CHAPTER 2

Malted Barley

Because malt is organic, and subject to the meteorological and soil conditions under which the barley type is grown, malts of the same type can vary substantially in appearance and composition, depending on the season and where and how they are grown. For instance, moist, cool seasons produce more starch and less protein and fat, whereas nitrogen-based fertilizers applied too heavily or too late in the season increase the protein content. A lack of nutrients and minerals will also affect growth and composition. Malt quality depends as well on the circumstances of its malting and subsequent handling. Furthermore, the different barley types are each composed of several varieties.

For these reasons, it is advisable to ask for a lot analysis of any malt to guide adjustments in the mash program so that a wort consistent with previous brews can be made. Commercial breweries evaluate malt at the time of purchase. Craft brewers and homebrewers should too, using the lot analysis provided by the maltster. At the minimum, the lot analysis should give information about the moisture content, color, dry basis fine grind extract, fine-coarse difference, diastatic power, total nitrogen (protein), soluble nitrogen ratio, mealiness, and size distribution of the particular batch of malt.

The lot analysis is generally given on a “dry basis”; that is, the parameters given in the analysis are adjusted to give values as if the malt were oven-dried to 0 percent moisture content. This makes comparisons between lots of malt easier, because no adjustments need to be made for varying percentages of moisture in the malt.

Maltsters generally publish “typical” analyses so that brewers can evaluate their products before purchase. A typical analysis should not be accepted as a substitute for a lot analysis; unless the brewer knows the laboratory parameters of the malt actually on hand, adjustments to brewing procedures cannot be made, and brew-to-brew consistency is not possible. Lot analyses that vary considerably from the parameters stated in the typical analysis are reason to find a new source of malt.

Typical and lot analyses provide the brewer with essential data regarding the general quality of a malt and the barley it is made from, and the suitability of a particular malt for a given mashing method. Without referring to a lot analysis, the brewer cannot know whether a given malt is suitable for infusion mashing or if it requires a protein rest, and if it does, what the duration of the rest should be. Lot-to-lot adjustments to the brew house program usually need to be made in response to changes in the parameters of the malt on hand.

“Base” malts are those malts that form the basis of the brew, usually making up 60 to 100 percent of the grain bill. They usually provide the bulk of the extract and the enzymes to produce it. Lager, Pilsen, Brewers’, Pale, Vienna, light Munich, and British mild ale malts are base malts. The last three resemble British pale malt, except that their colors are higher, and during malting, Vienna and Munich malts are converted somewhat less (fine grind– coarse grind difference 1.5 to 2.0 percent, lower soluble nitrogen ratio) than the British ale malts. Vienna malts have a diastatic power similar to European lager malts, while the range of diastatic power of Munich malts is similar to British malt. Consequently, Munich malt presents the potential for conversion problems if it is at all undermodified by the maltster, and cannot be used as a base malt in high-adjunct mashes.

Pilsen and lager malts originating in Britain and America usually resemble the brewers’ malts of those countries in everything but color; they need to be handled in the brew house accordingly. Generally, malts purchased from the country of origin of the beer style give better results than those originating elsewhere.

Any analysis is only of use to brewers if they understand the significance and acceptable ranges of the quoted values. For lot analyses, the common parameters are:

Moisture content, percent: The upper limit for acceptable moisture content in any malt is 6 percent. The closer a malt is to 1.5 percent moisture content, the less risk of mold growth and the less flavor and aroma loss there will be in storage. For the last two reasons especially, colored malts should never be higher in moisture content than 4 percent. Of the base malts, British ale malts have the lowest moisture content.

The moisture content reflects upon the quality of the malting; high moisture-content malts are very often lacking in other areas as well. Furthermore, each 1 percent increase in the moisture content adds 1 percent to the real cost of the malt.

