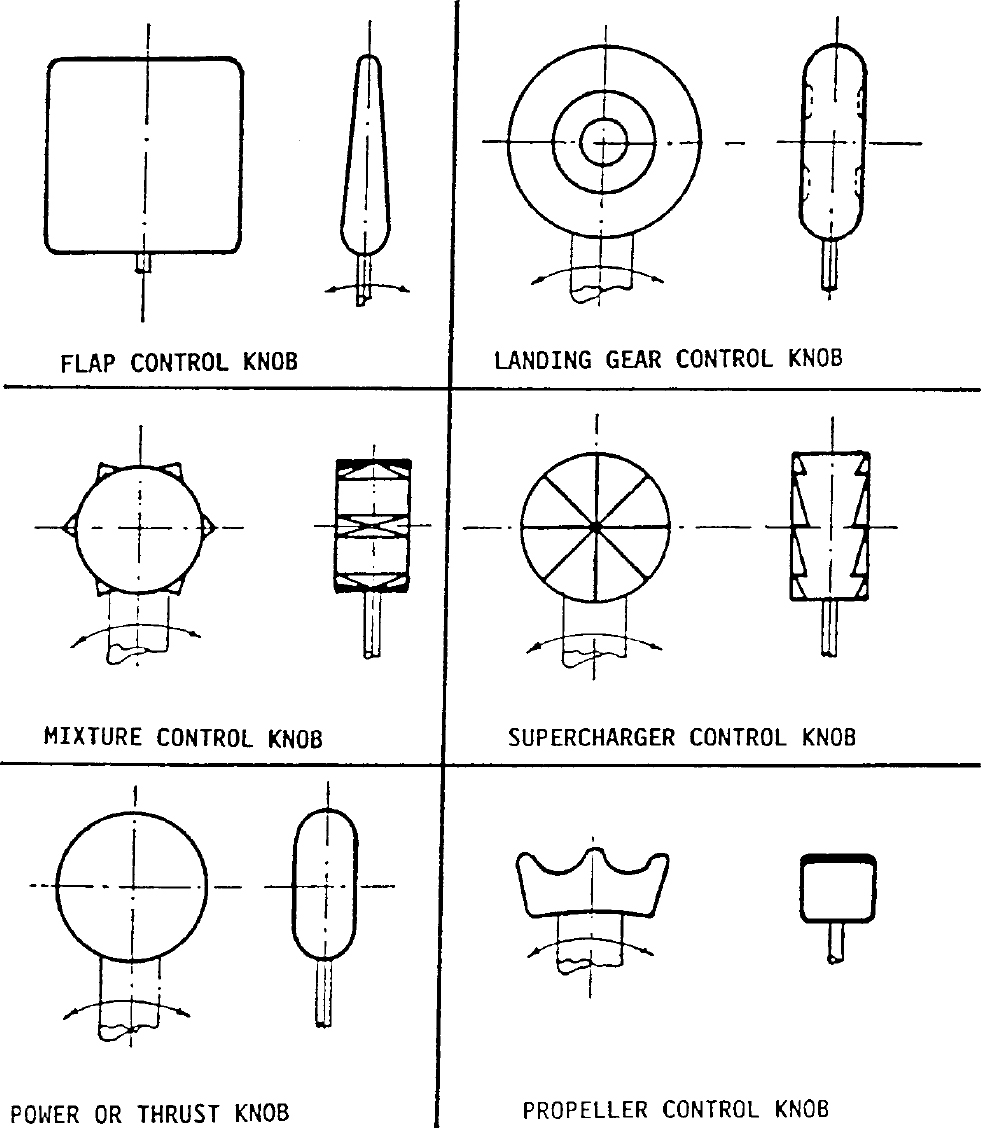

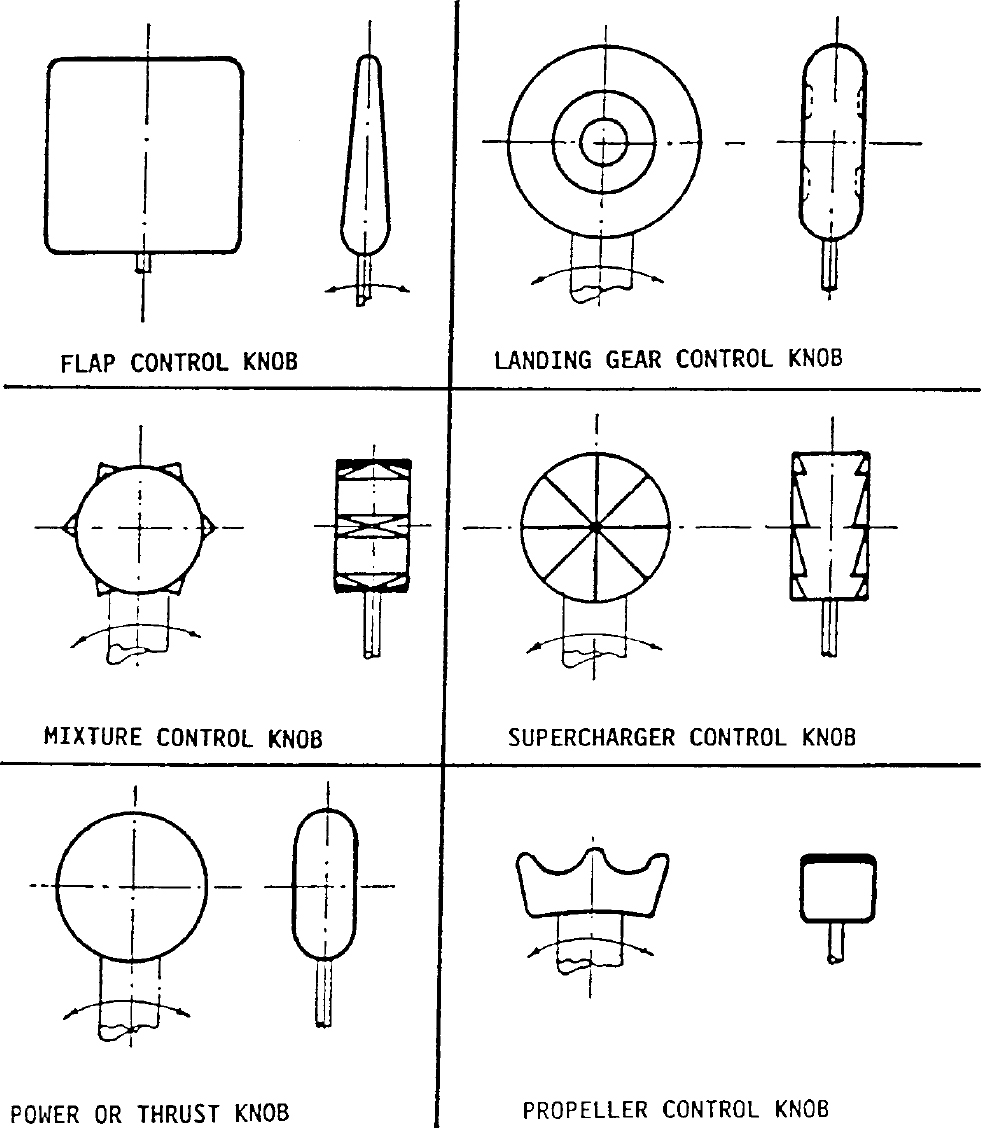

§25.781 Cockpit control knob shape.

Cockpit control knobs must conform to the general shapes (but not necessarily the exact sizes or specific proportions) in the following figure:

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25-72, 55 FR 29779, July 20, 1990]

§25.783 Fuselage doors.

(a) General. This section applies to fuselage doors, which includes all doors, hatches, openable windows, access panels, covers, etc., on the exterior of the fuselage that do not require the use of tools to open or close. This also applies to each door or hatch through a pressure bulkhead, including any bulkhead that is specifically designed to function as a secondary bulkhead under the prescribed failure conditions of part 25. These doors must meet the requirements of this section, taking into account both pressurized and unpressurized flight, and must be designed as follows:

(1) Each door must have means to safeguard against opening in flight as a result of mechanical failure, or failure of any single structural element.

(2) Each door that could be a hazard if it unlatches must be designed so that unlatching during pressurized and unpressurized flight from the fully closed, latched, and locked condition is extremely improbable. This must be shown by safety analysis.

(3) Each element of each door operating system must be designed or, where impracticable, distinctively and permanently marked, to minimize the probability of incorrect assembly and adjustment that could result in a malfunction.

(4) All sources of power that could initiate unlocking or unlatching of any door must be automatically isolated from the latching and locking systems prior to flight and it must not be possible to restore power to the door during flight.

(5) Each removable bolt, screw, nut, pin, or other removable fastener must meet the locking requirements of §25.607.

(6) Certain doors, as specified by §25.807(h), must also meet the applicable requirements of §§25.809 through 25.812 for emergency exits.

(b) Opening by persons. There must be a means to safeguard each door against opening during flight due to inadvertent action by persons. In addition, design precautions must be taken to minimize the possibility for a person to open a door intentionally during flight. If these precautions include the use of auxiliary devices, those devices and their controlling systems must be designed so that—

(1) No single failure will prevent more than one exit from being opened; and

(2) Failures that would prevent opening of the exit after landing are improbable.

(c) Pressurization prevention means. There must be a provision to prevent pressurization of the airplane to an unsafe level if any door subject to pressurization is not fully closed, latched, and locked.

