available at any rental center). Brace yourself and pay attention to avoid injury with this powerful tool.

Level the anchor carefully as it begins to bite into the tree. A big pipe wrench (and maybe a cheater bar) is the key to getting the anchor tight (below).

Cut three 2 × 10s to length about 24" longer than the outside dimension of the platform frame, so it will overhang the platform about 12" on each end. Crown the boards so any curvature along their length is facing up (convex side of curve is at the top of the beam). Sandwich the boards with their ends aligned and fasten them together with a 20d galvanized nail driven every 32" and two nails at each end.

The beam simply sits on top of the anchors and is secured to each anchor with a sliding or fixed bracket, as applicable. The brackets are a safety backup to keep the beam on top of the anchors during tree movement. Those used here are the sliding-type bracket available from the GL supplier.

Mark the positions of the brackets on the underside of the beam, and install the brackets with lag screws, as directed. Set the beam onto the anchors, slipping the brackets over the ends of the anchors, then add a nut (with a washer, if applicable) to secure the beam.

Nail three 2 × 10s together to create the built-up rear beam. Stagger the nails between the upper and lower portions of the beam.

With the beam in position, add a nut to the end of each anchor (using a washer, if applicable) to trap the bracket on the anchor.

With the rear beam in place, you can measure from it to create an accurate layout for the two concrete post footings. Transfer the beam’s location to the ground, using a plumb bob, and mark the ground with stakes or a string line. Measure straight out from the beam, and mark the centerpoint of each post with a stake. Here, the posts are centered 91-3/4" from the rear face of the rear beam and are spaced about 10 feet apart. (The front roof posts will bear on the front beam for additional support.)

At each post location, dig a hole for an 8"-diameter concrete tube form, digging below the frost line for your area (check with your local building department for the recommended footing depth), plus 3". Add a 3" layer of gravel and tamp it down. Cut a cardboard tube form to length so it extends 2" above the ground. Set the form in the hole and secure it all around with tamped soil, making sure the form is plumb.

Fill the form with concrete and smooth it off level with the top of the form. Set a 5/8"-diameter J-bolt into the concrete so it extends 3/4" to 1" above the concrete (or as directed by the post base manufacturer). Let the concrete cure as directed.

Embed an anchor bolt into the wet concrete of each footing. The bolt should be centered on the footing.

The front beam is made with two 2 × 12s nailed together, much like the rear beam. It will sit in notches cut into the top, inside faces of the posts. Cut the two pieces to length to match the rear beam. Crown the boards (convex curve points up), and nail them together with 10d galvanized nails spaced 16" apart, plus two nails on each end. If desired, you can make decorative cuts at the ends of the assembled beam.

Build the front beam with two 2 × 12 boards, staggering 10d nails with 16" spacing. Shape the ends with decorative cuts, if desired.

Level across from the top of the rear beam to mark the top cutoff lines on the posts.

Install a post base with a standoff plate on top of each footing, using a washer and nut secured to the anchor bolt. Set an 8-foot.-long 6 × 6 post onto each base, plumb the post in both directions, and secure it in place with 2 × 4 cross bracing. You can tack the post to the base with one nail to keep it from slipping.

With both posts plumbed and braced, level over from the rear beam with a long, straight board. Mark each post with a level line that is precisely level with the top of the beam. This line represents the top of the post, where you will cut the post to its final length.

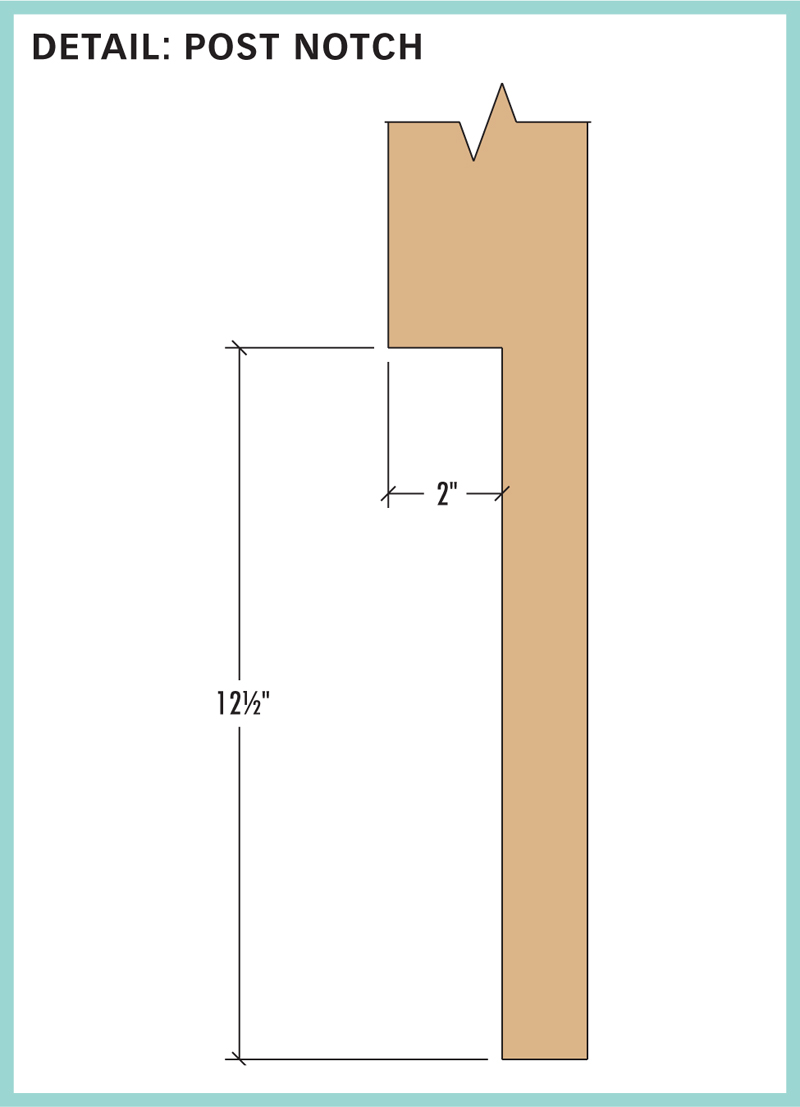

Remove the posts from their bases. Measure the depth (top-to-bottom dimension) and thickness of the front beam. Using these dimensions, mark a notch onto the rear and side faces of each post. The top of the notch is the top cutoff line you made in the last step. Cut each post at the top cutoff line, using a circular saw to cut along all four sides, then finish the cut through the center with a handsaw or reciprocating saw with a long wood blade. Cut out the notches using the same technique.

Use a square to extend the cutting lines across the post faces for the top end cutoff and notches.

Set the posts back in their bases and brace them plumb, as before. Set the front beam onto the notches of the posts (with the crown of the beam pointing up) so the beam overhangs the posts equally on both ends. Clamp the beam to the posts or tack it in place with nails. Confirm that the posts are plumb (you can adjust the base positions a bit, if needed), then anchor the posts to the bases with the manufacturer’s specified fasteners (for the bases shown, you can use galvanized nails or machine bolts, but not both).

Anchor each beam to its post with two 3/8" carriage bolts with washers. Drill a counterbore for the washers and nuts on the rear face of the beam. When all the nuts are tightened, fill the counterbores with caulk to prevent water intrusion and forestall rot.

Tack a couple of 2 × 4s across the tops of the beams to help brace the front beam and posts. Leave the posts’ cross bracing (installed earlier) in place until the treehouse platform is completed.

Fasten the posts to their bases. Make sure the base is tightened down to the anchor bolt with the provided nut.

Fasten the front beam to the posts with pairs of carriage bolts inserted through the posts and secured on the beam side with washers and nuts.

The two knee braces provide lateral support for the posts and add a traditional timber-frame look to the treehouse structure. They’re cut from a 10-foot 6 × 6 and meet the posts and front beam at a 45° angle. Note: All bracing for your project should be designed to suit your specific site conditions and house design.

Cut a 10-foot 6 × 6 in half, then miter one end of each piece at 45°. Mark the front face of each post about 36" down from the top of the front beam. Position each brace against the post and beam, with the long point of its mitered end aligned with the mark and its rear face against the front of the beam. Trace along the top and bottom of the beam onto the brace; these cuts represent the top cut and bottom of the notch for the beam.

On the inside portion of each brace, lay out the notch to match the thickness of the front beam. Cut the top end of the braces at 45°, then cut the notches with a circular saw and handsaw or reciprocating saw, as before.

Set each brace in position so its bottom end is on the original mark and its side faces are flush with the front and rear post faces. The top cut should be flush with the top of the beam. Clamp both ends of the brace in place. Drill counterbored pilot holes, and fasten the brace to the beam with two 3/8" carriage bolts and to the post with two 3/8" × 7 lag screws with washers.

Trace along the front beam to mark the top cuts and notches for the knee braces. When installed, the faces of the posts and braces are aligned.

Anchor the knee braces to the posts with lag screws driven straight through the inside faces of the braces, roughly centered on the joint.

Use a scrap of 6 × 6 post as a spacer when marking the joist layout and installing the joists. The roof posts should fit snugly between the joist pairs.

Metal framing connectors create a strong connection between the treehouse platform and the beams and are important for resisting wind uplift.

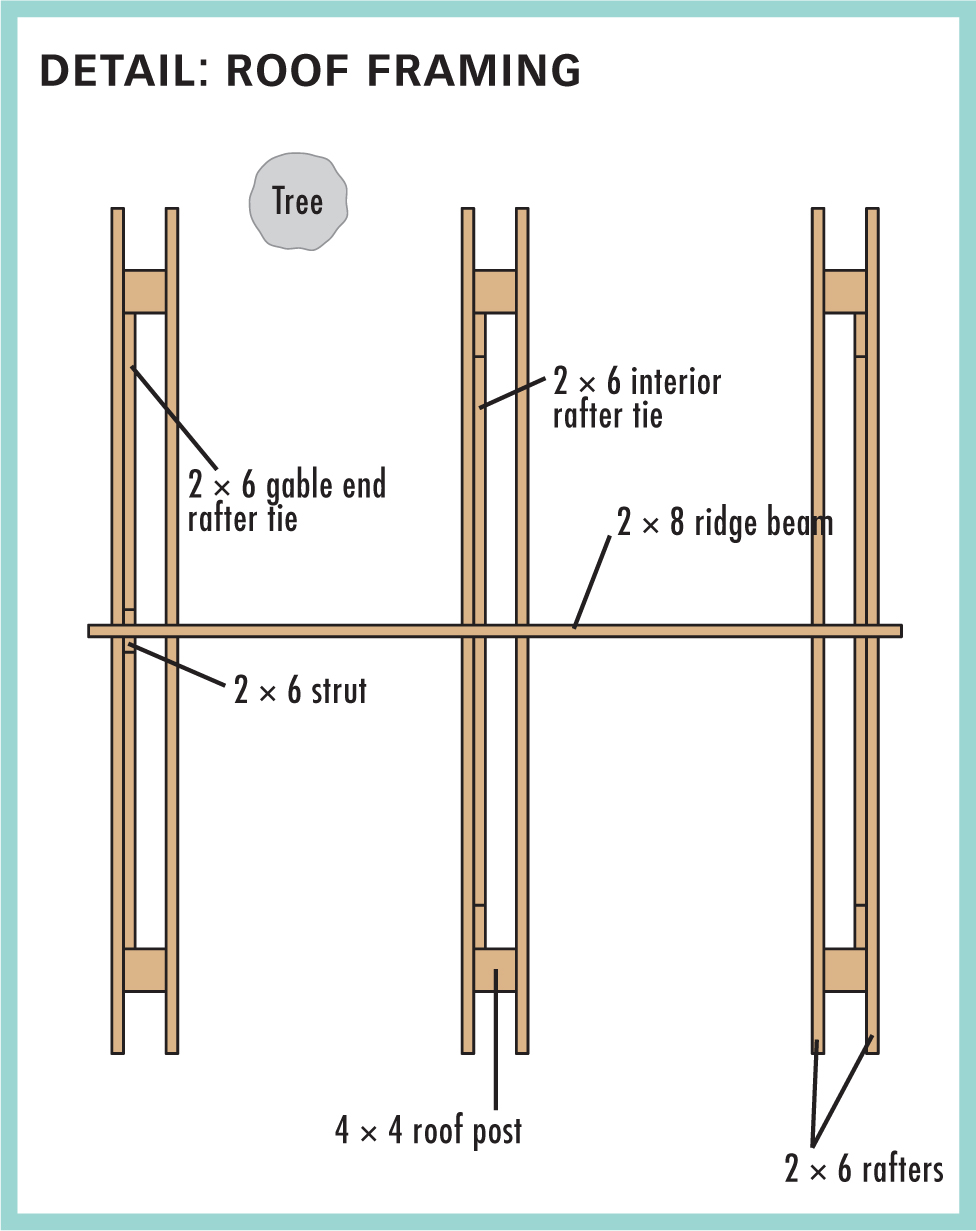

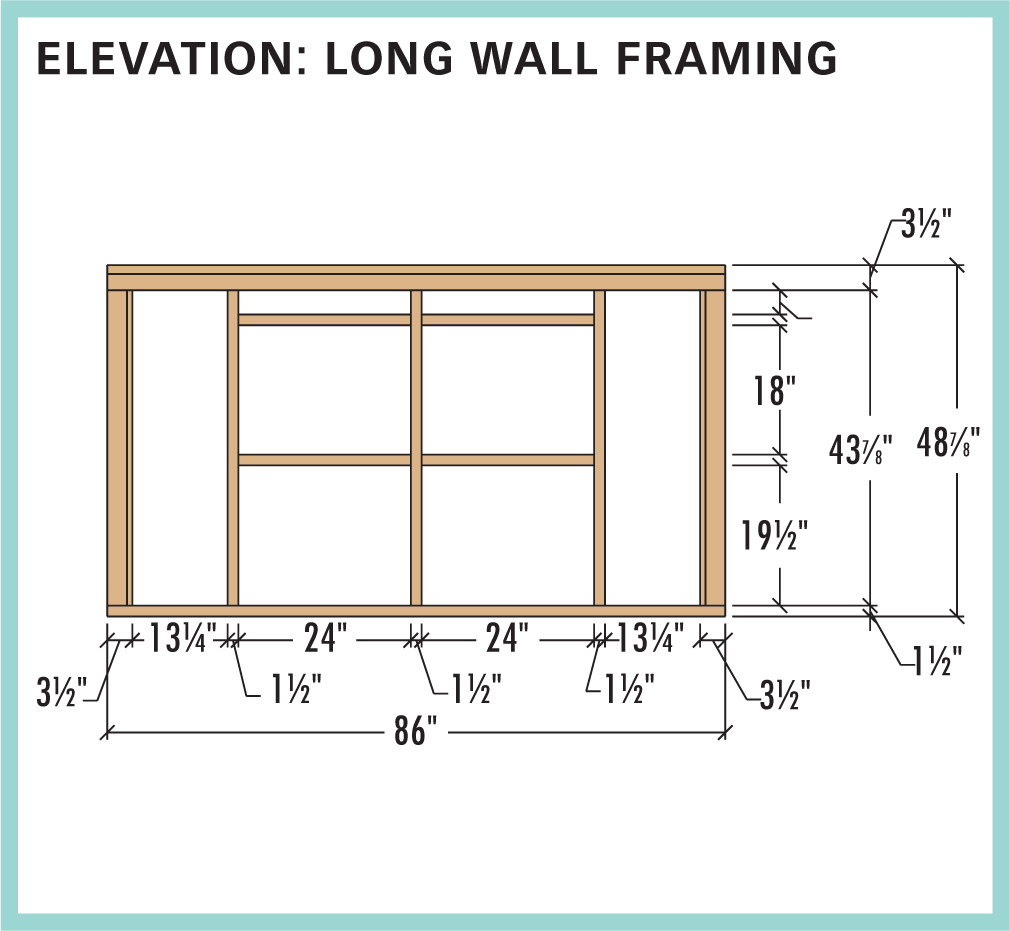

Cut two 2 × 8 rim joists to run the full length of the platform, then cut 11-2 × 8 joists equal to the full width (front to back) of the platform, minus 3". Mark the joist layout onto the rim joists, using a scrap piece of 6 × 6 post to set the spaces for the eight roof posts. The four corner posts are set 1-1/2" in from the end of each rim joist, and the two remaining posts on each side are spaced evenly in between. Gang the rim joists together to mark the layout, to ensure that all joists and posts are properly aligned.

