Table 13.1

Thinning Recommendations for Pome and Stone Fruits

Many temperate fruit crops develop excessively heavy fruit loads, which creates several problems. Some fruits, particularly apples and apricots, can develop a heavy crop one year and a very light crop the next year or sometimes two. Our goal is to produce annual, sustainable yields of large, high-quality fruit.

In many crops, having too many fruits on the tree reduces the size of the fruit. Excessive numbers of fruit also interfere with light distribution, decreasing the number of flower buds formed in some crops for the following season and creating poor fruit color. Crowding of fruits interferes with air movement and spray applications and allows adjacent fruits to touch one another, increasing pest and disease problems. Trees require large amounts of energy to develop fruits, and excessively heavy crops weaken and stunt trees, making them more susceptible to pests and diseases and increasing the likelihood that limbs and trunks will break.

Fruit crops naturally thin themselves. For most crops, flowers that have not been pollinated fall off without developing fruits. In pome fruits, very young fruits that have only a few seeds drop off in what is called “June drop.” June drop can be alarming for new fruit growers because it looks as if the entire crop will be lost or the tree has some terrible disease. In reality, you need only a small percentage of the total possible number of fruits that could develop on a tree to mature in order to obtain high yields and excellent-quality fruit. In the case of apples, up to 90 percent of young apples must be removed following a heavy fruit set in order to maintain good size and quality and consistent yields. Stone fruits also drop poorly developed fruits right after bloom and sometimes drop fruit later in the season, when the tree’s reserves cannot support the crop load. For all crops, fruit that is damaged by pests and diseases may fall.

Berry crops, including saskatoons, are usually only thinned through regular pruning. For some varieties that tend to overbear, you can prune the bushes rather heavily to reduce fruiting wood and remove some flower clusters.

For apples, pears, loquats, quinces, apricots, nectarines, peaches, and plums, fruit thinning in addition to natural fruit fall is required to maintain good quality, high yields, and healthy trees. Cherries, especially sweet cherries grown on highly productive rootstocks, also benefit from thinning. When to thin depends on the crop and the thinning method used.

Proper pruning techniques remove excess fruiting wood and are an important step in managing the crop loads of many tree crops. As we discussed in chapter 12, for example, special pruning techniques help reduce the crop load in sweet cherries that are grown on highly productive rootstocks like Gisela 5. Another example is the special pruning technique used for apples grown in the tall spindle training system. In both cases, careful pruning removes older wood that produces large numbers of small fruit.

Excessive pruning, however, delays the onset of fruiting and reduces yields. Pruning too heavily also stimulates excessive, upright, and unproductive wood that complicates training procedures, increases pest and disease problems, and requires more pruning and branch bending to correct. While pruning is an important step in managing crop load, it is not the only step. For some crops, additional thinning to remove some of the young fruits is needed.

Crop loads can be reduced by removing flowers; very young, green fruit; or older fruit. Thinning can be done by hand, with handheld devices, or by large, tractor-mounted machines.

By picking off some of the fruits, you leave more room and resources for the remaining fruits. Start by removing double fruits (fruits that are fused together), fruits that are smaller than average for the tree, and damaged or deformed fruits. Then remove additional fruits to achieve the densities shown in table 13.1 and described below.

While you can follow the guidelines for spacings in table 13.1 exactly — for example, spacing apples 4 to 8 inches apart — a better approach is to thin according to size and use the spacings as averages. Fruits that are small at the time of thinning will likely remain small at maturity. Leave larger fruits when possible, even if it means leaving a smaller spacing between some fruits and a larger spacing between others. Use the spacings given in the table as a guide for the average number of fruits that should be along a given branch. When thinning apples, for example, for every 48 inches of fruiting wood, you should leave 6 to 12 of the largest fruits. Space the individual fruits far enough apart that they do not push each other off the branches or rub against each other excessively as they enlarge. For apples, leave no more than two fruits per cluster and leave some fruiting spurs without fruit to ensure adequate return bloom the following season.

Pole thinning speeds up the thinning process and is especially useful where hand thinning requires a ladder. You can attach about 6 to 10 inches of rubber hose to the end of a broomstick or similar pole, or tape a piece of cloth around the end of a pole to serve as padding. The rubber or cloth softens the blows and helps prevent damaging the branches. Plastic or rubber-covered baseball bats also work well for thinning.

Pole thinning is less accurate than hand thinning but much faster, and with practice, you can obtain good results. Use the padded end of the pole to knock off individual fruits, but avoid breaking off the fruiting spurs. Also use the poles to thin out fruit clusters. Strike a cluster once or twice to break it up and remove some of the fruit.

Mechanical thinning is used in pome and stone fruit orchards. Early thinning methods included ropes mounted to rapidly spinning cylinders or disks, or high-pressure water jets. In these methods, the spinning ropes or water jets knocked some of the fruits off the trees. They did not produce uniformly effective results in orchards, however, and have given way to shakers and string thinners.

Regardless of the mechanical thinning method you use, you will need to follow up with hand and pole thinning to achieve optimum fruit sets. The advantage is that mechanical thinning reduces the amount and cost of hand thinning required.