(1) The provision must be designed to function after any single failure, or after any combination of failures not shown to be extremely improbable.

(2) Doors that meet the conditions described in paragraph (h) of this section are not required to have a dedicated pressurization prevention means if, from every possible position of the door, it will remain open to the extent that it prevents pressurization or safely close and latch as pressurization takes place. This must also be shown with any single failure and malfunction, except that—

(i) With failures or malfunctions in the latching mechanism, it need not latch after closing; and

(ii) With jamming as a result of mechanical failure or blocking debris, the door need not close and latch if it can be shown that the pressurization loads on the jammed door or mechanism would not result in an unsafe condition.

(d) Latching and locking. The latching and locking mechanisms must be designed as follows:

(1) There must be a provision to latch each door.

(2) The latches and their operating mechanism must be designed so that, under all airplane flight and ground loading conditions, with the door latched, there is no force or torque tending to unlatch the latches. In addition, the latching system must include a means to secure the latches in the latched position. This means must be independent of the locking system.

(3) Each door subject to pressurization, and for which the initial opening movement is not inward, must—

(i) Have an individual lock for each latch;

(ii) Have the lock located as close as practicable to the latch; and

(iii) Be designed so that, during pressurized flight, no single failure in the locking system would prevent the locks from restraining the latches necessary to secure the door.

(4) Each door for which the initial opening movement is inward, and unlatching of the door could result in a hazard, must have a locking means to prevent the latches from becoming disengaged. The locking means must ensure sufficient latching to prevent opening of the door even with a single failure of the latching mechanism.

(5) It must not be possible to position the lock in the locked position if the latch and the latching mechanism are not in the latched position.

(6) It must not be possible to unlatch the latches with the locks in the locked position. Locks must be designed to withstand the limit loads resulting from—

(i) The maximum operator effort when the latches are operated manually;

(ii) The powered latch actuators, if installed; and

(iii) The relative motion between the latch and the structural counterpart.

(7) Each door for which unlatching would not result in a hazard is not required to have a locking mechanism meeting the requirements of paragraphs (d)(3) through (d)(6) of this section.

(e) Warning, caution, and advisory indications. Doors must be provided with the following indications:

(1) There must be a positive means to indicate at each door operator’s station that all required operations to close, latch, and lock the door(s) have been completed.

(2) There must be a positive means clearly visible from each operator station for any door that could be a hazard if unlatched to indicate if the door is not fully closed, latched, and locked.

(3) There must be a visual means on the flight deck to signal the pilots if any door is not fully closed, latched, and locked. The means must be designed such that any failure or combination of failures that would result in an erroneous closed, latched, and locked indication is improbable for—

(i) Each door that is subject to pressurization and for which the initial opening movement is not inward; or

(ii) Each door that could be a hazard if unlatched.

(4) There must be an aural warning to the pilots prior to or during the initial portion of takeoff roll if any door is not fully closed, latched, and locked, and its opening would prevent a safe takeoff and return to landing.

(f) Visual inspection provision. Each door for which unlatching of the door could be a hazard must have a provision for direct visual inspection to determine, without ambiguity, if the door is fully closed, latched, and locked. The provision must be permanent and discernible under operational lighting conditions, or by means of a flashlight or equivalent light source.

(g) Certain maintenance doors, removable emergency exits, and access panels. Some doors not normally opened except for maintenance purposes or emergency evacuation and some access panels need not comply with certain paragraphs of this section as follows:

(1) Access panels that are not subject to cabin pressurization and would not be a hazard if open during flight need not comply with paragraphs (a) through (f) of this section, but must have a means to prevent inadvertent opening during flight.

(2) Inward-opening removable emergency exits that are not normally removed, except for maintenance purposes or emergency evacuation, and flight deck-openable windows need not comply with paragraphs (c) and (f) of this section.

(3) Maintenance doors that meet the conditions of paragraph (h) of this section, and for which a placard is provided limiting use to maintenance access, need not comply with paragraphs (c) and (f) of this section.

(h) Doors that are not a hazard. For the purposes of this section, a door is considered not to be a hazard in the unlatched condition during flight, provided it can be shown to meet all of the following conditions:

(1) Doors in pressurized compartments would remain in the fully closed position if not restrained by the latches when subject to a pressure greater than 1⁄2 psi. Opening by persons, either inadvertently or intentionally, need not be considered in making this determination.

(2) The door would remain inside the airplane or remain attached to the airplane if it opens either in pressurized or unpressurized portions of the flight. This determination must include the consideration of inadvertent and intentional opening by persons during either pressurized or unpressurized portions of the flight.

(3) The disengagement of the latches during flight would not allow depressurization of the cabin to an unsafe level. This safety assessment must include the physiological effects on the occupants.

(4) The open door during flight would not create aerodynamic interference that could preclude safe flight and landing.

(5) The airplane would meet the structural design requirements with the door open. This assessment must include the aeroelastic stability requirements of §25.629, as well as the strength requirements of subpart C of this part.

(6) The unlatching or opening of the door must not preclude safe flight and landing as a result of interaction with other systems or structures.

[Doc. No. 2003-14193, 69 FR 24501, May 3, 2004]

§25.785 Seats, berths, safety belts, and harnesses.

(a) A seat (or berth for a nonambulant person) must be provided for each occupant who has reached his or her second birthday.

(b) Each seat, berth, safety belt, harness, and adjacent part of the airplane at each station designated as occupiable during takeoff and landing must be designed so that a person making proper use of these facilities will not suffer serious injury in an emergency landing as a result of the inertia forces specified in §§25.561 and 25.562.

(c) Each seat or berth must be approved.

(d) Each occupant of a seat that makes more than an 18-degree angle with the vertical plane containing the airplane centerline must be protected from head injury by a safety belt and an energy absorbing rest that will support the arms, shoulders, head, and spine, or by a safety belt and shoulder harness that will prevent the head from contacting any injurious object. Each occupant of any other seat must be protected from head injury by a safety belt and, as appropriate to the type, location, and angle of facing of each seat, by one or more of the following:

(1) A shoulder harness that will prevent the head from contacting any injurious object.

(2) The elimination of any injurious object within striking radius of the head.

(3) An energy absorbing rest that will support the arms, shoulders, head, and spine.

(e) Each berth must be designed so that the forward part has a padded end board, canvas diaphragm, or equivalent means, that can withstand the static load reaction of the occupant when subjected to the forward inertia force specified in §25.561. Berths must be free from corners and protuberances likely to cause injury to a person occupying the berth during emergency conditions.

(f) Each seat or berth, and its supporting structure, and each safety belt or harness and its anchorage must be designed for an occupant weight of 170 pounds, considering the maximum load factors, inertia forces, and reactions among the occupant, seat, safety belt, and harness for each relevant flight and ground load condition (including the emergency landing conditions prescribed in §25.561). In addition—

(1) The structural analysis and testing of the seats, berths, and their supporting structures may be determined by assuming that the critical load in the forward, sideward, downward, upward, and rearward directions (as determined from the prescribed flight, ground, and emergency landing conditions) acts separately or using selected combinations of loads if the required strength in each specified direction is substantiated. The forward load factor need not be applied to safety belts for berths.

(2) Each pilot seat must be designed for the reactions resulting from the application of the pilot forces prescribed in §25.395.

(3) The inertia forces specified in §25.561 must be multiplied by a factor of 1.33 (instead of the fitting factor prescribed in §25.625) in determining the strength of the attachment of each seat to the structure and each belt or harness to the seat or structure.

(g) Each seat at a flight deck station must have a restraint system consisting of a combined safety belt and shoulder harness with a single-point release that permits the flight deck occupant, when seated with the restraint system fastened, to perform all of the occupant’s necessary flight deck functions. There must be a means to secure each combined restraint system when not in use to prevent interference with the operation of the airplane and with rapid egress in an emergency.

(h) Each seat located in the passenger compartment and designated for use during takeoff and landing by a flight attendant required by the operating rules of this chapter must be:

(1) Near a required floor level emergency exit, except that another location is acceptable if the emergency egress of passengers would be enhanced with that location. A flight attendant seat must be located adjacent to each Type A or B emergency exit. Other flight attendant seats must be evenly distributed among the required floor- level emergency exits to the extent feasible.

(2) To the extent possible, without compromising proximity to a required floor level emergency exit, located to provide a direct view of the cabin area for which the flight attendant is responsible.

(3) Positioned so that the seat will not interfere with the use of a passageway or exit when the seat is not in use.

(4) Located to minimize the probability that occupants would suffer injury by being struck by items dislodged from service areas, stowage compartments, or service equipment.

(5) Either forward or rearward facing with an energy absorbing rest that is designed to support the arms, shoulders, head, and spine.

(6) Equipped with a restraint system consisting of a combined safety belt and shoulder harness unit with a single point release. There must be means to secure each restraint system when not in use to prevent interference with rapid egress in an emergency.

(i) Each safety belt must be equipped with a metal to metal latching device.

(j) If the seat backs do not provide a firm handhold, there must be a handgrip or rail along each aisle to enable persons to steady themselves while using the aisles in moderately rough air.

(k) Each projecting object that would injure persons seated or moving about the airplane in normal flight must be padded.

(l) Each forward observer’s seat required by the operating rules must be shown to be suitable for use in conducting the necessary enroute inspection.

