|

||

In the mid-1850s New York City found itself at the centre of one of the most abominable food fraud and food safety scandals ever perpetrated: the ‘swill milk’ scandal. It all revolved around swill (or slop) milk, which came from cows that were housed adjacent to the city’s many distilleries and breweries and were fed the leftover mash, called swill, from the brewing process. A New York Times report in 1853 and an exposé in May 1858 by the news magazine Frank Leslie’s Illustrated Newspaper drew attention to the awful conditions of the so-called distillery-dairies of Manhattan and Brooklyn. The cows were tied up in dark narrow stalls in their hundreds, sometimes thousands. Inevitably, they would end up standing in their own excrement, covered in flies and suffering from a range of diseases. The swill milk being produced in these distillery-dairies was described in a New York Times editorial on 13 May 1858 as a ‘bluish, white compound of true milk, pus and dirty water, which, on standing, deposits a yellowish, brown sediment that is manufactured in the stables attached to large distilleries by running the refuse distillery slops through the udders of dying cows and over the unwashed hands of milkers ...’. The swill milk was then reportedly mixed with water, eggs, flour, burnt sugar and other ingredients to increase the volume and mask the adulteration. Swill milk was then falsely marketed as ‘pure country milk’ or ‘Orange County Milk’.

The New York Times editorial, entitled ‘How We Poison Our Children’, made some bold statements. It reported that Dr A. K. Gardner of the New York Academy of Medicine had provided the results of analyses that suggested a connection between swill milk and high levels of infant mortality in the city. They claimed that 8,000 children had died in 1857 owing to swill milk. Although these accusations were dismissed by the distillery owners, the New York Times journalist, John Mullaly, had also uncovered that 120,000 quarts (136,383 litres) of milk labelled as ‘country milk’ was delivered to New York residents each day, yet only 90,000 quarts (102,287 litres) was entering the city from the neighbouring countryside. Public opinion ultimately prevailed. The swill milk scandal led to an appraisal of both New York’s milk industry and a wide range of other food quality and food-related public hygiene issues.

Figure 6.1. ‘Swill milk’ tethered in its stall in one of New York’s distillery dairies in the mid-1800s.

Our special relationship with milk

As mammals, we have a very particular relationship with milk. It is a critical component of our diet as we develop from vulnerable infants and this is perhaps what makes it so shocking when there is malpractice or adulteration surrounding this fundamental food. Milk is a unique substance nutritionally: the perfect food produced by mammals to sustain their newborn young. Yet somewhere in our history we broke with mammalian tradition and began incorporating milk into our diet well beyond weaning age. And more oddly still, we began drinking the milk of other species! We can only guess at what motivated our ancestors to take this step. Perhaps it was desperation. Perhaps it was the realisation that nutrition can be gained from the animal’s flesh or its milk and one is clearly more finite than the other. Or perhaps it was the more contemplated conclusion that if babies grow so fast drinking milk, this must surely be an advantage in adults as well. Regardless of how or why, our ancestors eventually recognised the nutritional advantages of consuming dairy products from their recently tamed sheep, goats and cows. They began developing complex farming practices that eventually led us to rely on milk as part of our everyday diet.

Exactly when humans began to consume the milk of other animals is unknown. It appears from the archaeological evidence, including food residues in ancient cooking pots and animal bones of dairy herds,1, 2 that the practice probably dates back to the very origins of agriculture, more than 10,000 years ago. The journey from early prehistoric farmer to a twenty-first-century milk-consuming society has involved a complex sequence of events and some fundamental changes in both the animals that produce it and the humans that consume it.

