4

Brewing Pilsener Beer—Procedures

Choice of materials and equipment determines which procedures can be used in a particular brewery. For this reason, I recommend that you read this chapter on procedures for brewing Pilsener beer when considering your equipment’s capabilities. Both the previous chapter and this one examine the process of brewing Pilsener from different perspectives.

MASHING

The mash method is one of the most debatable aspects of Pilsener brewing. The choice clearly relates to the recipe formulation, which must be determined first. If the brewer elects to use raw cereals as adjuncts, he must use the mixed-mash system as defined in the previous chapter. Most microbrewers and homebrewers prefer all-malt formulations, however, and they can choose between step-infusion and decoction mashing as defined previously. The method selected may depend on the choice of pale malt. Undermodified Pilsener malts virtually demand a decoction mash. On the other hand, six-row malts probably should not be mashed by decoction because the repeated boiling extracts more tannin from the grain husks than the gentler, shorter infusion mash.

In other words, with undermodified, two-row malt, use the decoction process. With well-modified, domestic six-row malt, use step-infusion. With well-modified, two-row malt, either method will work. In fact, some German breweries now are making pale lagers with what is virtually a single-temperature infusion mash. However, domestic two-row barley has a higher level of protein and beta glucan than the Continental strains, and I believe that some type of multi-step mash, including a protein rest, is desirable with American or Canadian malt.

In most cases, I prefer step-infusion mashing because it is simpler, quicker, and less problematic. The difficulties of decoction mashing include not only tannin extraction but also the danger of scorching the mash during the decoctions. The chief advantage of the method is that it always yields more extract because the boiling bursts and gelatinizes all or most of the starch granules that were not modified during malting. This renders them available to the amylase enzymes that are active during the starch conversion rest. Decoction mashing also gives a lower mash pH without resorting to the addition of calcium because the boiling precipitates more phosphates from the malt.

It is also true that decoction gives a “cleaner” wort, as demonstrated by far less trub in the boiler. This is because the mash has already been boiled so that a large proportion of the proteins, tannins, gums, and other sludge components have already been coagulated and deposited. After boiling, worts produced by either mash method should be very clean. However, it is a fact that more care is needed during the lautering and sparging of an infusion wort in order to avoid bringing unconverted starch into the boiler.

If the brewer chooses the decoction system, he must decide on the number of decoctions and the temperature of the rests to be given. By varying the strike heat of the liquor and the grist-to-liquor ratio, the mash-in temperature can be set at any point. Likewise, by varying the fraction of the mash that is removed and boiled, the temperature of subsequent rests can be controlled. One of the difficulties of decoction mashing is establishing values for these parameters. Variations in the physical characteristics of the brewing equipment make it impossible to follow hard and fast rules; exact procedures must be determined by experience.

In brewing a Pilsener beer, some general considerations influence brewers’ choices. One of these is tradition. The traditional Pilsener mash is the classic triple-decoction method. In this system, the grist is mashed-in with a small amount of cold liquor and brought to 95 degrees F (35 degrees C) with an infusion of boiling liquor. After an “acid rest” at this temperature, one-third of the mash is removed, brought to a boil [with a rest at 158 degrees F (70 degrees C) for saccharification] and returned to the mash kettle to raise the temperature to 122 degrees F (50 degrees C) for protein conversion. Subsequent decoctions raise the mash temperature to 149 degrees F (65 degrees C) and finally to 168 degrees F (75 degrees C). This is a very long mash process since each decoction involves the following steps: (1) boosting to saccharification temperature; (2) saccharification rest of fifteen minutes or longer; (3) boost to boiling and, finally; (4) a fifteen minute boil. With each decoction, starch that would otherwise be lost is rendered available. Also, the repeated boiling progressively lowers the pH. Then, after the boiling fraction of mash is returned to the main mash, a rest of twenty minutes or longer is given to allow the enzymes to do their work. This means that it is hardly possible to run a triple-decoction mash in less than five or six hours.

Jean deClerck observed in his A Textbook of Brewing (Chapman-Hall Ltd, 1957) that this mash method has been criticized as being too intensive. It is ideal for the specific materials used in Plzeň; i.e., low-calcium mash water (which requires that other measures be taken to lower the pH) and undermodified malt. It is unnecessary with more normal water supplies and well-modified malt. The norm for brewing Pilsener in Germany is a two-step decoction process with the mash-in at protein rest temperatures.