| Malt Analysis, Dry Basis, Comparative Analysis of Acceptable Ranges | |||||

|---|---|---|---|---|---|

|

Malt Analysis Dry Basis Acceptable Ranges |

Traditional 2-Row Lager |

European 2-Row Lager |

American 2-Row Brewers |

American 6-Row Lager |

British 2-Row Best Pale |

|

Moisture content, % |

3.5–4.5 |

3.5–4.5 |

3.5–4.5 |

3.5–4.5 |

1.5–3.5 |

|

Color, SRM (°L, ASBC) |

1.2–1.6 |

1.4–1.8 |

1.4–2.0 |

1.4–2.0 |

2.0–2.7 |

|

Color, °EBC |

2.0–3.0 |

2.5–3.5 |

2.5–4.0 |

2.5–4.0 |

4.0–6.0 |

|

Extract, DBFG |

80.0–82.0 |

80.0–82.0 |

79.0–81.5 |

78.0–79.5 |

80.5–82.5 |

|

Extract, DBCG |

78.0–80.5 |

78.0–80.5 |

77.0–80.5 |

76.0–78.1 |

79.0–81.5 |

|

FG-CG, difference |

1.5–2.2 |

1.5–2.0 |

1.0–2.0 |

1.4–2.0 |

1.0–1.5 |

|

HWE (L°/kg at 20° C), .2M |

309–316 |

309–316 |

305–315 |

301–307 |

311–318 |

|

CWE |

16–18 |

18–20 |

18–21 |

18–21 |

18–22 |

|

Hartong 45°, % |

30–34 |

32–38 |

36–42 |

38–42 |

36–42 |

|

Alpha-amylase, DU |

44–48 |

40–48 |

40–45 |

35–45 |

25–35 |

|

DP, °Lintner |

70–100 |

75–110 |

100–150 |

125–160 |

50–70 |

|

DP, °WK |

200–325 |

220–350 |

375–450 |

400–500 |

150–220 |

|

Conversion, min |

10–15 |

10–15 |

5–10 |

5–10 |

10 |

|

Protein, % |

9.0–11.0 |

9.0–11.0 |

11.5–12.5 |

12.0–13.5 |

9.0–10.0 |

|

Soluble protein, % |

3.0–4.2 |

3.5–4.6 |

4.2–5.3 |

4.8–5.8 |

3.5–3.8 |

|

TN, % |

1.4–1.75 |

1.4–1.75 |

1.8–2.0 |

1.9–2.2 |

1.4–1.55 |

|

TSN, % |

.48–.67 |

.50–.75 |

.65–.85 |

.7–.93 |

.5–.6 |

|

SNR, % (S/T, SN/TN, %) |

33–38 |

36–42 |

36–42 |

40–45 |

38–42 |

|

Mealy, % |

92–97 |

95–97 |

95–97 |

92–97 |

97–99 |

|

Half-glassy, % |

2–8 |

2–4 |

2–4 |

2–8 |

1–3 |

|

Glassy, % |

0–1 |

0–1 |

0–1 |

0–1 |

0 |

|

Friability, % |

80–85 |

80–90 |

80–90 |

75–85 |

85–95 |

|

On 7/64" scrn.-plump % |

75–85 |

75–85 |

60–70 |

45–55 |

80–85 |

|

On 6/64" screen % |

10–20 |

10–20 |

20–30 |

35–45 |

10–20 |

|

On 5/64" scrn. %<2.2 mm |

0–3 |

0–3 |

7–13 |

10–20 |

0–2 |

|

Thru 5/64" scrn.-thin % |

0–2 |

0–2 |

0–2 |

0–2.5 |

0 |

|

Wort pH |

5.8–5.9 |

5.7–5.9 |

5.7–5.9 |

5.7–5.9 |

5.5–5.8 |

|

Viscosity, cP |

165–1.75 |

1.55–1.65 |

1.52–1.62 |

1.60–1.70 |

1.45–1.55 |

|

Odor of mash |

Aromatic |

Aromatic |

Aromatic |

Aromatic |

Aromatic |

|

Speed of filtration |

Norm.–Slow |

Norm.–Rapid |

Normal |

Norm.–Slow |

Norm.–Rapid |

|

Degree of clarity |

Clr.–Sl. hazy |

Clear |

Clear |

Sl. Hazy |

Clear |

The brewer always needs to take into account the moisture content of each lot of malt to calculate its real extract potential. Given two malts with 81 percent DBFG extract (see below), malt at 6 percent moisture content will give only 76.1 percent potential extract as-is, while a malt at 3 percent moisture content will give 78.6 percent.

Color, SRM (°Lovibond, ASBC color): The color given for the lot of malt being evaluated should be within, or close to, the color parameters given in tables 1 and 16. Moreover, for batch-to-batch beer consistency, the grain bill needs to be adjusted to reflect malt color change, especially regarding highly colored malts.

Color may not be stated as SRM/ASBC/°L units. Where EBC units are given, the formula ASBC = (°EBC + 1.2)/2.65 gives reasonable but not entirely accurate transposition. The color for English malts is often given as Color IOB, EBC method. IOB color is only approximately 80 percent of EBC color. Where IOB units are given, the formula ASBC = [(IOB/.80) + 1.2]/2.65 can be used.

HCU color units are a summary measurement of wort color that is equal to the sum of the SRM/°Lovibond of all the malts used to make a wort. HCU units and SRM wort color are comparable up to about 10 °SRM; after that, corrections must be made. See the conversion chart in table 15 to convert from HCU color to approximate °SRM.

The color ranges for most malt types vary widely, depending on the country of origin and the maltster. From the maltster’s point of view, it is of some advantage to have a “unique” color range, since it requires any brewer using the malt to make serious adjustments in the brew house program in order to switch suppliers. To some extent, this diversity also benefits brewers, but on the whole, color variation in the same nominal malt types is a problem for the brewer seeking predictable results.

Extract, DBFG: Extract yield, dry basis (0 percent moisture content) fine grind, from an ASBC laboratory mash. The “fine grind” is standardized as being crushed on a Buhler-Miag disc mill at a .2 millimeter setting (often given as 2 Miag), giving 10 percent (±1 percent) of the yield held on a .0232-inch screen, or 40 percent flour. The fine-grind extract gives the maximum potential yield of any malt. It indicates the quality of the barley and the proficiency of its malting. The higher the DBFG extract, the better the malt. Any base malt that does not give at least 78 percent DBFG extract is substandard.

Extract, DBCG: Extract yield, dry basis coarse grind, from an ASBC standard laboratory mash, to 113 degrees F (45 degrees C), malt ground at .7 millimeters on a Buhler-Miag disc mill (7 Miag), giving 75 percent (±1 percent) of the yield as grits held on a .0232-inch screen, or 20 percent flour. Again, extract is given on the dry basis of the malt, for ease of comparison. DBCG indicates the yield that the malt is capable of giving, because it approximates the crush experienced in the brew house. Brew house yield, however, is always lower than the coarse-grind figure predicts, because the value is given on a dry basis (see above), and because the laboratory crush and mash are always more efficient than that actually experienced in the brewery.