[Amdt. 25-72, 55 FR 29780, July 20, 1990, as amended by Amdt. 25-88, 61 FR 57956, Nov. 8, 1996]

§25.787 Stowage compartments.

(a) Each compartment for the stowage of cargo, baggage, carry-on articles, and equipment (such as life rafts), and any other stowage compartment, must be designed for its placarded maximum weight of contents and for the critical load distribution at the appropriate maximum load factors corresponding to the specified flight and ground load conditions, and to those emergency landing conditions of §25.561(b)(3) for which the breaking loose of the contents of such compartments in the specified direction could—

(1) Cause direct injury to occupants;

(2) Penetrate fuel tanks or lines or cause fire or explosion hazard by damage to adjacent systems; or

(3) Nullify any of the escape facilities provided for use after an emergency landing.

If the airplane has a passenger-seating configuration, excluding pilot seats, of 10 seats or more, each stowage compartment in the passenger cabin, except for under seat and overhead compartments for passenger convenience, must be completely enclosed.

(b) There must be a means to prevent the contents in the compartments from becoming a hazard by shifting, under the loads specified in paragraph (a) of this section. For stowage compartments in the passenger and crew cabin, if the means used is a latched door, the design must take into consideration the wear and deterioration expected in service.

(c) If cargo compartment lamps are installed, each lamp must be installed so as to prevent contact between lamp bulb and cargo.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25-32, 37 FR 3969, Feb. 24, 1972; Amdt. 25-38, 41 FR 55466, Dec. 20, 1976; Amdt. 25-51, 45 FR 7755, Feb. 4, 1980; Amdt. 25-139, 79 FR 59430, Oct. 2, 2014]

§25.789 Retention of items of mass in passenger and crew compartments and galleys.

(a) Means must be provided to prevent each item of mass (that is part of the airplane type design) in a passenger or crew compartment or galley from becoming a hazard by shifting under the appropriate maximum load factors corresponding to the specified flight and ground load conditions, and to the emergency landing conditions of §25.561(b).

(b) Each interphone restraint system must be designed so that when subjected to the load factors specified in §25.561(b)(3), the interphone will remain in its stowed position.

[Amdt. 25-32, 37 FR 3969, Feb. 24, 1972, as amended by Amdt. 25-46, 43 FR 50596, Oct. 30, 1978]

§25.791 Passenger information signs and placards.

(a) If smoking is to be prohibited, there must be at least one placard so stating that is legible to each person seated in the cabin. If smoking is to be allowed, and if the crew compartment is separated from the passenger compartment, there must be at least one sign notifying when smoking is prohibited. Signs which notify when smoking is prohibited must be operable by a member of the flightcrew and, when illuminated, must be legible under all probable conditions of cabin illumination to each person seated in the cabin.

(b) Signs that notify when seat belts should be fastened and that are installed to comply with the operating rules of this chapter must be operable by a member of the flightcrew and, when illuminated, must be legible under all probable conditions of cabin illumination to each person seated in the cabin.

(c) A placard must be located on or adjacent to the door of each receptacle used for the disposal of flammable waste materials to indicate that use of the receptacle for disposal of cigarettes, etc., is prohibited.

(d) Lavatories must have “No Smoking” or “No Smoking in Lavatory” placards conspicuously located on or adjacent to each side of the entry door.

(e) Symbols that clearly express the intent of the sign or placard may be used in lieu of letters.

[Amdt. 25-72, 55 FR 29780, July 20, 1990]

§25.793 Floor surfaces.

The floor surface of all areas which are likely to become wet in service must have slip resistant properties.

[Amdt. 25-51, 45 FR 7755, Feb. 4, 1980]

§25.795 Security considerations.

(a) Protection of flightcrew compartment. If a flightdeck door is required by operating rules:

(1) The bulkhead, door, and any other accessible boundary separating the flightcrew compartment from occupied areas must be designed to resist forcible intrusion by unauthorized persons and be capable of withstanding impacts of 300 joules (221.3 foot pounds).

(2) The bulkhead, door, and any other accessible boundary separating the flightcrew compartment from occupied areas must be designed to resist a constant 250 pound (1,113 Newtons) tensile load on accessible handholds, including the doorknob or handle.

(3) The bulkhead, door, and any other boundary separating the flightcrew compartment from any occupied areas must be designed to resist penetration by small arms fire and fragmentation devices to a level equivalent to level IIIa of the National Institute of Justice (NIJ) Standard 0101.04.

(b) Airplanes with a maximum certificated passenger seating capacity of more than 60 persons or a maximum certificated takeoff gross weight of over 100,000 pounds (45,359 Kilograms) must be designed to limit the effects of an explosive or incendiary device as follows:

(1) Flightdeck smoke protection. Means must be provided to limit entry of smoke, fumes, and noxious gases into the flightdeck.

(2) Passenger cabin smoke protection. Means must be provided to prevent passenger incapacitation in the cabin resulting from smoke, fumes, and noxious gases as represented by the initial combined volumetric concentrations of 0.59% carbon monoxide and 1.23% carbon dioxide.

(3) Cargo compartment fire suppression. An extinguishing agent must be capable of suppressing a fire. All cargo-compartment fire suppression systems must be designed to withstand the following effects, including support structure displacements or adjacent materials displacing against the distribution system:

(i) Impact or damage from a 0.5-inch diameter aluminum sphere traveling at 430 feet per second (131.1 meters per second);

(ii) A 15-pound per square-inch (103.4 kPa) pressure load if the projected surface area of the component is greater than 4 square feet. Any single dimension greater than 4 feet (1.22 meters) may be assumed to be 4 feet (1.22 meters) in length; and

(iii) A 6-inch (0.152 meters) displacement, except where limited by the fuselage contour, from a single point force applied anywhere along the distribution system where relative movement between the system and its attachment can occur.

(iv) Paragraphs (b)(3)(i) through (iii) of this section do not apply to components that are redundant and separated in accordance with paragraph (c)(2) of this section or are installed remotely from the cargo compartment.

(c) An airplane with a maximum certificated passenger seating capacity of more than 60 persons or a maximum certificated takeoff gross weight of over 100,000 pounds (45,359 Kilograms) must comply with the following:

(1) Least risk bomb location. An airplane must be designed with a designated location where a bomb or other explosive device could be placed to best protect flight-critical structures and systems from damage in the case of detonation.

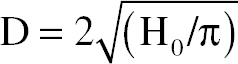

(2) Survivability of systems. (i) Except where impracticable, redundant airplane systems necessary for continued safe flight and landing must be physically separated, at a minimum, by an amount equal to a sphere of diameter

(where H0 is defined under §25.365(e)(2) of this part and D need not exceed 5.05 feet (1.54 meters)). The sphere is applied everywhere within the fuselage—limited by the forward bulkhead and the aft bulkhead of the passenger cabin and cargo compartment beyond which only one-half the sphere is applied.

(ii) Where compliance with paragraph (c)(2)(i) of this section is impracticable, other design precautions must be taken to maximize the survivability of those systems.

(3) Interior design to facilitate searches. Design features must be incorporated that will deter concealment or promote discovery of weapons, explosives, or other objects from a simple inspection in the following areas of the airplane cabin:

(i) Areas above the overhead bins must be designed to prevent objects from being hidden from view in a simple search from the aisle. Designs that prevent concealment of objects with volumes 20 cubic inches and greater satisfy this requirement.

(ii) Toilets must be designed to prevent the passage of solid objects greater than 2.0 inches in diameter.

(iii) Life preservers or their storage locations must be designed so that tampering is evident.

(d) Each chemical oxygen generator or its installation must be designed to be secure from deliberate manipulation by one of the following:

(1) By providing effective resistance to tampering,

(2) By providing an effective combination of resistance to tampering and active tamper-evident features,

(3) By installation in a location or manner whereby any attempt to access the generator would be immediately obvious, or

(4) By a combination of approaches specified in paragraphs (d)(1), (d)(2) and (d)(3) of this section that the Administrator finds provides a secure installation.

(e) Exceptions. Airplanes used solely to transport cargo only need to meet the requirements of paragraphs (b)(1), (b)(3), and (c)(2) of this section.

(f) Material Incorporated by Reference. You must use National Institute of Justice (NIJ) Standard 0101.04, Ballistic Resistance of Personal Body Armor, June 2001, Revision A, to establish ballistic resistance as required by paragraph (a)(3) of this section.

(1) The Director of the Federal Register approved the incorporation by reference of this document under 5 U.S.C. 552(a) and 1 CFR part 51.

(2) You may review copies of NIJ Standard 0101.04 at the:

(i) National Institute of Justice (NIJ), http://www.ojp.usdoj.gov/nij, telephone (202) 307-2942; or

(ii) National Archives and Records Administration (NARA). For information on the availability of this material at NARA, call (202) 741-6030, or go to http://www.archives.gov/federal-register/cfr/ibr-locations.html.

(3) You may obtain copies of NIJ Standard 0101.04 from the National Criminal Justice Reference Service, P.O. Box 6000, Rockville, MD 20849-6000, telephone (800) 851-3420.

[Amdt. 25-127; 121-341, 73 FR 63879, Oct. 28, 2008, as amended at 74 FR 22819, May 15, 2009; Amdt. 25-138, 79 FR 13519, Mar. 11, 2014; Doc. No. FAA-2018-0119, Amdt. 25-145, 83 FR 9169, Mar. 5, 2018]

EMERGENCY PROVISIONS

§25.801 Ditching.