Other variations are even quicker. For example, some brewers use a single-decoction mash in which the boost to saccharification is accomplished by decoction but the final boost to mash-out at 168 degrees F (75 degrees C) is done by directly heating the mash-tun. This program is arguably more sensible than the double-decoction method because starch released during the second boil may not be converted during the mash-out rest (the amylase enzymes are rapidly destroyed at such temperatures) and might cause hazes in the wort and finished beer. However, both methods have been shown to work well with fully modified malt.

Decoction mashing requires planning and experience, and I recommend that you read Brewing Lager Beer by Greg Noonan (Brewers Publications, 1986) for a complete discussion of the process. However, I would like to offer a couple of suggestions to beginners. First, all the experts recommend removing the thickest part of the mash for boiling. But do not make the decoction so thick that it is hard to stir effectively because the slightest scorching may ruin the finish of a Pilsener. Scorching is not such a problem in a kettle heated by pressurized steam, and traditionalist microbrewers who want to make Pilseners with the decoction method should seriously think about investing in a steam generator.

The second suggestion is, don’t make your decoction too small. If you are not sure how much it takes to achieve a particular temperature rest, guess high rather than low. This is especially important if you are using a main mash kettle that cannot be heated. It is always possible to add the decoction to the main mash a little at a time, and to cool it, if necessary, in order to get the rest temperature you want. But if you take too little, there is not much you can do to rectify the situation.

I must restate my preference for infusion mashing with domestic malts. Infusion mashing is simple and has been well-described in the standard reference works. Furthermore, domestic malts are quite well-modified, and the difference in extract yield between decoction and infusion is not likely to exceed 2 percent. But is step-infusion mashing necessary in order to provide a protein rest? Recent research indicates that relatively little protein degradation takes place in the mash, regardless of temperature. One consideration that complicates the issue is that other substances besides protein are degraded at the low-temperature rest, particularly beta glucans and other gummy carbohydrates. American barleys contain large amounts of these substances, which can cause hazes and a slow runoff in the lauter tun. For this reason, a low-temperature rest may be useful even if proteins have been adequately broken down during malting. Following is a temperature program optimal for each enzyme group:

- • mash-in and fifteen-minute rest at 113 degrees F (45 degrees C), which is optimum for peptidase,

- • fifteen-minute rest at 140 degrees F (60 degrees C), which is optimum for glucanase and protease,

- • rest at 150 F (65 degrees C) until starch conversion (confirmed by iodine test),

- • rest for five minutes at 168 degrees F (75 degrees C), which is mash-out.

In my own brewing I follow a simpler schedule, involving only a single low-temperature rest at 131 degrees F (55 degrees C) for thirty minutes. This temperature is not optimal for any of the enzymes, but it is a good compromise. When I use wheat malt, I lower the rest temperature to 122 degrees F (50 degrees C) to favor protein degradation (most important with this grain) and lengthen the time to forty-five minutes.

Pilseners are usually dry, well-attenuated beers so I generally favor a starch conversion temperature on the low end of the scale. For the same reason, a low mash pH, which favors beta amylase, is helpful. However, these recommendations may have to be modified according to the brewer’s experience, the materials he has to work with, and the exact results desired.

Some breweries omit the mash-out rest, but I believe this is a mistake. The wort runs off much more readily at 160 to 168 degrees F (71 to 76 degrees C), and sparging is therefore quicker and extraction is often higher if a mash-out is used. At the same time, in doing an infusion mash, it is very important that the sparge water temperature not be allowed to rise over 168 degrees F (76 degrees C). If it does, unconverted starch washes through into the sweet wort, which increases the chance of problems with haze and certain types of amylolytic microorganisms. Anheuser-Busch uses a sparge water temperature of 163 degrees F (72 degrees C), which is just about ideal for infusion or mixed mashes.

The mixed mash method is used only with uncooked cereal adjuncts. The procedure is well-described in standard textbooks and need only be outlined briefly here. The malt is milled and about 10 percent of it is mixed with the rice or corn meal. This mixture then is infused in cold water, which is raised to the starch conversion temperature of around 155 degrees F (68 degrees C) and held for fifteen to thirty minutes. The purpose of this rest is to allow the malt amylases to saccharify the loose starch before the porridge is boiled. This reduces problems with sticking but the mixture must still be stirred frequently throughout the process. Then the heat is raised, and the cereal mash is boiled for at least fifteen minutes. Longer times may be needed with rice, as this starch does not gelatinize as readily as corn starch. After the cereal mash has been through starch conversion, the main load of malt is mashed in and held at protein rest temperatures for about half an hour. The exact temperature is not very important and should be set so that the addition of the cereal mash to the main mash raises the whole to the desired temperature for saccharification. As in the decoction method, a mixed mash requires experimentation before you achieve consistency in your procedures because equipment and the recipe variations make it almost impossible to count on fixed rules or formulas.