In reality, brew-house efficiency is only 85 to 95 percent of what coarse grind predicts. The brew-house yield can be calculated from the dry basis coarse grind by adjusting it to account for the moisture content given in the lot analysis (as-is coarse grind), then factoring in the anticipated brew-house efficiency:

DBCG/(1 + moisture content) - .002 = AICG (as-is coarse grind)

For example, where DBCG is 80 percent and moisture content is 5 percent, the result would be

(.80/1.05)-.002 = .7599

Seventy-six percent is the yield a brewer could expect from the malt if mashing and lautering were 100 percent efficient. For a brew house averaging 92 percent efficiency, anticipated brew-house yield would be

[(.80/1.05)-.002].92 = .699, or 70% brew-house yield

The adjusted brew-house extract yield can be used to predict the degrees Plato or specific gravity that each pound of malt will give in a gallon of wort by the formulas

Adjusted yield x 11.486 = °Plato of 1 lb. of malt in 1 gal. of wort

Adjusted yield x 46.214 = excess gravity, 1 lb. in 1 gal. of wort

.699 x 11.486 = 8.02 °Plato

.699 x 46.214 = G 32.3, or SG 1032.3

Conversely, the actual density of the wort yielded can be used to calculate the brew-house efficiency:

Brew-house efficiency = [(°Plato x gal. of wort)/11.486]/[DBCG/(1 + moisture content) - .002)] x lb. of malt

FG-CG, difference: The fine grind–coarse grind difference indicates the modification of the malt. When a “steely” (vitreous) malt is crushed at 7 Miag, the large grits are not as accessible to diastatic enzymes as grits from a mealy malt. The difference between the extract yield of the fine-grind and coarse-grind mashes will be greater with a steely malt. An FG-CG difference of up to 2.2 percent is acceptable if a decoction or step mash is being employed, but brewers are well advised to purchase malts with a difference less than 2.0 percent, and below 1.8 percent when infusion mashing.

HWE (hot-water extract, liter degrees/kilogram at 68 degrees F [20 degrees C], dry basis): The IOB method of measuring the dissolved extract from malt. A loose laboratory EBC Congress mash is made from fine-ground malt. L°/kg expresses the excess gravity of one liter of wort that a kilogram of the given malt could produce. The HWE can be compared to ASBC DBFG by dividing it by the factor 3.86 (300/3.86 = 77.7 percent). A reasonably good malt gives at least 300 L°/kg, dry basis, and a good malt 305 to 315 L°/kg.

An IOB lot analysis may give the HWE at 7 Miag, which is equivalent to the DBCG rather than the DBFG; the yield from such a lot will be correspondingly lower. It can be compared to the DBCG by dividing it by 3.86.

HWE (pounds per quarter): Expressing the hot water extract in pounds per quarter, or pounds per barrel, is an outmoded British means of measuring extract potential. It was based on dividing the weight of a barrel of extract derived from a quarter of malt (336 pounds) by the weight of one UK barrel of plain water (360 pounds). The weight of the wort in excess of the weight of the water gives the pounds of extract per barrel:

Brewer’s pounds per barrel = weight of wort - 360, or G (excess gravity) x .36

Brew-house extract was expressed as pounds per quarter of malt:

Specific gravity was obtained by the formula

sg gr = weight of 1 UK barrel of the wort/360

CWE (cold-water extract): The amount of soluble material that is present in any malt before mashing, obtained from a three-hour stirred mash of coarse-ground malt at 68 degrees F (20 degrees C), containing ammonia to inhibit enzyme activity. It is an indicator of malt modification; the higher the CWE value, the more complete the beta-glucanase dissolution of endosperm cell walls has been, and the more soluble starch and protein the malt contains. A CWE of 18 percent indicates well-modified malt, and higher than 20 percent “forced” or overmodified malt. The range of 18 to 22 percent is acceptable for infusion mashing, and 15 to 18 percent for decoction and step mashing; for Vienna and Munich malts, 17 to 20 percent is more usual. The CWE as an indicator of modification should be judged in relationship to the soluble nitrogen ratio (see below) for a more complete picture of the malt character.

Hartong 45 degrees: An expression of malt modification, based upon mashing a lot sample by the Congress mash method and at 113 degrees F (45 degrees C). The yield obtained from the 45-degree mash as a percentage of the yield obtained from the Congress mash is given as the Hartong 45-degree percentage, or VZ45 value. Like CWE and SNR, it is an indicator of malt modification.

Another value, known as the Hartong extract, compiled from mashes at four different temperatures, was used to indicate malt quality, with well-modified malt giving a value greater than 5. The Hartong extract is no longer commonly used.

Alpha-amylase, DU: ASBC measurement of dextrinizing units/100 grams, dry weight. Each unit represents the quantity of alpha-amylase that dextrinizes one gram of soluble starch in one hour at 68 degrees F (20 degrees C). One hundred grams of six-row malt should give thirty-five to forty-five units, and American two-row malts forty to fifty. Pilsener malts, because they are kilned at lower temperatures, should range between forty-four and forty-eight, and higher-kilned lager and Vienna malts in the range of forty to forty-five. Munich and ale malts give the least alpha-amylase, because extensive conversion and higher kilning temperatures have caused greater enzyme depletion.