(a) If certification with ditching provisions is requested, the airplane must meet the requirements of this section and §§25.807(e), 25.1411, and 25.1415(a).

(b) Each practicable design measure, compatible with the general characteristics of the airplane, must be taken to minimize the probability that in an emergency landing on water, the behavior of the airplane would cause immediate injury to the occupants or would make it impossible for them to escape.

(c) The probable behavior of the airplane in a water landing must be investigated by model tests or by comparison with airplanes of similar configuration for which the ditching characteristics are known. Scoops, flaps, projections, and any other factor likely to affect the hydrodynamic characteristics of the airplane, must be considered.

(d) It must be shown that, under reasonably probable water conditions, the flotation time and trim of the airplane will allow the occupants to leave the airplane and enter the liferafts required by §25.1415. If compliance with this provision is shown by buoyancy and trim computations, appropriate allowances must be made for probable structural damage and leakage. If the airplane has fuel tanks (with fuel jettisoning provisions) that can reasonably be expected to withstand a ditching without leakage, the jettisonable volume of fuel may be considered as buoyancy volume.

(e) Unless the effects of the collapse of external doors and windows are accounted for in the investigation of the probable behavior of the airplane in a water landing (as prescribed in paragraphs (c) and (d) of this section), the external doors and windows must be designed to withstand the probable maximum local pressures.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25-72, 55 FR 29781, July 20, 1990]

§25.803 Emergency evacuation.

(a) Each crew and passenger area must have emergency means to allow rapid evacuation in crash landings, with the landing gear extended as well as with the landing gear retracted, considering the possibility of the airplane being on fire.

(b) [Reserved]

(c) For airplanes having a seating capacity of more than 44 passengers, it must be shown that the maximum seating capacity, including the number of crewmembers required by the operating rules for which certification is requested, can be evacuated from the airplane to the ground under simulated emergency conditions within 90 seconds. Compliance with this requirement must be shown by actual demonstration using the test criteria outlined in appendix J of this part unless the Administrator finds that a combination of analysis and testing will provide data equivalent to that which would be obtained by actual demonstration.

(d)-(e) [Reserved]

[Doc. No. 24344, 55 FR 29781, July 20, 1990]

§25.807 Emergency exits.

(a) Type. For the purpose of this part, the types of exits are defined as follows:

(1) Type I. This type is a floor-level exit with a rectangular opening of not less than 24 inches wide by 48 inches high, with corner radii not greater than eight inches.

(2) Type II. This type is a rectangular opening of not less than 20 inches wide by 44 inches high, with corner radii not greater than seven inches. Type II exits must be floor-level exits unless located over the wing, in which case they must not have a step-up inside the airplane of more than 10 inches nor a step-down outside the airplane of more than 17 inches.

(3) Type III. This type is a rectangular opening of not less than 20 inches wide by 36 inches high with corner radii not greater than seven inches, and with a step-up inside the airplane of not more than 20 inches. If the exit is located over the wing, the step-down outside the airplane may not exceed 27 inches.

(4) Type IV. This type is a rectangular opening of not less than 19 inches wide by 26 inches high, with corner radii not greater than 6.3 inches, located over the wing, with a step-up inside the airplane of not more than 29 inches and a step-down outside the airplane of not more than 36 inches.

(5) Ventral. This type is an exit from the passenger compartment through the pressure shell and the bottom fuselage skin. The dimensions and physical configuration of this type of exit must allow at least the same rate of egress as a Type I exit with the airplane in the normal ground attitude, with landing gear extended.

(6) Tailcone. This type is an aft exit from the passenger compartment through the pressure shell and through an openable cone of the fuselage aft of the pressure shell. The means of opening the tailcone must be simple and obvious and must employ a single operation.

(7) Type A. This type is a floor-level exit with a rectangular opening of not less than 42 inches wide by 72 inches high, with corner radii not greater than seven inches.

(8) Type B. This type is a floor-level exit with a rectangular opening of not less than 32 inches wide by 72 inches high, with corner radii not greater than six inches.

(9) Type C. This type is a floor-level exit with a rectangular opening of not less than 30 inches wide by 48 inches high, with corner radii not greater than 10 inches.

(b) Step down distance. Step down distance, as used in this section, means the actual distance between the bottom of the required opening and a usable foot hold, extending out from the fuselage, that is large enough to be effective without searching by sight or feel.

(c) Over-sized exits. Openings larger than those specified in this section, whether or not of rectangular shape, may be used if the specified rectangular opening can be inscribed within the opening and the base of the inscribed rectangular opening meets the specified step-up and step-down heights.

(d) Asymmetry. Exits of an exit pair need not be diametrically opposite each other nor of the same size; however, the number of passenger seats permitted under paragraph (g) of this section is based on the smaller of the two exits.

(e) Uniformity. Exits must be distributed as uniformly as practical, taking into account passenger seat distribution.

(f) Location. (1) Each required passenger emergency exit must be accessible to the passengers and located where it will afford the most effective means of passenger evacuation.

(2) If only one floor-level exit per side is prescribed, and the airplane does not have a tailcone or ventral emergency exit, the floor-level exits must be in the rearward part of the passenger compartment unless another location affords a more effective means of passenger evacuation.

(3) If more than one floor-level exit per side is prescribed, and the airplane does not have a combination cargo and passenger configuration, at least one floor-level exit must be located in each side near each end of the cabin.

(4) For an airplane that is required to have more than one passenger emergency exit for each side of the fuselage, no passenger emergency exit shall be more than 60 feet from any adjacent passenger emergency exit on the same side of the same deck of the fuselage, as measured parallel to the airplane’s longitudinal axis between the nearest exit edges.

(g) Type and number required. The maximum number of passenger seats permitted depends on the type and number of exits installed in each side of the fuselage. Except as further restricted in paragraphs (g)(1) through (g)(9) of this section, the maximum number of passenger seats permitted for each exit of a specific type installed in each side of the fuselage is as follows:

Type A |

110 |

Type B |

75 |

Type C |

55 |

Type I |

45 |

Type II |

40 |

Type III |

35 |

Type IV |

9 |

(1) For a passenger seating configuration of 1 to 9 seats, there must be at least one Type IV or larger overwing exit in each side of the fuselage or, if overwing exits are not provided, at least one exit in each side that meets the minimum dimensions of a Type III exit.

(2) For a passenger seating configuration of more than 9 seats, each exit must be a Type III or larger exit.

(3) For a passenger seating configuration of 10 to 19 seats, there must be at least one Type III or larger exit in each side of the fuselage.

(4) For a passenger seating configuration of 20 to 40 seats, there must be at least two exits, one of which must be a Type II or larger exit, in each side of the fuselage.

(5) For a passenger seating configuration of 41 to 110 seats, there must be at least two exits, one of which must be a Type I or larger exit, in each side of the fuselage.

(6) For a passenger seating configuration of more than 110 seats, the emergency exits in each side of the fuselage must include at least two Type I or larger exits.

(7) The combined maximum number of passenger seats permitted for all Type III exits is 70, and the combined maximum number of passenger seats permitted for two Type III exits in each side of the fuselage that are separated by fewer than three passenger seat rows is 65.

(8) If a Type A, Type B, or Type C exit is installed, there must be at least two Type C or larger exits in each side of the fuselage.

(9) If a passenger ventral or tailcone exit is installed and that exit provides at least the same rate of egress as a Type III exit with the airplane in the most adverse exit opening condition that would result from the collapse of one or more legs of the landing gear, an increase in the passenger seating configuration is permitted as follows:

(i) For a ventral exit, 12 additional passenger seats.

(ii) For a tailcone exit incorporating a floor level opening of not less than 20 inches wide by 60 inches high, with corner radii not greater than seven inches, in the pressure shell and incorporating an approved assist means in accordance with §25.810(a), 25 additional passenger seats.

(iii) For a tailcone exit incorporating an opening in the pressure shell which is at least equivalent to a Type III emergency exit with respect to dimensions, step-up and step-down distance, and with the top of the opening not less than 56 inches from the passenger compartment floor, 15 additional passenger seats.

(h) Other exits. The following exits also must meet the applicable emergency exit requirements of §§25.809 through 25.812, and must be readily accessible:

(1) Each emergency exit in the passenger compartment in excess of the minimum number of required emergency exits.

(2) Any other floor-level door or exit that is accessible from the passenger compartment and is as large or larger than a Type II exit, but less than 46 inches wide.

(3) Any other ventral or tail cone passenger exit.

(i) Ditching emergency exits for passengers. Whether or not ditching certification is requested, ditching emergency exits must be provided in accordance with the following requirements, unless the emergency exits required by paragraph (g) of this section already meet them:

(1) For airplanes that have a passenger seating configuration of nine or fewer seats, excluding pilot seats, one exit above the waterline in each side of the airplane, meeting at least the dimensions of a Type IV exit.

(2) For airplanes that have a passenger seating configuration of 10 of more seats, excluding pilot seats, one exit above the waterline in a side of the airplane, meeting at least the dimensions of a Type III exit for each unit (or part of a unit) of 35 passenger seats, but no less than two such exits in the passenger cabin, with one on each side of the airplane. The passenger seat/ exit ratio may be increased through the use of larger exits, or other means, provided it is shown that the evacuation capability during ditching has been improved accordingly.