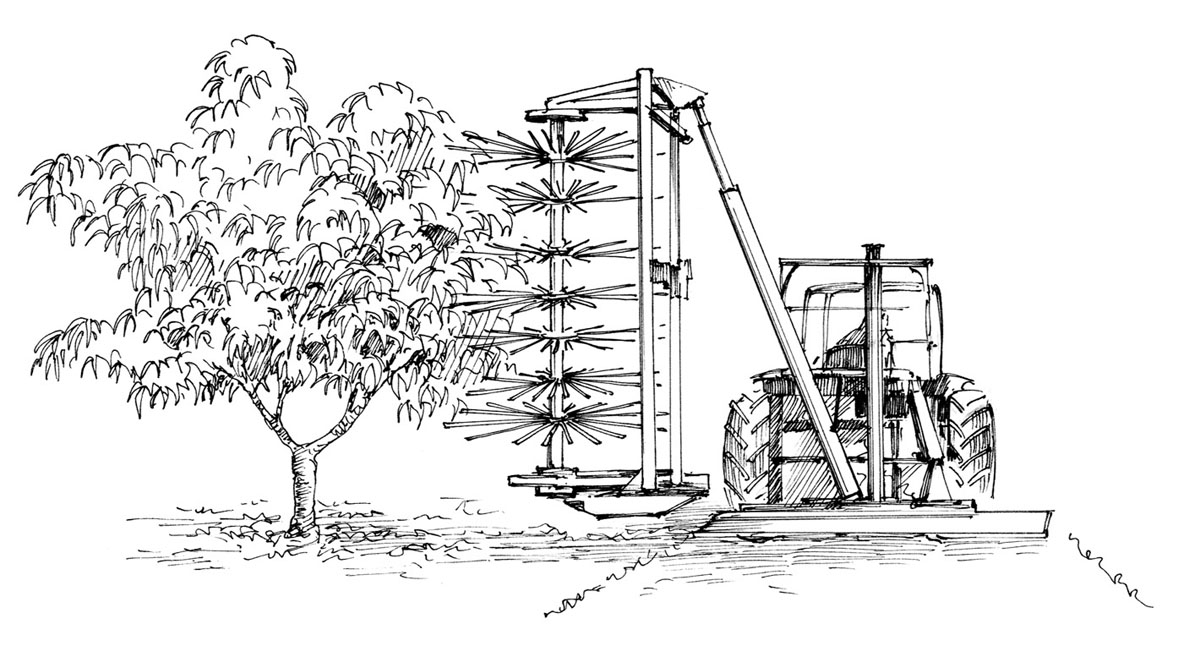

Shakers. In fruit thinning trials, researchers found that shaker devices can be quite effective, and the method is now being adopted by orchardists, particularly for peaches. These devices also hold promise for apple and plum orchards. Several versions have been developed by the U.S. Department of Agriculture and private sources and are being tested across the United States. Essentially, they are modified citrus and raspberry harvesters with long rods mounted to oscillating spindles or drums. As the tractor travels along the alley, the rods reach into the canopy and shake the branches. The devices are probably best used 40 to 55 days after full bloom to remove green fruits, although they have been tested during bloom and can effectively remove flowers. The type of crop, variety, and canopy design, as well as other factors, affect the thinning process. You will need to run some tests in your orchard to determine the best time to thin using a shaker. The shakers have primarily been developed and tested for use in narrow canopy designs, particularly perpendicular-V and quad-V training systems for peaches. Figure 13.1 shows a tractor-mounted shaker used for thinning fruit trees.

