A Primer

Investigating Paleolithic cultures, whether in the Old World or the New, is a great challenge because the principal artifacts we have to work with are flaked stone tools and flaking debris. Fortunately, archaeologists have found sites with animal bones, bone and ivory tools, hints of other perishable artifacts, and even rare cases of art, but these are exceptional. Geological and environmental settings can tell us some things, such as the probable conditions in which people lived, but the minuscule representation of the past provided by stone artifacts can give us more details about our distant human heritage. Along with its excellent preservation, flaked stone is important because it directly reflects specific behaviors of individuals within their cultural and environmental contexts, and these behaviors can to some extent be reconstructed. While tool forms are interesting in their own right, we focus on how tools were made; that is, their technology. Many investigated sites from the ancient past represent only specific activities that a group of people performed, and therefore the types of tools found at these places only represent those specific activities. On the other hand, the underlying way that a group makes its tools tends to be reflected in all of its various types of sites. Our technological interpretations are based on decades of studying archaeological remains and decades of flintknapping.

This primer is not intended as a comprehensive discussion of all flaked stone technologies, which would fill multiple volumes. We hope that it will help the reader to understand the basic principles of knapping, including some of the main issues related to the technological comparisons we use to suggest historical linkages. Additionally, since the archaeological literature is full of technological terms whose usage may vary from researcher to researcher, this chapter presents our definitions. We have italicized the key terms to make them easier to refer back to as you read through the book. You may also find them in the extensive index.

Flaked stone artifacts can be classified into two general categories for the sake of discussion and communication: flakes and cores. A flake is the fragment of stone removed from the parent material through the application of force, and a core is the parent material after the removal of a flake or flakes. Each flake removal leaves a negative scar. The concave area immediately below the core platform is known as a negative bulb.

Flakes and cores can be subdivided into many additional categories depending on form, size, patterning, and the like. The stones best suited to flaking technology have fracturing characteristics that most closely resemble those of glass. The mechanics of fracture are complex and have been the subject of numerous studies.1 For our purposes, it is enough to know that some types of stone break in a predictable way, with knowable mechanical principles, and that the fractures can be controlled to make usable and specific products. Of course, the flaking qualities of stones vary considerably, as do the understanding and skill of the people who select and flake them. Knowledge of this sort does not lie solely in the mystical past. Recent decades have seen a resurgence of practical interest in stone flaking, for both academic and artistic reasons.2 Hundreds of people in North America make flaked stone artifacts, primarily as a hobby. Expertise in knapping—making stone items by flaking—gained through experiment and experiential analogy is now frequently applied to the analysis and interpretation of prehistoric assemblages.3

To fracture a flakable stone, one must apply force. This can be accomplished in two basic ways: Percussion flaking is done either directly, by hitting the stone with another object, or indirectly, by hitting an intermediate object placed between the stone and the striking object.4 Pressure flaking is accomplished by placing a tool against the stone and applying pushing force directly to it to remove a flake. The tools used to apply these forces are made from either hard material, such as other stones (hammerstones), or softer material, such as antler, bone, and even dense wood, in which case they are usually called billets.

The surface where the force is applied is known as the platform, and it produces different results depending on whether it is a smooth flake scar (plain), convex with fine ridges (faceted), roughened by grinding (ground), a natural exterior surface (cortical), or any combination of the preceding. Since these variations are under the control of the knapper, platforms are a critical component of flaking technology. Archaeologists have long recognized that flake platforms reflect knapping technology, and almost every analysis of flakes includes observations about them.5 This is possible because a portion of the core platform usually detaches with each flake.

Generally speaking, the greater the effort a knapper puts into preparing a platform, the greater the flaking control he or she can achieve. How a platform is placed in relation to the flaking surface is crucial to the formation of the flake. Platform preparation can be relatively simple or very complex, taking up a large amount of time and effort. This is especially true for thinned bifaces and some types of blades (see below for a description of these forms). Platform details are such an important aspect of particular technologies that, for example, many Clovis flake platforms can be identified as Clovis even when they are not associated with the more readily recognized characteristic projectile points.6