I advise beginners to make the main mash as thick as it can be initially, but to make the cereal mash thin because the grits absorb a lot of water as they are brought to a boil. I suggest three quarts of water for every pound of grain. You may wish to experiment with this. As with decoction, add the cereal mash slowly and keep track of the temperature so that you don’t overshoot and destroy the malt enzymes.

In reading these pitfalls of a mixed mash, you may be thinking that flaked adjuncts are a reasonable choice. Any type of flake may be used in either a decoction or an infusion mash, though obviously they are preferable (in terms of saving time and work) in the latter. Flaked corn and flaked rice contain little protein or gum and can be mixed with hot water and added to the mash before the starch conversion begins. However, it is easier just to mix them into the grist before mashing in. Note that flaked barley must be handled in this way because it is rich in haze-forming components and needs the benefit of a low-temperature rest.

Sparging technique is no different with Pilsener mashes than with any others. An extra measure of caution is required because, as with other pale beers, Pilseners are highly susceptible to haze. The sparge water temperature must not be too high. Also, the pH of the runoff must not be allowed to get above 6.0 and preferably not above 5.7, particularly when the grist is based on six-row or domestic two-row malts.

The last question to be addressed in this section has to do with the clarity of the runoff. It is my strong belief that, because pale beers such as Pilsener must be as clear as possible, it is vital to recirculate the first runnings until the filter bed is well established and the runoff is reasonably clear. Of course, the first runnings will have some protein haze, but this should be very slight once the filter is settled. If the first runoff is not recirculated, grits and fine-ground pieces of husk are bound to wash into the boiler. This increases the chances of starch and tannin hazes and astringency in the finished beer.

BOILING AND COOLING

In brewing Pilsener beers, boil time is an issue mainly because of its effect on wort color. In Plzeň, the wort is boiled for two hours, but Pilsner Urquell is darker than most examples of the style, and a shorter boil makes it easier to get the lighter color of a typical Pilsener. Some breweries boil under pressure for only a few minutes, but for ordinary boiling at atmospheric pressure, a time of at least forty-five minutes is needed to get an adequate hot break. I usually boil the wort for seventy-five minutes, adding the first lot of hops after thirty minutes of boiling. The reason for this procedure is to get maximum coagulation of the wort proteins with the harsh, astringent malt tannins before adding hops (the other major source of tannin in beer). However, I have not been able to verify the effectiveness of this procedure. The total time is short enough to minimize wort darkening, even with a direct-fired kettle.

When brewing with malt extract, even shorter boils are called for. To avoid darkening and caramelization, I suggest a maximum boil time of forty-five minutes. Extract worts begin to break even before reaching the boil, so boils as short as 15 minutes are quite adequate when you are using pelletized hops.

It is customary in some breweries to add the first lot of hops before the wort reaches the boil. The hops hold down foaming and minimize the danger of a boilover. This may be necessary if the boiler capacity is close to the batch size. However, if the boiler is at least 25 to 30 percent larger than the volume of wort that is run into it, boilovers can be avoided simply by regulating the heat under the copper. In order to save time, most breweries begin applying heat as soon as the sweet wort covers the bottom of the boiling kettle. The wort reaches the boil as soon as the copper is filled. For Pilsener brewing, especially when using a direct-fired kettle, I advise caution with this procedure. The first runnings are of high gravity and are easily caramelized, or even scorched. A few experiments may be needed to determine when the boiler can be fired up without darkening the wort.

At Plzeň, hops are added in three stages over the course of the boil. This procedure gives a full hop flavor because different fractions of the hop aromatics are retained according to boil time. The customary method for imparting the characteristic hop aroma to Pilsener is to add the last fraction of “finishing” hops either shortly before (say five minutes) the end or at the very end of the boil. Some brewers add their finishing hops to the hop back instead.