A shaker device used to thin green fruits and sometimes to thin flowers

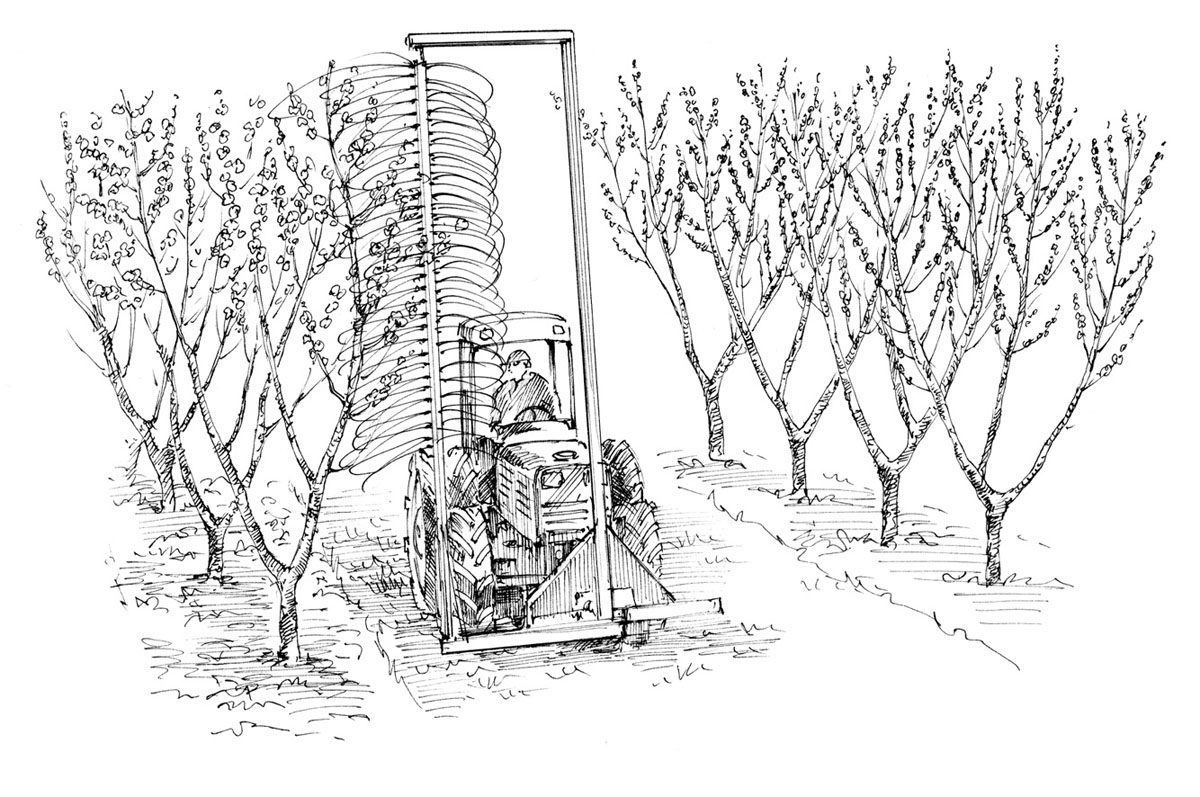

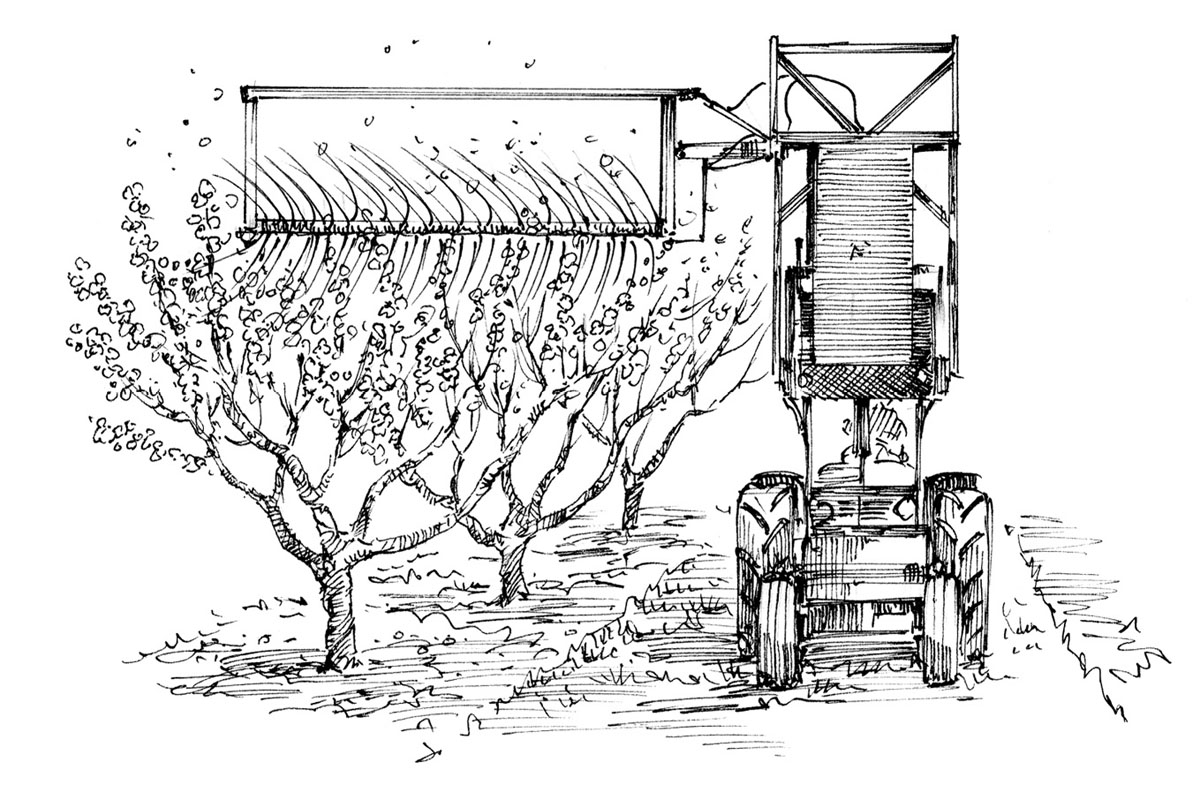

String thinners. Trials in Ontario, Pennsylvania, and Washington State have shown quite good results using a specially designed, tractor-mounted string thinner. The Darwin string thinner consists of long, spinning, vertical cylinders equipped with hundreds of strings. The tractor is driven about 2.5 to 3 miles per hour through the alleys, with the strings striking the flowers. The best time to thin is when about 20 percent of the flowers have opened. Typically, about 30 to 50 percent of the flowers and flower buds are removed. You only need about 10 to 15 percent of the flowers that set to produce sustainable crops of apples, pears, peaches, and nectarines. Various designs are emerging with long single-spindle thinners, shorter and independent upper and lower spindles, and horizontal over-the-tree thinners. Figure 13.2 shows several tractor-mounted string thinner designs for orchard thinning.

Some models allow the thinner to be operated vertically along the rows or horizontally over the tops of the trees.

A) Thinner positioned vertically or at an angle.

B) Thinner positioned horizontally above the tree canopy.

The vertically mounted tractor-mounted string thinner works best with narrow-row, flat canopies. For other training systems, researchers are testing handheld string trimmers that have been modified for use in fruit tree thinning, and one version (Bonner) is marketed commercially by a German firm.

Advantages and disadvantages. Mechanical thinning shows promise and is being adopted commercially, but we are in the early part of the learning curve using these methods. While mechanical thinners effectively remove flowers and green fruits, they can damage the trees, increasing their susceptibility to diseases. We do not yet know how much damage the thinners will cause and how they will affect the long-term health of the tree. The design of the canopy also influences the effectiveness of thinning techniques and their damage to the trees. Pennsylvania peach growers have found that branches that project into the alleys suffer greater damage from string thinning than those within the crop rows. Trials in West Virginia have shown that large, rigid limbs are more susceptible to damage than thinner, more flexible branches.

Growers with high labor costs for thinning should consider testing mechanical thinning. Do your homework and evaluate the devices that are available. At present, the string thinner approach seems to be somewhat more popular with commercial orchardists than the shakers, but both designs continue to evolve. The most effective approach will probably be to use a combination of the two methods: string thinning to remove flowers, followed by shaker thinning to remove green fruits. This technique reduces hand thinning more than either thinning method alone, and it allows you to judge how many fruits to remove in mid-season after the fruits have set.

Test the devices on small blocks within your orchard. Compare fruit size, yields, quality, and tree health over several years before adopting the approach throughout your entire orchard. You may find that you need to adjust your training methods and canopy designs to optimize thinning and reduce tree damage.

Chemical thinning has a greater impact on pome fruit size and fruit bud formation than does hand or pole thinning and is a standard practice in conventional apple orchards. Unfortunately, despite decades of research, no effective and reliable chemical thinners have been found for organic stone fruits. Chemical thinning is discussed under specific fruits, below.

While the general principles of thinning apply to most stone fruit and pome fruit crops, the specific methods vary slightly from crop to crop. We cover these specifics in the following sections.

In pome crops, if a flower receives abundant, compatible pollen and weather conditions are favorable, many seeds form. The presence of these seeds stimulates growth, causing a large and uniformly shaped fruit. If a flower receives only a fraction of the pollen that it requires, only a few seeds form in the fruit. Fruits that have a small number of seeds are typically small and often misshapen. Some of these fruits fall naturally during June drop. Those that remain continue to compete for nutrients, reducing the size of well-formed fruits on the same tree.

Hand thinning. In apples, the centermost blossom is called the “king” blossom. King blossoms usually open first in a cluster and produce the largest fruits. When hand or pole thinning, try to target the smaller surrounding fruits; ideally, you want to leave one apple on every other spur. Spurs that do not have apples are more likely to develop fruit buds for next year’s crop. As mentioned above, however, keep the larger fruits when possible and leave 6 to 12 fruits for every 48 inches of fruiting wood.

Chemical thinning. Growers in conventional apple orchards have applied chemical sprays during and shortly after bloom for many years to cause some of the flowers and fruits to fall. For a long while, the materials of choice were carbaryl insecticide, usually combined with synthetic plant growth regulators like naphthalene acetic acid (NAA). None of these materials can be used in certified organic orchards.

Using synthetic chemicals is an extremely effective and relatively inexpensive way to thin fruits. Not only are the chemicals effective, but they can be applied over an extended time during bloom and early fruit development. This long period allows you to see how many fruits have been formed and to accurately remove just enough fruit to ensure annual crops of large fruits.

Organic apple orchardists have more limited chemical thinning options. Researchers have tried salt (sodium chloride) and vinegar, but they have not produced consistently effective or reliable results. The most popular thinning agents at this time are a combination of oil (usually fish oil) and liquid lime sulfur (LLS). Fish oil and LLS sprays proved so successful in Washington State trials that some conventional growers have adopted the practice.

A typical thinning spray consists of 2.5 percent fish oil and 2 to 4 percent liquid lime sulfur. Use the lower rates when you expect fruit set to be lower. Use the higher rates if you expect a particularly heavy fruit set. According to Cornell University, Crocker’s Fish Oil (Quincy, Washington), was used in their thinning trials, although other fish oil products may be equally as effective. In thinning trials, fish oil was somewhat more effective than mineral crop oils. California researchers reported that soybean and cottonseed oil were more effective thinning agents than was fish oil.

As of this writing, fish oil was not registered as a thinning agent in California, and researchers there found that soybean and cottonseed oil were more effective than fish oil. Note that not all liquid lime sulfur products are approved for thinning by certified organic fruit growers. Check all of your oil and sulfur products to ensure that they are approved for thinning before applying them.