Overly modified malts generally have low DU values. On the other hand, the less well modified a malt is, the greater the DU value needs to be for it to be infusion mashed. When a lot analysis gives an alpha-amylase value below the quoted ranges and modification indicators are relatively usual, the mash may need to be thicker and longer for it to yield the usual brew-house efficiency.

DP, °Lintner (diastatic power ASBC, .25 maltose equivalent): Diastatic power expresses the combined alpha- and beta-amylase strength of the malt. DP measures digestion of a standard starch solution by titration with ferricyanide. Diastatic power is compared to dextrinizing units as a measure of beta-amylase strength, and considered together with mealiness/vitreosity as a measure of how well a malt will respond to mashing. The DP may be as low as 35 to 40 for a well-converted, low-protein ale malt, 100 for a lager malt, 125 for an American high-protein two-row lager malt, and as high as 160 for six-row brewers’ malt. Diastatic power decreases as malt color increases.

IOB DP units give values similar to °Lintner.

DP, °WK (diastatic power, degrees Windisch-Kolbach, WK units): The EBC unit of measurement for diastatic strength. °WK may be as low as 100 for ale malts or as high as 600 for green malt. The °WK value can be converted to degrees Lintner by the formula °Lin = (°WK + 16)/3.5. The reciprocal equation is °WK = (°Lin x 3.5) - 16.

Conversion time, min: Indicates modification and diastatic power under real, albeit ideal, mash conditions, by the time it takes a laboratory mash to reach iodine end point. “Base” malts such as pale and Pilsener should convert within fifteen minutes, British ale malts within ten, and better converted, high-enzyme base malts, such as brewer’s two- and six-row, in less than ten minutes.

Protein, percent: Equal to the total nitrogen times a factor of 6.25. For all-malt beers, protein should not exceed 12 percent; 9 to 10 percent is usual for European lager and British ale malts.

Soluble protein, percent: See TSN, percent, below.

TN, percent: Expresses the total nitrogen as a percentage of the weight of the malt. Since 30 to 40 percent of malt nitrogenous matter ends up as “permanently soluble nitrogen” and composes 5 to 6 percent of the dissolved solids in the boiled wort, the nitrogen content of any malt is of concern to the brewer. Total nitrogen includes poorly soluble proteins and polypeptides, and affects extract yield, clarity, head formation, and fermentation. There needs to be enough nitrogen, but not too much; malt of 2 percent or more nitrogen creates the risk of haze problems in an all-malt beer.

TSN, percent (total soluble nitrogen, percent of total nitrogen by weight): The percentage of nitrogen in solution in a wort. Generally, about half the soluble nitrogen in wort is formed by proteolysis during mashing; the other half exists in the malt. TSN is used in the soluble nitrogen ratio, below.

SNR (Kolbach Index, S/T, SN/TN, soluble nitrogen/total nitrogen ratio): The soluble nitrogen (or protein) figure, divided by the percent total nitrogen (or protein) is another indicator of malt modification. The higher the percentage, the more highly modified the malt sample is. For traditional lager malts, 30 to 33 percent indicates undermodification, and 37 to 40 percent overmodification. Malts to be infusion mashed should have an SNR of 38 to 42 percent. Malt is seldom rejected on the basis of the SNR unless it approaches 50 percent for infusion mashing, and 40 percent for decoction mashing. At 50 percent SNR, the beer brewed will inevitably lack body. Generally, when the percentage given exceeds that recommended for the type of malt, the brewer increases the temperature or shortens the duration of protein and saccharification rests; when it is lower, the saccharification rest is lengthened or the temperature is lowered, or a protein rest is added or extended.

Mealy, percent: By convention, malt is classified as being mealy, half-glassy/glassy-ends, and glassy (steely or vitreous). Mealy kernels are those in which the endosperm is not more than 25 percent glassy. Half-glassy endosperm is 25 to 75 percent glassy, and the endosperm of glassy kernels is more than 75 percent vitreous. The better and more extensive the malting, the higher the percentage of mealy kernels. Glassy malt does not crush well and is not readily hydrolyzed because it contains a higher percentage of beta-glucans and complexed protein, so it gives less extract than mealy malt. If a malt is to be infusion-mashed, it must be at least 95 percent mealy, and for any mash program should be at least 90 percent mealy. Where mealiness is expressed as mealy/half-glassy/glassy, for base malts the ratio should be 92/7/1 percent or better for decoction and step mashing, and 95/4/1 percent or better for infusion mashing.

Friability, percent (vitreosity): Another method of analyzing malt conversion. The ASBC/EBC method measures the percentage friable and the percentage unmodified by standardized crushing, sieving, and weighing. Any malt should be at least 80 percent friable, and for infusion mashing 85 percent friable.

By another method sometimes used, a sample of thirty or so kernels are split lengthwise in a farinator box, then examined and classified. The factor 1 expresses vitreous, glassy endosperm, .5 is half-glassy, .25 indicates glassy ends, and 0 is the value given to completely modified (mealy) kernels. The average result is given. The range is 0 to 1.0, with a vitreosity of 0 to .25 preferred. By itself, the vitreosity value is of questionable use, since it doesn’t clearly pinpoint either the exact problem or the extent to which it occurs. Moreover, it is very subjective.