While we can all consume milk in early life, the ability of adult humans to digest milk is a relatively recent evolutionary development. The normal state for all mammals, including humans, is to lose the capacity to digest milk after infancy. Our ancestral farmers would not initially have been adapted to drinking milk as adults; however, as milk drinking became widespread, an evolutionary change occurred that allowed many people to drink milk throughout their lives. The enzyme lactase is needed to break down the milk sugar lactose. The gene that codes for this enzyme is switched on in infants and then is turned off after weaning. A mutation occurred, mostly in European populations, that kept this gene switched on into adulthood. People with this mutation were at an advantage, with researchers estimating that they may have produced up to 19 per cent more fertile offspring than their peers. It became possible for humans to incorporate milk into their everyday diet.3 Today, about 35 per cent of the human population can digest lactose into adulthood, and most of these have European ancestry, though there are other lactase hotspots in West Africa, the Middle East and South Asia.

Without the enzyme lactase, people are said to be lactose intolerant or lactase non-persistent. Lactose intolerance is an inability to digest the milk sugar lactose, which can cause abdominal bloating and cramps, flatulence, diarrhoea, nausea, rumbling stomach and even vomiting. Those early lactose-intolerant farmers would potentially have been quite ill if they had consumed large amounts of milk from their animals. However, they began to get around this by adopting processing techniques that remove or reduce the lactose concentration to non-toxic levels.

Reducing the lactose content can be done in two main ways. The lactose can be physically separated, such as in butter or cheese making, where the lactose is left in the liquid whey, or it can be reduced through fermentation, such as in yogurt. It seems as though our ancestors had hints of this, as evidence of milk processing and cheese making dates back to the earliest stages of milk consumption more than 7,000 years ago.4

There is a huge cultural influence on the types of milk products made and consumed, creating enormous diversity globally. There are 1,000 different types of cheese produced in the world, with France alone accounting for 400 of these. As we learned with olive oil, increasing the different types or classes of a food can increase the potential for fraud, particularly when there are large price differentials, as there can be among the mind-boggling diversity of milk products. Within one UK supermarket the price for cheese ranges from £2.45/kg (US$8.36/lb) for a soft (cream) cheese to £21/kg (US$71.68/lb) for a Parmesan. Add to this the fact that while the vast majority of milk is produced from cows, milk can also be produced commercially from other animals, including buffalo, goat, sheep, camel, donkey, horse, reindeer, yak and even moose. Combined, these account for only around 15 per cent of the global production of milk. Though not necessarily sold in quantity, they may carry a premium; cheese made from donkey milk in Serbia, known as pule, is one of the most expensive dairy products in the world, sometimes selling for as much as £176/kg (US$600/lb). Clearly, including the milk of different animals expands the range of speciality or gourmet milk products still further.

Billions of people consume milk or milk products in some form on a regular basis. As well as pouring milk over our cereal and frothing it into our lattes, we use milk and milk products in a large amount of our cooking and confectionery. Global annual milk production currently stands at 800 million tonnes coming from around 1.5 billion cows; this is a 60 per cent growth in production since the early 1980s. This growth is largely due to an expansion in production (and consumption) in South Asia and, to a lesser extent, Africa. Dairy products are a vitally important component of agricultural production in the developed and developing world. In the developing world animal products, such as milk and other dairy products, are of great importance in preventing malnutrition by providing a vital source of high-quality protein.5

The high production levels and globalisation of the dairy industry has pushed prices down. This inevitably squeezes profit margins, a pattern which can lead to fraudulent activities to protect profits. Next to olive oil, milk is the next biggest target of food fraud, constituting just over 24 per cent of reported food fraud incidents in the last 30 years. Fraud in the dairy industry includes increasing water content, reducing fat content, misrepresenting species origin or country of origin, addition of non-dairy protein, addition of vegetable or animal fats to milk fat and wrongful addition of a wide range of other ingredients – from detergent to formaldehyde – to various dairy products, including infant formula. Other activities include the fraudulent addition of whey to other dairy products or the inappropriate use of certain dairy processing technologies, such as membrane filtration to remove high-value milk protein fractions. The diversity of dairy products requires tight regulations on product labelling. The detailed legislation on dairy foods has required extensive standardisation of testing methods, which have been compiled by the Association of Analytical Chemists, the European Commission and the International Dairy Federation. Yet, despite tight regulations and standardised testing methods, criminals are messing with our milk.6

What is milk made of?