Assemble the platform frame on top of the beams. Start by nailing the rear rim joist to all of the joists, using three 16d nails for each. Then, move to the front of the frame and nail the front rim joist onto the ends of the joists. When the frame is assembled, center it side-to-side over both beams, and measure diagonally between opposing corners to check for square: When the measurements are equal the frame is square. Tack the frame to the beam with several nails to hold it in place, then reinforce the connection with metal framing connectors (consult a building professional or your local building department for recommendations on the best connectors for your project).

Follow chalk lines to set the initial rows of decking (since you can’t start at the edge of the platform). A few extra chalk lines can help you stay on track during the installation.

The platform frame is decked with 2 × 6 or 5/4 × 6 boards to create the treehouse floor. Thinner 5/4 × 6 decking is suitable for up to 24" of joist spacing if the wood is pine or hemlock; for cedar and redwood, 2 × 6 decking is recommended. At this stage, most of the decking is installed to facilitate working from the platform, but a few boards are left off at each side to provide access for installing the roof posts.

Use a scrap piece of your decking material to mark layout lines on the joists. This is to ensure that you won’t reach the edge of the platform and discover that the last board is just a sliver. The decking should run perpendicular to the interior joists (parallel to the rim joists) and stop flush with the outside faces of the two outside joists.

Step off each row of decking, leaving a 1/4" gap between rows for drainage and easy cleaning, working from the front edge of the platform to the rear. If the last board is less than half a width, plan to rip down the boards of the starting row (at the front) so the starting and end rows are roughly equal in width. Once you’re satisfied with the layout, snap chalk lines to guide the installation.

Following your layout, install the decking with deck screws sized for the decking material. Drill pilot holes, and drive two screws at each joist connection. Remember not to install the last few rows of decking at the front and rear of the platform.

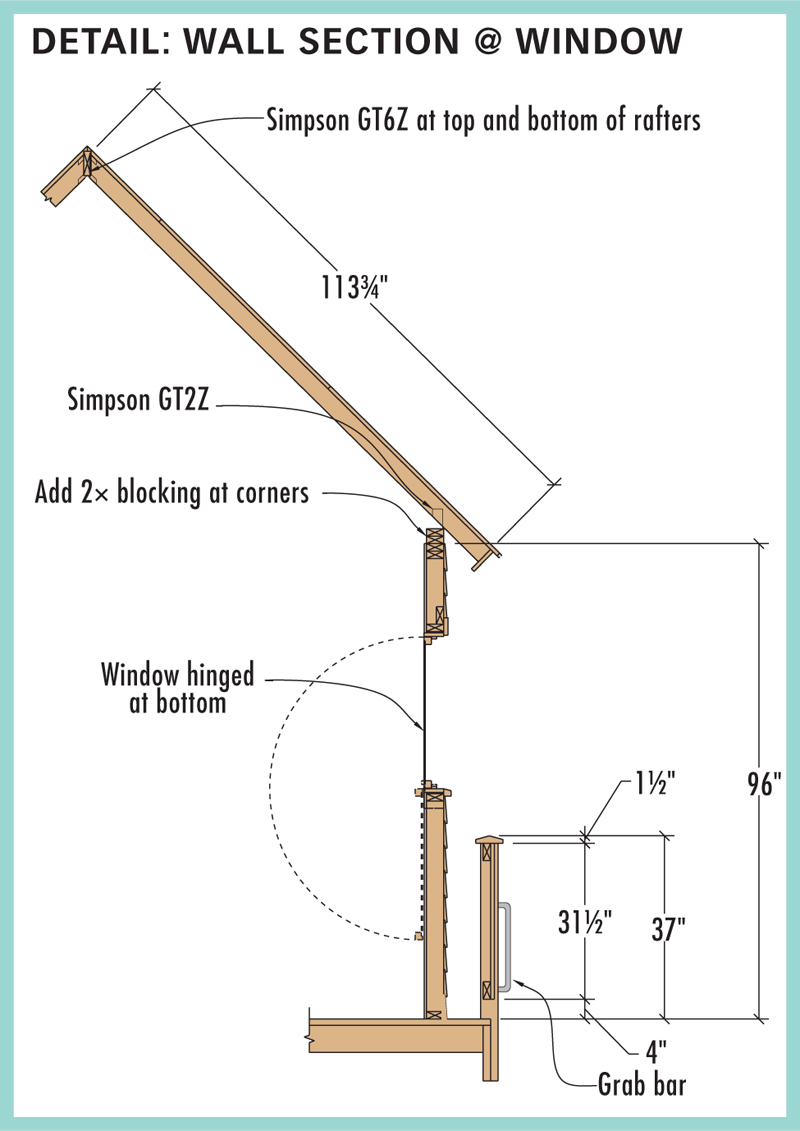

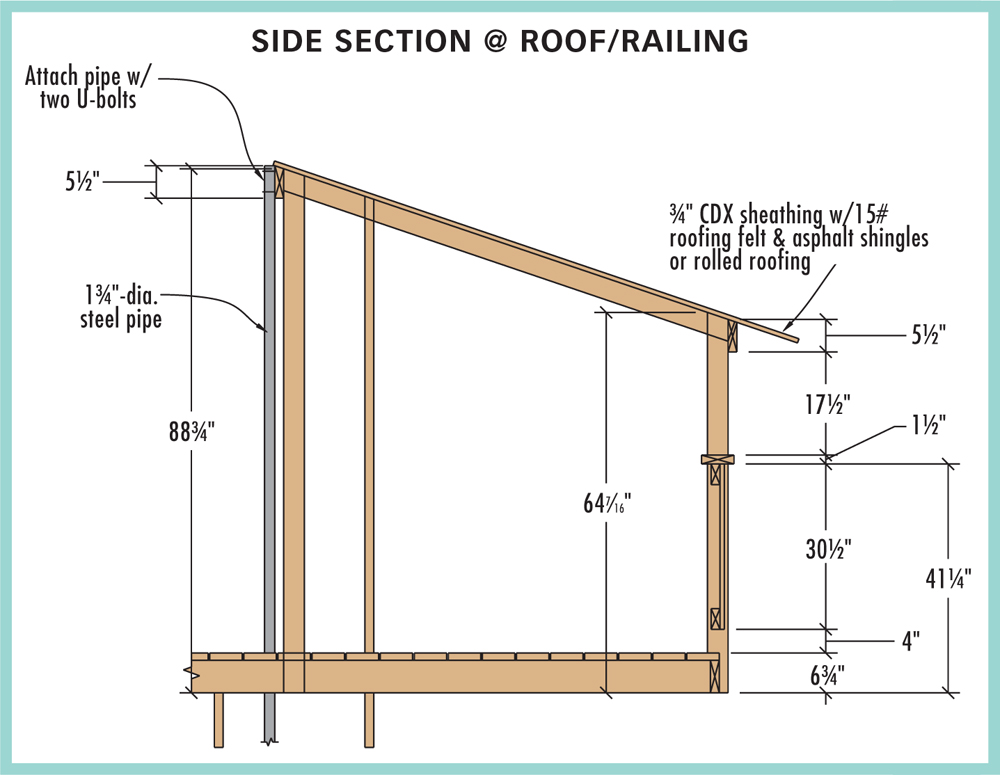

The 6 × 6 roof posts extend from the bottom of the platform frame to the tops of the rafters. They support the entire roof structure as well as the treehouse railing. Cut the top ends of each 8-foot 6 × 6 post at a 33.7° angle; this follows the 8-in-12 slope of the roof. Then, measuring from the long point of the beveled end, cut the post to length with a square cut, based on the desired height of the roof. For the project shown, the roof posts are about 89" long from the square bottom end to the long point of the top end.

Set each corner post into its place between the closely spaced pairs of platform joists. Clamp it between the joists so it stands perfectly plumb and its bottom end is flush with the bottom of the joists, resting on the beam below. Drill pilot holes, and fasten the post to both neighboring joists with four 3/8" carriage bolts. You don’t have to counterbore for these bolts, but the bolt heads should be on the outsides of the outer joists.

Run a taut string line between the two corner posts on each side of the platform, parallel to the beams. Install the two remaining posts on each side in the same manner, using the string line to make sure all four posts are aligned.

Complete the platform decking to fill in the openings left for the post installation. Notch the deck boards as needed to fit around the posts. The decking should be flush with the outsides of the platform frame.

Anchor the bottom ends of the roof posts with carriage bolts, sandwiching the posts between the joists at either side.

Use a string line to ensure the posts are on the same plane across each side of the treehouse.

Cut the ends of the pattern rafters at 33.7° and test-fit them on a pair of roof posts, using a piece of 2 × 8 scrap to serve as the ridge beam.

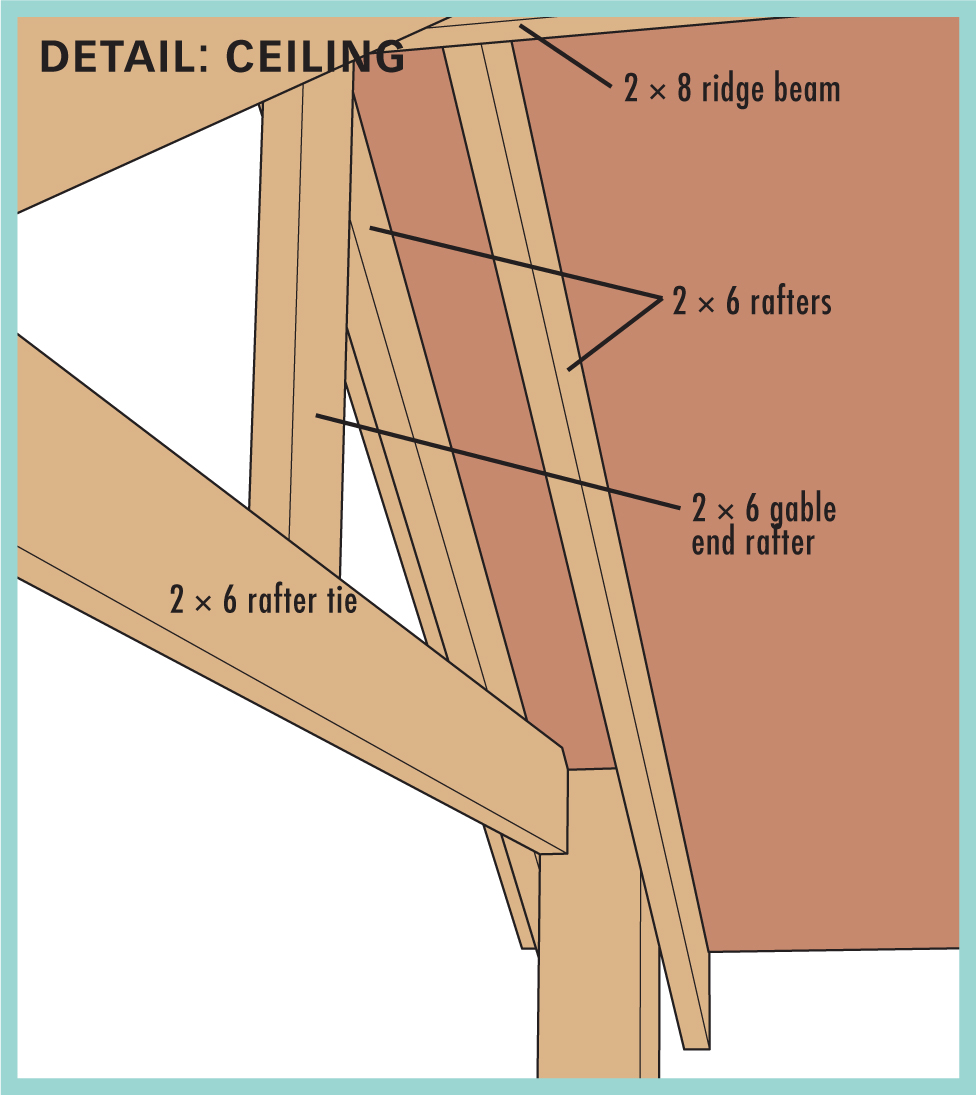

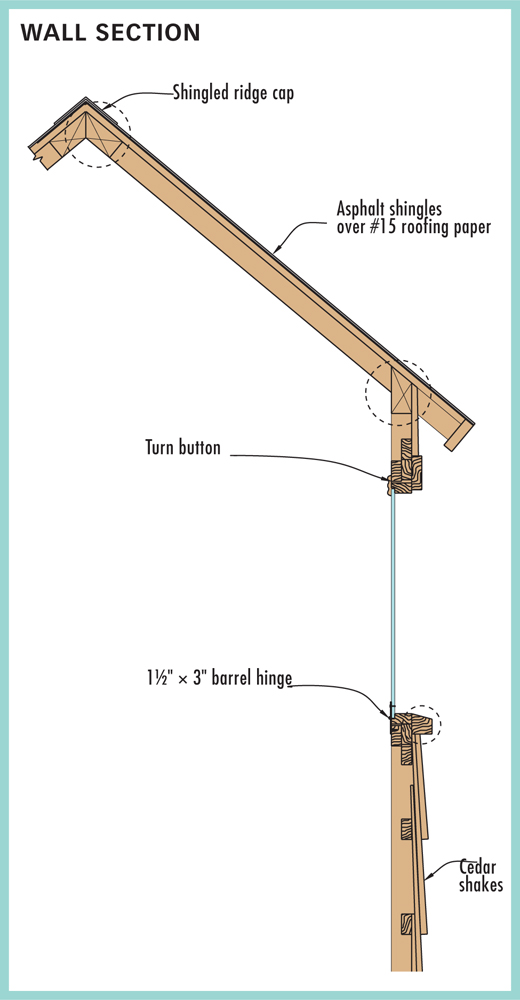

The roof is framed much like a standard gable roof, but here the rafters are easier to cut because they have no bird’s mouth cuts. Instead of sitting atop the walls, the rafters here simply fasten to the sides of the roof posts. Cut two 2 × 6 pattern rafters with an 8-in-12 slope (33.7°), following the techniques described on pages 118 to 119. Use a scrap of 2 × 8 to represent the ridge beam. The tops of the rafters should be flush with the top ends of the roof posts and extend about 8" (measured horizontally) beyond the outsides of the posts.

Use the pattern rafters to mark and cut the remaining 14 rafters, for a total of 16. Cut the 2 × 8 ridge beam to length so it overhangs the outer roof posts by about 4-1/2", or as desired.

Mark the rafter layout onto the ridge beam by clamping the ridge across the roof posts on one side of the treehouse so the ridge is flush with the tops of the posts and overhangs the outer posts equally on both ends (photo 20). Trace along both side faces of each post; these lines represent the inside faces of the rafters. Use a square to transfer the marks to the other face of the ridge.

Install the four outermost rafters and ridge beam, using 16d galvanized nails. Drive four nails through each rafter and into the roof post, and use two nails to fasten the rafter to the ridge. Next, install the pairs of rafters on the outside faces of the two sets of interior posts. At this point, only one side of each post has a rafter on it.