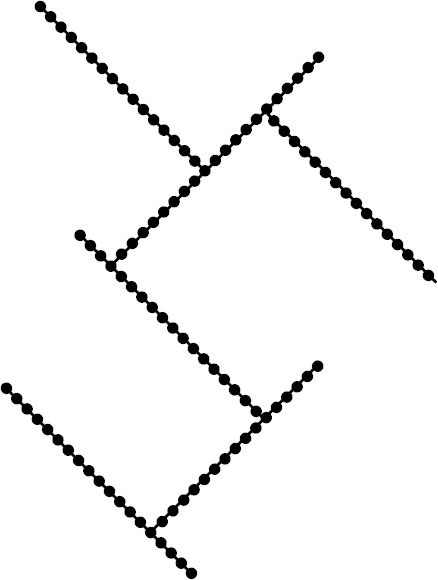

Size (plump/thin, screen separation less than 2.2 millimeters): Size is most clearly expressed as screen separations, but is just as commonly given as plump/thin. European malts often list only the percentage that can be sieved through 2.2-millimeter openings (thins, 5/64 inch diameter and smaller). Generally, the plumper the kernels, the better the yield; however, the uniformity of malt size is just as important. Because of this, some analyses list homogeneity instead of sizes. Any lot of malt that will crush reasonably well must have kernels that are at least 90 percent adjacent sizes, regardless of the plumpness. Brewers generally demand malt that is of 95 percent or greater homogeneity.

Malt is also rejected for containing more than 1 percent thin kernels or more than 2 percent of kernels smaller than 2.2 millimeters, because their presence indicates unmodified kernels.

Wort pH: Base malts should give a pH of 5.5 to 5.8, with ale malts giving the lower value and lager malts the higher. The pH value is used by the brewer to adjust liquor acidity for the particular lot of malt.

Viscosity, cP (centipoise units): The viscosity is a measure of the breakdown of beta-glucans (endosperm cell walls) during malting. A malt that gives a laboratory wort of high viscosity (more than 1.75) will not run off well during sparging. The higher the viscosity, the slower lautering and filtering will be, and the greater the need for a decoction program, or less effectively, a step mash. Boiling and a protein rest help break down beta-glucans to less viscous gums and polysaccharides.

Where given, the IOB 70-degree mash viscosity should be 6.3 to 6.8.

Odor of mash: This measure is primarily used to indicate off-odors, such as moldy, green-malt, or burnt. With colored malts, very aromatic should be expected.

Speed of filtration: The lower the modification or the higher the protein and beta-glucan content, the slower any malt will filter in the lab. Slow filtration with presumably well-converted malts indicates conversion problems.

Degree of clarity: Brewers generally accept slightly hazy as an acceptable degree of clarity, but it does indicate protein or starch conversion shortcomings. A review of the other parameters of the lot analysis should pinpoint changes in the brew-house program that can be made to improve the runoff from the mash.

Several other parameters may be given in a lot analysis. Some of these, and their usual values, are the following: 1,000-kernel weight (36 to 45) or bushel weight (42 to 44), DMS-P (DMS precursor, 5 to 15 parts per million for lager malts), and growth (acrospire 0 to ¼, ¼ to ½, ½ to ¾, ¾ to full, overgrown; 80 percent minimum of ¾ to full growth for American and British/fully modified malts, and ½ to ¾ for multirest lager malts). Other evaluation techniques may be performed by the brewer to judge the quality of any malt.

Ultimately, only experience with the particular barley type, its origin, season of growth, age, and malting permits finite procedural adjustments.

Evaluation

Good malt should be plump and firm, even in size and shape, and of a light, straw-colored hue. A sample handful should contain almost no straw, rootlets, dust, or debris. The malt kernel should be easily crushed between the fingers, and uniformly soft from end to end. When broken, the kernel should write like chalk and show no air pockets within the husk.

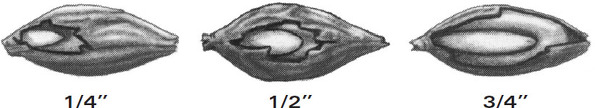

If no growth specifications are given in the lot analysis, it is advisable to check growth when the malt is received. The acrospire can be exposed by cutting or rubbing away the husk over the acrospire of fifty kernels, or by boiling the kernels for an hour to turn the husks translucent. At least 80 percent of the kernels of any malt delivery must fall within a single size group for the malt to be uniformly crushed and mashed. Moreover, malt that is 5 percent or more ungerminated (zero to one-fourth growth) is unacceptable for decoction mashing; 2 percent or more is unacceptable for infusion mashing. Malt to be mashed by only one temperature rest must have been uniformly sprouted, and the acrospire growth should uniformly be from three-fourths to the full length of the kernel. Malt that has been kilned when the acrospire growth is only from one-half to three-fourths the length of the grain can yield a greater amount of extract than fully modified malt, but it should be step or decoction mashed. Malt of widely varying acrospire growth also should be step or decoction mashed. Brewing-quality malt should yield no appreciable number of kernels with acrospire growth less than one-half the length of the grain.