(3) If it is impractical to locate side exits above the waterline, the side exits must be replaced by an equal number of readily accessible overhead hatches of not less than the dimensions of a Type III exit, except that for airplanes with a passenger configuration of 35 or fewer seats, excluding pilot seats, the two required Type III side exits need be replaced by only one overhead hatch.

(j) Flightcrew emergency exits. For airplanes in which the proximity of passenger emergency exits to the flightcrew area does not offer a convenient and readily accessible means of evacuation of the flightcrew, and for all airplanes having a passenger seating capacity greater than 20, flightcrew exits shall be located in the flightcrew area. Such exits shall be of sufficient size and so located as to permit rapid evacuation by the crew. One exit shall be provided on each side of the airplane; or, alternatively, a top hatch shall be provided. Each exit must encompass an unobstructed rectangular opening of at least 19 by 20 inches unless satisfactory exit utility can be demonstrated by a typical crewmember.

[Amdt. 25-72, 55 FR 29781, July 20, 1990, as amended by Amdt. 25-88, 61 FR 57956, Nov. 8, 1996; 62 FR 1817, Jan. 13, 1997; Amdt. 25-94, 63 FR 8848, Feb. 23, 1998; 63 FR 12862, Mar. 16, 1998; Amdt. 25-114, 69 FR 24502, May 3, 2004]

§25.809 Emergency exit arrangement.

(a) Each emergency exit, including each flightcrew emergency exit, must be a moveable door or hatch in the external walls of the fuselage, allowing an unobstructed opening to the outside. In addition, each emergency exit must have means to permit viewing of the conditions outside the exit when the exit is closed. The viewing means may be on or adjacent to the exit provided no obstructions exist between the exit and the viewing means. Means must also be provided to permit viewing of the likely areas of evacuee ground contact. The likely areas of evacuee ground contact must be viewable during all lighting conditions with the landing gear extended as well as in all conditions of landing gear collapse.

(b) Each emergency exit must be openable from the inside and the outside except that sliding window emergency exits in the flight crew area need not be openable from the outside if other approved exits are convenient and readily accessible to the flight crew area. Each emergency exit must be capable of being opened, when there is no fuselage deformation—

(1) With the airplane in the normal ground attitude and in each of the attitudes corresponding to collapse of one or more legs of the landing gear; and

(2) Within 10 seconds measured from the time when the opening means is actuated to the time when the exit is fully opened.

(3) Even though persons may be crowded against the door on the inside of the airplane.

(c) The means of opening emergency exits must be simple and obvious; may not require exceptional effort; and must be arranged and marked so that it can be readily located and operated, even in darkness. Internal exit-opening means involving sequence operations (such as operation of two handles or latches, or the release of safety catches) may be used for flightcrew emergency exits if it can be reasonably established that these means are simple and obvious to crewmembers trained in their use.

(d) If a single power-boost or single power-operated system is the primary system for operating more than one exit in an emergency, each exit must be capable of meeting the requirements of paragraph (b) of this section in the event of failure of the primary system. Manual operation of the exit (after failure of the primary system) is acceptable.

(e) Each emergency exit must be shown by tests, or by a combination of analysis and tests, to meet the requirements of paragraphs (b) and (c) of this section.

(f) Each door must be located where persons using them will not be endangered by the propellers when appropriate operating procedures are used.

(g) There must be provisions to minimize the probability of jamming of the emergency exits resulting from fuselage deformation in a minor crash landing.

(h) When required by the operating rules for any large passenger-carrying turbojet-powered airplane, each ventral exit and tailcone exit must be—

(1) Designed and constructed so that it cannot be opened during flight; and

(2) Marked with a placard readable from a distance of 30 inches and installed at a conspicuous location near the means of opening the exit, stating that the exit has been designed and constructed so that it cannot be opened during flight.

(i) Each emergency exit must have a means to retain the exit in the open position, once the exit is opened in an emergency. The means must not require separate action to engage when the exit is opened, and must require positive action to disengage.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25-15, 32 FR 13264, Sept. 20, 1967; Amdt. 25-32, 37 FR 3970, Feb. 24, 1972; Amdt. 25-34, 37 FR 25355, Nov. 30, 1972; Amdt. 25-46, 43 FR 50597, Oct. 30, 1978; Amdt. 25-47, 44 FR 61325, Oct. 25, 1979; Amdt. 25-72, 55 FR 29782, July 20, 1990; Amdt. 25-114, 69 FR 24502, May 3, 2004; Amdt. 25-116, 69 FR 62788, Oct. 27, 2004]

§25.810 Emergency egress assist means and escape routes.

(a) Each non over-wing Type A, Type B or Type C exit, and any other non over-wing landplane emergency exit more than 6 feet from the ground with the airplane on the ground and the landing gear extended, must have an approved means to assist the occupants in descending to the ground.

(1) The assisting means for each passenger emergency exit must be a self-supporting slide or equivalent; and, in the case of Type A or Type B exits, it must be capable of carrying simultaneously two parallel lines of evacuees. In addition, the assisting means must be designed to meet the following requirements—

(i) It must be automatically deployed and deployment must begin during the interval between the time the exit opening means is actuated from inside the airplane and the time the exit is fully opened. However, each passenger emergency exit which is also a passenger entrance door or a service door must be provided with means to prevent deployment of the assisting means when it is opened from either the inside or the outside under nonemergency conditions for normal use.

(ii) Except for assisting means installed at Type C exits, it must be automatically erected within 6 seconds after deployment is begun. Assisting means installed at Type C exits must be automatically erected within 10 seconds from the time the opening means of the exit is actuated.

(iii) It must be of such length after full deployment that the lower end is self-supporting on the ground and provides safe evacuation of occupants to the ground after collapse of one or more legs of the landing gear.

(iv) It must have the capability, in 25-knot winds directed from the most critical angle, to deploy and, with the assistance of only one person, to remain usable after full deployment to evacuate occupants safely to the ground.

(v) For each system installation (mockup or airplane installed), five consecutive deployment and inflation tests must be conducted (per exit) without failure, and at least three tests of each such five-test series must be conducted using a single representative sample of the device. The sample devices must be deployed and inflated by the system’s primary means after being subjected to the inertia forces specified in §25.561(b). If any part of the system fails or does not function properly during the required tests, the cause of the failure or malfunction must be corrected by positive means and after that, the full series of five consecutive deployment and inflation tests must be conducted without failure.

(2) The assisting means for flightcrew emergency exits may be a rope or any other means demonstrated to be suitable for the purpose. If the assisting means is a rope, or an approved device equivalent to a rope, it must be—

(i) Attached to the fuselage structure at or above the top of the emergency exit opening, or, for a device at a pilot’s emergency exit window, at another approved location if the stowed device, or its attachment, would reduce the pilot’s view in flight;

(ii) Able (with its attachment) to withstand a 400-pound static load.

(b) Assist means from the cabin to the wing are required for each type A or Type B exit located above the wing and having a stepdown unless the exit without an assist-means can be shown to have a rate of passenger egress at least equal to that of the same type of non over-wing exit. If an assist means is required, it must be automatically deployed and automatically erected concurrent with the opening of the exit. In the case of assist means installed at Type C exits, it must be self-supporting within 10 seconds from the time the opening means of the exits is actuated. For all other exit types, it must be self-supporting 6 seconds after deployment is begun.

(c) An escape route must be established from each overwing emergency exit, and (except for flap surfaces suitable as slides) covered with a slip resistant surface. Except where a means for channeling the flow of evacuees is provided—

(1) The escape route from each Type A or Type B passenger emergency exit, or any common escape route from two Type III passenger emergency exits, must be at least 42 inches wide; that from any other passenger emergency exit must be at least 24 inches wide; and

(2) The escape route surface must have a reflectance of at least 80 percent, and must be defined by markings with a surface-to-marking contrast ratio of at least 5:1.

(d) Means must be provided to assist evacuees to reach the ground for all Type C exits located over the wing and, if the place on the airplane structure at which the escape route required in paragraph (c) of this section terminates is more than 6 feet from the ground with the airplane on the ground and the landing gear extended, for all other exit types.

(1) If the escape route is over the flap, the height of the terminal edge must be measured with the flap in the takeoff or landing position, whichever is higher from the ground.

(2) The assisting means must be usable and self-supporting with one or more landing gear legs collapsed and under a 25-knot wind directed from the most critical angle.

(3) The assisting means provided for each escape route leading from a Type A or B emergency exit must be capable of carrying simultaneously two parallel lines of evacuees; and, the assisting means leading from any other exit type must be capable of carrying as many parallel lines of evacuees as there are required escape routes.

(4) The assisting means provided for each escape route leading from a Type C exit must be automatically erected within 10 seconds from the time the opening means of the exit is actuated, and that provided for the escape route leading from any other exit type must be automatically erected within 10 seconds after actuation of the erection system.

(e) If an integral stair is installed in a passenger entry door that is qualified as a passenger emergency exit, the stair must be designed so that, under the following conditions, the effectiveness of passenger emergency egress will not be impaired:

(1) The door, integral stair, and operating mechanism have been subjected to the inertia forces specified in §25.561(b)(3), acting separately relative to the surrounding structure.

(2) The airplane is in the normal ground attitude and in each of the attitudes corresponding to collapse of one or more legs of the landing gear.