Cut the two 2 × 6 interior rafter ties to span between the rafter pairs so their bottom edges are about 80" above the platform deck. Make sure the ties are level, and fasten them to the inside faces of the rafters with 2-1/2" screws at each end.

To create the truss detail at each gable end of the roof frame, cut a 2 × 6 rafter tie to span between the rafters so their bottom edges are about 76" above the platform deck. Fasten these to the inside faces of the outermost rafters. Next, cut a 2 × 6 strut to fit between the top of the rafter tie (gable ends only) and the tops of the rafters, cutting the top end of the strut to a point. Then, notch the strut’s top end to fit snugly around the ridge beam. Nail the strut to the top edge of the rafter tie and to the rafters and ridge beam.

Install the remaining rafters to complete the roof frame.

Mark the ridge beam for rafters, using the roof posts. Make an “X” to the outside of each post marking to show where the rafter goes.

Interior rafter ties span across the rafters on the interior roof posts. Their ends are cut to match the roof slope.

The decking material for the roof is 5/8" or 3/4" T&G roof sheathing rated for a 40" rafter span. Since the underside and edges of the sheathing will remain exposed, it’s best to use “Exterior” sheathing (as opposed to “Exposure 1” or “Exposure 2”). As an optional addition, you can install 3/8" cedar plywood on the underside of the sheathing, to create a decorative “ceiling” finish.

Install the roof decking following the techniques described on page 122, overhanging the outermost rafters by about 3" at the gable ends of the roof. If desired, cover the underside of the roof deck with exterior cedar plywood (or other outdoor material), using construction adhesive and short trim screws or brads.

Complete the roof with building paper and asphalt (composition) shingle roofing, following the techniques described on pages 122 through 124. If you chose to cover the underside of the deck with decorative plywood, be sure the roofing nails are short enough that they won’t come through the plywood.

The gable-end rafter ties are combined with a strut to create a truss detail. The strut is notched to fit around the ridge beam (inset).

Tongue-and-groove roof decking is required for the relatively wide spans of the rafters. Follow the manufacturer’s specifications for gapping between panels.

A decorative layer of cedar plywood conceals roofing nails and creates a finished ceiling. Notch the panels as needed to fit around the roof framing.

Composition shingles make for an inexpensive, long-lasting roof. Consider the shingle color carefully, as you’ll probably be looking at it most of the year.

The railing has horizontal 2 × 4 rails that support 2 × 2 balusters, much like you find with many deck designs. The top of the railing gets a 2 × 6 cap, which makes a nice surface to lean against to enjoy a view or to set down drinks. You can modify the railing design as desired, but make sure yours meets the minimum standards for safety: Most importantly, the railing must be at least 36" tall, from the deck surface to the top of the railing, and the balusters must be spaced just under 4" apart (if a 4"-diameter ball can fit between the balusters, they’re too far apart); see page 93 for more railing design and safety information.

To install the 2 × 4 rails, make two marks on each corner roof post, 7-1/2" and 34-1/2" up from the treehouse floor. Snap chalk lines across all of the roof posts at these marks; the lines represent the top edges of the 2 × 4 rails.

Cut the 2 × 4 rails to span across the roof posts, using single pieces for each run, if possible. You can wrap around the outsides of the posts with mitered or butted joints. Fasten through the rails and into the posts with 3" deck screws. Note: If you want to create built-in stops on the latch side of the gate opening, extend the rails about 1-1/2" into the opening, as shown on page 182).

Mark the baluster layout onto the inside faces of the rails. Create a layout for each space between neighboring posts, working from the center so that the gaps between balusters is the same at both ends of the space.

Cut the 2 × 2 balusters to length so they extend from the top of the top rail to the bottom edge of the bottom rail, mitering the bottom ends, if desired. Position each baluster so it’s flush with the top of the top rail, check it for plumb, and fasten it with 2-1/2" deck screws.

To install the 2 × 6 railing caps, rough-cut each piece a little longer than you need. Set the board in place on top of the top rail, on the outside of the roof posts, and mark the positions of the posts onto the cap. Notch the cap at the marks, setting the notch depth so that the cap will overhang the outsides of the rails by 1-1/2". Test-fit the cap, then mark the ends for final cuts. It looks best if you miter the caps at the corner joints. Fasten the caps to the rails and the balusters (as needed) with 3" deck screws.

Install the rails with their top edges on the chalk lines. The 3" gap below the bottom rail makes it easy to sweep off the treehouse deck.

Use a baluster and level to mark the sides of each baluster location, and use a 2 × 4 block cut to length at 3-7/8" to set the gaps between balusters.

Notch the caps to fit around the posts (inset), leaving about a 1-1/2" overhang on the outside of the railing and a 1" overhang on the inside.

Self-closing hinges keep the gate closed when it’s not in use—a handy safety feature for anyone using the treehouse.

The gate shown here is built just like the railing and is hung with self-closing hinges, with the gate swinging in for safety. Another important safety (and longevity) feature is a stop that supports the gate when it’s closed and prevents it from being pushed through the wrong way. Notches cut into the rails and caps of the railing and gate create strong, built-in stops that require no hardware.

Build the gate with the same materials and baluster spacing used for the treehouse railing, making it a little narrower than the gate opening to allow for hinge and swing clearance. Reinforce the gate with a turnbuckle and rods (running from the top hinge corner to the bottom latch corner) or a wood or metal cross brace (running from the top latch corner to the bottom hinge corner). Hang the gate with heavy-duty self-closing hinges mounted to the roof post.

Mating notches in the caps and rails of the gate and treehouse railing create safety stops that also prevent undue wear and tear on the gate.

Given its versatile, “all-ages” design, this treehouse should have a relatively pedestrian means of access, such as sturdy ladder steps or even a full-fledged staircase. If you won’t use the house during the cold months of the year, you might prefer to use ladder steps that you can remove so the house is inaccessible in the off-season.

As for accessories, you can hang all manner of climbing and play things from the front beam and platform joists—swings, trapeze, knotted climbing rope, rings, you name it. The posts are ideal for stringing up a hammock, either in the treehouse or down below between the platform posts. You could even hang a little two-seater porch swing from the rafter ties.

Access to this treehouse happens to be at the front, but it could also be at either end or even the back, if you’d prefer a cleaner look at the front.

Strategically placed accessories, such as swings and climbing ropes, turn the treehouse into the best kind of backyard play structure.

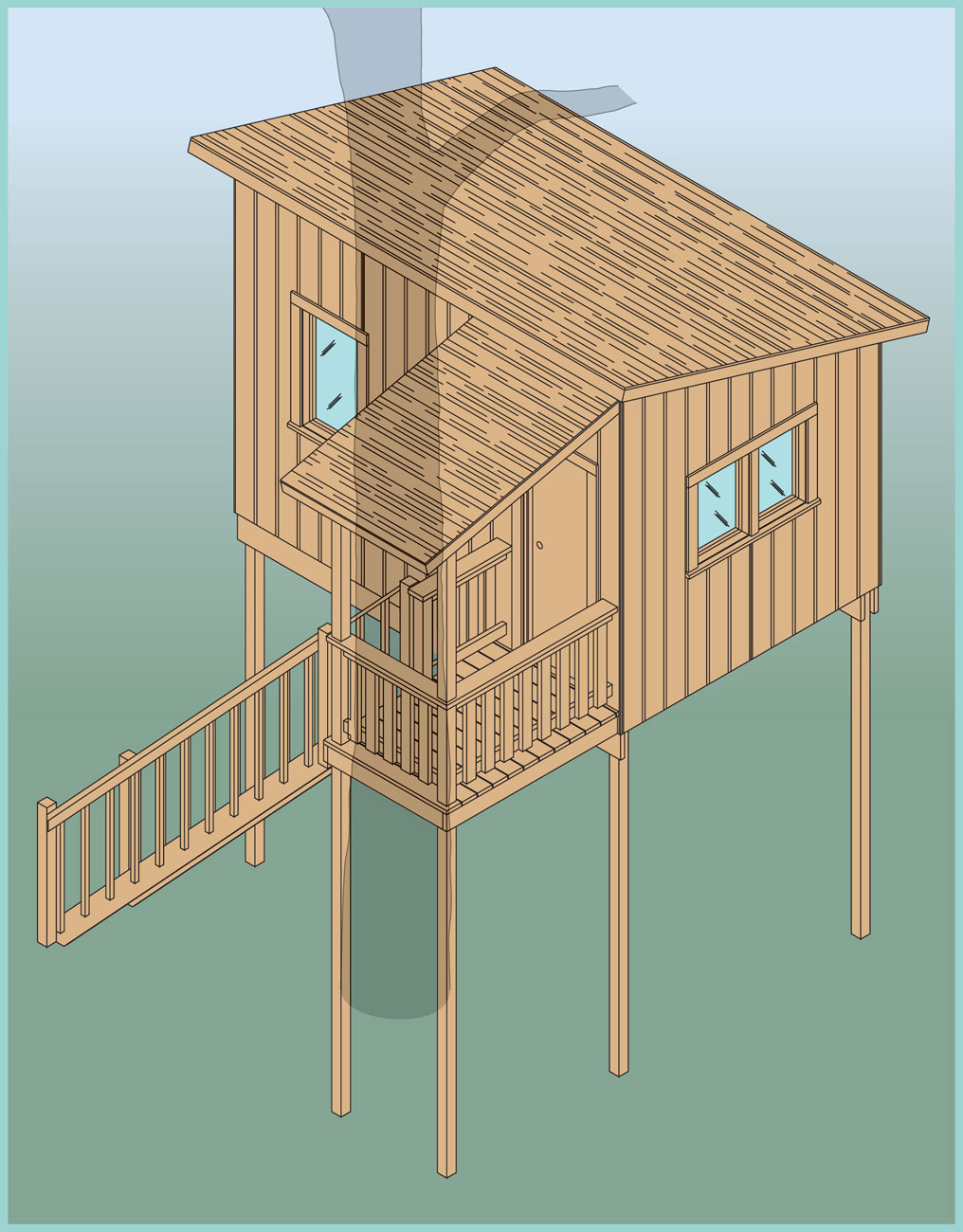

Gable House with Entry Deck

Gable House with Entry Deck

A treehouse that feels like a home. Solid walls, sturdy windows and doors, and some simple decorative touches add up to a cozy retreat where kids can really let their imaginations run wild.

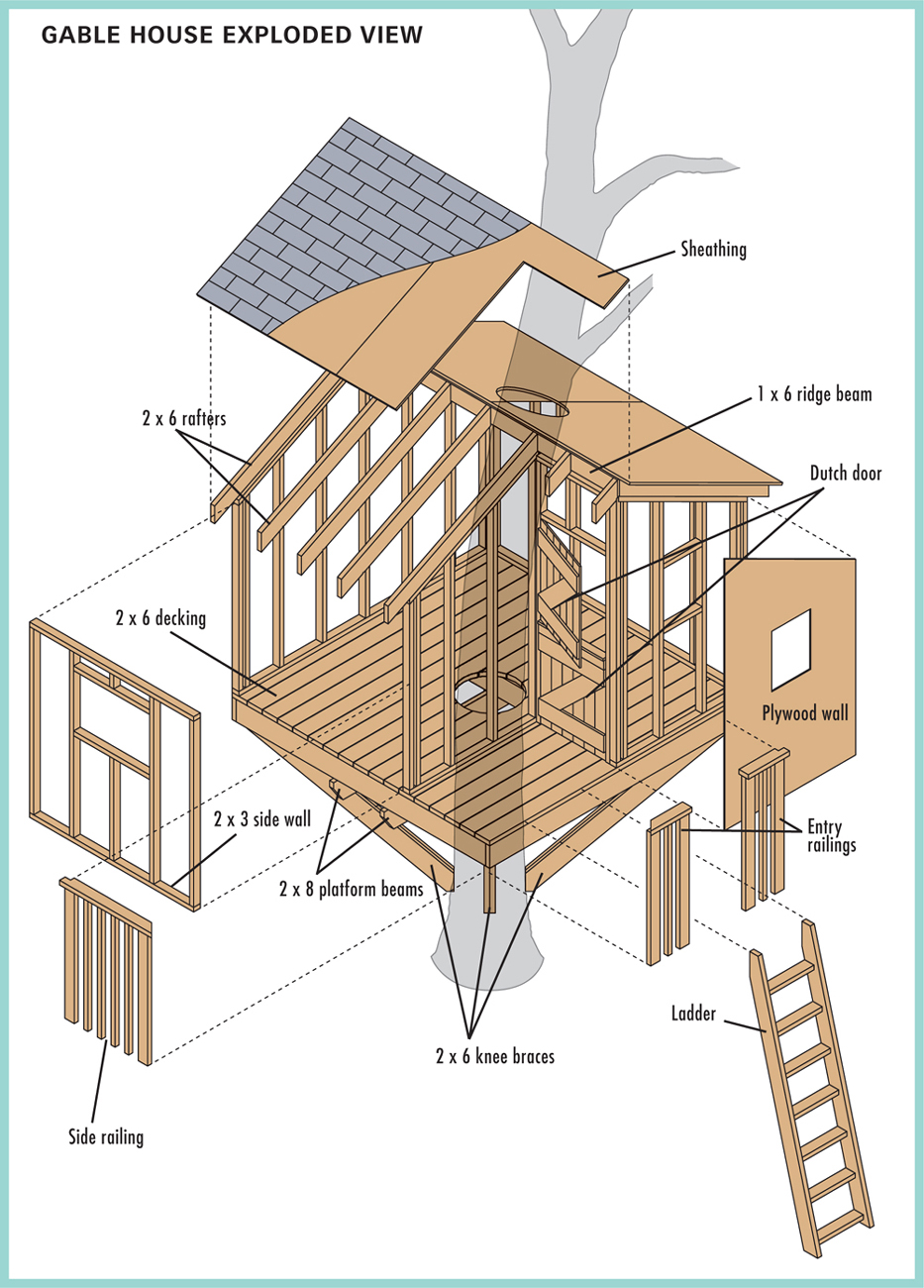

This nicely proportioned house is a great example of what you can do with one good, stout tree. And the design is simpler than it looks. It starts with a square platform that’s framed around the trunk and supported by knee braces at the corners. Apart from the cutout for the door and entry deck, the house is just a box with a gable roof, much like the houses you find in kids’ drawings. This classic look is no coincidence—with its traditional lines and fully enclosed interior, the treehouse has an especially homey feel, a theme that’s enhanced by the Dutch door and playhouse-size entry deck. The interior layout also lends itself to built-in accessories, like shelves and tables.

A single-tree house of this size requires a large, mature tree. The specimen must be healthy, of course, and should measure at least 5 feet in circumference at its base. Because the tree alone will bear the burden of the house and its occupants, it’s a good idea to have it inspected by an arborist before making any serious construction plans. Think about where you’d like to place the house, so you can give special attention to the installation areas.

Note: The instructions here provide a detailed overview of building the house as shown, for this particular site. They can serve as a general guide to help you design and build a similar house of your own. However, all of the construction specifications for your project must be geared for your specific house design, the intended use of the house, the tree, and the building site, as well as any applicable local building codes and zoning restrictions.

Self-closing hinges keep the gate shut when it’s not in use—a handy safety feature for anyone using the treehouse.