Malt

Acrospire Growth

Acrospire growth should be considered in conjunction with examination of the endosperm. Thirty or so kernels are split lengthwise, and the starch is examined for steeliness/vitreosity; short acrospires and steely ends indicate insufficient sprouting, whereas steeliness irrespective of acrospire length indicates poor drying/kilning.

Another test of germination/modification is made by the “sinker” test. Fifty kernels are shaken into water, and then let rest for ten minutes. After ten minutes, the floaters and sinkers are counted. Ungerminated and undermodified kernels will sink. At the very least, thirty-five of the kernels (70 percent) should float; with good malt, 95 percent will float parallel to the surface of the water. Vertical floaters indicate poor modification.

The malt should yield 65 to 80 percent sugar by weight after mashing and test between 1.4 and 2.0 percent nitrogen. Malt of greater than 2 percent nitrogen should only be used when brewing with low-protein adjuncts.

Malt should be selected by its color and modification to suit the type of beer being brewed and the brewing method.

Avoid malt of very high protein content because it has correspondingly fewer carbohydrates. The protein can retard starch conversion during mashing and increases the likelihood of hazing in the beer. Finally, there is no substitute for tasting the malt. The better the flavor and aromatics of the malt, the better the malt complement of the finished beer will be.

| Grading by Size | |

|---|---|

|

Grade |

Characteristic |

|

1 |

Remains on 7/64" screen, plump |

|

2 |

Remains on 3/32" screen |

|

3 |

Remains on 5/64" screen, “thin” European |

|

4 |

Falls through 5/64" screen, “thin” American |

|

The two larger sizes will mash well and produce high yields. The small kernels have greater husk content and will give lower extracts. |

|

| Grading Pale Malt by Character | ||

|---|---|---|

|

Mealy |

(mellow, soft) |

Will mash well |

|

Half-glassy |

(semihard) |

Must employ a longer, more thorough mashing |

|

Glassy |

(hard, translucent, grayish white) |

Unsuitable for brewing |

Carbohydrates

Carbohydrates are compounds formed by molecules of carbon, hydrogen, and oxygen. They include simple sugars, chains of four or more sugars called oligosaccharides, and polysaccharides, formed by the union of ten or more monosaccharides. Barley and malt are largely made up of carbohydrates, as are 90 to 95 percent of the wort solids. The barley carbohydrate group is composed of insoluble cellulose (the membranes and casing of the barley corn) and soluble hemicellulose, starch, dextrins (alpha-glucans), and the simpler mono-, di- and trisaccharides that we call sugars.

Cellulose is an insoluble compound-sugar (50 to 5,000 molecules of C6H10O5) that makes up the barley husk; it is irreducible by malt enzymes. It constitutes roughly 5 to 10 percent of the malt by weight. Although it is structurally similar to starch, cellulose does not contribute fermentable extract or desirable flavors to the malt extract. But as malt husks, cellulose is employed in the lauter-tun to form a filter bed through which the mash extract is strained. Extraction by high temperature and alkaline sparging leaches harsh tannins from the husk into the extract to the detriment of the beer.

Hemicellulose and soluble gums bind the aleurone layer of the barley kernel together, and are constituents of endosperm cell walls that encapsulate starch granules. They account for about 10 percent of the weight of the barley kernel. They are both polysaccharide mixtures complexed with protein. The malt gums are largely pentosans of xylose, arabinose, galactose, and complexed glucose, which may be dissolved at temperatures of 160 to 176 degrees F (71 to 80 degrees C). They compose about 20 percent of the endosperm cell walls. They can be fully reduced to simple sugars in a thorough mash cycle.