In the equipment section, I have already discussed the various options for removing the hops from the wort and cooling it. The main point is to avoid oxidation of the hot wort. Some American breweries use open-air cooling in order to maximize the evaporation of certain sulfury compounds (especially DMS) from the finished beer. But since small amounts of these compounds are part of the flavor profile of typical European Pilseners, there is no reason to go to extremes in order to remove them. Also, in a small-scale operation, it is relatively easy to get all the wort chilled shortly after the boil, and once the wort is cool, DMS is no longer formed. In fact, homebrewers using an immersion cooler in the boiler may want to let the hot wort sit for a short time, in order to increase the DMS content of their European-style Pilseners.

The final step that needs to be considered in wort processing is trub removal. This is important because it greatly affects the flavor of the finished beer. To minimize fusel alcohol production, all the hot break must be removed before fermentation begins. Furthermore, it is advantageous to remove a large proportion (at least 40 percent) of the cold break as well. This further reduces fusel alcohols and make it unnecessary to skim the kraeusen of the fermenting beer.

The usual procedure is to run the hot wort through a hop back (if whole hops are used) and into a whirlpool, where the break material collects in a compact mass at the bottom of the tank. Then the wort is chilled and run into a starting tank where the yeast is pitched. During the lag period, the cold break partially settles, and this sediment is left behind when the wort is racked once more into the primary fermenter. This system works well and gives very clean beers. The only problem I can see is that it requires an extra fermenting vessel (the starter tank).

At Plzeň, coolships are used, but the wort is first run through a closed heat exchanger (which avoids wort oxidation), and the main function of the coolship is to allow cold break material to form and settle out before the wort is pitched. I suggest a simpler alternative for small-scale brewers: use a whirlpool, but chill the wort before whirlpooling it. Like the Plzeň coolships, the whirlpool then removes both hot and cold break material and allows the wort to be pitched in the primary fermenter. Also, I suggest chilling the wort as much as possible, down to 40 degrees F (4 degrees C) at least. This reduces the need for subsequent measures to remove chill haze, which is a major problem with all-malt Pilsener beers. The only drawback to this method is that there is a greater accumulation of break material in the heat exchanger so that more frequent cleaning is necessary. Also, the cooler may need to be slightly larger because the deposition of sludge reduces its efficiency.

FERMENTATION

The traditional fermentation of Pilsener beer is a long, slow process requiring three months or more. Pilsner Urquell is still made in this way, and the finished product is a testimony to the efficacy of this system. On the other hand, economic pressures have forced most breweries to adopt shorter schedules in order to maximize their output. Fortunately, scientific research has explained many of the mysteries of fermentation, and greater understanding of the process has enabled brewers to reduce fermentation time without compromising the quality of the beer. However, there are limits. Pilseners with the traditional European flavor cannot be produced by a two- or three-week fermentation cycle.

One trend in modern lager brewing is the use of a separate starter tank, as described previously. The wort usually is held in this tank during the lag phase at a relatively high temperature, perhaps 60 or 65 degrees F (15 to 18 degrees C). The wort is cooled to fermentation temperature after yeast activity begins. This can cut a full day off production time. However, careful monitoring is required or esters and diacetyl may be increased. The traditional fermentation method is to pitch the yeast into the wort at 40 to 48 degrees F (4 to 8 degrees C). This guarantees minimum production of diacetyl, but it also gives a long lag period. In order to get a reasonable fermentation (six to ten days), it is important to pitch a large amount of strong, active yeast. Pitching rate should not be less than 0.67 to 1.3 fluid ounces of slurry per gallon (20 to 40 fluid ounces per U.S. barrel).

The trend in America is toward relatively warm fermentations, typically around 55 degrees F (12 degrees C). This shortens fermentation time, and with a suitable yeast, esters and other byproducts are not noticeable in the finished beer. Nonetheless, the flavor is affected. Acetic acid and DMS, for example, are actually lowered by a warm fermentation, and these compounds are part of the characteristic flavor profile of European Pilseners. For this reason I recommend that the wort temperature be no higher than 50 degrees F (10 degrees C) during the initial stages of fermentation.