[Amdt. 25-72, 55 FR 29782, July 20, 1990, as amended by Amdt. 25-88, 61 FR 57958, Nov. 8, 1996; 62 FR 1817, Jan. 13, 1997; Amdt. 25-114, 69 FR 24502, May 3, 2004]

§25.811 Emergency exit marking.

(a) Each passenger emergency exit, its means of access, and its means of opening must be conspicuously marked.

(b) The identity and location of each passenger emergency exit must be recognizable from a distance equal to the width of the cabin.

(c) Means must be provided to assist the occupants in locating the exits in conditions of dense smoke.

(d) The location of each passenger emergency exit must be indicated by a sign visible to occupants approaching along the main passenger aisle (or aisles). There must be—

(1) A passenger emergency exit locator sign above the aisle (or aisles) near each passenger emergency exit, or at another overhead location if it is more practical because of low headroom, except that one sign may serve more than one exit if each exit can be seen readily from the sign;

(2) A passenger emergency exit marking sign next to each passenger emergency exit, except that one sign may serve two such exits if they both can be seen readily from the sign; and

(3) A sign on each bulkhead or divider that prevents fore and aft vision along the passenger cabin to indicate emergency exits beyond and obscured by the bulkhead or divider, except that if this is not possible the sign may be placed at another appropriate location.

(e) The location of the operating handle and instructions for opening exits from the inside of the airplane must be shown in the following manner:

(1) Each passenger emergency exit must have, on or near the exit, a marking that is readable from a distance of 30 inches.

(2) Each Type A, Type B, Type C or Type I passenger emergency exit operating handle must—

(i) Be self-illuminated with an initial brightness of at least 160 microlamberts; or

(ii) Be conspicuously located and well illuminated by the emergency lighting even in conditions of occupant crowding at the exit.

(3) [Reserved]

(4) Each Type A, Type B, Type C, Type I, or Type II passenger emergency exit with a locking mechanism released by rotary motion of the handle must be marked—

(i) With a red arrow, with a shaft at least three-fourths of an inch wide and a head twice the width of the shaft, extending along at least 70 degrees of arc at a radius approximately equal to three-fourths of the handle length.

(ii) So that the centerline of the exit handle is within ±1 inch of the projected point of the arrow when the handle has reached full travel and has released the locking mechanism, and

(iii) With the word “open” in red letters 1 inch high, placed horizontally near the head of the arrow.

(f) Each emergency exit that is required to be openable from the outside, and its means of opening, must be marked on the outside of the airplane. In addition, the following apply:

(1) The outside marking for each passenger emergency exit in the side of the fuselage must include a 2-inch colored band outlining the exit.

(2) Each outside marking including the band, must have color contrast to be readily distinguishable from the surrounding fuselage surface. The contrast must be such that if the reflectance of the darker color is 15 percent or less, the reflectance of the lighter color must be at least 45 percent. “Reflectance” is the ratio of the luminous flux reflected by a body to the luminous flux it receives. When the reflectance of the darker color is greater than 15 percent, at least a 30-percent difference between its reflectance and the reflectance of the lighter color must be provided.

(3) In the case of exists other than those in the side of the fuselage, such as ventral or tailcone exists, the external means of opening, including instructions if applicable, must be conspicuously marked in red, or bright chrome yellow if the background color is such that red is inconspicuous. When the opening means is located on only one side of the fuselage, a conspicuous marking to that effect must be provided on the other side.

(g) Each sign required by paragraph (d) of this section may use the word “exit” in its legend in place of the term “emergency exit”.

[Amdt. 25-15, 32 FR 13264, Sept. 20, 1967, as amended by Amdt. 25-32, 37 FR 3970, Feb. 24, 1972; Amdt. 25-46, 43 FR 50597, Oct. 30, 1978; 43 FR 52495, Nov. 13, 1978; Amdt. 25-79, 58 FR 45229, Aug. 26, 1993; Amdt. 25-88, 61 FR 57958, Nov. 8, 1996]

§25.812 Emergency lighting.

(a) An emergency lighting system, independent of the main lighting system, must be installed. However, the sources of general cabin illumination may be common to both the emergency and the main lighting systems if the power supply to the emergency lighting system is independent of the power supply to the main lighting system. The emergency lighting system must include:

(1) Illuminated emergency exit marking and locating signs, sources of general cabin illumination, interior lighting in emergency exit areas, and floor proximity escape path marking.

(2) Exterior emergency lighting.

(b) Emergency exit signs—

(1) For airplanes that have a passenger seating configuration, excluding pilot seats, of 10 seats or more must meet the following requirements:

(i) Each passenger emergency exit locator sign required by §25.811(d)(1) and each passenger emergency exit marking sign required by §25.811(d)(2) must have red letters at least 11⁄2 inches high on an illuminated white background, and must have an area of at least 21 square inches excluding the letters. The lighted background-to-letter contrast must be at least 10:1. The letter height to stroke-width ratio may not be more than 7:1 nor less than 6:1. These signs must be internally electrically illuminated with a background brightness of at least 25 foot-lamberts and a high-to-low background contrast no greater than 3:1.

(ii) Each passenger emergency exit sign required by §25.811(d)(3) must have red letters at least 11⁄2 inches high on a white background having an area of at least 21 square inches excluding the letters. These signs must be internally electrically illuminated or self-illuminated by other than electrical means and must have an initial brightness of at least 400 microlamberts. The colors may be reversed in the case of a sign that is self-illuminated by other than electrical means.

(2) For airplanes that have a passenger seating configuration, excluding pilot seats, of nine seats or less, that are required by §25.811(d)(1), (2), and (3) must have red letters at least 1 inch high on a white background at least 2 inches high. These signs may be internally electrically illuminated, or self-illuminated by other than electrical means, with an initial brightness of at least 160 microlamberts. The colors may be reversed in the case of a sign that is self-illuminated by other than electrical means.

(c) General illumination in the passenger cabin must be provided so that when measured along the centerline of main passenger aisle(s), and cross aisle(s) between main aisles, at seat arm-rest height and at 40-inch intervals, the average illumination is not less than 0.05 foot-candle and the illumination at each 40-inch interval is not less than 0.01 foot-candle. A main passenger aisle(s) is considered to extend along the fuselage from the most forward passenger emergency exit or cabin occupant seat, whichever is farther forward, to the most rearward passenger emergency exit or cabin occupant seat, whichever is farther aft.

(d) The floor of the passageway leading to each floor-level passenger emergency exit, between the main aisles and the exit openings, must be provided with illumination that is not less than 0.02 foot-candle measured along a line that is within 6 inches of and parallel to the floor and is centered on the passenger evacuation path.

(e) Floor proximity emergency escape path marking must provide emergency evacuation guidance for passengers when all sources of illumination more than 4 feet above the cabin aisle floor are totally obscured. In the dark of the night, the floor proximity emergency escape path marking must enable each passenger to—

(1) After leaving the passenger seat, visually identify the emergency escape path along the cabin aisle floor to the first exits or pair of exits forward and aft of the seat; and

(2) Readily identify each exit from the emergency escape path by reference only to markings and visual features not more than 4 feet above the cabin floor.

(f) Except for subsystems provided in accordance with paragraph (h) of this section that serve no more than one assist means, are independent of the airplane’s main emergency lighting system, and are automatically activated when the assist means is erected, the emergency lighting system must be designed as follows.

(1) The lights must be operable manually from the flight crew station and from a point in the passenger compartment that is readily accessible to a normal flight attendant seat.

(2) There must be a flight crew warning light which illuminates when power is on in the airplane and the emergency lighting control device is not armed.

(3) The cockpit control device must have an “on,” “off,” and “armed” position so that when armed in the cockpit or turned on at either the cockpit or flight attendant station the lights will either light or remain lighted upon interruption (except an interruption caused by a transverse vertical separation of the fuselage during crash landing) of the airplane’s normal electric power. There must be a means to safeguard against inadvertent operation of the control device from the “armed” or “on” positions.

(g) Exterior emergency lighting must be provided as follows:

(1) At each overwing emergency exit the illumination must be—

(i) Not less than 0.03 foot-candle (measured normal to the direction of the incident light) on a 2-square-foot area where an evacuee is likely to make his first step outside the cabin;

(ii) Not less than 0.05 foot-candle (measured normal to the direction of the incident light) for a minimum width of 42 inches for a Type A overwing emergency exit and two feet for all other overwing emergency exits along the 30 percent of the slip-resistant portion of the escape route required in §25.810(c) that is farthest from the exit; and

(iii) Not less than 0.03 foot-candle on the ground surface with the landing gear extended (measured normal to the direction of the incident light) where an evacuee using the established escape route would normally make first contact with the ground.

(2) At each non-overwing emergency exit not required by §25.810(a) to have descent assist means the illumination must be not less than 0.03 foot-candle (measured normal to the direction of the incident light) on the ground surface with the landing gear extended where an evacuee is likely to make first contact with the ground outside the cabin.

(h) The means required in §§25.810(a)(1) and (d) to assist the occupants in descending to the ground must be illuminated so that the erected assist means is visible from the airplane.

(1) If the assist means is illuminated by exterior emergency lighting, it must provide illumination of not less than 0.03 foot-candle (measured normal to the direction of the incident light) at the ground end of the erected assist means where an evacuee using the established escape route would normally make first contact with the ground, with the airplane in each of the attitudes corresponding to the collapse of one or more legs of the landing gear.