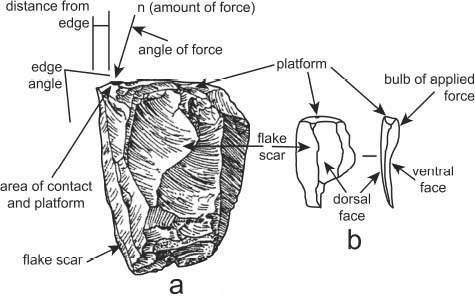

The knapper must also consider many details when making specific flaking decisions. Although slight variations in the effect of each action are not usually enough to determine the final outcome of a knapping episode, the knapper’s decisions and skill do matter because every piece of stone is different in flakability and form. By understanding flaking processes, it was and is possible for knappers to produce and reproduce desired products within predetermined ranges of variation in size, weight, shape, proportions, edge form, and even flake scar patterns. This is why we see similar tools reappearing together in time and space, forming recognizable tool kits (specific sets of tools brought together for a particular task or set of tasks) and assemblages (associated groups of artifacts that represent activities over a relatively short time period, also called techno-complexes) that differ from those of other people or cultures. Various standard terms used to describe characteristics of flaked stone artifacts are shown in figure 1.1.

A few simple statements can express the expected results of a specific flaking action. Flake thickness depends on how far from the edge the force is applied: the greater the distance, the thicker the flake. The area of contact depends on the platform shape and the size and contour of the striking tool. A sharply pointed hammerstone will have a smaller area of contact than a gently curved antler. Usually, the greater the amount of applied force, the greater the mass of the product. Length is controlled by the angle of the strike in relation to the platform angle. Generally, the closer the angle of force is to 90 degrees, the longer the flake will be, and the more acute the edge angle, the straighter into the core the striking angle must be to create a long flake. The contour of the surface from which flakes are removed determines their form: fracture tends to follow and is guided by the surface ridges and convexities, which are frequently remnants of scars of preceding flaking. For every flake removed (a positive), a negative impression remains (the scar).

What is of paramount importance in understanding flaked stone technology is that every action influences potential future actions and is equally influenced by previous actions. Flaking is a series of causes and effects based on human decisions and actions. The more complex the flaking, the greater the planning and skill in application that are required. By achieving an understanding of these complexities, a Clovis knapper, for example, could produce artifacts with predetermined specifications over and over again. Without this understanding and the skill to apply it, the knapper could not produce Clovis points or other specific forms consistently.

FIGURE 1.1.

Knapping terminology shown (a) on a core; (b) on a flake.

Consistency comes with skill. It is easy to train almost anybody to make a reasonably predictable flake with a bit of basic instruction and a fair amount of practice. However, it is quite another matter for a knapper to attain the ability to make many of the flaked stone artifacts we find in Solutrean, pre-Clovis, and Clovis sites. It is one thing to understand how to do it, but it is quite another to actually produce a complex flaked stone artifact, for example a Clovis point.

We recognize four global flaked stone traditions during Upper Paleolithic times (circa 40,000–10,000 years ago): flake, blade, inset blade, and biface. These general technologies can be divided into numerous subsets; for example, we distinguish between thinned and thickened biface traditions (see below for discussions of manufacturing techniques).

The main products of flake traditions were modified or unmodified flake tools, either handheld or hafted as single pieces (figure 1.2a). While most flakes were used unmodified, many were shaped by the removal of small flakes from their edges (retouch). The mechanics of retouching were the same as those of larger flake production, but retouching was mainly done to modify tool edges rather than to produce usable flakes. Retouch was accomplished with either percussion or pressure. In the simplest definition, blades are flakes that are at least twice as long as they are wide (figure 1.2b). They were sometimes produced with no particular preparation of the core, but more often a core was shaped to allow the production of many blades from one piece of stone. We use the term blade for these more complexly formed flakes. There were also many different ways blade and flake cores were prepared, which are often diagnostic of a particular techno-complex. Like flake tools, blade tools were made to be used unmodified or modified by retouch, either handheld or hafted singly.

FIGURE 1.2.

Basic tool forms: (a) flake; (b) blade; (c) inset; (d) biface.

Inset technologies used multiple small blades or flakes mounted in sequences in grooves in bone, antler, ivory, or wood objects to produce cutting edges (figure 1.2c). Inset technologies may employ blades or flakes of any size but usually used small, specially made stone pieces.