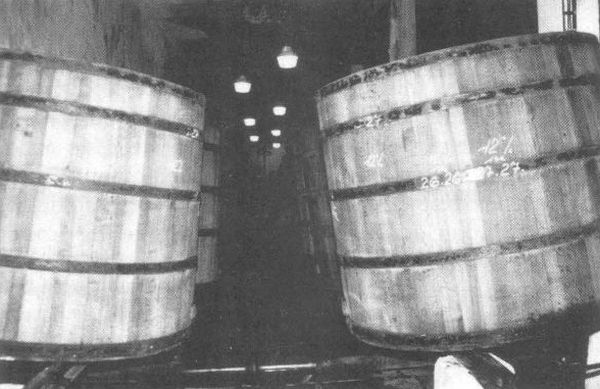

Primary fermentation in oak tubs at the Pilsner Urquell Brewery.

Open fermenters at the Protivin Brewery, Czechoslovakia.

The traditional method of brewing Pilsener calls for a temperature held steady throughout primary fermentation, after which the beer is racked to the lager tanks while secondary fermentation is still in progress. This is in sharp contrast to a newer method wherein the temperature is allowed to rise to about 53 degrees F (11 degrees C) as fermentation progresses. The beer is often held in “ruh storage” for twenty-four to forty-eight hours after fermentation before being transferred to the lager tanks. This allows the yeast to reduce diacetyl to below threshold levels before the beer is racked and lagered. Lagering is not required to mature the beer’s flavor and is used mostly for clarification. With the traditional method, several months of cold secondary fermentation are needed before diacetyl is reduced and the terminal gravity of the beer is reached.

One part of traditional Pilsener brewing technique that continues to be popular is kraeusening. This is used mainly for carbonation, but it has other purposes as well. For one thing, the introduction of fresh, active yeast at the end of fermentation gives a boost to the diacetyl reducing process. Just as important, it tends to give a more complete fermentation, which means a lower terminal gravity and a dryer finish to the beer. At the same time, the content of certain “young beer” components (such as acetaldehyde) is increased in the finished beer, which may or may not be desirable.

While kraeusening is an excellent technique, it is not always practical, especially for small-scale brewers who do not often brew Pilsener. It is quite possible to get a true Pilsener flavor without kraeusening, especially because the modern fermentation system tends to give some of the same benefits (diacetyl reduction, complete fermentation). Both natural and artificial carbonation can be used, with the latter typically taking place very late in the process, after lagering has been completed. Natural carbonation without kraeusening is very simple, especially when using pressure-resistant tanks for secondary fermentation. The only point to remember is that, if a brief storage time is desired, the temperature should not be dropped as soon as the tank is sealed. The young beer should be allowed to ferment out at 53 degrees F (11 degrees C) before the thermostat is lowered.

It has been mentioned in passing that lagering traditionally served three purposes: clarification, carbonation, and flavor maturation. The last of these can be largely eliminated by modern fermentation technique, as outlined above, and the second can be done artificially. It might therefore be supposed that by the use of filters for clarification, lagering could be eliminated entirely. This may be true in theory, but it does not work out well in practice. Young unfinished beer contains so many yeast cells that an enormous amount of filter material would be necessary to remove them. Also, filters work by adsorption (gathering particles on a surface in a condensed layer) and are quite indiscriminate. Yeast cells are so small that they cannot be filtered out without also removing a certain amount of protein material that is important for the head retention, flavor, and body of the finished beer. Therefore, if the brewer aims to make a full-flavored, traditional Pilsener, his only choice is to allow most of the yeast to drop out naturally during lagering and thus minimize the need for filtration.

The time needed for lagering depends on many factors. One is the flocculation characteristics of the yeast; obviously, the faster the dropout after fermentation, the shorter the lagering time. Many breweries use fining agents to enhance the dropout rate. Isinglass, which is very popular in British ale brewing, is not used much in lager brewing. One popular, traditional method is the addition of beech or other hardwood chips to the lager tank. These provide an ideal surface for the yeast cells to adhere to and thus speed up the clarification process considerably. The only drawback is that they are difficult to clean and sanitize. Aluminum “chips” also work and are much easier to maintain, but they are not as effective as the wood chips.

Another factor that influences lager time is the quality of the malt. In order to get a sparkling clear Pilsener, more than the yeast must be eliminated. Colloidal haze, whose chief constituents are protein and tannin, also clouds beer. Haze slowly continues to form and settle out at any temperature, but it forms much more rapidly at low temperatures—hence the well-known phenomenon of chill haze. In any case, haze continues to form in the lager tank, but the amount of haze depends greatly on the amount of haze precursors in the beer. Higher quality malts contain less protein and tannin than those of lesser quality, and therefore require less lagering time. Dr. George Fix, author of Principles of Brewing Science (Brewers Publications, 1990), is of the opinion that four to five weeks of lagering is optimal for beers brewed with Continental two-row malt; five to six weeks for beers brewed with American two-row malt; and seven to eight weeks for beers brewed with six-row malt.