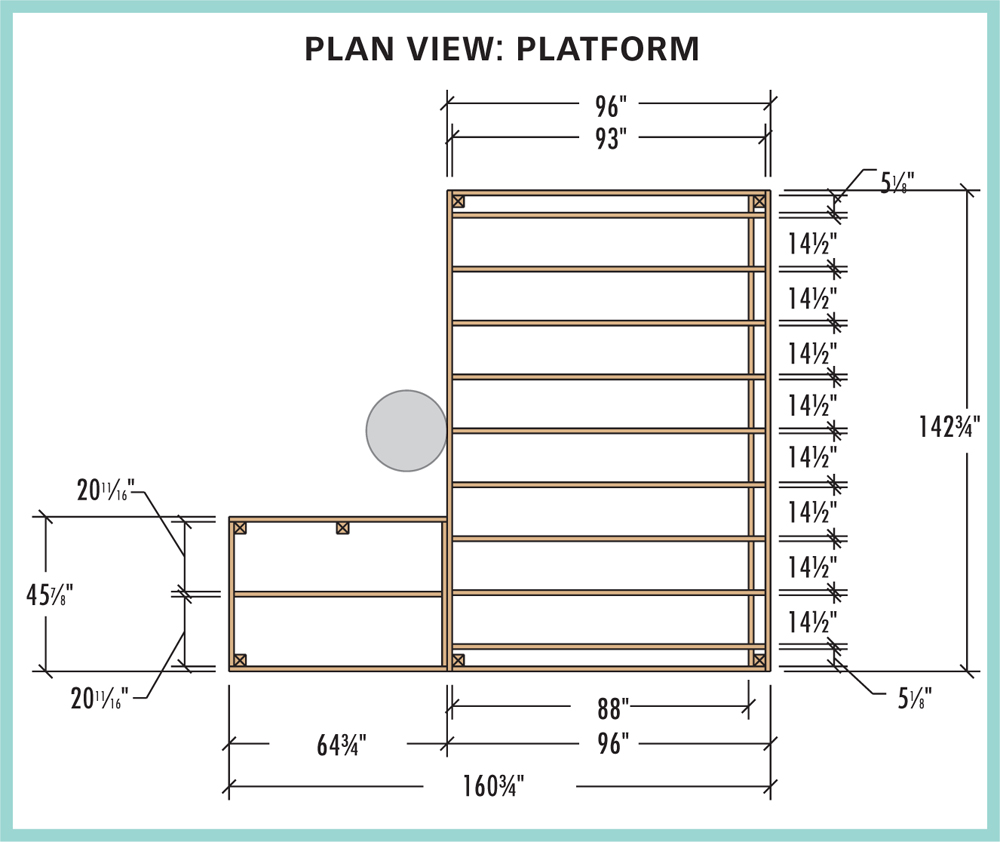

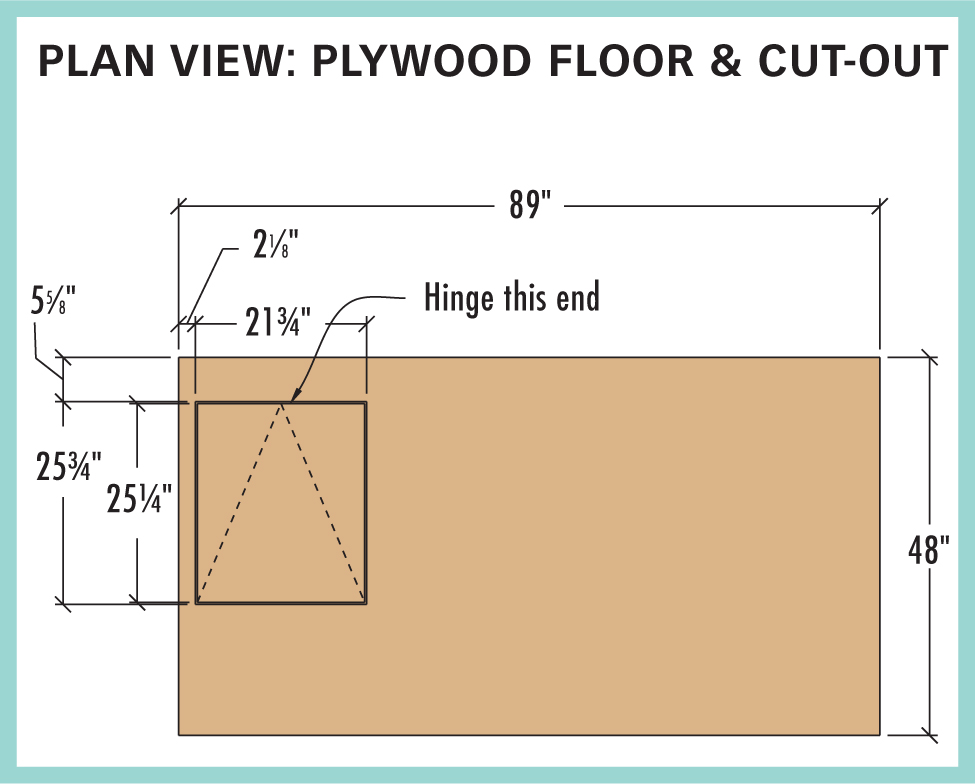

The treehouse platform has four 2 × 8 beams, all of which are anchored to the tree with a single 3/4" lag screw and washers. Cut the lower pair of beams to the full width of the platform. If desired, angle-cut the bottom corners of the beams for decorative embellishment. Mark the tree at the desired height of the finished platform minus 83/4" (the combined depth of the platform frame and decking); this represents the top edges of the lower beams.

Drill clearance holes in the beams and pilot holes in the tree, and anchor the beams to the tree following the techniques described for fixed anchors, on page 61. The lag screws should be centered along the length of the beam and point towards the center of the tree trunk. Make sure the second beam is perfectly level with the first before installing it.

Cut the two upper beams to the full length of the platform minus 3". These beams are integrated into the platform frame and are the same length as the common joists. Install the upper beams perpendicular to the lower beams, with their bottom edges resting on the lower beams.

In the project as shown, the platform frame was assembled before the knee braces were installed. Initially, 2 × 6 knee braces were anchored to the tree with special brackets (see page 190), then an additional 2 × 6 was sistered to each brace for added rigidity. For your own project, you might prefer to install the knee braces after only the perimeter joists are installed. It’s also an option to use 4 × 6s for the knee braces; however, this requires a specially sized bracket that may need to be custom-fabricated. Note: Don’t use the platform for support until the knee braces are installed.

Cut the two 2 × 8 rim joists to match the length of the lower beams, and cut the four 2 × 8 common joists to the same length as the upper beams (your project may call for more joists, depending on the size of the platform and the decking material). Set the common joists on edge atop the lower beams, and fasten one of the rim joists to each common joist with three 16d nails or 3-1/2" deck screws. Install the other rim joist on the other ends of the commons.

Square up the frame using a framing square (you can’t measure the diagonals, because the tree is in the way), and toenail the frame to the lower beams with 16d nails. Level the platform in both directions, then secure it in position with a few temporary posts extending to the ground.

Anchor the lower beams to the center of the tree. Remember that the lag screws should be just below center (top-to-bottom) on the beams.

Install the upper beams, checking all of the beams for level as you go. If necessary, use wood shims to make a beam stand plumb against the tree (inset).

Cut the knee braces so they fit between the inside of each corner of the platform frame and extend down to the tree at a 45° angle. Cut the top ends of the braces at 45°, and cut the bottom ends to fit the anchor brackets. Use the knee braces to mark the precise locations of the anchor brackets, and install the brackets as directed by the manufacturer. The brackets used here are installed with a single lag screw to the tree (don’t use two fasteners close together, which promotes tree rot) and a single lag screw into the end of the knee brace.

Install the braces, toenailing the top ends to the platform frame, then reinforcing each joint with a framing connector. Add a second knee brace, if applicable, sistering the two with 10d nails or 3" deck screws.

Install the 2 × 6 (or 5/4 × 6) decking so it runs perpendicular to the common joists and is flush with outside of the framing on all sides. Fasten deck boards to each joist with pairs of 3" deck screws. Be sure to leave a 2" gap between the decking and the tree to allow for growth.

Because the house’s interior will be enclosed, you don’t have to leave gaps between the boards for drainage, if you prefer not to. However, you might want to gap them a bit for expansion, and larger gaps make for easier cleaning. If you prefer a continuous floor surface, you can also save some money by using plywood instead of 2 × 6s.

Fasten the rim joists to the common joists with nails or screws. Here, the interior common joists are centered between the outer commons and the upper beams.

Secure the knee braces to the tree with anchor brackets (inset) and to the platform frame with toenailed screws or nails and framing connectors.

Custom fit the decking boards around the tree by butting each piece up to the tree and using a compass set at 2" to transfer the tree’s contours to the board.

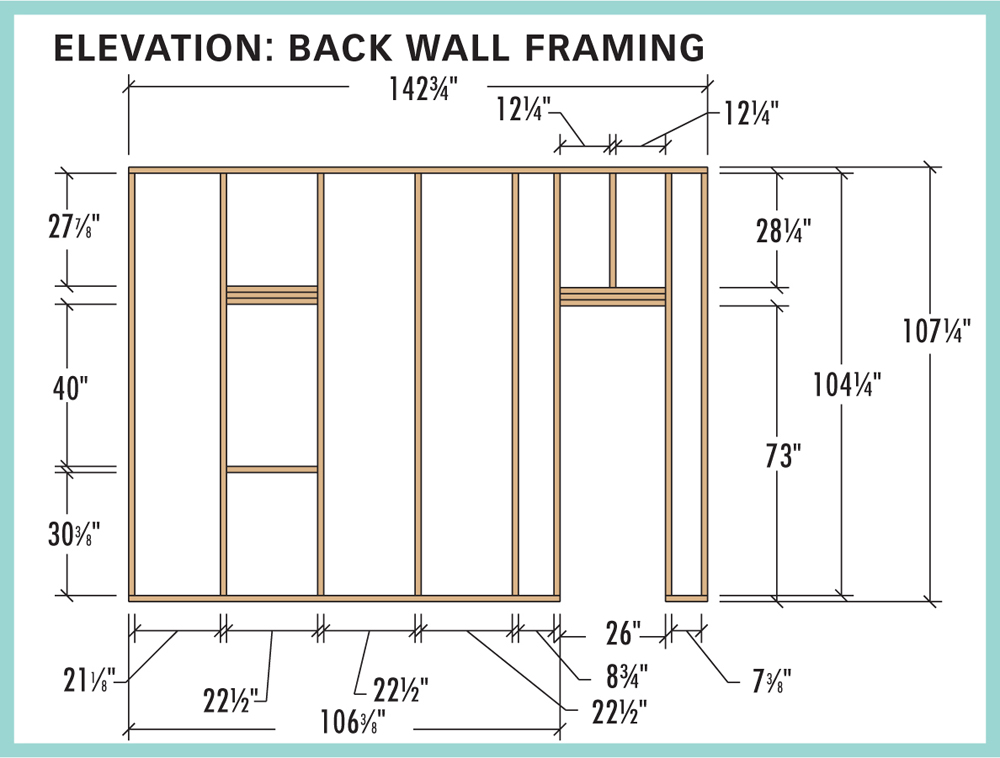

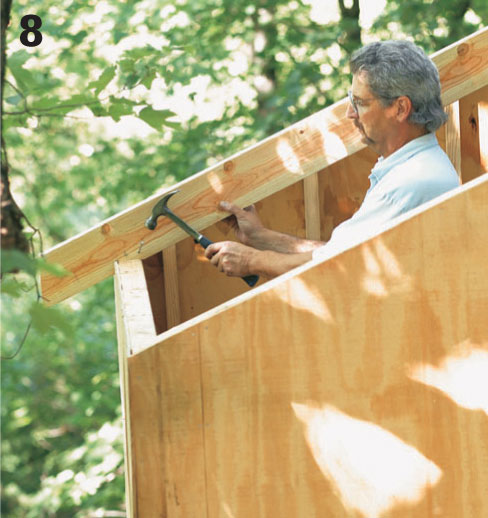

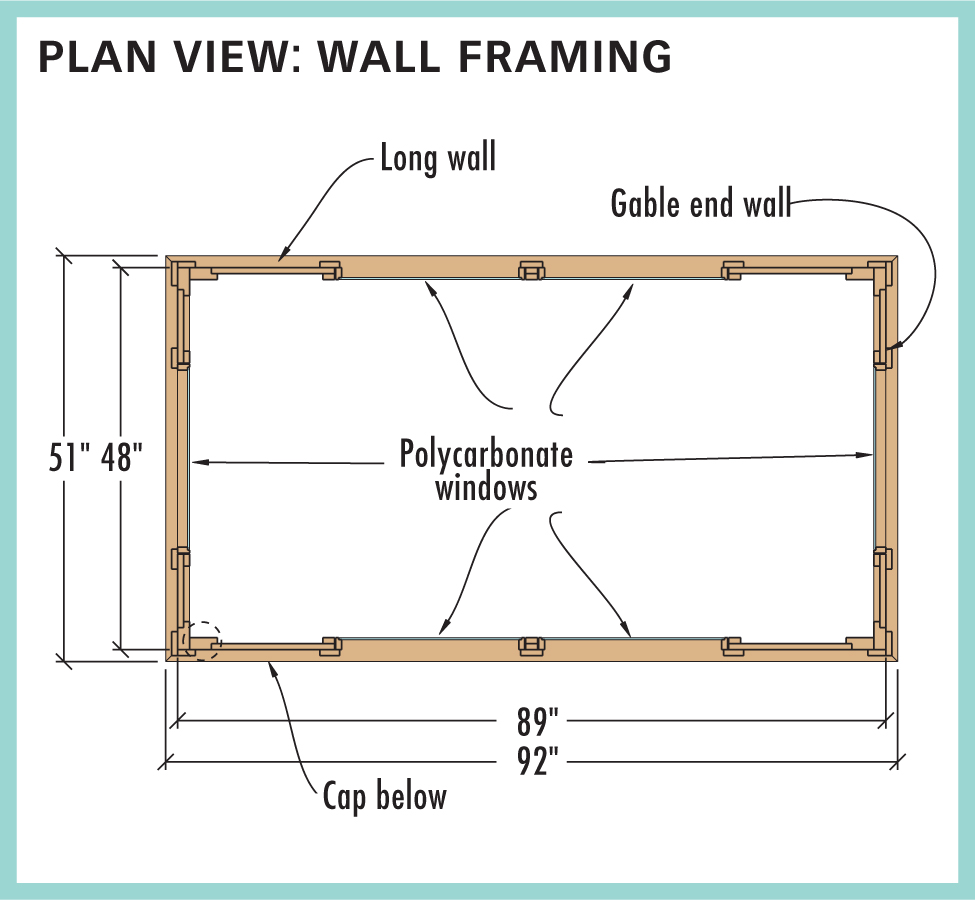

The left gable wall spans the width of the house and is centered on the roof peak. The extra stud at each end is for installing interior finishes.