Milk has an extremely complex chemical composition, which luckily is of considerable value in detecting fraud. The beautiful opaque white colour of milk comes from the emulsion (or colloid) of milk fat globules in water, together with dissolved carbohydrates, protein aggregates and minerals. Water is the main constituent of milk – about 87 per cent in cow’s milk. The milk fat (butter) is a mixture of triacylglycerol, with three fatty acid molecules linked to glycerol as you may recall from the oils in Chapter 3. The number of carbon atoms in the fatty acids in butter ranges from 4 to 18. This differs from the composition of ruminant body fat and vegetable oil, which generally range between 14 and 18 carbon atoms. This gives rise to a much more complex triacylglycerol composition in milk fat; at least 120 different triacylglycerol are present, while in animal body fat and vegetable oil there are only around 40 different triacylglycerol.7, 8, 9 The triacylglycerol fat globules are surrounded by a thin layer or skin made up of a related group of compounds, known as phospholipids, and proteins. This layer works as an emulsifying agent, keeping the individual globules separate and suspended in the water. The fat globules also contain low concentrations of diacylglycerols and monoacylglycerols, free cholesterol and cholesteryl esters (a dietary lipid), free fatty acids and fat soluble vitamins A, D, E and K.

Normal bovine milk contains 30–35 grams of protein per litre (1.9–2.2oz/pint), of which around 80 per cent is the casein proteins. The water-soluble whey proteins, mainly lactoglobulin, make up the remaining 20 per cent of protein in milk. Unfortunately, many people have allergies to one or more of the many milk proteins. A milk allergy is different from lactose intolerance. While the effects of lactose intolerance (being unable to digest milk sugars) are brought on by the consumption of larger amounts of milk, an allergic reaction to milk protein is triggered by the consumption of any milk. If someone is diagnosed as having a genuine milk allergy, the recommendation is total avoidance of milk proteins.

The whey (what’s left over when you take the fat and caseins out) also contains carbohydrates. The main carbohydrate is lactose (around 5 per cent), which is made up of the two sugars glucose and galactose. The carbohydrates remain in the whey, together with the whey proteins, when the curds are coagulated, as in cheese making. Milk also contains a number of important minerals, including calcium, phosphorus, magnesium, sodium, potassium and chloride. Furthermore, it’s rich in vitamins B6, B12, C, thiamine, niacin, biotin, riboflavin, folates and pantothenic acid. Cow’s milk also contains white blood cells, mammary gland cells, various bacteria and enzymes. The bottom line is that milk is a highly complex ‘soup’ of nutrients, so any fraudulent activity is likely to have significant health impacts on individuals who rely on it.

In search of dairy substitutes

So widespread are our society’s milk product-based eating habits that we have gone to great lengths to develop a wide range of milk and dairy product substitutes that are capable of filling this niche for those who avoid these animal products – whether through personal choice or adverse health reactions to milk. While these products are wonderful legitimate alternatives to milk, they also illustrate that a white liquid substance can be copied relatively easily.

The most obvious of the milk product substitutes are the plant ‘milks’, such as soy, almond, rice, coconut and hemp milk. Other alternatives are appearing on the market, including quinoa milk, oat milk, potato milk, 7-grain milk (from oats, rice, wheat, barley, triticale, spelt and millet) and sunflower milk. However, as indicated above, there’s much more to milk than its colour, taste and texture, and while some of these milk substitutes might seem perfectly palatable, milk plays such an important role in meeting our nutritional needs that milk substitutes can probably never provide a complete replacement for milk’s exceptional nutritional properties. However, they can, if properly matched to the nutritional profile of dairy milk and fortified with essential minerals and vitamins, be a perfectly acceptable part of a diet containing other whole foods.

The origins of genuine dairy substitutions can provide insight and context for dairy fraud. Whether spurred on by dietary requirements or economic hardships, the methods used in the development of some of these products have also been utilised by fraudsters – the difference, of course, being what’s declared on the label.