Shorter lagering times are certainly possible, and indeed, many American brewing companies do not use a traditional cold lager process. The beer is aged for two to three weeks at fermentation temperature to allow the yeast to settle at least partially, and the beer is chilled briefly (perhaps for twenty-four hours) just before it is filtered and packaged. This method relies on the filters, along with treatments that remove precursors, to eliminate colloidal haze.

- A Note on Lagering for Homebrewers -

The discussion of lagering above is aimed mostly at microbrewers and at homebrewers who serve most of their beer on draft from stainless steel “soda” kegs. These kegs are ideal lager tanks, built to withstand pressure, and a draft system makes it easy to apply polish filtration (if necessary) at the end of the lager period, using carbon dioxide (CO2) pressure to push the beer through the filter into another keg. This places them in essentially the same position, with the same resources, as their commercial brethren.

On the other hand, homebrewers who use the simple, old-fashioned technique of priming (or kraeusening) and bottle fermentation for carbonation, face a different situation. They cannot rely on filtration at all and therefore must use other means to achieve clarity of their finished beers. In my view, the ideal way of dealing with this problem is to ferment the beer out and then rack to a carboy or other closed fermenter to allow partial settling of the yeast. Dry hopping can also be done at this stage, and clarifying agents such as Polyclar™ can be added. This settling period should be not less than five days, and two weeks is preferable. At the end of this time, the beer should be primed, bottled, and stored at fermentation temperature for at least a week to allow the bottle fermentation to take place. At this point the beer should, if possible, be put into cold storage for one to two months. At the end of this time the beer should be clear when warmed to serving temperature, though it may still be hazy at the 32 to 34 degrees F (0 to 1 degrees C) lager temperature.

The idea here is to regard each bottle as a miniature lager tank. It is possible to make Pilseners with a true European flavor with this system. In fact, if the wort was well-chilled before pitching, and you are willing to apply a dose of Polyclar™ in the carboy, you can get a clear, chillproofed beer even if it is stored at fermentation or cellar temperature. The problem is that there is always a bit of oxygen pickup with home bottling (unless the bottling is done from a draft keg using a counterpressure filter), and the first thing that goes when beer is oxidized is the hop aroma. Therefore, it is better to store homebrewed Pilsener cold, if for no other reason than to forestall oxidation.

FILTRATION AND CLARIFICATION

A light, polish filtration is generally required to get a sparkling, clear Pilsener. A four-micron filter generally will do an adequate job unless the beer has not been properly lagered and handled. Only a minimum of filtration should be necessary. A hazy beer clogs the filters in short order, leading to air pickup and the resulting destruction of delicate hop aroma.

Air pickup must be avoided at all costs. For this reason I recommend that microbrewers use the same system as homebrewers; that is, push the carbonated beer through the filter with CO2 pressure while maintaining a slight bleed in the bright beer (receiving) tank, which has been filled with CO2 beforehand. With this system, dissolved oxygen is actually removed from the beer during transfer. By contrast, all types of pumps introduce some air into the beer.

The need for clarification, like filtration, can be kept to a minimum by sound brewing practices. I have found that chilling the wort as much as possible after boiling, in order to maximize the formation and precipitation of cold trub, greatly reduces the need for clarifiers later on. However, Polyclar™ is very useful with American malts as it selectively adsorbs polyphenols (tannins) from the fermented beer and reduces chill haze considerably. Polyclar™ powder can be added to the lager tank after chilling, or treatment can be combined with filtration by selecting a filter element that is impregnated with the compound. The only drawback is that it adsorbs isohumulone to a slight degree and so reduces hop bitterness. This must be compensated for in the recipe formulation.

The other compounds used to clarify and chillproof beer work by adsorbing or breaking down protein. Since this affects the mouthfeel and head retention of the finished beer, I consider these compounds less desirable than Polyclar™. However, with beers that have a severe haze problem, a combined attack may be needed, and silica gel (which adsorbs protein) may be added to the lager tank along with Polyclar™. Protein-degrading enzymes, such as papain, also are employed sometimes. However, they are hard to control, so unless the beer will be pasteurized (which deactivates the enzymes after a definite period), they must be regarded as a second choice.