Biface traditions employed single bifacially flaked stone artifacts as handheld or hafted implements (figure 1.2d). These finished tools are generically referred to as bifaces but may also be identified by their inferred uses—for example, as knives, adzes, or projectile points. Many biface technologies also made bifacial flake and blade cores, and caution must be exercised not to misidentify these as implements. There are cases where a bifacial flaking technique was used to shape a core but no finished bifacial implements were produced within that particular techno-complex. These are not considered biface technologies.

Biface technology developed very early and was the main method of making implements worldwide at the end of the Lower Paleolithic, between 150,000 and 500,000 years ago depending on the region. It was used to make many different products, including knives and hand axes. The latter are bifacial tools that occur in a variety of forms.7 Although termed axes, they are generally thought to have been multipurpose butchering implements and not used to cut down trees. Non-agricultural North American flaked stone traditions were almost exclusively based on bifacial technologies.8 In Eurasia biface technology gave way to flake technologies during the Middle Paleolithic, a shift from an emphasis on tools made on whole pieces of stone (core tools) to those made on flakes (flake tools). The early biface technologies were perhaps more complex, but they also demanded a larger amount of stone to produce tools. Some of the Middle Paleolithic flake technologies were also conceptually complex and demanded a significant degree of skill to produce. Once flake technologies were adopted, bifaces only occasionally reappeared until the Neolithic in the Old World. All flaked stone technologies declined as they were replaced by metals, until by the Late Bronze Age they had disappeared or became extremely simple. An exception to this is seen in the eighteenth and nineteenth centuries in Eurasia, where several flaking technologies were developed to supply the demand for gunflints.

Many Stone Age cultures made their tools according to a single basic flaked stone tradition. An example is the Late Upper Paleolithic culture on Zhokhov Island in the Siberian High Arctic, whose only flaked stone products identified to date are inset microblades glued into grooves in bone and ivory points, primarily used to kill polar bears.9 Other cultures employed more than one technology but had one dominant tradition. Examples include Solutrean and Clovis, which were mainly biface traditions but in some areas had a significant blade technology component.10 Other examples are the terminal Pleistocene northeastern Siberian cultures that employed an inset blade technology but also made a small number of thick biface tools.11

The distribution of general technologies gives some insight into the past, but we contend it is informative to go beyond this to determine whether similarities and differences in specific technologies may have had direct historical relationships. To this end, we make technological comparisons on a very fine scale. For example, all that was necessary to make small blades was to prepare a platform at an appropriate angle to a flaking surface, from which blades with straight sections could be produced. This sounds simple, but it is amazing how many different ways people developed do it. One approach was to make a thick flake, use its flat ventral surface as the platform, with only simple edge grinding for platform preparation, and remove the first blade from a natural ridge at one corner. In an other example a small pebble had one end removed to form the platform. A guide ridge was then pressure-flaked and the first blade removed down this ridge. There are almost infinite combinations of techniques expressed in the archaeological record, yet it seems each one was adequate to produce the desired and needed products. In the end, as long as a technology worked, the choice of whether to use it was cultural. We therefore investigate the details of flaking technologies to determine whether such different cultures were related.

FIGURE 1.3.

Blade core production initiation options: (a) natural ridge; (b–c) simple ridge shaping; (d) all over complex shaping. Arrows indicate the place and angle used to strike the first blade.

Blade and inset blade technologies developed along the same technological lines and had similar production strategies; the main difference was how the blades were used. Knappers had three main choices for blade production initiation: selection of raw material forms that allowed blade production without preshaping (figure 1.3a); simple preshaping of the material (figure 1.3b–c); and complex preshaping (figure 1.3d). The method chosen seems to have been culturally or traditionally determined.

The shaping options of complex precores—blade cores shaped by knappers before detaching the first blade—provide the greatest opportunity to assess whether similarities between traditions were historically connected or the result of independent invention: the more complex the blade technology, the more likely it was to be related to similar technologies.

Biface technology may also be relatively simple or extremely complex. Once again, different methods and techniques were developed to achieve the desired products from the available raw materials. Sometimes the materials were less important than the methods: in some archaeological examples, it is possible to observe that although a specific technology did not work well with a particular stone, the knapper persisted without major modification of his or her traditional knapping habits.