(2) If the emergency lighting subsystem illuminating the assist means serves no other assist means, is independent of the airplane’s main emergency lighting system, and is automatically activated when the assist means is erected, the lighting provisions—

(i) May not be adversely affected by stowage; and

(ii) Must provide illumination of not less than 0.03 foot-candle (measured normal to the direction of incident light) at the ground and of the erected assist means where an evacuee would normally make first contact with the ground, with the airplane in each of the attitudes corresponding to the collapse of one or more legs of the landing gear.

(i) The energy supply to each emergency lighting unit must provide the required level of illumination for at least 10 minutes at the critical ambient conditions after emergency landing.

(j) If storage batteries are used as the energy supply for the emergency lighting system, they may be recharged from the airplane’s main electric power system: Provided, That, the charging circuit is designed to preclude inadvertent battery discharge into charging circuit faults.

(k) Components of the emergency lighting system, including batteries, wiring relays, lamps, and switches must be capable of normal operation after having been subjected to the inertia forces listed in §25.561(b).

(l) The emergency lighting system must be designed so that after any single transverse vertical separation of the fuselage during crash landing—

(1) Not more than 25 percent of all electrically illuminated emergency lights required by this section are rendered inoperative, in addition to the lights that are directly damaged by the separation;

(2) Each electrically illuminated exit sign required under §25.811(d)(2) remains operative exclusive of those that are directly damaged by the separation; and

(3) At least one required exterior emergency light for each side of the airplane remains operative exclusive of those that are directly damaged by the separation.

[Amdt. 25-15, 32 FR 13265, Sept. 20, 1967, as amended by Amdt. 25-28, 36 FR 16899, Aug. 26, 1971; Amdt. 25-32, 37 FR 3971, Feb. 24, 1972; Amdt. 25-46, 43 FR 50597, Oct. 30, 1978; Amdt. 25-58, 49 FR 43186, Oct. 26, 1984; Amdt. 25-88, 61 FR 57958, Nov. 8, 1996; Amdt. 25-116, 69 FR 62788, Oct. 27, 2004; Amdt. 25-128, 74 FR 25645, May 29, 2009]

§25.813 Emergency exit access.

Each required emergency exit must be accessible to the passengers and located where it will afford an effective means of evacuation. Emergency exit distribution must be as uniform as practical, taking passenger distribution into account; however, the size and location of exits on both sides of the cabin need not be symmetrical. If only one floor level exit per side is prescribed, and the airplane does not have a tailcone or ventral emergency exit, the floor level exit must be in the rearward part of the passenger compartment, unless another location affords a more effective means of passenger evacuation. Where more than one floor level exit per side is prescribed, at least one floor level exit per side must be located near each end of the cabin, except that this provision does not apply to combination cargo/passenger configurations. In addition—

(a) There must be a passageway leading from the nearest main aisle to each Type A, Type B, Type C, Type I, or Type II emergency exit and between individual passenger areas. Each passageway leading to a Type A or Type B exit must be unobstructed and at least 36 inches wide. Passageways between individual passenger areas and those leading to Type I, Type II, or Type C emergency exits must be unobstructed and at least 20 inches wide. Unless there are two or more main aisles, each Type A or B exit must be located so that there is passenger flow along the main aisle to that exit from both the forward and aft directions. If two or more main aisles are provided, there must be unobstructed cross-aisles at least 20 inches wide between main aisles. There must be—

(1) A cross-aisle which leads directly to each passageway between the nearest main aisle and a Type A or B exit; and

(2) A cross-aisle which leads to the immediate vicinity of each passageway between the nearest main aisle and a Type 1, Type II, or Type III exit; except that when two Type III exits are located within three passenger rows of each other, a single cross-aisle may be used if it leads to the vicinity between the passageways from the nearest main aisle to each exit.

(b) Adequate space to allow crewmember(s) to assist in the evacuation of passengers must be provided as follows:

(1) Each assist space must be a rectangle on the floor, of sufficient size to enable a crewmember, standing erect, to effectively assist evacuees. The assist space must not reduce the unobstructed width of the passageway below that required for the exit.

(2) For each Type A or B exit, assist space must be provided at each side of the exit regardless of whether an assist means is required by §25.810(a).

(3) For each Type C, I or II exit installed in an airplane with seating for more than 80 passengers, an assist space must be provided at one side of the passageway regardless of whether an assist means is required by §25.810(a).

(4) For each Type C, I or II exit, an assist space must be provided at one side of the passageway if an assist means is required by §25.810(a).

(5) For any tailcone exit that qualifies for 25 additional passenger seats under the provisions of §25.807(g)(9)(ii), an assist space must be provided, if an assist means is required by §25.810(a).

(6) There must be a handle, or handles, at each assist space, located to enable the crewmember to steady himself or herself:

(i) While manually activating the assist means (where applicable) and,

(ii) While assisting passengers during an evacuation.

(c) The following must be provided for each Type III or Type IV exit—(1) There must be access from the nearest aisle to each exit. In addition, for each Type III exit in an airplane that has a passenger seating configuration of 60 or more—

(i) Except as provided in paragraph (c)(1)(ii), the access must be provided by an unobstructed passageway that is at least 10 inches in width for interior arrangements in which the adjacent seat rows on the exit side of the aisle contain no more than two seats, or 20 inches in width for interior arrangements in which those rows contain three seats. The width of the passageway must be measured with adjacent seats adjusted to their most adverse position. The centerline of the required passageway width must not be displaced more than 5 inches horizontally from that of the exit.

(ii) In lieu of one 10- or 20-inch passageway, there may be two passageways, between seat rows only, that must be at least 6 inches in width and lead to an unobstructed space adjacent to each exit. (Adjacent exits must not share a common passageway.) The width of the passageways must be measured with adjacent seats adjusted to their most adverse position. The unobstructed space adjacent to the exit must extend vertically from the floor to the ceiling (or bottom of sidewall stowage bins), inboard from the exit for a distance not less than the width of the narrowest passenger seat installed on the airplane, and from the forward edge of the forward passageway to the aft edge of the aft passageway. The exit opening must be totally within the fore and aft bounds of the unobstructed space.

(2) In addition to the access—

(i) For airplanes that have a passenger seating configuration of 20 or more, the projected opening of the exit provided must not be obstructed and there must be no interference in opening the exit by seats, berths, or other protrusions (including any seatback in the most adverse position) for a distance from that exit not less than the width of the narrowest passenger seat installed on the airplane.

(ii) For airplanes that have a passenger seating configuration of 19 or fewer, there may be minor obstructions in this region, if there are compensating factors to maintain the effectiveness of the exit.

(3) For each Type III exit, regardless of the passenger capacity of the airplane in which it is installed, there must be placards that—

(i) Are readable by all persons seated adjacent to and facing a passageway to the exit;

(ii) Accurately state or illustrate the proper method of opening the exit, including the use of handholds; and

(iii) If the exit is a removable hatch, state the weight of the hatch and indicate an appropriate location to place the hatch after removal.

(d) If it is necessary to pass through a passageway between passenger compartments to reach any required emergency exit from any seat in the passenger cabin, the passageway must be unobstructed. However, curtains may be used if they allow free entry through the passageway.

(e) No door may be installed between any passenger seat that is occupiable for takeoff and landing and any passenger emergency exit, such that the door crosses any egress path (including aisles, crossaisles and passageways).

(f) If it is necessary to pass through a doorway separating any crewmember seat (except those seats on the flightdeck), occupiable for takeoff and landing, from any emergency exit, the door must have a means to latch it in the open position. The latching means must be able to withstand the loads imposed upon it when the door is subjected to the ultimate inertia forces, relative to the surrounding structure, listed in §25.561(b).

[Amdt. 25-1, 30 FR 3204, Mar. 9, 1965, as amended by Amdt. 25-15, 32 FR 13265, Sept. 20, 1967; Amdt. 25-32, 37 FR 3971, Feb. 24, 1972; Amdt. 25-46, 43 FR 50597, Oct. 30, 1978; Amdt. 25-72, 55 FR 29783, July 20, 1990; Amdt. 25-76, 57 FR 19244, May 4, 1992; Amdt. 25-76, 57 FR 29120, June 30, 1992; Amdt. 25-88, 61 FR 57958, Nov. 8, 1996; Amdt. 25-116, 69 FR 62788, Oct. 27, 2004; Amdt. 25-128, 74 FR 25645, May 29, 2009]

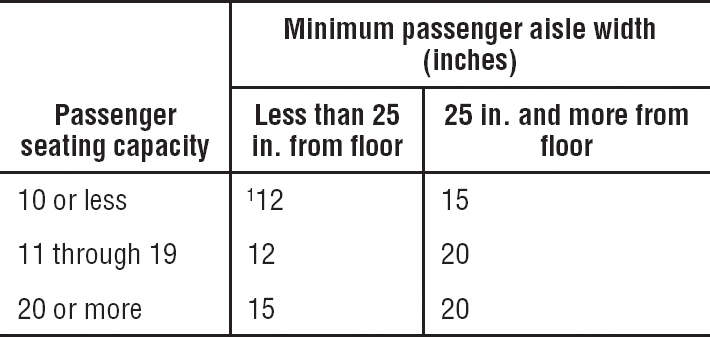

§25.815 Width of aisle.