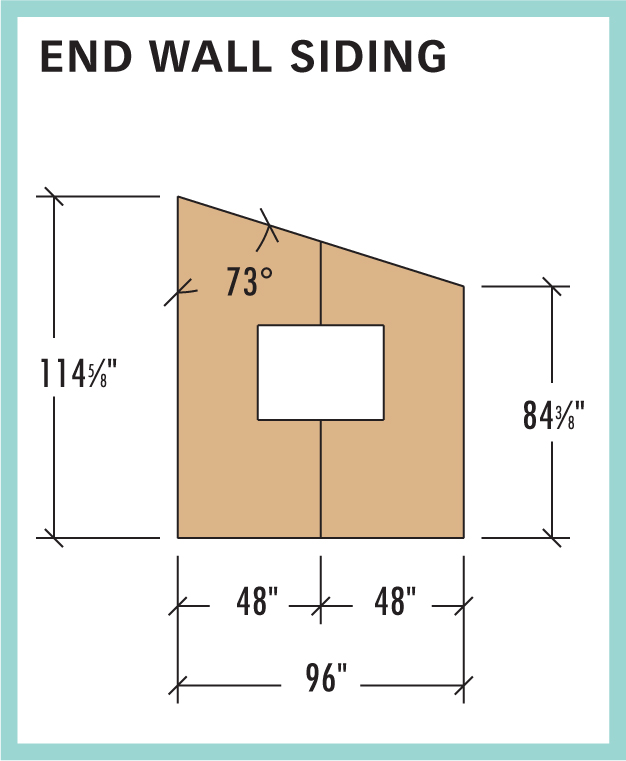

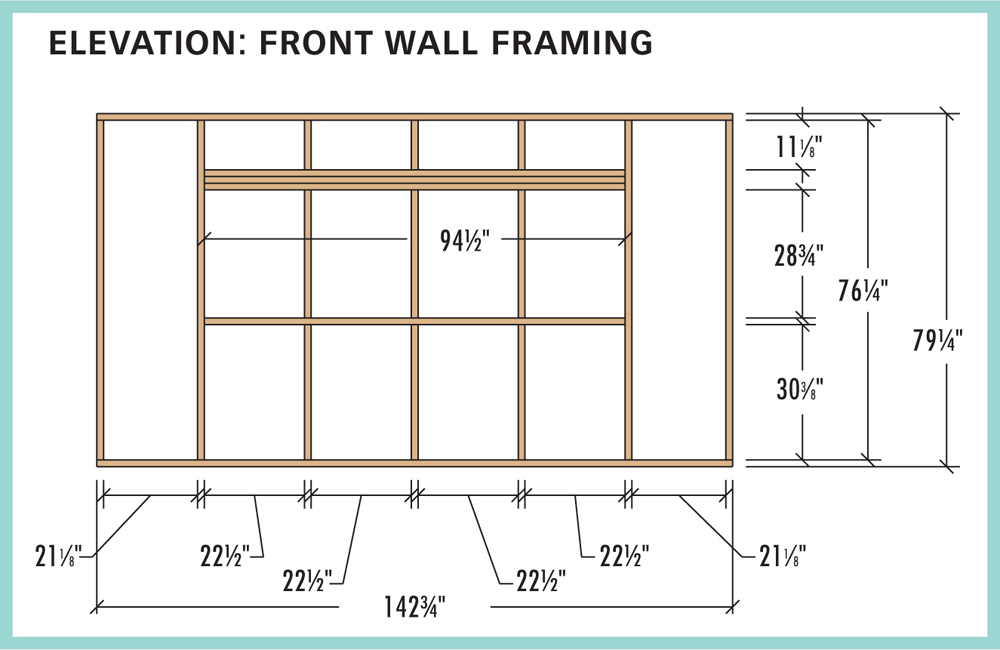

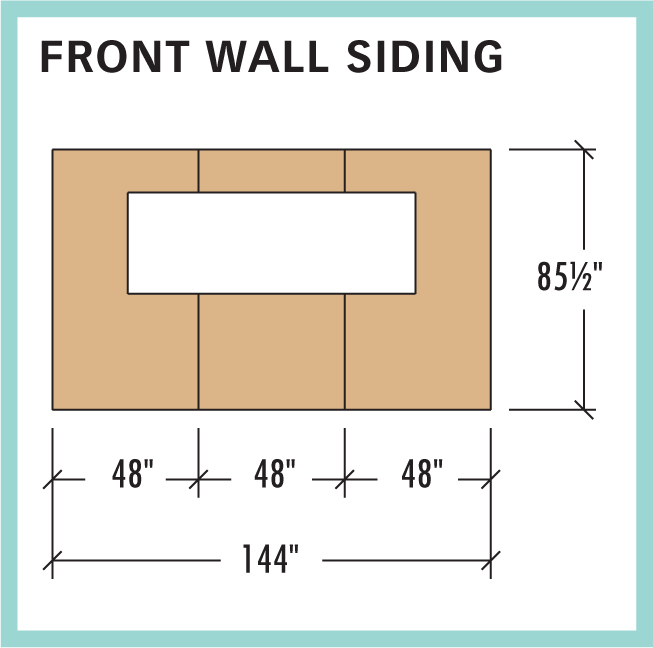

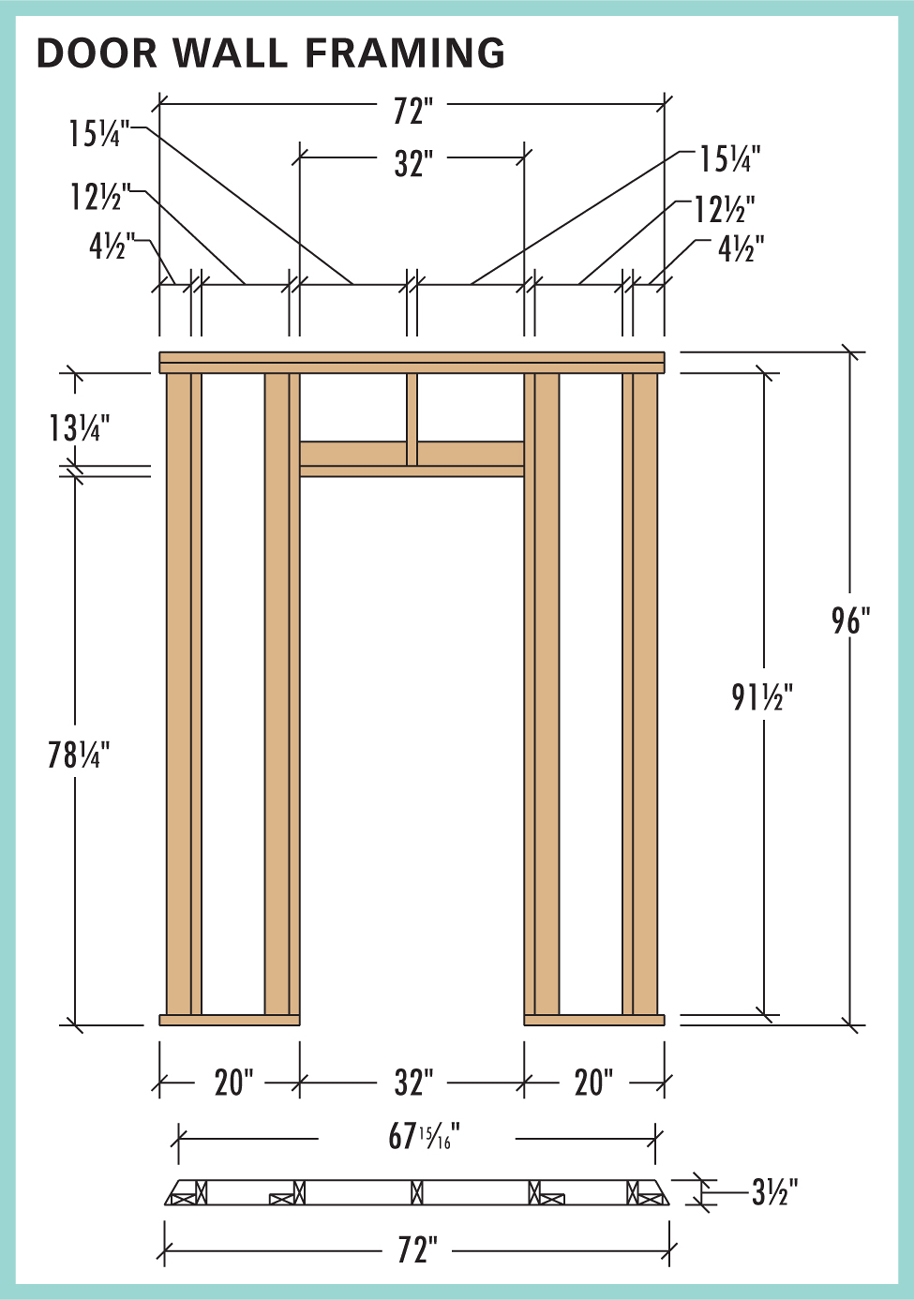

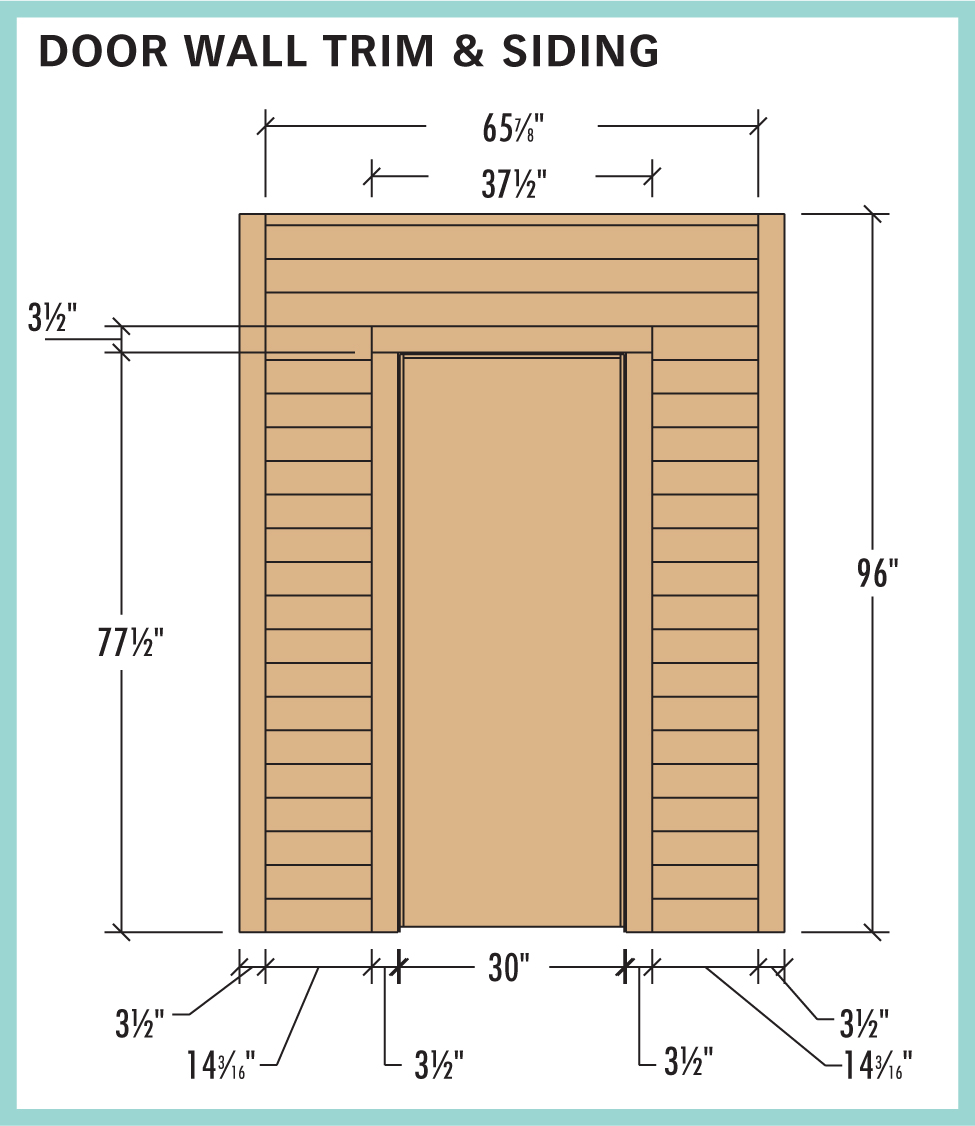

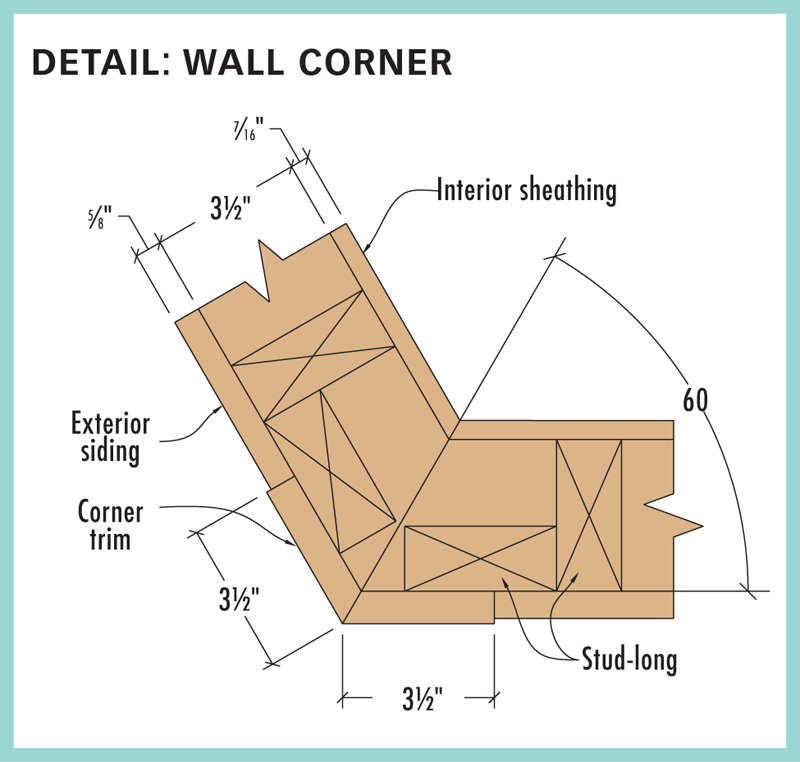

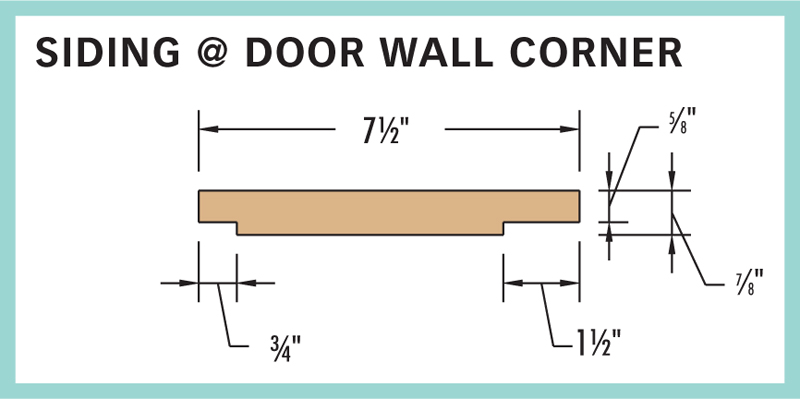

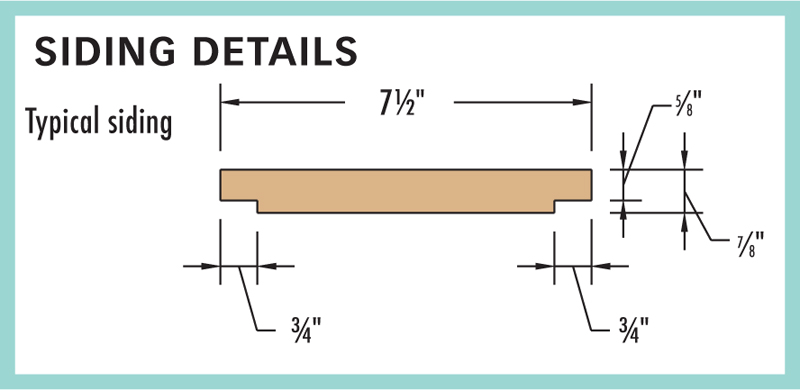

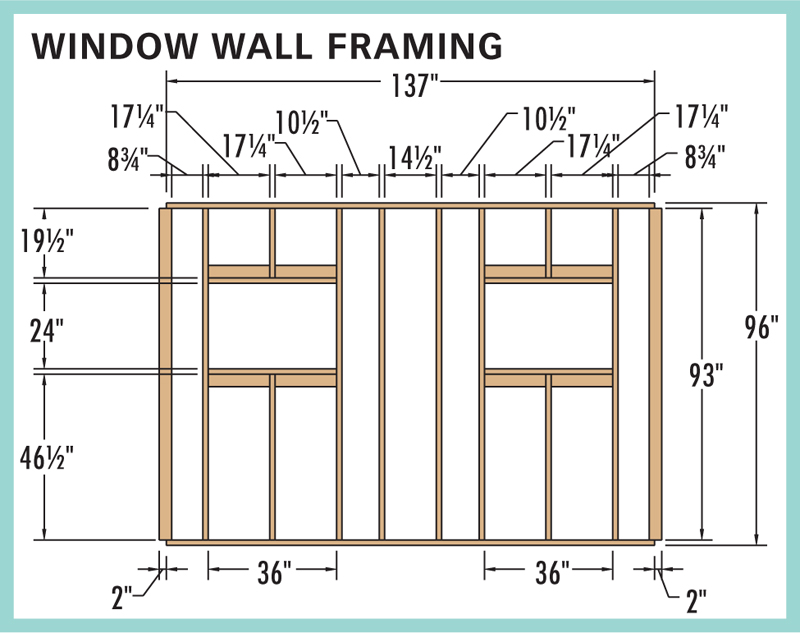

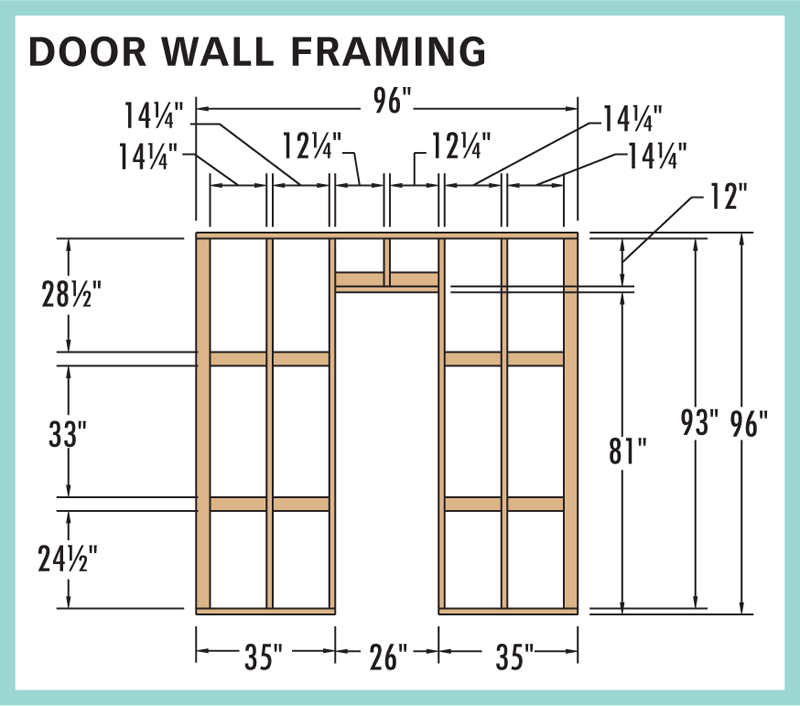

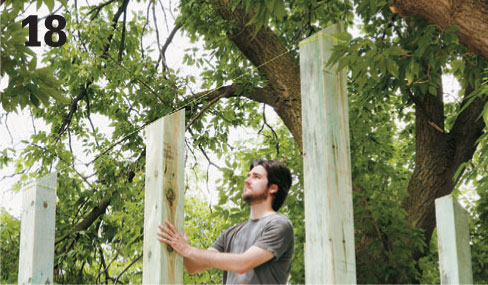

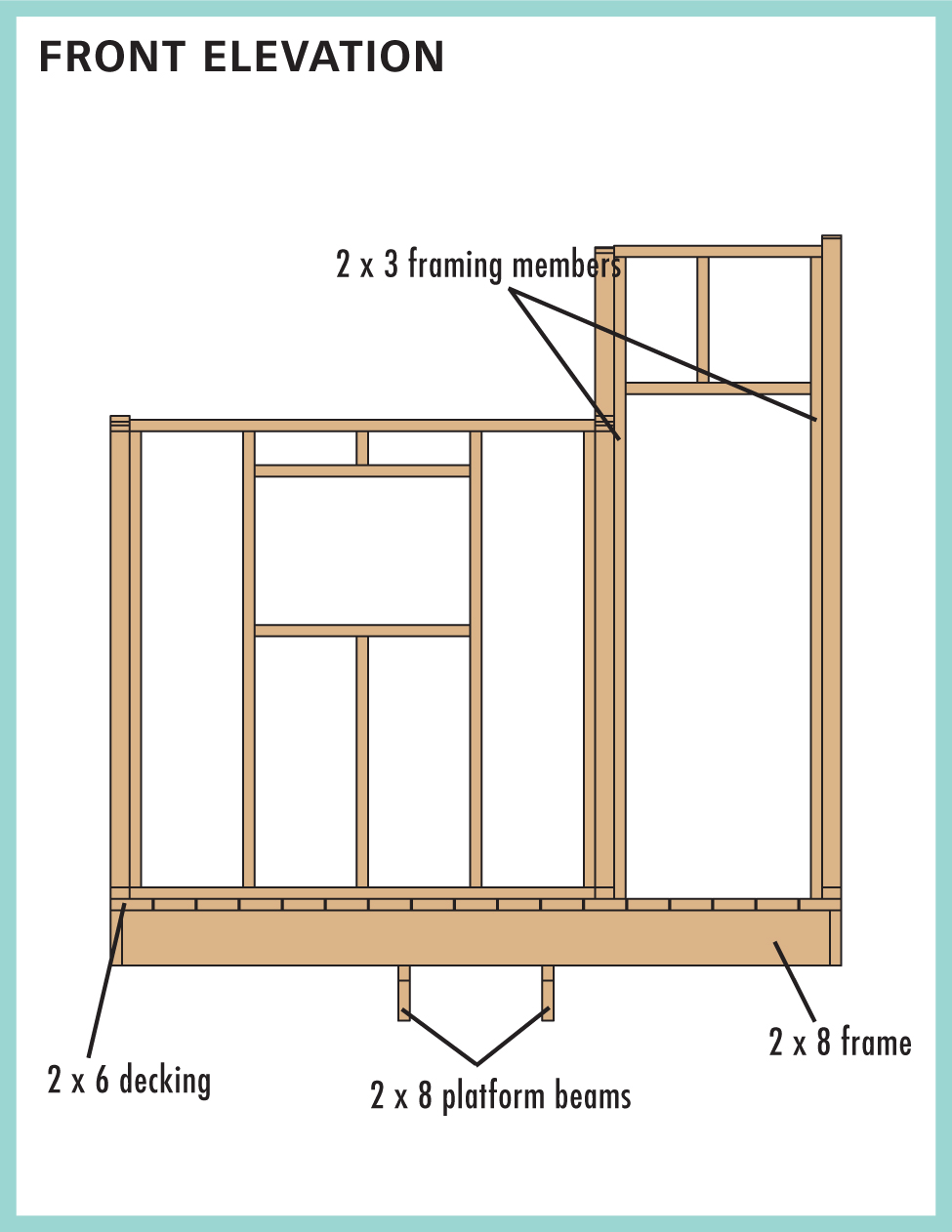

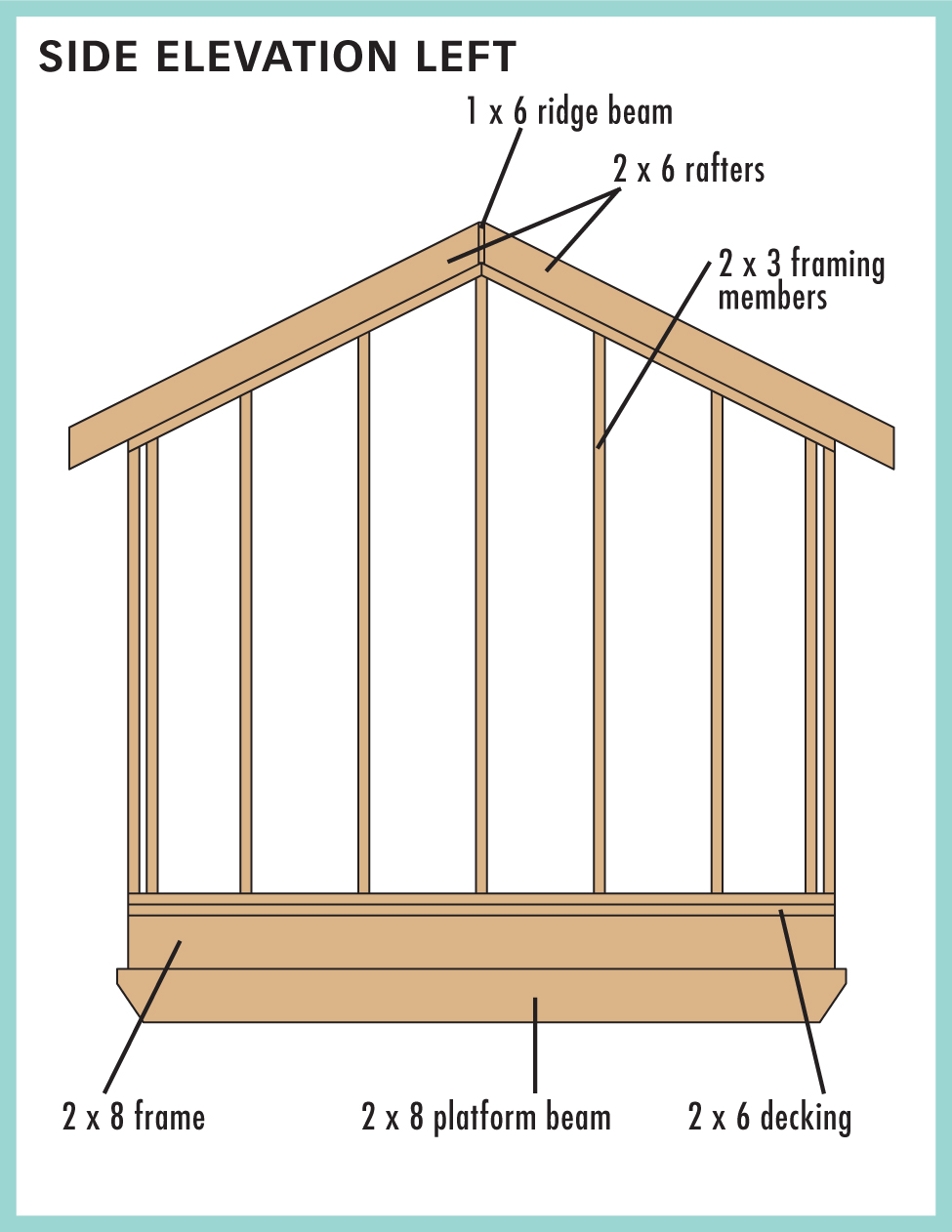

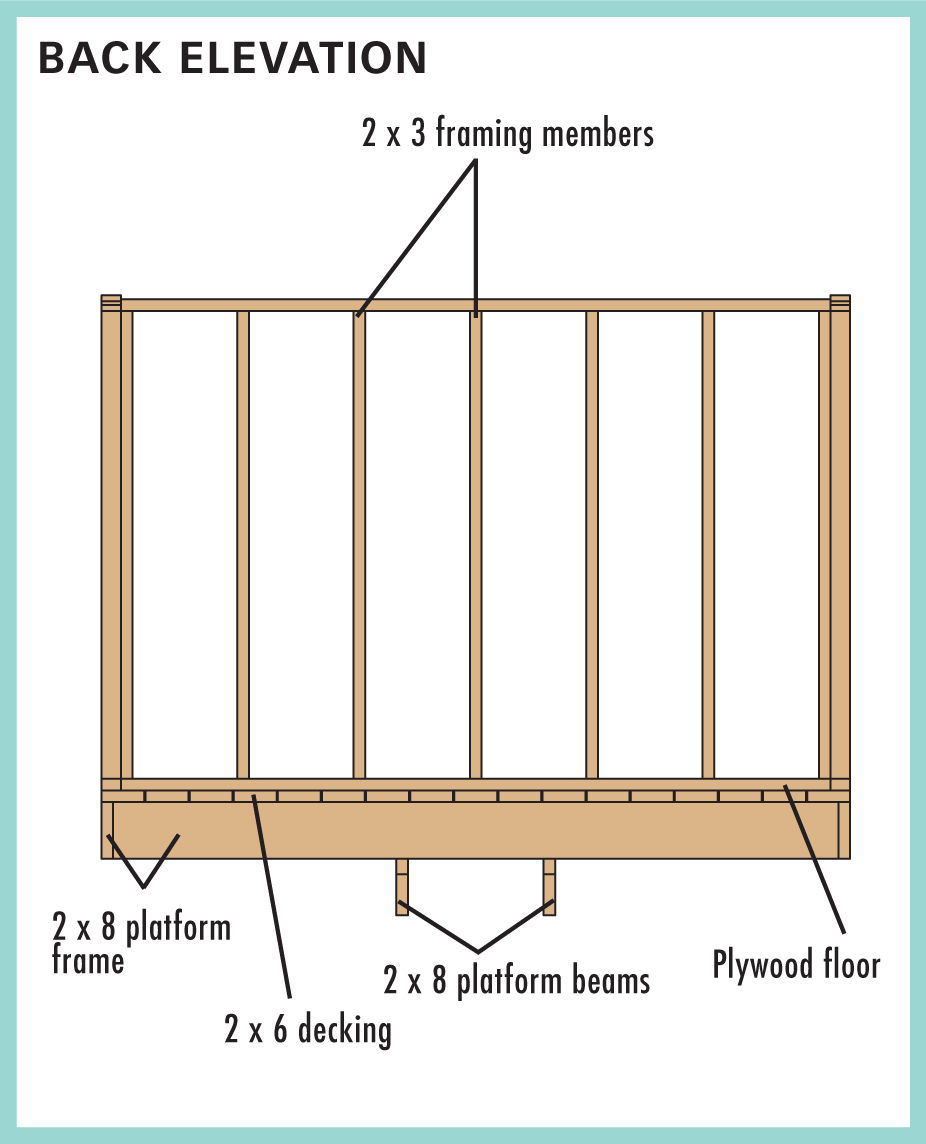

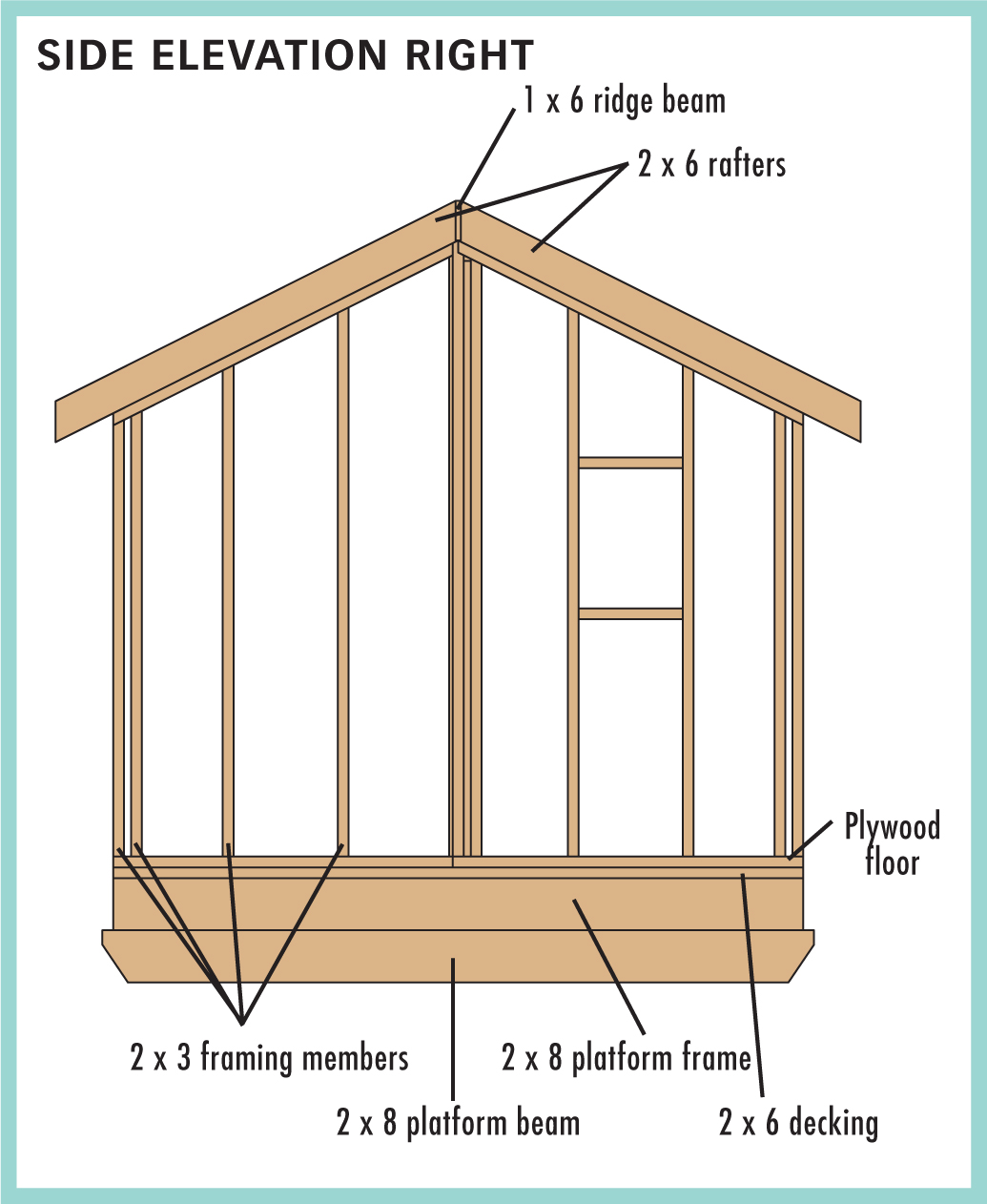

The walls of this house are framed with 2 × 3 lumber and are small enough that they can be framed and sided on the ground, then hoisted up onto the platform for installation. The left and right sides of the house have gable walls that create the roof slope. The left gable is one assembly, while the right gable is made up of two sections separated by a short section of the front wall, creating a jog that becomes the door wall. The single rear wall and two front walls are standard rectangular walls.

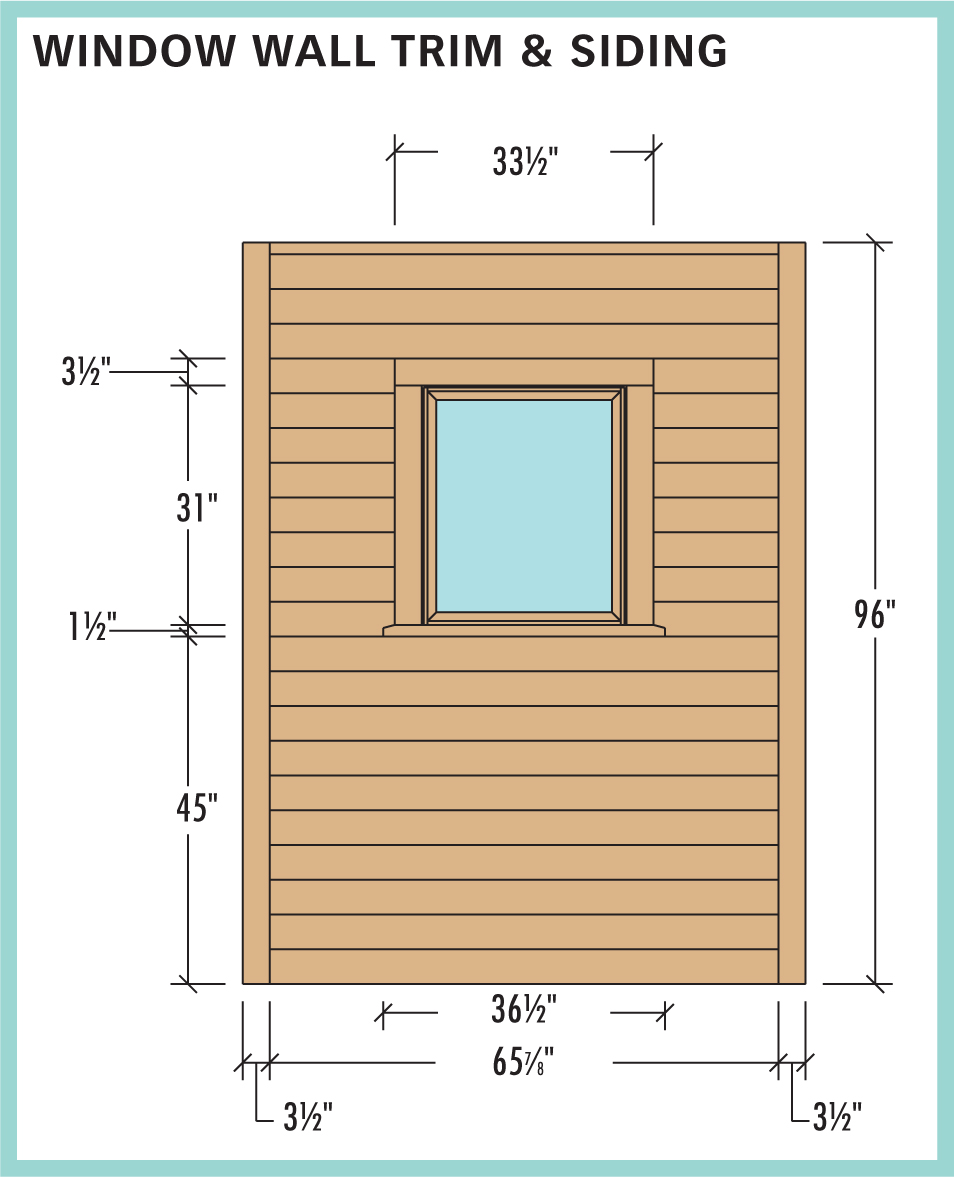

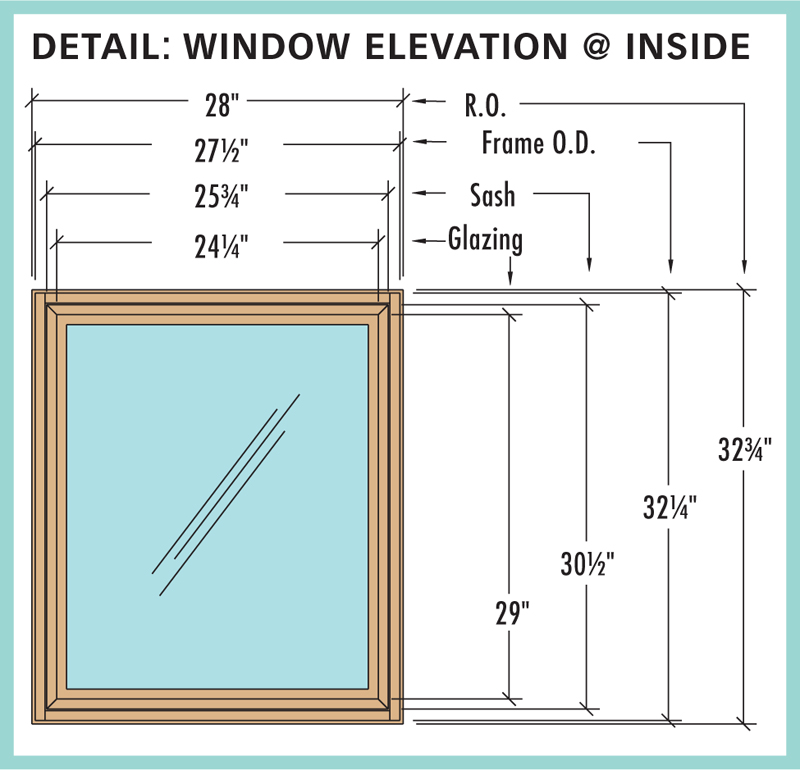

Start the framing with the left gable wall, following the techniques described on pages 83 and 84. The roof shown here has a slope of 6-in-12, so the top ends of the studs are cut at 26.6°. Frame the two right gable wall sections so that each one matches one half of the left wall. The rear section gets a rough opening for a custom-made window at any size or height you like.

Frame the rear wall to the same height as the sides of the left gable wall; make this a butt wall (see page 83) that will fit inside the two adjacent gable walls. Determine the size of the door wall based on the desired width of the door, adding several inches at either side of the door. The door wall section will act as a butt wall at the right side of the house and as a through wall where it meets the front half of the left gable wall. Frame the other front wall section to include a salvaged or homemade window, if desired.

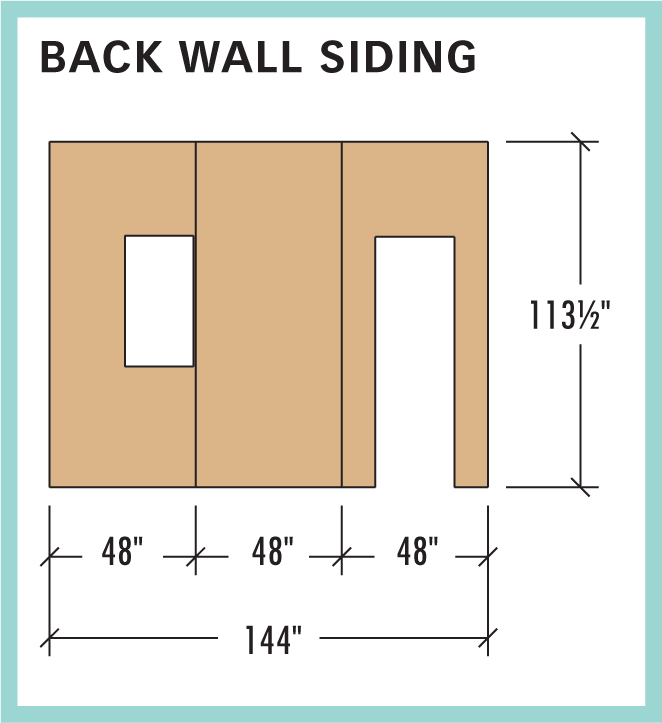