When to spray. Washington State fruit specialists recommend applying a fish oil/LLS spray during bloom. Unfortunately, at that time you do not yet know what the fruit set will be and you run the risk of thinning too heavily. For example, cold, wet weather can interfere with pollination and fertilization. A late frost can damage flowers and developing fruits, as can hail and heavy winds. In the generally warm, arid or semiarid fruit growing regions of western North America, applications during bloom appear suitable. The objectives in this region are to thin out some of the flowers and to reduce pollination and the percentage of fruit set. For eastern fruit growers, Cornell University suggests waiting to make the first application of fish oil/LLS until petal fall, when danger of frost has passed and you can better determine how much fruit has set. Apply a second spray 4 to 7 days after the first, and a third spray may be needed.

The downside of the Cornell approach is that it appears to be less effective than making applications during full bloom, and there is a greater risk that the lime sulfur will damage the leaves and fruit. Lime sulfur is also toxic to beneficial organisms and repeated applications of LLS can increase pest problems. The present theory for why the oil/LLS sprays work is that:

Cornell fruit specialists note that dark, cloudy weather for about 2 days or more before or after applying chemical thinners increases the thinning response. If you expect cloudy weather just before or after applying oil/LLS, consider reducing your rate of application.

Temperatures also influence the effectiveness of chemical thinners. In general, higher temperatures increase the rates at which chemical reactions take place. Night temperatures of 65°F (18°C) or greater and daytime temperatures of 85°F (29°C) or greater during the 3 to 5 days after applying sprays can increase the thinning response. If you observe or expect temperatures in these ranges, consider using the lower application rates.

For commercial production, you must thin loquat fruits to produce fruits of acceptable size. Loquats also tend to develop an alternate year bearing pattern like apples. You can thin clusters to help reduce alternate bearing and remove flowers and fruits to increase loquat fruit size.

Loquats set about nine or ten fruits per cluster. By leaving three to five fruits per cluster, you will increase fruit size and the percentage of marketable fruits. In Chinese trials, enclosing the fruits in bags (bagging) after thinning reduced the amount of sunburned and rusty fruit from about 48 percent to less than 1 percent and greatly increased the percentage of premium-quality fruits. Bagging tree fruits in fabric or weather-resistant paper to protect the fruits from pest, disease, and environmental damage and increase the percentage of premium-grade fruit is a common practice in parts of the Orient.

There is a trade-off to thinning loquats, however. Worldwide, purple spot is the most serious physiological disorder affecting loquat, causing the rind to discolor and dry out. In Spanish trials, thinning to leave five fruits per cluster when the fruits were ⅜ inch in diameter increased the incidence of purple spot from about 2 percent to about 6 percent. Leaving three fruits per cluster increased purple spot to 12 percent of the fruits, and leaving one fruit per cluster increased purple spot to 36 percent of the fruits. The cause of purple spot is not yet known, but it correlates with the amount of mineral nutrients in the fruits. Thinning alters the concentrations of mineral nutrients in the fruit. In short, be careful not to overthin.

You can use several approaches to thin loquats. One approach is to thin out the flower clusters, usually at or shortly after full bloom. Clip off about 50 percent of the flower clusters, leaving the remaining clusters evenly distributed throughout the tree. Alternatively, you can clip off about half of the flowers from each of the clusters.

You can also thin the fruits shortly after petal fall but before the normal drop, when the fruits are about ⅜ inch in diameter. By removing fruit clusters that set late during the bloom, you harvest larger fruits in a shorter period. Larger commercial growers desire a concentrated harvest. For home and market production, you might want to keep some of the later fruits in order to extend the harvest. Using this approach, remove some clusters entirely or remove some of the fruits from each cluster. When removing some of the fruits from the clusters, leave roughly three to five fruits per cluster. In Japan, the ‘Tanaka’ variety is thinned to one fruit per cluster and ‘Mogi’ to two fruits per cluster.

Some growers use chemical thinning methods for loquats, particularly those in Taiwan, but the results have been variable and the materials used are not allowed in organic production.

Pears generally require less thinning than apples, although some thinning is generally required with European varieties to produce large fruits. Asian varieties require heavier thinning than European varieties, and the following recommendations work for both crops. Although some growers thin by clipping off all but two or three flowers per cluster during bloom, thinning normally starts immediately after June drop, when you can estimate the crop load.

Some fruit specialists recommend removing all pear fruits from trees for the first few years after planting in order to allow more energy for tree development. This practice is most likely to be useful on trees that are grafted to dwarfing rootstocks.

For average or light crops, you can usually leave one to three fruits per spur. ‘Bartlett’ and ‘Bosc’ normally set three to five fruits per spur and can often mature them if the crop load is not too heavy. ‘Bartlett’ also usually self-thins enough by itself to produce marketable crops.

When pears set an unusually heavy crop, you may want to remove all but the single largest fruit per spur. Another approach is to space the pears an average of 4 to 8 inches apart along the branches. As with apples, this works out to be 6 to 12 fruits for every 48 inches of fruiting wood.

When crop loads are light to moderate, you can wait until harvest to pick the largest fruits from each cluster first and leave the remaining fruits on the trees for another 7 to 10 days to develop more size. If you choose to harvest in two stages, be careful not to leave ‘Bartlett’ fruit on the tree too long, as this variety is prone to a physiological disorder called water core. Water core results in soft, watery, discolored flesh near the core, decreasing the market value of the fruit.

The organic chemical thinning practices we discussed using on apples may also apply to pears, but more research is needed before making recommendations for how to chemically thin organic pears.

Quinces generally do not need to be thinned unless the trees set an unusually heavy crop. Some precocious varieties of quince, such as ‘Aromatnaya’, begin bearing fruit very young and can benefit from thinning during the first few years to develop a vigorous tree with good structure. In mature trees, crops are usually managed through pruning to remove long, weeping branches. Thinning, if needed, is done by hand.

Mayhaws produce small, crab apple–sized fruits and are not thinned. Medlars are normally not thinned. In the case of an unusually heavy crop, you might reduce the number of fruits somewhat by hand thinning shortly after June drop. Saskatoons are not thinned.

Apricots tend to overbear and produce small fruits. Just after June drop, when the developing fruits are about 1 inch in diameter, thin them by hand or with a pole. Over the past 30 years, recommendations for the spacing between thinned apricots have ranged from 1 to 2 inches to 6 to 8 inches. A good compromise is to leave an average of one fruit every 3 to 5 inches (6 to 10 fruits per 30 inches of fruiting wood); this will produce large fruits and economical yields. If possible, leave only one fruit per cluster.

As yet, no effective and reliable chemical thinners are available for organic apricot production. Remember that apricots are easily damaged by sulfur, and liquid lime sulfur (LLS) should not be applied to apricot trees.