The passenger aisle width at any point between seats must equal or exceed the values in the following table:

1A narrower width not less than 9 inches may be approved when substantiated by tests found necessary by the Administrator.

[Amdt. 25-15, 32 FR 13265, Sept. 20, 1967, as amended by Amdt. 25-38, 41 FR 55466, Dec. 20, 1976]

§25.817 Maximum number of seats abreast.

On airplanes having only one passenger aisle, no more than three seats abreast may be placed on each side of the aisle in any one row.

[Amdt. 25-15, 32 FR 13265, Sept. 20, 1967]

§25.819 Lower deck service compartments (including galleys).

For airplanes with a service compartment located below the main deck, which may be occupied during taxi or flight but not during takeoff or landing, the following apply:

(a) There must be at least two emergency evacuation routes, one at each end of each lower deck service compartment or two having sufficient separation within each compartment, which could be used by each occupant of the lower deck service compartment to rapidly evacuate to the main deck under normal and emergency lighting conditions. The routes must provide for the evacuation of incapacitated persons, with assistance. The use of the evacuation routes may not be dependent on any powered device. The routes must be designed to minimize the possibility of blockage which might result from fire, mechanical or structural failure, or persons standing on top of or against the escape routes. In the event the airplane’s main power system or compartment main lighting system should fail, emergency illumination for each lower deck service compartment must be automatically provided.

(b) There must be a means for two-way voice communication between the flight deck and each lower deck service compartment, which remains available following loss of normal electrical power generating system.

(c) There must be an aural emergency alarm system, audible during normal and emergency conditions, to enable crewmembers on the flight deck and at each required floor level emergency exit to alert occupants of each lower deck service compartment of an emergency situation.

(d) There must be a means, readily detectable by occupants of each lower deck service compartment, that indicates when seat belts should be fastened.

(e) If a public address system is installed in the airplane, speakers must be provided in each lower deck service compartment.

(f) For each occupant permitted in a lower deck service compartment, there must be a forward or aft facing seat which meets the requirements of §25.785(d), and must be able to withstand maximum flight loads when occupied.

(g) For each powered lift system installed between a lower deck service compartment and the main deck for the carriage of persons or equipment, or both, the system must meet the following requirements:

(1) Each lift control switch outside the lift, except emergency stop buttons, must be designed to prevent the activation of the life if the lift door, or the hatch required by paragraph (g)(3) of this section, or both are open.

(2) An emergency stop button, that when activated will immediately stop the lift, must be installed within the lift and at each entrance to the lift.

(3) There must be a hatch capable of being used for evacuating persons from the lift that is openable from inside and outside the lift without tools, with the lift in any position.

[Amdt. 25-53, 45 FR 41593, June 19, 1980; 45 FR 43154, June 26, 1980; Amdt. 25-110; 68 FR 36883, June 19, 2003]

§25.820 Lavatory doors.

All lavatory doors must be designed to preclude anyone from becoming trapped inside the lavatory. If a locking mechanism is installed, it must be capable of being unlocked from the outside without the aid of special tools.

[Doc. No. 2003-14193, 69 FR 24502, May 3, 2004]

VENTILATION AND HEATING

§25.831 Ventilation.

(a) Under normal operating conditions and in the event of any probable failure conditions of any system which would adversely affect the ventilating air, the ventilation system must be designed to provide a sufficient amount of uncontaminated air to enable the crewmembers to perform their duties without undue discomfort or fatigue and to provide reasonable passenger comfort. For normal operating conditions, the ventilation system must be designed to provide each occupant with an airflow containing at least 0.55 pounds of fresh air per minute.

(b) Crew and passenger compartment air must be free from harmful or hazardous concentrations of gases or vapors. In meeting this requirement, the following apply:

(1) Carbon monoxide concentrations in excess of 1 part in 20,000 parts of air are considered hazardous. For test purposes, any acceptable carbon monoxide detection method may be used.

(2) Carbon dioxide concentration during flight must be shown not to exceed 0.5 percent by volume (sea level equivalent) in compartments normally occupied by passengers or crewmembers.

(c) There must be provisions made to ensure that the conditions prescribed in paragraph (b) of this section are met after reasonably probable failures or malfunctioning of the ventilating, heating, pressurization, or other systems and equipment.

(d) If accumulation of hazardous quantities of smoke in the cockpit area is reasonably probable, smoke evacuation must be readily accomplished, starting with full pressurization and without depressurizing beyond safe limits.

(e) Except as provided in paragraph (f) of this section, means must be provided to enable the occupants of the following compartments and areas to control the temperature and quantity of ventilating air supplied to their compartment or area independently of the temperature and quantity of air supplied to other compartments and areas:

(1) The flight crew compartment.

(2) Crewmember compartments and areas other than the flight crew compartment unless the crewmember compartment or area is ventilated by air interchange with other compartments or areas under all operating conditions.

(f) Means to enable the flight crew to control the temperature and quantity of ventilating air supplied to the flight crew compartment independently of the temperature and quantity of ventilating air supplied to other compartments are not required if all of the following conditions are met:

(1) The total volume of the flight crew and passenger compartments is 800 cubic feet or less.

(2) The air inlets and passages for air to flow between flight crew and passenger compartments are arranged to provide compartment temperatures within 5 degrees F. of each other and adequate ventilation to occupants in both compartments.

(3) The temperature and ventilation controls are accessible to the flight crew.

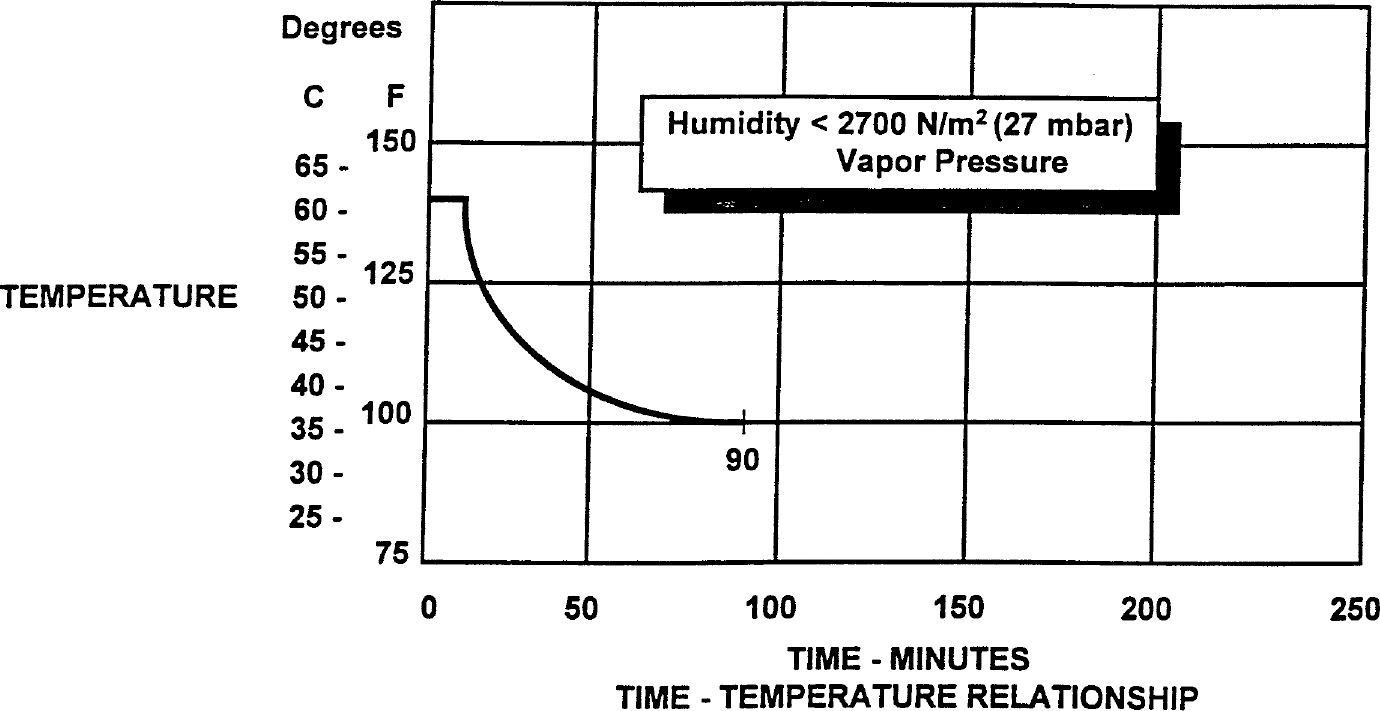

(g) The exposure time at any given temperature must not exceed the values shown in the following graph after any improbable failure condition.

[Doc. No. 5066, 29 FR 18291, Dec. 24, 1964, as amended by Amdt. 25-41, 42 FR 36970, July 18, 1977; Amdt. 25-87, 61 FR 28695, June 5, 1996; Amdt. 25-89, 61 FR 63956, Dec. 2, 1996]

§25.832 Cabin ozone concentration.

(a) The airplane cabin ozone concentration during flight must be shown not to exceed—

(1) 0.25 parts per million by volume, sea level equivalent, at any time above flight level 320; and

(2) 0.1 parts per million by volume, sea level equivalent, time-weighted average during any 3-hour interval above flight level 270.

(b) For the purpose of this section, “sea level equivalent” refers to conditions of 25 °C and 760 millimeters of mercury pressure.