| Degree of Modification | |

|---|---|

|

Acrospire Growth: |

Characteristic of: |

|

0"–¼" |

Cereal malt, unmodified |

|

½"–⅔" |

Steely lager malt |

|

½"–¾" |

Lager malt |

|

¾"–Full |

British malt, American brewers’ malt |

| Malt Colors | ||||

|---|---|---|---|---|

|

Malt |

Type |

SRM |

EBC |

IOB |

|

Diastatic |

Base malt |

1.0–1.4 |

1.5–2.5 |

1.2–2.0 |

|

Pilsener |

Base malt |

1.2–1.6 |

2.0–3.0 |

1.6–2.4 |

|

Lager |

Base malt |

1.4–1.8 |

2.5–3.5 |

2.0–2.8 |

|

Brewers |

Base malt |

1.4–2.0 |

2.5–4.0 |

2.0–3.2 |

|

CaraPils |

Vitreous |

1.4–4.0 |

2.5–9.0 |

2.0–7.2 |

|

British pale |

Base malt |

2.0–2.7 |

4.0–6.0 |

3.2–4.8 |

|

Vienna |

Base malt |

3–5 |

7–12 |

5.6–9.6 |

|

Munich |

Toasted |

6–12 |

15–30 |

12–24 |

|

Light caramel/Carastan |

Vitreous |

5–45 |

12–120 |

10–96 |

|

Amber/Biscuit/Dunkles |

Toasted |

20–30 |

50–80 |

40–64 |

|

Crystal/Caramel 50 |

Vitreous |

45–60 |

120–160 |

96–130 |

|

Brown |

Roasted |

45–60 |

120–160 |

96–130 |

|

Caramel 80 |

Vitreous |

75–85 |

200–225 |

160–180 |

|

Caramel 120 |

Vitreous |

100–122 |

265–325 |

210–260 |

|

Chocolate |

Roasted |

340–500 |

900–1325 |

720–1060 |

|

Roast barley |

Roasted |

270–650 |

725–1700 |

580–1400 |

|

Black/Roast |

Roasted |

550–650 |

1450–1700 |

1220–1400 |

Hemicelluloses are more complex and stubbornly resist hydrolysis. They give a purple-to-black color with iodine. Very viscous beta-glucan is the major constituent of barley hemicellulose, accounting for about 75 percent of the cell walls. In intermediate stages of cell-wall solubilization, the release of beta-glucan inhibits lautering and filtering and cause hazes. One consequence of forced malting is insufficient hydrolysis of beta-glucans to glucose by beta-glucanase enzymes, which are denatured above 140 degrees F (60 degrees C) and do not usually survive kilning. High wort viscosity indicates excessive beta-glucans in the malt. With reasonably well converted malt, manageable amounts of beta-glucans may be liberated from hemicellulose by proteolytic enzymes during a 95 to 113 degree F (35 to 45 degree C) mash rest and contribute to a beer’s fermentability, body, and foam head.

Starch

Native starch (in malt, 20 to 400 molecules of C6H10O5) occurs as granules that are insoluble in cold water, accounting for about 60 percent of the malt’s weight. If the native starch granule is crushed to flour, it readily combines with moisture to form a pastelike gel. In warm water, amylose, the small fraction of a granule that is water soluble, can be diffused out of native starch. In hot water, the starch granule swells until it finally bursts, exposing insoluble amylopectin as well.

Amylose occurs as straight helical chains of glucose molecules joined by 1-4 links. Exposed to amylose, iodine becomes entrapped within the coils, giving an intense blue-black color. Amylose is reduced to maltose and maltotriose from the nonreducing end of the chain by the beta-amylase enzyme. The alpha-amylase enzyme facilitates this process by randomly severing amylose chains, yielding glucose, maltose, and maltotriose, and exposing more chain ends to beta-amylase activity.

Starch

Cellulose

Amylopectin accounts for about 75 percent of the malt starch; consequently, its decomposition is central to mashing. It occurs as highly branched glucose chains that give a red color with iodine. The chain and branches are formed by 1-4-linked glucose molecules, but the glucose molecules at the branching points are joined in a 1-6 configuration.

Dextrins

Dextrins, or alpha-glucans (C6H10O5) ⋅ H2O, are residual, unfermentable fractions of amylopectin of from four to thirty glucose molecules. Dextrins occur in brewing because neither alpha- nor beta-amylase can sever the 1-6 links of amylopectin or the 1-4 links near those branching points. In malting, limit dextrinase debranches amylopectin by separation of the 1-6 links, but this enzyme group does not survive malting and mash temperatures. In the mash, beta-amylase is only able to effect a slight reduction of amylopectin, liberating maltose only at the nonreducing ends of the many branches. The large dextrins it leaves behind are called ß-limit dextrins. ß-limit dextrins give a mahogany (reddish-brown) color to iodine.

Amylose

![]()

Amylopectin Fragments

Maltose

Isomaltose

Sucrose

ß-limit dextrins are dismantled in the mash by alpha-amylase. It randomly breaks 1-4 glucose links in the amylopectin complex, exposing new nonreducing ends for beta-amylase to convert to maltose. Acting together, the amylases reduce amylopectin to much smaller a-limit dextrins. Small a-limit dextrins give no color with iodine, while the largest give a faint red-to-violet color.

Melibiose

Fructose

Mannose

Galactose

Glucose

Sugars

Monosaccharides (C6H12O6) are single-molecule carbohydrates. Glucose, photosynthesized in the leaves of green plants from carbon dioxide and water, is the primary sugar associated with grains. However, it accounts for only 1 to 2 percent of the malt’s weight. After mashing, it accounts for 7 to 10 percent of the wort extract. Fructose (an isomer, or molecular rearrangement, of glucose), galactose and mannose are other monosaccharides found in malt. They are all readily and wholly fermentable. Galactose is a constituent of many oligosaccharides and polysaccharides, occurring especially in gums and pectins.

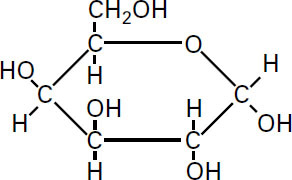

The disaccharides are double sugars (C12H22O11). Maltose, the sugar most closely associated with brewing, is the simplest compound sugar. It is formed by two molecules of glucose, joined together at their 1 and 4 carbon atoms by the removal of a water molecule (C6H12O6 + C6H13O6 - H2O = C12H22O11 x H2O). Although it makes up only 1 percent of malt’s weight, it is the sugar that is primarily derived from the hydrolysis of starch, and accounts for 40 to 55 percent of the wort solubles. It is slowly but very surely fermentable.

Other disaccharides present in malt are sucrose (one molecule each of glucose and fructose), lactose (an isomer of sucrose), and melibiose (one molecule each of galactose and glucose). Sucrose is readily fermentable, lactose is unfermentable, and melibiose is fermentable only by Saccharomayces uvarum. Of these disaccharides, only sucrose is present in malt in any appreciable amount, composing 3 to 5 percent of the wort extract.