Butter, arguably one of the most wonderful products of milk, is in such demand that butter substitutes are very common. Real butter is made by the simple churning of fresh or fermented cream or milk, to separate the butterfat from the buttermilk. The butter produced is an emulsion of fat, protein and water. We all recognise butter’s soft pale yellow colour, which comes from the plant pigments in the animals’ diet. However, butter can be pale – almost white – so food colourings are sometimes added during manufacturing to enhance the colour. One of the less desirable properties of butter is that it gets hard in the refrigerator, so being able to spread it on morning toast requires some forward planning. The most familiar butter substitutes are the margarines or related ‘spreads’, which look like butter, but must be properly labelled as such.

The search for a butter substitute began in the 1860s when Emperor Napoleon III of France offered a prize to anyone who could make a satisfactory butter ‘copy’, suitable for use by his army and the working classes. Napoleon wanted a cheaper version as edible fats were in short supply in Europe at the time. A French chemist, Hippolyte Mège-Mouriès, came up with the idea of mixing beef fat with skimmed milk to give a cheap butter substitute, which he called ‘oleomargarine’. This name later became shortened to the familiar trade name ‘margarine’. But this was only the beginning of the margarine story. The aim was still to produce a cheap butter substitute, so reducing the milk content would reduce the cost even further. In 1871, Henry W. Bradley from New York State patented a process for creating what he described as a ‘new and improved article of manufacture, a lard, vegetable butter, or shortening’, which involved steam-treating a blend of animal fats and vegetable oil.10

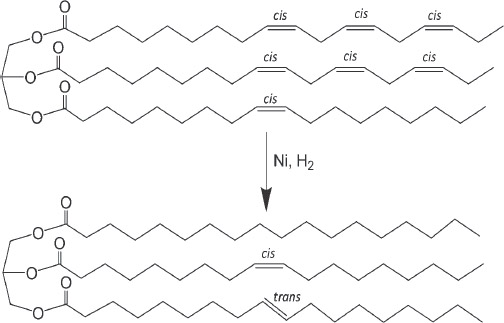

The next major advance in butter substitutes came with the discovery of vegetable oil ‘hydrogenation’.11 In this process, hydrogen gas is bubbled through the vegetable oil in the presence of a metal catalyst (nickel) at about 60°C (140°F). The result is frighteningly simple and effective: hardened oil. As discussed in Chapter 3, vegetable oils are made up of three fatty acids linked to a glycerol backbone to make triacylglycerol. Although the same basic structure exists for animal fats, including butter, the fatty acids in vegetable oils are more unsaturated (they have high numbers of carbon-carbon double bonds, C=C), while in animal fats they are mostly ‘saturated’ (they have fewer C=C bonds and more single C-C bonds). This is what makes vegetable oils liquid and animal fats solid. The hydrogenation process adds hydrogen to the ‘unsaturated’ fatty acids, turning them into ‘saturated’ fatty acids and making them hard at room temperature, just like animal fats. In Figure 6.2, you can count the number of C=C bonds in the triacylglycerol molecule before hydrogenation (seven) and after hydrogenation (two) – the fewer the double bonds, the harder the fat will be.

The introduction of hydrogenated vegetable oils meant that butter substitutes could be produced from cheap vegetable oils without the use of animal products of any sort. This helped get around all sorts of supply problems during times of shortage, such as during World War II rationing. It provided those avoiding animal products with an alternative spread and it was perceived as a healthier choice for those trying to reduce their consumption of saturated animal fats. By the 1950s no margarines containing animal fat of any sort were being produced. However, this did not halt developments aimed at a better margarine or ‘spread’. The challenge in the 1960s became one of producing a spreadable butter substitute that actually tasted like butter! The only way of doing this seemed to be by incorporating some milk products back into the vegetable oil spreads that had proliferated in the market.

Figure 6.2 Catalytic hydrogenation of vegetable oil in margarine making reduces the number of double bonds which would produce a hard fat. Note also the change to a trans shape for one of the double bonds in the lower triacylglycerol.