It is clear in other cases that the strategy did change during production. This most often involved switching from proportional to thickening or thinning biface flaking (figure 1.4). Proportional flaking is accomplished by removing flakes that end just past the longitudinal midline of the biface (figure 1.4a1), proportionally removing as much from the face as from the edge. The resulting biface is lenticular in cross section and has a width-thickness ratio between 3:1 and 4:1 (figure 1.4b). In thickening, flaking does not extend through the thickest area (figure 1.4a2), so only the width is reduced. The resultant piece has a width-thickness ratio of less than 3:1. Thinning produces flakes that remove proportionally more of the face than the edge (figure 1.4a3), creating bifaces with flat or slightly biconvex cross sections and width-thickness ratios greater than 4:1 (figure 1.4c). As might be imagined, thinning was a risky business, with a probability of failure greatly exceeding that of proportional or thickening flaking.

The best-known and best-described example of biface thickening in North America is Eden point manufacturing technology (figure 1.4d). This point style was clearly intended to be relatively thick, and it took several sequences of carefully controlled pressure flaking to achieve the desired goal.12 Modern knappers have had a tendency to try to make everything thin because this is one of the greatest challenges, yet Eden points are one of the most difficult technologies to reproduce. The control exercised by Eden knappers was extraordinary, especially considering the fact that the same people were also making some of the thinnest bifaces, known as Cody knives.13

Along with proportional flaking, at least three strategies can produce bifaces with high width-thickness ratios: diving, full-face, and overshot flaking. Diving flaking drives thinning flakes to near the midline, where they end in either hinge or step fractures (figure 1.4a2), which look the same as thickening because both methods result in flakes meeting at the midline. Hinge and step flakes end abruptly, leaving a relatively deep gouge on the surface, which the removal of a flake from the opposite edge can eliminate, creating a flat and even concave area in the middle. Individual platform preparation and the angle and force of the blow control flake termination. Although this method produces many flakes, they tend to be thin and fragile and of little use except for light cutting. Carefully controlling this process on both faces, however, makes it possible to produce extremely thin bifaces. These tools are very efficient for tasks such as slicing meat, and they can also be used as large but relatively light projectile points. At times they may have been an expression of aesthetics and style: many of the largest flaked pieces used for ritual purposes were thin bifaces. Most archaeological cultures that made very thin bifaces, for example Folsom, used diving flaking.14 The many examples separated by time and space suggest that this method was independently developed a number of times in different parts of the world.

In full-face flaking, flakes travel all the way across the biface, terminating just before the opposite edge (figure 1.4a3). This method is difficult to control and, as the bifaces become thinner, often results in breakage. However, if carefully controlled, this method can produce thin, flat bifaces. Overshot flaking is a variation of full-face flaking. In this case flakes travel all the way across the face and remove a portion of the opposite edge (figure 1.4a4). Although this technique may seem counterproductive in that it removes parts of both edges, it eliminates enough mass to significantly thin the biface. It also forms a beveled angle on the edge opposite the platform that frequently requires only minor preparation to be ideal for flaking the other face. Both full-face and overshot flaking require the removal of only a few large flakes from each face to produce a biface that is both thin and uniformly flat. This regularity allows edge and surface finishing, resulting in symmetrical and attractive products, and probably enhances the flakes’ functionality. In addition, the flakes are relatively large and straight and are useful as tools themselves. However, these flaking methods are difficult to control, and even small mistakes can result in total failure.

FIGURE 1.4.

Examples of biface flaking options: (a) initial biface; (b) proportional; (c) thickened; (d) thinned. W is width, th is thickness, and w/th is width-to-thickness ratio.

To a modern flintknapper the overshot method is counterintuitive. It seems to waste material, decreases thinning (because parts of both edges are removed), and is extremely difficult to control. Most flintknappers have denied its practicality even in the face of clear archaeological evidence of widespread use. After extensive experimentation, practice, and examination of Clovis and Solutrean assemblages, however, we are completely convinced of its advantages and that it was intentionally used in both traditions. Overshot flaking’s complexity and difficulty suggest that it is unlikely to have been independently invented very often. Indeed, we have examined many of the biface traditions around the world and so far have recognized purposeful overshot biface thinning only in Clovis and Solutrean assemblages and on bladelet cores in the Neolithic of Qatar.15 As this method becomes better known by archaeologists, more overshot technologies may be identified. Nevertheless, it is apparent that this technique was rare.