Although trials are still underway around the world, thinning sweet cherries remains controversial. For most varieties on vigorous rootstocks, flower or fruit thinning is not required. For self-fruitful varieties on highly productive rootstocks, small fruit size has been a problem. While chemical thinners have been effective in reducing fruit loads, the reduction in crop load has generally not increased fruit size.

Washington State University has been conducting experiments using the tractor-mounted string thinners discussed earlier to thin sweet cherries. The best results generally come when the trees are thinned when the buds have swollen to about 1⁄4 inch in early spring. The results show some promise for thinning, but they are too preliminary to make recommendations.

For self-fruitful varieties grown on Gisela 5, Gisela 6, and other highly productive rootstocks, follow the pruning recommendations in chapter 12 to help manage crop loads.

Tart cherries do not require thinning.

Peaches and nectarines require thinning to develop large fruits. Thinning is also required in commercial orchards for fruit destined for processing in order to achieve uniform sizes. Hand thinning has been the standard and is still required in commercial orchards. Researchers are testing both mechanical and chemical thinners, and mechanical thinners have proven very effective in reducing the amount of hand thinning needed. For large commercial orchards, reducing the amount of labor required to thin fruit often makes a large economic difference.

Shakers and string thinners. Commercial growers are adopting shakers and string thinners for peach production. In research trials, these methods produced more consistent and effective results than did the chemical thinners tested, and they increased fruit size and greatly reduced the amount of follow-up hand thinning that was needed. In Pennsylvania trials, the drum shaker reduced crop load more than all of the other treatments, produced fruit of a similar size to the fruit that was string thinned, and required about 15 worker hours per acre for follow-up hand thinning. The string thinner also increased average fruit size and reduced the variability in fruit size. About 22 worker hours per acre were required for hand thinning after using the string thinner. Blocks that were thinned only by hand required about 40 worker hours per acre of thinning.

So far, researchers have noted little damage to the trees when using mechanical thinners, except for damage done by string thinners to large limbs sticking out into the alleys. Most of the trials have involved relatively flat canopies, primarily quad-V and perpendicular-V training systems. The overhead string thinner can be used with any training system, but it will not be effective in thinning fruit in the lower canopy. For large peach and nectarine orchards, the most effective approach will probably involve using a combination of a vertically mounted string thinning at 20 percent bloom followed by shaker thinning 40 to 55 days after full bloom.

Chemical sprays. Chemical thinning in research and commercial orchards has proven less reliable with stone fruits than with apples and pears, although recent research shows some promise for developing effective chemical thinners that can be used in organic orchards. Vegetable oil emulsions applied to the dormant buds have produced some thinning and increased fruit size. In Pennsylvania research trials, a caustic fertilizer (ammonium thiosulfate) and various surfactants normally used in pesticide applications were tested and found to produce less consistent results than mechanical thinners. Organic oils applied with synthetic surfactants have shown promising results, but these materials cannot be used in organic orchards. While ongoing research shows some promise, no effective chemical thinners are yet available for organic peach and nectarine production.

Hand thinning. Hand and pole thinning, whether used alone or as a follow-up to mechanical thinning, remains the standard for peach and nectarine production. Begin hand and pole thinning after June drop, which is usually about 5 to 8 weeks after full bloom. Start with the earliest-maturing varieties.

Spacing. Table 13.1 suggests spacing the fruits an average of 3 to 6 inches apart (6 to 12 fruits per 36 inches of fruiting wood), although you can find other recommendations for wider spacings up to 8 inches apart. Much depends on the intended use of the fruits and the variety. Although counterintuitive, small-fruiting varieties require wider spacing than varieties that naturally set larger fruit. You might want to space fruit intended for fresh use somewhat farther apart than fruit intended for processing. Vigorous, well-exposed 1-year-old wood produces the largest and best fruits. Remove most or all of the fruits from thin and shaded wood.

In general, try to leave 30 to 40 full-sized leaves for each peach or nectarine on the tree. With a little counting and practice, you can visually estimate the numbers of fruit to leave. If the load is unbalanced and only part of the branches bears heavy crops, you might need to do little or no thinning. The goal is to adjust the crop load for the entire tree.

In commercial orchards, hand thinning is complex and based on total crop load, leaf surface, tree spacing, and tree health. The science behind the process is that it takes a certain amount of leaf surface to set and fully mature a high-quality peach of a given size. The process is very sophisticated in the clingstone peach industry, where the fruit is destined for canning.

Experienced growers of commercial processing peaches, for example, can accurately develop uniform peaches of a particular size by leaving a certain number of fruits per tree. Growers determine how many fruits to leave based on the size of the fruit at a specific reference date, typically 10 days after pit hardening. Pit hardening is determined by slicing through the fruits with a sharp knife. With a little practice, you can detect the hardening pit.

If the peaches are smaller than a certain diameter at pit hardening, you will need to thin heavily. Slightly larger fruits require less thinning and fruits that are above a given size require no thinning. According to Modern Fruit Science, diameters of 33, 36, and 38 mm, respectively, at the time of pit hardening serve as starting points. With experience, growers may adopt different threshold diameters based on climate, cultural practices, and varieties.

Plums need to be heavily thinned in order to develop large, uniform-sized fruits with good color. Thinning also helps ensure that the trees are vigorous, and it reduces limb breakage due to heavy crops. Hand and pole thinning work well for plums. Leave European varieties an average of 2 to 4 inches apart (9 to 18 fruits per 36 inches of fruiting wood). Japanese plums set more heavily, and an average of 3 to 4 inches between fruits (9 to 12 fruits per 36 inches of fruiting wood) is better.

Some varieties, including ‘Burbank’ and ‘Friar’, often set heavily when cross-pollination and weather conditions are good. These varieties may need somewhat heavier thinning. Varieties that tend to self-thin throughout the growing season include ‘Climax’ and ‘Santa Rosa’. Wait until just after June drop to thin by hand.

Commercial growers have long used mechanical trunk shakers designed for harvesting cherries to thin plums. Thin about 7 to 10 days after pit hardening to remove green fruits. Fruits will continue to drop naturally after this point, so be careful not to thin too heavily.

The mechanical shaker described for apples and peaches shows promise for plums as well, although little research has been published on the practice. Trials, however, show that large, rigid branches suffer more injury from the shakers than do smaller, more limber branches. For commercial orchards, you may need to adjust your pruning and training practices to facilitate mechanical thinning. Because plum trees are generally not trained to flat walls, thinning with a tractor-mounted string thinner is not a particularly effective method.

Researchers have tested chemical thinners for plums, but the practice has not been widely adopted by commercial growers. The available materials cannot be used in organic orchards.

Bush cherry and bush plum varieties do not require thinning.

For home orchardists, few things beat tree-ripened fruit. For market and larger commercial orchards, however, determining when to harvest in order to get the best-quality fruit to your customers becomes more complicated. Some fruits also do not lend themselves to ripening on the tree.