When all the walls are framed, tip them up for a quick test assembly. Check the outside dimensions of the assembly, and make sure the walls are square and are aligned properly for the roof planes. This is also the time to plan the siding installation and figure out where the siding should overhang the framing to cover the end of the mating wall, as applicable.

Install the siding according to your plan. The material used here is 3/8" cedar plywood siding; see page 87 for basic installation steps.

Snap chalk lines on the treehouse deck to guide the installation. Raise and install the walls following the basic process discussed on page 92. For this project, the corner trim isn’t added until the end of the house construction.

Use ropes and a pulley, a block and tackle, or any other mechanical aids to hoist the walls up to the platform.

Fasten the walls together at the corners with deck screws, following the same plan you used for the dry assembly on the ground.

The rafters overhang the front and rear walls by about 8" (measured horizontally) to create the traditional eaves.

This house’s roof has an eave overhang along the gabled sides as well as the bottom edges at the front and rear. To create the gable extensions, simply cut the 1 × 6 ridge beam so it overhangs the left and right sides of the house by about 6", or as desired. Mark the rafter layout on the ridge, then tack the ridge in place with a few nails.

Cut two 2 × 6 pattern rafters, following the steps described on pages 118 to 119. These are for the common (full-size) rafters; later, you will make custom-sized rafters for the gables and the roof overhang above the door. Use the patterns to mark and cut the remaining seven common rafters. The front section of the roof gets three commons, and the rear section gets six commons. Install the common rafters.

Cut the custom rafters along the gables so they sit on top of the wall plates and their top edges are level with the tops of the common rafters. These rafters don’t get bird’s mouth cuts, so their bottom edges on the eave ends are a little higher than those of the common rafters. Install the gable rafters.

Finally, cut and install the three short rafters along the door wall. These should extend roughly the same distance as the eave ends of the common rafters. Install the short rafters by toenailing them to the ridge beam.

The custom gable rafters are installed so their outside faces are flush with the outside of the wall siding.