Making margarine industrially currently involves taking vegetable oils and fats and chemically modifying their physico-chemical properties using fractionation (separation), interesterification (moving fatty acids between triacylglycerol molecules) and/or hydrogenation. The modified oils and fats are then mixed with skimmed milk and the mixture emulsified, chilled to solidify and whisked or stirred to improve the texture. Alternatively, if no solid fats are added to the vegetable oils, full or partial hydrogenation is necessary to harden the oil. The hardened oil is then mixed with water, citric acid, colouring, vitamins and milk powder, lecithin (emulsifier) to help keep the added water evenly distributed throughout the oil, salt and preservatives.

A factor having serious effects on the margarine market and related parts of the food industry is that the ingenious and seemingly innocuous hydrogenation process appears to produce damaging health effects. When vegetable oils are ‘partially hydrogenated’, owing to the conditions used in the hydrogenation vessel, some of the carbon-carbon double bonds are not fully hydrogenated. This causes the double bonds (C=C in the triacylglycerol molecules) to change their geometry, flipping from what is known in chemistry as the ‘cis’ shape to the ‘trans’ shape (see Figure 6.2). This produces the much talked about ‘trans fats’, which have been seriously implicated in cardiovascular disease.12 Indeed, there is sufficient evidence that trans fat consumption lowers good cholesterol and raises bad cholesterol for the US FDA to appear to be on the verge of finally banning trans fats as an allowable ingredient. Interestingly, the fats of ruminant animals (cows, sheep, goats, and so on), including milk fat, contain trace amounts of trans fatty acids, which are produced in their digestive system through a natural bio-hydrogenation process, although the amounts consumed from this source are regarded as minor.

And so was the rise and fall of margarine. It was developed in response to animal fat supply shortages in the nineteenth century and didn’t truly become popular until nearly a century later, when people began avoiding animal fats for perceived health reasons. It then fell out of favour 60 years later as federal governments – the very same ones that supported its original development – cracked down on trans fatty acids. It is yet another example of the complicated road we pave when we process foods.

I can’t believe it’s not butter

Milk fat, hence butter or ghee (a type of clarified butter that’s produced by evaporating the water from butter), is the most valued component of milk. This makes it an obvious target for adulteration or substitution. As the market for butter substitutes grew and processing methods such as hydrogenation developed, the temptation just became too much for the fraudsters. Thankfully, the adulteration of butter is relatively easy to detect, largely on account of its distinctive chemistry.

Mixing vegetable oil into butter is the most likely adulteration. However, it’s extremely easy to determine this by performing a sterol analysis using GC or HPLC. Sterols are common compounds in plants and animals; they are major components of cell membranes and they are precursors to steroid hormones. Animals only produce the sterol cholesterol, while the plants used for vegetable oils produce the closely related sterol, sitosterol (see Figure 6.3). Therefore, the presence of sitosterol can be used to determine whether animal-based fat (butter) has been adulterated with an undeclared vegetable-based fat (oil). Though it may seem difficult to spot the difference between these two compounds, the branch side-chain on sitosterol means it is heavier than cholesterol and it will appear at a later time in a gas chromatogram, giving a different peak on the chromatogram from cholesterol. Plants produce other sterols that may also be found together with sitosterol, including stigmasterol and campesterol (together known as phytosterols). The presence of any of these compounds in butter is definitive proof of its adulteration and this analysis is a European Commission (EC) approved procedure for butter authentication.

A recent survey of a range of butters from Polish supermarkets illustrated the power of these approaches in detecting butter fraud.13 Of 16 butters investigated, two showed detectable sitosterol, indicating a vegetable oil component. This was supported by an analysis of the triacylglycerols, which showed an abnormally high concentration of polyunsaturated fatty acids, which was consistent with vegetable oil being added. Sterol analysis cannot, however, be used to detect the addition of animal carcass fats to butter as all animal fats contain cholesterol. As we mentioned earlier in this chapter, there are differences in the distribution of fatty acids in the triacylgycerols in milk fat versus body fat. These differences can therefore be used to detect the addition of other animal fats to butter.