There are a few things to consider when harvesting fruit. The first is not to mix fruit that has been damaged by pests, diseases, or weather with healthy fruit. There is great truth to the adage that one rotten apple spoils the barrel. Rot organisms can spread from infected to healthy fruits during picking, transport, sorting, packing, and storage.

Some fruits, like apples, also naturally produce ethylene gas as part of the ripening process. Ethylene causes fruits to ripen more quickly. Damaged apples and other ethylene-producing fruits produce more ethylene than normal and can cause the stored fruits to overripen.

Similarly, be cautious about salvaging dropped fruits from the orchard floor. For market and commercial orchards, it is often best to cull the fruit, which may contain insect pests or diseases. Dropped fruit is also typically bruised from the fall. In some cases, you can carefully examine dropped apples and cull infested or diseased fruit, then press the good ones for cider.

Cleanliness is critical. Before harvest, ensure that your bins and anything else that the fruit will touch are clean and disinfected.

Be gentle! Bruised fruit loses much of its appeal and marketability. Damaged fruits are also more susceptible to storage rots, and some generate excessive amounts of ethylene during storage. Even with mechanically harvested fruits, the goal is to reduce the damage as much as possible. For hand harvesting, pick the fruit into small containers or a picking bag worn about your waist. If you are transferring the fruit to bins, gently pour the fruit onto the bin floor or onto the fruit already in the bin. Do not drop the fruit into the bins.

For most fruits, cooling the fruit as quickly as possible after harvest slows the ripening process and helps reduce storage diseases. In commercial packing houses, fruits that benefit from refrigeration are placed into large walk-in coolers where tarps, tunnels, and fans are used to force cold air around the fruit to cool it quickly. We will discuss some exceptions below.

If you wash your fruit or cool it with cold water during packing, make sure that the fruit is thoroughly dry before placing it into storage. High humidity during storage is desirable for most refrigerated fruits. Droplets and films of water on the surface of the fruit are not.

Determining when to harvest pome fruits is usually more difficult than with stone fruits. ‘Red Delicious’ apples, for example, develop water core if allowed to ripen on the tree. European pears are usually harvested before they are fully ripe and allowed to ripen off the tree. The situation is especially complicated if the fruit will be kept for long periods in refrigerated or controlled atmosphere storage.

The developmental stage at which apples should be harvested depends greatly on the variety, its intended use, and how it will be stored. Fruit that is picked too early is typically undersized and has poor taste and texture. Overripe apples become soft and mealy, and red varieties can develop dark, greasy skins. Fruit that is overripe also does not store or ship well. ‘Red Delicious’ develops scald disorder during storage if picked too early but develops water core if left on the tree too long.

If immediately consuming or processing, you want the fruit to be fully ripe; firmness, texture, and taste are good indicators of ripeness. If the fruit is to be stored inside a refrigerator for an extended period or in controlled atmosphere storage, you will want to pick the fruit after it is mature but not fully ripe.

Gauging ripeness. Many methods have been used to determine the ripeness stage of apples, including the number of days from full bloom, the air temperature, the sugar concentration, and the skin and ground color. Results from these methods vary too much due to weather and cultural practices to be reliable. Measuring ethylene production is more accurate, but it requires advanced equipment and training. Two methods have emerged that are reliable and easy.

As fruits ripen, they soften. Handheld firmness meters quickly and accurately determine fruit firmness. Testers cost anywhere from one hundred to several hundred dollars and are available from orchard supply companies. To use the meter, remove just the peel of the apple over a small area. Special peelers make this process quick, easy, and reproducible. Some meters come with interchangeable tips to allow them to be used on different fruits. Simply press the meter against the flesh of the apple and take the reading. Take readings from several representative samples to determine an average firmness. For apples, a firmness of 16 pounds at harvest for storage apples and 10 to 14 pounds for fresh sales are about average. You will probably use different values, depending on the variety and whether the fruit will go to controlled atmosphere storage, refrigeration, or fresh markets. By correlating readings with the starch test described below, you can develop a chart of suitable firmness values for your varieties and marketing strategy.

When using a firmness meter, use uniform-sized fruits and avoid those that are larger than average. Testing only large apples will give you misleading readings. Likewise, do not test apples that have developed water core.

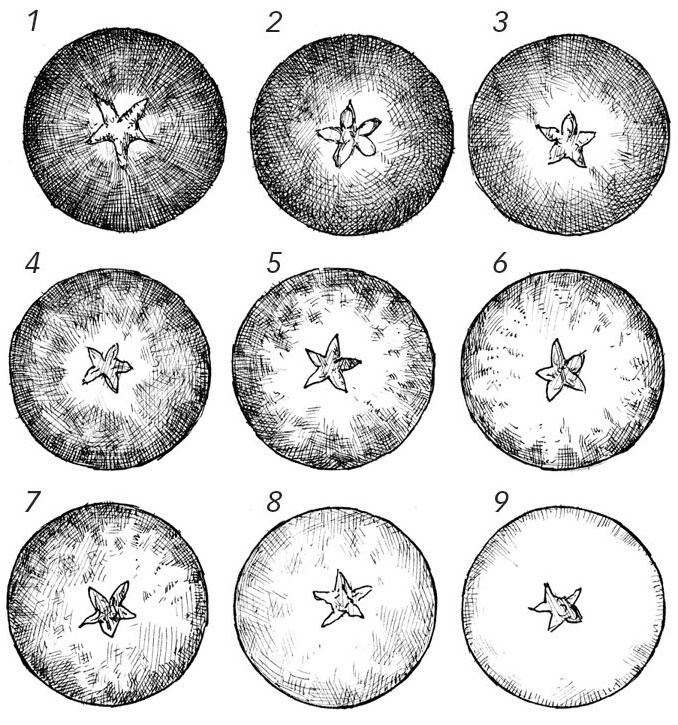

A simple and reliable method that has long been used by commercial growers is the iodine test. As apples form and grow, they are first composed mostly of starch. As they mature, the starch is converted to sugar. Iodine reacts with starch to form a blue color, but it does not react with sugar. To use this method, collect several apples of each variety. Cut the apples in half to obtain a cross section perpendicular to the stem. Spray a standard iodine solution, available from orchard supply companies, on the cut surface. Starchy areas will appear blue. Areas that have converted to sugar remain yellowish-white. Rate your apples by comparing the staining pattern with pictures on standardized charts that are available for popular varieties.

Typical ratings range from 1.0 (immature) to 6.0 (fully ripe), although different systems have ranges of 1 to 9. Although the scale differs somewhat between apple varieties, ratings of about 2.0 to 2.5 indicate the time to harvest for long-term controlled atmosphere storage. Ratings of about 3.0 to 4.0 indicate the time for long-term refrigerated storage. Ratings of 4.5 to 6.0 indicate the fruit is ready to eat. Start making your iodine tests twice weekly beginning 2 weeks before your expected harvest date, based on days from full bloom. Figure 13.3 shows iodine test patterns and harvest maturity for ‘Liberty’ apples.