The treehouse can have any roofing material you like. Here, the roofing is asphalt (composition) shingles laid over 1/2" plywood sheathing. Because the edges and some of the underside of the sheathing will remain exposed, it’s best to use “Exterior” sheathing (as opposed to “Exposure 1” or “Exposure 2”), which is designed for permanent exposure. Sheathe and shingle the roof following the techniques on pages 122 through 124.

The treehouse as shown has two windows. One is an octagonal window bought at an architectural salvage shop, a great place to find one-of-a-kind windows and other curiosities for a treehouse. You can also find used windows at building materials recyclers (including Habitat for Humanity outlets) and antique shops. The octagonal window shown here came with exterior trim (“brick molding”) attached. It was installed by nailing through the molding and into the wall siding and framing with galvanized casing nails. A continuous bead of exterior caulk applied along the perimeter of the molding prevents leaks.

Salvaged windows with exterior trim are a breeze to install. Others might call for some creative carpentry, but they’re well worth the effort.

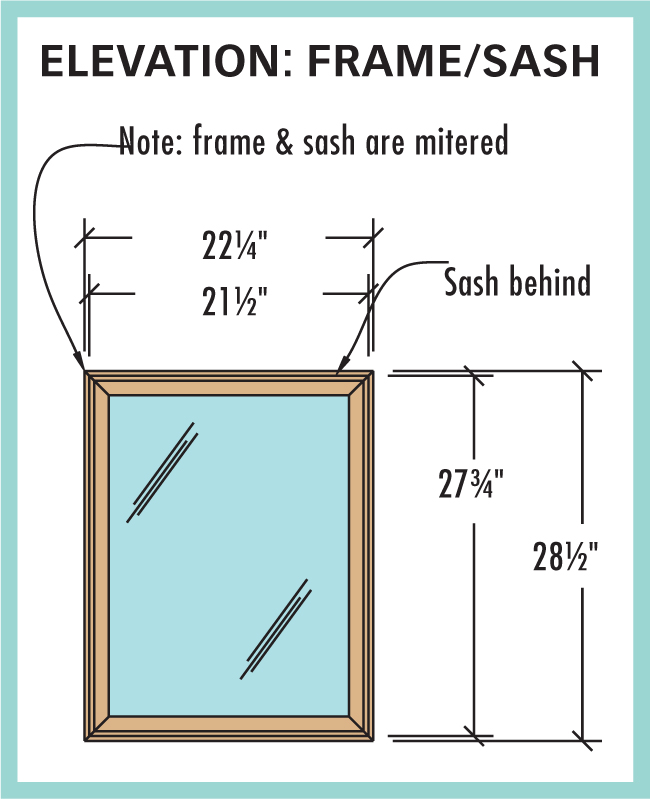

Preassembling a homemade window can save you some trips to and from the treehouse, but it requires careful measuring of the window opening.

The other window is totally handmade from 1× and 2× lumber, some molding, and polycarbonate sheeting for the “glass.” The steps on pages 106 through 112 walk you through the process of building your own window to any size you need. You can create the window piece-by-piece right in the rough opening of the wall, or you can use the same basic process and assemble the parts on the ground, then install the completed window in the opening.

To install a pre-assembled window, center the window frame inside the rough opening of the wall, with the window sill resting on the 2 × 3 rough sill and the horns of the sill tight against the outside of the siding. Use tapered cedar shims, if necessary, to snug the side and top jambs to the rough opening. Fasten through the jambs and sill and into the framing with galvanized finish nails. Another option is to pre-install the trim on the window unit, allowing you to fasten the window through the front of the trim and into the siding and framing.