Figure 6.3. Spot the difference between sterols: cholesterol from animals, sitosterol and campesterol common in many plants, and brassicasterol diagnostic of rapeseed oil.

I can’t believe it’s not cheese

Our fascination with cheese is summed up in Monty Python’s famous Cheese Shop sketch wherein John Cleese visits Mr Wensleydale’s (played by Michael Palin) artisan cheese shop. Cleese’s litany of ‘fermented curd’ from around the world captures how we have diversified this amazing food. As Cleese says, cheese is made by curdling milk and then separating the curds from the whey. The curds can then be fermented (or not in the case of fresh cheeses like ricotta) with an appropriate bacterial culture. The resulting product helps overcome the lactose intolerance problem, since most of the lactose is left in the whey and most of the whey is removed from the curd (though many softer cheeses still contain some whey). But it also provides a food that is more transportable with a vastly longer shelf life than raw milk, while still retaining many of its highly beneficial nutritional properties. Given the diversity of cheese and the huge demand for this premium product, it is no wonder that it is on the agenda of the fraudsters.

The first cheese that John Cleese mentions is Red Leicester – characterised by its intense orange/red colour. The yellow colour of cheese naturally comes from the carotene pigment (see Appendix) in the grass the cows eat, which is transferred through the digestive system and mammary gland into the milk and is retained in the cheese. It was realised by English cheesemakers several hundred years ago that they could make more money if they skimmed off the cream and sold it separately or made butter from it. However, the yellow pigment was removed with the cream and the butter, so the lower fat cheese produced was white. Because the yellow colour of cheese was seen as a mark of quality, the crafty cheesemakers used yellow plant dyes to colour their cheese and pass it off for the genuine full fat cheese. The practice of colouring cheese still goes on. Indeed, since the eighteenth century Red Leicester has been coloured orange by adding annatto extract, which is made from the seeds of the achiote tree (Bixa orellana) and is widely used as a natural food colouring (see Appendix).

If the yellow/orange colour is a sort of visual diagnostic for cheese within our own internal databases of quality food, then you can see why producers of fake cheese or what’s called by the food industry ‘cheese substitute’ might use yellow colouring to lure us into thinking a product is more authentic than it actually is. Food colouring can legitimately be added to cheese substitute and there is nothing illegal in producing cheese substitutes, provided the labelling clearly displays exactly what they are. Of course this is where things get messy.

If you go into your local takeaway pizza shop and buy a pizza with nice stringy melted cheese on it you would be forgiven for thinking you were buying a pizza with mozzarella cheese, as this is the most popular pizza cheese globally. However, in the US it’s estimated that only around 30 per cent of cheese on pizzas is mozzarella – either the American version or the traditional version from southern Italy. Most of our pizzas are adorned with a cheese substitute. Food scientists have done a lot of work to produce the perfect pizza cheese; real cheese is added mainly as a flavouring, while components such as vegetable oil, whey protein and salts help with the emulsification. In February 2014, the Guardian newspaper in Britain reported the results of an investigation, conducted by the Lancashire Trading Standards office, of pizzas being sold in their county. The report describes how officers sampled pizzas from 20 outlets and performed tests on ingredients used in hundreds of pizzas sold to customers. The Trading Standards report said ‘EVERY takeaway they investigated ... has been selling customers pizzas containing “fake cheese”.’ The report emphasised that ‘It is not illegal to use cheese analogue but it should be properly identified as such.’ The analyses for other pizza toppings were little better, with four pepperoni samples containing animal species in addition to beef or pork. As many as 67 per cent (10 out of 15) ham pizzas also contained turkey DNA. Lancashire County Council Trading Standards are working with takeaway owners and wholesalers to ensure they comply with labelling regulations.