Two other integral parts of knapping are flake sequencing and flake spacing. As stated earlier, each flake removal is enabled and influenced by what came before and affects what is possible after. To create products with specific characteristics, such as blades with two parallel ridges running down the outside surface, the spacing of the flake removals is critical for establishing the proper morphology of the core (for more on blade characteristics, see chapters 2 and 7).

Spacing and sequencing of flake removals are integrally linked, but sequencing may also be done to create a particular surface pattern. Some knapping sequences produce distinct, sometimes culturally diagnostic, flake scar patterns. For example, special flint knives were produced in predynastic Egypt with a unique pressure flaking pattern called S-flaking.16 This is tricky to accomplish, and we can see no functional advantage to it, so it may have had aesthetic significance.

Those of us over forty years old may remember the cowboy and Indian movies in which a corpse full of arrows is discovered. The hero (often John Wayne) would pull out one of the arrows and after close examination proclaim “Apache.” Not only does this make for good movies, but there is also plenty of historical support for the idea that certain artifacts are identifiable with a particular culture, ethnic group, or even individual maker. This was certainly true in the past, and it may have been an important aspect of flaked stone style or even technology in some cultures.17 Highly sophisticated and complex techniques, such as controlled overshot flaking, may be the traits that indicate historical connections.18

FIGURE 1.5.

Variations in fluting technology: (a) Clovis diagonal/angled fluting; (b) Cumberland parallel fluting; (c) Barnes parallel first fluting of both faces, followed by angled fluting of both faces; (d) Folsom parallel fluting and angled fluting.

Longitudinal thinning is another important aspect of early North American technologies. When accomplished during the course of producing preforms (unfinished bifaces whose final form is evident) it is called end thinning, even when done to a tip rather than a base. When applied so that the finished piece retains the resulting flake scar or scars on its base, it is called fluting. While some bifaces have basal thinning, it is not well enough developed and the flake scars are not long enough for it to be considered fluting. Intentional patterned fluting as part of specific techno-complexes is clearly an American invention. There is some evidence of the development and adoption of this technique in the pre-Clovis materials in eastern North America, but it is totally developed and nearly universally applied in Clovis biface technologies. Clovis is the first assemblage where fluting is well established but by no means the last, and it is even possible to distinguish between several variations in application in post-Clovis fluted point technologies.

We recognize two basic approaches to fluting through the intentional removal of substantial flakes (channel flakes) from the bases of points near the end of manufacture. Diagonal or angled fluting happens when flake removal originates so that the resulting basal edge, on the longitudinal section, is directly in line with the biface plane formed by the rest of the point but the scar is at a diagonal to this plane (figure 1.5a). The second approach is to set up the channel flake platform to project toward the face to be fluted so that when the flake is removed the resulting edge still projects parallel to the biface plane (figure 1.5b). We call this parallel fluting.

We can see little advantage of one of these methods over the other, and the approaches were used separately and in combination. For example, in Clovis the flutes on both sides were diagonal, resulting in a sharp basal edge that was in the point’s biface plane without additional flaking. A third combination is seen in the point fluting in the Cumberland and Barnes sites of eastern North America. Both faces were fluted with parallel removals, necessitating significant post-fluting flaking to obtain a sharp base in line with the point’s biface plane. This was sometimes accomplished with multiple small pressure flakes (figure 1.5b), but another, very distinct option was also used, called flute under flute: following the long parallel flute removals, shorter, diagonal flutes were removed from both faces, producing a superimposed channel flake scar on each face (figure 1.5c, 3rd and 4th). Finally, the first flute of a Folsom point was a parallel removal and the second, on the opposite face, a diagonal removal (figure 1.5d).19 After the first fluting, a substantial adjustment of the basal margin was necessary to set up the diagonal flute, but its removal created a sharp edge in line with the point’s biface plane.

The action of flaking stone leaves a record of human thought and behavior not unlike the combining of letters to form words, phrases, and sentences. Archaeologists recover fragments of evidence; now we just need to learn to decipher the languages. This primer presents the background needed to allow a basic understanding of the technological stories we have gathered.