The Dutch door adds some fun to the house design and even some practicality: closing the bottom half of the door keeps little ones safely corralled inside the house without having to shut off the opening entirely. Of course, a standard door would work just fine for the house, too. Instructions for building both door types are given on page 115.

The Dutch door shown here essentially is two short versions on the standard Z-brace door. Construct the two doors to fit the rough opening frame, leaving about 7/8" between the doors for a 1 × 4 shelf at the top of the bottom door, plus a 1/8" gap for clearance. Hang the doors so they swing out toward the front gable wall. Install 1 × 4 trim along the outside edges of the jambs, and add a latch to the lower door. Align the doors and install a slide bolt or barrel bolt (one that locks in the retracted position) onto the upper door so the barrel extends straight down into a hole (with a metal plate, if desired) in the lower door, to latch the doors together.

This sample Dutch door shows the simple construction of tongue-and-groove siding boards joined with 1 × 6 Z-bracing.

For this particular project, the railing and ladder were left off until now to facilitate construction, but you could add either whenever it’s convenient.

To build the railing, cut six 2 × 4 posts to length at 431/4" (or longer, if you prefer to make the railing higher than the code minimum of 36" above the platform decking). Install one post at each end of the railing, overlapping the house wall by 1-1/2" or so, and install two posts at the outside corner of the platform, forming an “L” with one post overlapping the edge of the other. Install the last two posts at the outsides of the ladder opening. Anchor each post to the platform joist with two 3" lag screws and washers driven through pilot holes. Also fasten the end posts to the treehouse walls. The posts should be perfectly plumb, with their bottom ends flush with the bottom edges of the joists.

Cut pieces of 2 × 4 railing cap to span over the tops of the neighboring posts (except within the ladder opening). Round the corners of the caps and sand the edges to remove sharpness and prevent splintering. Fasten the caps to the posts with 3-1/2" deck screws so the inside edges of the caps overhang the insides of the posts by 1-1/2".

Cut 2 × 2 support cleats to run along the inside faces of the posts, and install them up against the cap using 2-1/2" screws driven into the posts and cap. Cut the 2 × 2 balusters to the same length as the posts. Install the balusters with even spacing so the resulting gaps are no more than 4". Fasten the balusters to the platform joists with pairs of 3" deck screws and to the support cleats with 2-1/2" deck screws.

Access to this house is provided by a flat-rung ladder. Instructions for this are on page 128. Other good options include a double-rung ladder (pages 126 and 127) and conventional outdoor stairs (pages 130 to 133). If you choose to build a ladder, be sure to include a safety rail running across the top of the ladder opening in the treehouse railing.

This simple railing is made with 2 × 4s and 2 × 2s anchored to the platform framing and the house walls.

If you used plywood siding on the walls, now is the time to add the 1 × 4 corner trim at the outside corners of the house. Basic techniques for installing trim are covered on pages 90 to 91. The corner trim material should match or complement the exterior trim for the house’s windows and door.

Now it’s time to add color. This house design looks great with a semi-transparent stain on the plywood siding and dark paint on the trim, door, and roof structure. Painting the siding can work well, too, but stick with a contrasting color for the trim and roof to add definition to the building and make the trim details “pop.” The railing also should be finished to prevent premature weathering and roughening of the wood.

Inside the house, a few thoughtfully placed features can create a fun and functional living space. Finish the walls with paneling and trim, build a custom flip-down bunk or two, or add a flip-up table and a few shelves. See pages 96 through 103 for help with these and other custom projects.

More Treehouse Plans

More Treehouse PlansNo two treehouses are exactly alike because no two trees are the same. But that doesn’t mean building plans are worthless when it comes to treehouses. In fact, we’ve decided to wrap up this book by including six fully developed plans for your consideration and inspiration. It’s unlikely that you’ll be able to use them exactly as they are shown, so we’ve left out some dimensions and details that you’ll need to fill in yourself based on your tree or trees and on your needs and plans. But we think you’ll find them to be a good leaping off point for your venture into the trees.

Plan 1: Gable Roof with Auxiliary Posts

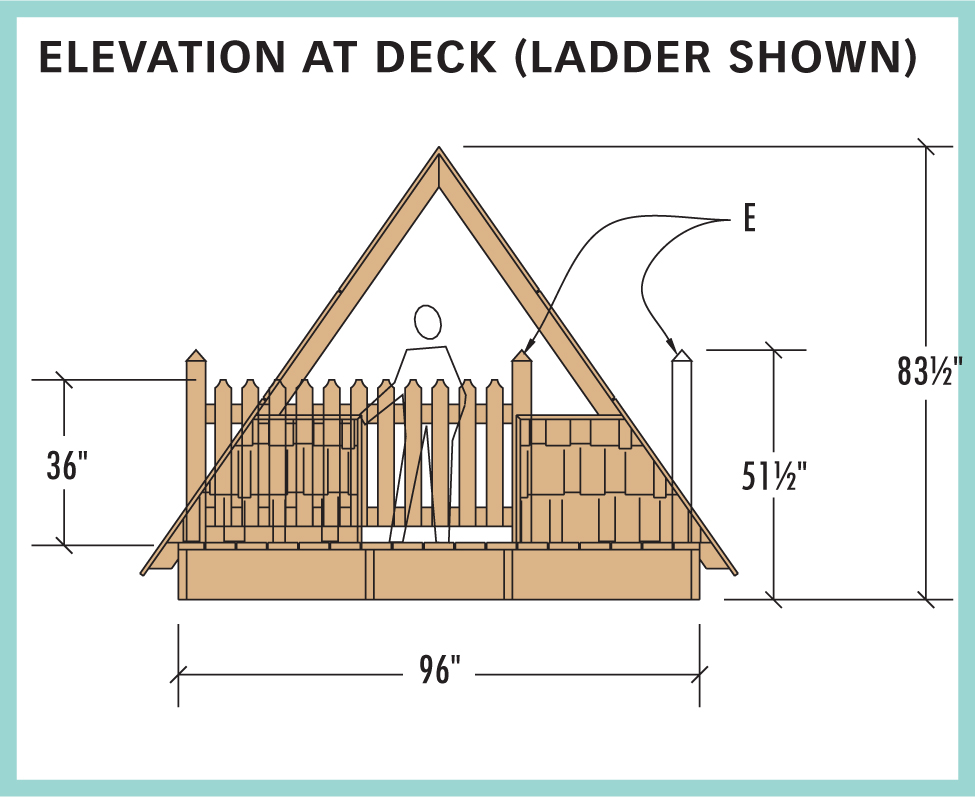

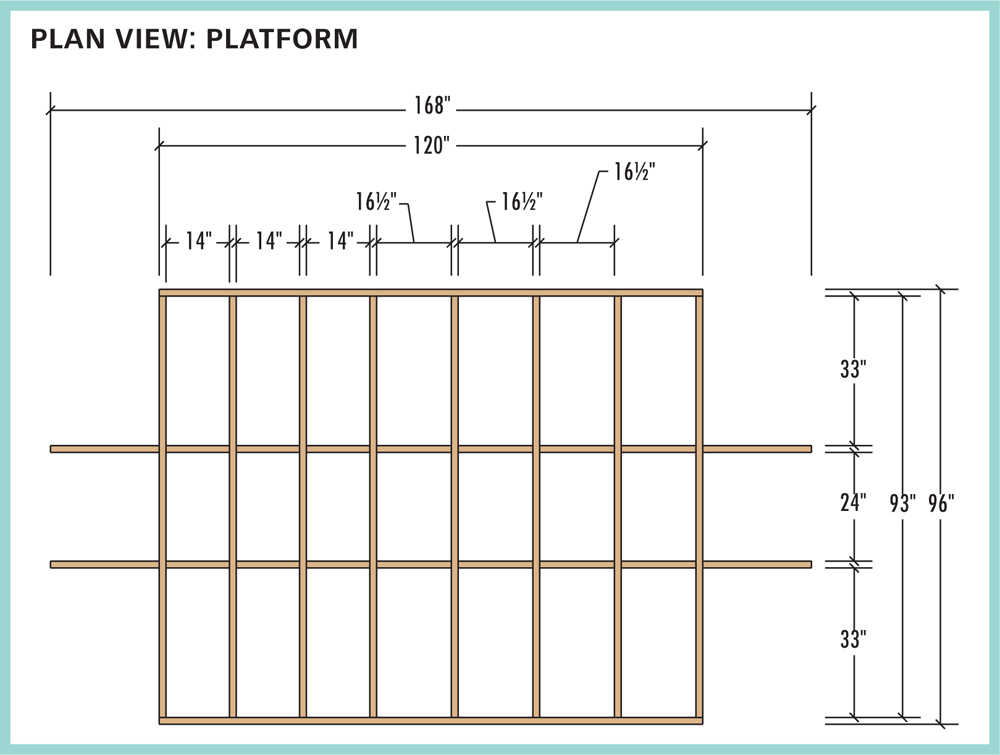

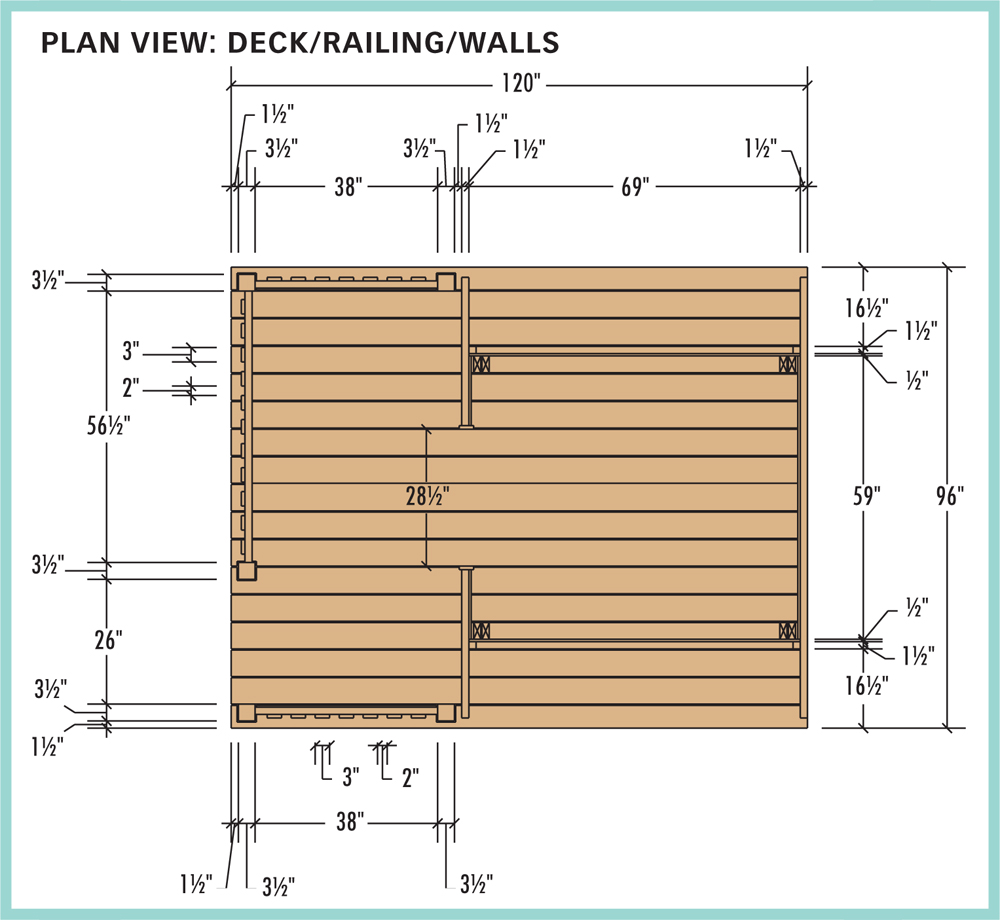

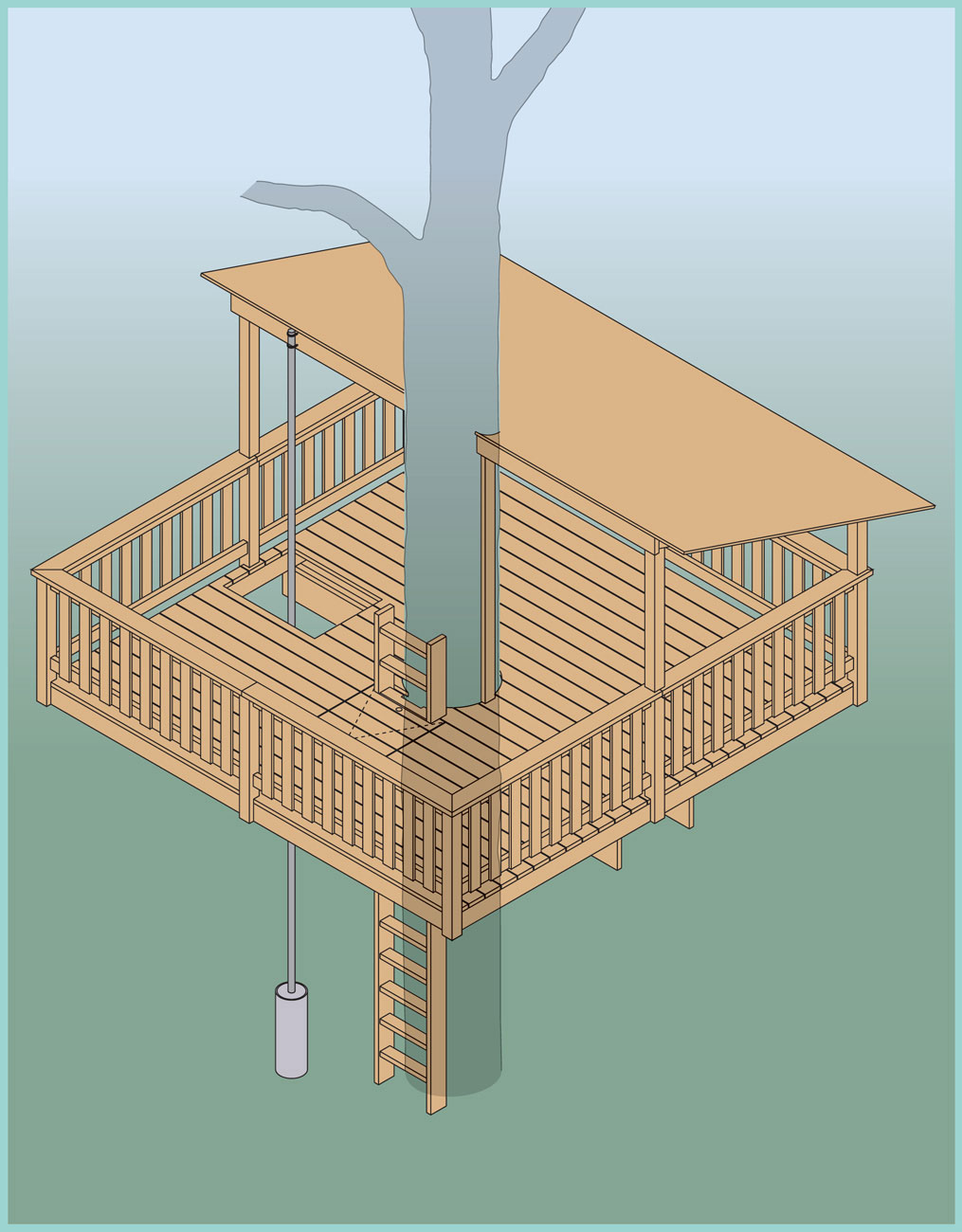

Plan 2: A-Frame with Walkout Deck

Plan 3: Half-covered Crow’s Nest

Plan 4: Wraparound Shed on Stilts