Trisaccharides are three-molecule sugars. In malt, they are maltotriose, glucodifructose, and fructosant; raffinose, which is present in barley, disappears during malting. Maltotriose (three molecules of glucose) is slowly fermentable by most strains of brewing yeast. It is the only significant trisaccharide in brewing, accounting for up to 15 percent of the wort solids.

Protein

Carbohydrates alone do not form a satisfactory brewing extract; malt protein is essential as a yeast nutrient and to give the beer body and head. In the barley kernel, protein serves as plant food for the embryo. During malting and mashing, it is reduced by protein-metabolizing enzymes to less-complex albumins (an outdated but useful term that groups together all coagulable and water soluble protein fractions) or even simpler amino acids. In solution with mineral salts, some of the protein forms acids, causing the pH of the mash to drop.

The term protein strictly defines very complex polymeric coils of amino acid chained together by peptide links (molecular weight 17,000 to 150,000), but in a wider sense, it also includes the products of their decomposition. This reference to protein on the one hand as an unwieldy malt constituent (e.g., high-molecular-weight albumin and less soluble globulin, glutelin, and hordein), and on the other as a source of a beer’s body and head can be confusing. In fact, the brewer does not strive to eliminate the proteins but to simplify them to a range of colloidable and soluble fractions. Only when an excessive number of complex proteins (molecular weight 10,000 to 100,000, average 30,000) are carried into the beer will they result in chill haze, an irreversible cloudiness, or off-flavors caused by oxidation.

The large protein complexes of the malt must be largely reduced to intermediate albumins (molecular weight 5,000 to 12,000), such as proteoses and peptones, and peptides (molecular weight 400 to 1,500) during mashing, so that they are simple enough to dissolve, or colloid with hop resins, and be carried over into the finished beer. Considerable nitrogenous matter must be present: amino acids and peptides to sustain culture-yeast activity, and simple albumin to form the body of the beer. Three to 6 percent of the wort extract is usually nitrogen-based. A beer brewed so that it had little or no low-molecular-weight protein fractions (molecular weight 12,000 to 20,000) left in it would be unable to form or support a foam head. Generally, 25 to 50 percent of the malt protein is carried into the ferment as simple nitrogen complexes (amino acids, peptides, albumin).

Because enzymes are proteins, the protein content of any malt is an indication of its enzymatic strength. In general, protein-rich, six-row malts are more apt to cloud beer than are other malts, but they do produce stronger enzymatic activity. Low-protein malts are less apt to cause hazing, but as a consequence have less enzymatic power and must be carefully mashed.

Other Malt Fractions

Nonprotein nitrogen accounts for up to 10 percent of the total malt nitrogen. Peptides, although not true proteins, are intermediate forms between protein and amino acids. They are nitrogen based, as are vitamins and nucleic acids. Peptides, which enhance the beer’s viscosity (palate fullness), may also oxidize to high-molecular-weight polypeptides. Polypeptides are unstable and contribute to nonbiological haze formation.

The vitamins in malt are principally of the B complex; they are necessary for yeast growth. Products of the decomposition of nucleic acids account for only .1 percent of the wort extract, but contribute to both yeast nutrition and flavor enhancement.

Polyphenols, phosphates, lipids, and fatty acids are other significant malt constituents. Polyphenols from the husk, pericarp, and aleurone layers of the malt kernel are acidic precursors of tannins and give beer an unpleasantly bitter, astringent taste and reddish hue. With highly kilned malt, oxidation of phenolic melanoids (pigments) to aldehydes, such as by hot-side aeration, contribute to stale flavors in beer. Complex polyphenol polymers are true tannins and counteract the solubility of otherwise stable proteins. They should be eliminated from the extract by a well-roused kettle boil; in the cooled wort and the ferment, the oxidative polymerization of polyphenols to tannins causes medicinal off-flavors, astringency, and haze formation.

Phosphates in the malt, principally organic phytin, are major factors in the acidulation of the mash. They give up phytic acid (phytate) at high kiln temperatures during malting, and by enzymatic reduction during an acidifying mash rest at below 128 degrees F (53 degrees C).

Lipids are fatlike substances composing roughly 3 percent of the malt; they range from straight-chain to complex branched-ring hydrocarbons, including neutral fats, fatty acids, alcohols, aldehydes, and waxes. About one-third of malt lipids occur as reserves in the embryo, and most of the rest are concentrated in the aleurone layer. Triacylglycerol and other triglycerides (triesters of glycerol and long-chain fatty acids) are the predominant neutral lipids in barley. They support respiration of the embryo during malting.

Fatty acids (CnH2nO2), or vegetable oils, are fat-derived (aliphatic) hydrocarbon chains. In barley malt, these are the relatively long-chain linoleic (C18H32O2), palmitic (C6H32O2), and oleic (C18H34O2) acids. Proportionally more of these than other malt lipids are carried into the wort. Although they are essential in the yeast cell as reserves and they comprise only .05 percent of the malt extract, if excessive amounts of lipids are washed into the runoff by overzealous sparging they will reduce foam stability and give rise to “cardboardy,” “goaty,” and “soapy” stale flavors in beer.

Finally, considerable silica and inorganic phosphate are leached out of the malt, along with a wide range of trace minerals necessary for yeast metabolism.