BIOLOGICAL STABILITY

Pilseners are especially susceptible to showing off-flavors in the finished beer. Therefore, sanitation is the first line of defense against biological hazes from bacteria or yeast. Without proper sanitation, all subsequent measures are likely to fail.

Beyond sanitation measures, active yeast works against other organisms competing with it, creating chemical conditions that favor its own survival. This means that one of the best ways of assuring the biological stability of a finished beer is not to remove the active yeast. It is common knowledge that filtered homebrews are much more prone to infection than those primed and bottled with active yeast. The problem is that bacteria are much smaller than yeast cells, and the light polish filtration recommended for removing yeast haze and yeasty, “young-beer” flavor notes from Pilsener does not remove completely the lactobacilli and pediococci that can wreak havoc on Pilsener flavor and clarity. There are basically three techniques that can be used to avoid the problem.

The first is the conservative method used (of necessity) by many homebrewers; either don’t filter or filter very lightly so that some live yeast remains in the beer, then keep the beer cool and drink it quickly. Most American breweries do not pasteurize their draft beer because they know it will be stored under refrigeration and consumed within a week after it is racked. Brewpubs can follow the same approach.

The second method is to pasteurize the beer. Most European Pilseners exported to the United States are pasteurized, as are most domestic bottled beers. Pasteurization can assure long-term biological stability if carried out properly. At Plzeň, bottled beer exported to Western Europe is pasteurized at 145 degrees F (63 degrees C) for thirty minutes. Beer shipped to America is pasteurized for sixty minutes in order to give it a greater degree of stability commensurate with the long sea voyage and extremes of temperature it is likely to encounter. The problem with pasteurization is that the high temperatures used greatly accelerate oxidation, which leads to stale, winey or cardboardy flavors, as well as destruction of the fine, fresh-hop aroma so vital to a Pilsener. If bottled beer is pasteurized, there are three points to remember:

- 1) the wort and beer must be maintained in a reduced (unoxidized) state as much as possible at every stage of production or pasteurization can bring about oxidation even though there was no dissolved air in the beer when it was bottled;

- 2) beer must not be aerated during bottling, and air must be eliminated from the headspace, which means using a good counterpressure bottle filler and knocking the bottles before capping; and

- 3) pasteurization should be carried out at the lowest temperature for the shortest time needed to achieve biological stability (flash pasteurization is particularly attractive but, since it is applied prior to bottling, sanitation in the bottling plant must be very carefully attended to).

The third method of attaining biological stability is sterile filtration but, because this has the net effect of stripping out much of the body and flavor, this process is entirely inappropriate for any European style of lager beer, including Pilsener.

SERVING

When they bottle, homebrewers face the problem of flat beer that must be primed in order to bring about a bottle fermentation that will carbonate the beer. The problem can be overcome by a two-step procedure. First, fill the bottles carefully to a rather high level. Leave only about five milliliters of air in the neck of each bottle; this means filling a standard longneck to the line that marks the bottom of the bulge beneath the lip. Second, carefully place the bottle caps on all the bottles after filling, and let them sit for half an hour before crimping the caps down. This allows the priming fermentation, which begins immediately, to displace the air in the headspace with carbon dioxide. This gas is heavier than air and therefore tends to expel it. This trick adds time to the bottling procedure and requires an extra degree of caution to avoid knocking off the caps while they are being crimped. But I have proved its worth in my own brewing. As of this writing, I still have in my basement a few bottles of Pilsener that were bottled six months ago. The beer was made using standard, primitive homebrewing techniques, including glucose priming and bottle carbonation. Nonetheless, this beer maintains a fresh hop aroma after half a year of storage.

The finished product is available here. A wealth of roadside cafes offer travellers a chance to buy Czech beer before crossing the East German border.

On draft, European Pilsener tends to draw slower than American lager because of its greater viscosity. This must be accepted. Increasing gas pressure on the keg will not speed up the flow appreciably.

The temperature at which Pilsener is served is critical because low temperatures numb the taste buds and high temperatures do not allow the beer to remain well-carbonated as a Pilsener should be. In my opinion, a serving temperature of 45 degrees F (7 degrees C) is ideal for this style of beer. Microbrewers and brewpubs may have to educate their customers (including bar owners) about the taste advantages of this relatively high serving temperature. Homebrewers face no resistance but their own to the higher temperatures, but they may need a “dedicated” refrigerator for their beers if they want to maintain the proper serving temperature for Pilsener.