This sample starch-iodine index chart for ‘Liberty’ apple is based on a chart published by the University of Massachusetts. Charts for different apple varieties are available from several university and commercial sources.

Picking and storing. When picking apples, lift the fruit upward and twist. You should break the fruit stem off at the spur. If the stems pull out of the fruit, rot organisms can enter. Broken spurs attached to the apples are the result of improper harvest techniques, and they reduce the following year’s crop.

Once harvested, cool the fruit as quickly as possible to between 32 and 34°F (0 and 1°C). Increasing the temperature from 32 to 40°F (0 to 4°C) doubles the rate of ripening. Going from 40 to 50°F (4 to 10°C) doubles the rate again, as does going from 50 to 70°F (10 to 21°C). In other words, fruit can be held at 32°F eight times longer than it can be held at 70°F.

Details on commercial apple packing and controlled atmosphere storage are beyond the scope of this book. If you use an off-farm packing house or CA storage, be very careful to avoid mingling organic fruit with fruit coming from uncertified orchards. If your organic fruit is mingled or stored with fruit from uncertified orchards, you will no longer be able to market it as organic. Packing houses that deal with organic fruit typically maintain separate rooms for organic and conventionally grown fruits.

Loquat fruits typically reach maturity for harvest about 90 days after full bloom. The best indicator of ripeness appears to be a fully developed skin color typical for that variety, although the fruits become softer as they ripen. It is critical that you time the harvest properly because fruits that are not ripe when picked do not ripen properly after harvest and can be unpleasantly acidic. If using the fruits in baking, harvest them slightly before full ripeness.

Remember that loquats are very tender and are easily damaged during harvest. Rather than picking the fruits by hand, use a sharp knife or pair of clippers to cut them off individually from the clusters. After harvesting, place in shallow containers to prevent bruising and crushing.

Loquats remain usable for up to 10 days at room temperature. Cooling extends shelf life, but be aware that these fruits are susceptible to injury during chilling if kept at too low a temperature. Properly stored, the fruits can be kept for up to 2 months. Work in Lebanon showed that a storage temperature of 41°F (5°C) preserved the fruits much better than a temperature of 54°F (12°C).

Loquats are generally packed into small containers around 2.2 pounds or less. If picked and placed in wooden or paper containers, wrap the containers with cellophane film to preserve freshness and reduce shriveling. Research has shown that using wooden boxes increases fruit bruising. Clear plastic clamshell packaging is a good alternative.

Mayhaw fruits are small, and commercial growers use trunk shakers and tarps on the ground to collect the falling fruits. If harvesting by hand, pick the fruits as you would apples.

Most mayhaws are destined for processing, in which case the fruit should be at or near full ripeness for harvest. If the fruit will be refrigerated for an extended period before processing, pick them after they are mature but before they are fully ripe.

Medlar fruits are hard, acidic, and not considered edible until they have been softened on the tree by frost or allowed to partially decompose during storage in a process called “bletting.” As the fruit ripens, it softens and the skin wrinkles and darkens. Once the fruit is suitable for eating, the flesh takes on a brown color and develops a texture that has been likened to applesauce, baked apples, and baked sweet potatoes. The aroma is rather earthy or musky, and depending on whom you ask, the flavor is described as being similar to applesauce, figs, kumquats, loquats, and Persian dates. At that point, the fruits can be eaten fresh, like applesauce, or processed into jelly or custards.

In regions where medlar is traditionally grown, the fruits are harvested in November, often after having been exposed to several frosts. Once harvested, the fruits are placed in a cool, dry location to continue ripening, usually for at least 2 weeks.

Determining the point at which pears should be harvested, particularly for commercial harvests, is somewhat more difficult than for apples. As the fruit ripens, the underlying “ground color” of the skin gradually changes from green to yellow, the aroma and sugar concentrations increase, and the fruit softens. Although charts are available to help judge the ground color, this evaluation remains subjective and is less useful on red varieties. Likewise, basing harvest maturity on aroma is highly subjective.

Firmness meters described for apples work well for pears. If the fruit will be stored in refrigerators, the firmness ranges from 11 to 23 pounds, depending on variety. Harvest Asian pears at about 13 pounds firmness, ‘Anjou’ at 15 pounds, ‘Bosc’ at 16 pounds, and ‘Bartlett’ at 19 to 22 pounds. As with apples, the firmness of fruit ready for sale will be lower, ranging from 7 to 10 pounds for Asian varieties, to 11 to 13 for ‘Bosc’, 10 to 14 for ‘Anjou’, and 15 to 18 pounds for ‘Bartlett’.

For other varieties, keep a record of firmness measurements and correlate them with storage and quality evaluations. You will soon be able to develop a chart of firmness standards for your varieties and markets.

Firmness readings are sometimes combined with measurements of the sugar concentrations in the flesh (called total soluble solids or TSS) as measured with refractometers. Good-quality optical and digital refractometers are available from orchard supply companies at a relatively low cost.

European pears are usually picked before they are fully ripe in order to develop maximum quality and storability. This is particularly true of ‘Bartlett’. ‘Anjou’ and ‘Bosc’ are allowed to ripen a bit more before harvest but are still not fully ripe. Pears that are destined for canning are allowed to nearly ripen on the tree before harvest.

Like quinces, firm pears are still susceptible to bruising and must be handled gently. Once harvested, pears are stored at 30 to 31°F (−1 to −0.5°C). Sugar in the fruit prevents the flesh from freezing at temperatures above about 28°F (−2°C). Varieties differ greatly in their storability. “Fall pears,” such as ‘Clapp’s Favorite’, ‘Red Clapp’, and ‘Starkrimson’, can be kept in storage at 30 to 31°F for only about 2 to 6 weeks. “Winter pears” can be stored much longer. ‘Red Angelo’, for example, can be held at 30 to 31°F for up to 10 months. The most popular pear variety, ‘Bartlett’, can be stored for about 31⁄2 months.

For commercial orchards, temperature control is critical. If the storage temperature rises to between 34 and 35°F (1 to 2°C), some varieties, such as ‘Bosc’, will fail to ripen properly, when removed from cold storage.

European pears are best ripened off the tree at temperatures of 60 to 70°F (16 to 21°C) and 80 to 86 percent relative humidity. At higher temperatures, the fruits may not ripen properly, and when ripened at low humidity, the fruits can become shriveled.

Pear fruits can be kept in controlled atmosphere storage, similar to apples, where temperatures are kept near freezing, ethylene is removed from the air, and the oxygen and carbon dioxide concentrations are manipulated. High concentrations of CO2, however, cause pears to develop postharvest breakdown.

Unlike their European cousins, Asian pears can be tree ripened and eaten right from the trees.

Home and market orchard growers do not really need firmness meters and refractometers. Given some experience growing pears at your location, you can estimate fairly closely by the calendar date when to harvest. Use changes in ground color and the ease with which the pears detach from the spurs to fine-tune your timing. As pears reach harvest maturity, they detach easily from the spur. Immature fruits will cling to the spurs and should be left where they are to ripen a bit more. As with European pears, flavor and softening are good indicators of maturity.

In warm, long-season climates, quince fruits can remain on the trees long enough to soften and become sweet enough to eat out of hand. In most of North America, the practice is to leave the fruits on the trees as long as possible, but not to the point that they are exposed to frost. At this stage, the fruits are very firm, acidic, and astringent. They are, and will remain, quite gritty. Although they are firm, they still bruise easily and must be handled with the same care given to apples.

The fruits usually need to be stored for a few weeks in order to mature them to the point where they can be eaten. One practice is to store the fruits in single layers in a cool, dry location to continue ripening. Once ripe, the fruits can be kept refrigerated for a few weeks.

Quinces are sometimes eaten fresh, but they are more commonly made into jams and jellies or baked. Their flavor and aroma are very strong, and a small amount of quince can be added to processed apples and pears to provide flavor and aroma.

Saskatoon fruits are allowed to fully ripen before harvest. The fruits will become an even blue color, soften, and be sweet and flavorful. At this stage, the fruits are rather delicate, and you must be gentle. If harvesting by hand, pluck, strip, or roll the ripe berries off the clusters, leaving unripe fruits on the cluster to ripen for a later harvest.

Commercially, saskatoons are hand harvested or mechanically harvested using over-the-row harvesters similar to those used for raspberries and blueberries. After harvest, store the berries at 32 to 34°F (0 to 1°C) and high humidity.

Unlike apples, pears, and medlars that can be stored for months, stone fruits generally have short storage and shelf lives — typically three weeks or less. For long-term storage, freeze, can, or dry the fruits.

Harvest apricots when they begin to soften and develop their characteristic aromas. If shipping, pick the fruits when they have fully colored but are still firm. Store the fruits at 35 to 40°F (2 to 4°C) for up to 3 weeks.

Unlike for apples and pears, there are no objective measurements for determining the harvest maturity for either sweet or tart cherries. Also unlike apples and pears, cherries do not continue to ripen after they are harvested. Combined with the fact that cherry fruit size and yields continue to increase in the latter stages of ripening, most growers prefer to delay harvest until the fruits are fully ripe. At this point, the fruits should be quite soft and flavorful.

Varieties that develop very firm fruits provide a longer harvest window than soft-fruited varieties. Regardless, allowing for no more than a 10- to 14-day harvest is a good practice.

Ripe cherries are easily bruised and must be handled gently and cooled quickly. Fresh-market fruits are harvested by hand. By using the training methods and rootstocks we discussed earlier, pickers should be able to harvest about 80 percent or more of the fruits without using ladders. By keeping your pickers’ feet on the ground, you can greatly speed up harvest; this is especially desirable for U-pick orchards, where customers and ladders are a poor combination from a liability standpoint.

For commercial orchards, most tart cherries and sweet cherries destined for processing are mechanically harvested using trunk shakers equipped with padded grips to reduce damage to the trees.

Cherries are highly perishable but can be held in cold storage for up to 14 days at 32 to 35°F (0 to 2°C). By maintaining high humidity but preventing free moisture from accumulating on the fruit, you can help extend shelf life.

For home use, allow peaches and nectarines to fully ripen on the trees in order to obtain maximum flavor and the desirable texture and firmness. You can use several indicators to judge harvest maturity. As with other fruits, the underlying ground color changes from green to either yellow or white, depending on the flesh color of the variety. The fruits will round out, losing the flat side typical of peaches and nectarines. The flesh softens, and the fruits become aromatic, sweet, and juicy.

Fully ripe fruits are too soft to allow much handling or shipping and typically arrive at the market bruised, overly soft, and with unattractive skins. For that reason and the fact that the first fruits at the market can bring premium prices, some growers tend to pick the fruits too early, when their size, texture, and flavor resemble those of a baseball.

For distant markets, pick fruits about 3 to 6 days before they are fully ripe. You will be able to judge this with a little practice. For markets close to home, pick the fruits when they are still firm and just before they are fully ripe. Peaches and nectarines bruise very easily and must be handled with extreme care throughout the harvest, packing, and shipping steps.

Unlike cherries, where an entire tree is harvested at one time, you only pick the peaches and nectarines at the optimum harvest maturity. Small fruits remain on the trees to continue ripening. This means each tree will be picked at least several times, and generally more.

If the fruits will be processed, commercial growers often use mechanical harvesters to reduce labor costs. Mechanically harvested trees must be trained to specific canopy structures to allow the fruits to fall into catch devices and to avoid damage to the tree limbs caused by the mechanical harvester. Mechanically harvested fruit is transported very quickly to the processing facility to prevent bruises from developing.

It is very important that peaches and nectarines are rapidly and continually cooled. To ensure freshness, keep the temperature at about 32°F (0°C) from packing to the consumers’ tables.

The harvest maturity of plums is largely determined by changes in color at the tips of the fruits and by the firmness of the flesh.

The level of firmness appropriate for harvest depends on the variety and the amount of time before the fruits reach consumers. An average firmness of 8 to 10 pounds works for most plum varieties that will be cooled quickly after picking and before shipping. If you cannot precool the plums before shipping, pick them earlier, when firmness is in the 13- to 15-pound range. Fully ripe plums are very soft, measuring around 4 pounds of firmness. For home fresh use and local fresh markets, harvest plums when they are fully colored and still firm. Plums destined for processing can be allowed to fully ripen on the trees.

Like peaches and nectarines, plums continue to ripen after harvest. Being even softer than peaches and nectarines, plums intended for shipping are picked mature but still firm and before they achieve their full color.

With the exception of loquats, plums and prunes are the most fragile fruits covered in this book and must be handled with great care. When picking, use a lifting and twisting motion to detach the fruits from the tree. For fresh market and shipping plums, the stems should remain attached to the fruit. Ripe plums in good condition can be stored for several weeks at 30 to 32°F (−1 to 0°C).

Prunes are allowed to fully ripen on the trees before harvest, usually when they measure at about 4 pounds of firmness. The skins should be smooth and fully colored. On a commercial scale, prunes are often machine-harvested. They are dried inside ovens, or the prunes can be sun-dried.

Bush cherries and plums are harvested fully ripe, when they have developed full color and flavor and have softened. They can be stored for 1 to 2 weeks at 30 to 32°F (−1 to 0°C).