Venezuelan Beaver cheese (which incidentally has its own website, venezuelanbeavercheese.com) was among the 45 cheeses listed by John Cleese in the Cheese Shop sketch. Obviously, this is a fictitious cheese, Venezuela having no native populations of beaver and beavers being unlikely candidates for milking if they did. Yet cheese is made from the milk of quite a range of different animals, and whether owing to low yields or the general disposition of certain species when being milked, some are more expensive, based on the species alone. So how can we tell the type of animal that cheese comes from? For example, the popular mozzarella (the Italian version), manchego, feta and Roquefort cheeses are made from non-cow’s milk and so methods are required to check whether these cheeses contain solely water buffalo (mozzarella), sheep (manchego, feta and Roquefort) or goat (feta) milk or whether cow’s milk has also been added. Protein analysis is one of the main methods used to authenticate cheese, as different species produce different proteins, and curd, if you recall, is protein. Electrophoresis, specifically isoelectric focusing (which we discussed in Chapter 4), separates proteins based on their movement within a gel under the influence of an electrical field and has been adopted as the standard method for cheese authentication within the EU. The method can detect as little as 0.5 per cent cow’s milk within sheep, goat and water buffalo milk, based upon γ3- and γ2-casein analyses. DNA analysis using PCR with species-specific primers has recently been shown to be a highly sensitive technique for the qualitative detection of cow’s milk, even in overripe mixed cheeses (see note 6).

Concerned about the possibility of fake cheese in shops in the UK, the consumer organisation Which? teamed up with Professor Chris Elliott (author of the UK government’s independent review into food crime) to investigate the possible adulteration of goat cheeses with milk from other species. Of 76 samples of goat cheese purchased from supermarkets, delis and markets around the UK, nine samples were found to be adulterated to varying degrees with sheep cheese.

The same problem has been found with other cheeses. Italian mozzarella, as we mentioned, is made from the creamy milk of the Italian Mediterranean buffalo. Whether by chance or not, the Italian word for buffalo, bufala, also means hoax or fraud. Mozzarella mogul Giuseppe Mandara, owner of Italy’s biggest manufacturer of buffalo mozzarella, has been in the headlines off and on for years over adulteration of the cheese with common cow’s milk – as well as Mafia offences and money laundering. The problem reportedly also exists in the Italian hard cheese market, where the estimate of forgeries of such brands as Parmesan, Asiago and Pecorino Romano are estimated at 20 per cent, which is a large proportion when the value of the annual trade is in the hundreds of millions of dollars.14 The Switzerland Cheese Marketing Association used random DNA testing to prove that about 10 per cent of supposed Emmental on grocery store shelves is actually fake, such as Italian forgeries falsely claiming to be made in Switzerland. Since the testing was introduced the fakes appear to have dwindled.15 Thankfully, none of these frauds appear to have had health impacts. However, there are parts of the world, particularly Asia, where fraud surrounding dairy products is especially rife, with fatal and life-changing consequences for the defenceless consumers.

I can’t believe it’s not milk

The cow is sacred in India, but sadly the same cannot be said of the milk on offer to large numbers of the country’s population. India is the world’s largest milk-producing nation, with nearly 130 million tonnes of milk produced in 2012. However, the volume available per capita of the country’s population was less than a third to a quarter of that consumed by most Europeans and North Americans. With demand outstripping supply, the fraudsters have devised some imaginative ways of extending the amounts available. If the levels of fraud are to be believed, then India is probably now the world’s number one fake milk producer. The nature of such frauds ranges from diluting milk with water to the complete fabrication of milk.

So many reports abound in the media, including a number of documentary footages on YouTube, it is difficult to know where to start. One very detailed report in the Bihar Times in 2010 describes officials making a surprise visit to the main slum of Mumbai where they found people removing milk from branded packets and replacing it with water. Entire households, including children, were found with all the equipment for committing the crime: hundreds of plastic bags of branded milk, pots of questionable water, a straw to suck the milk out of the bag, a funnel to put water into the bag and candles to seal the packets afterwards. Some reports suggest that only a small amount of the milk is replaced with water, while others indicate the milk is replaced entirely with ‘white water’.

The government’s own investigation in 2011 by the FSSAI suggests that a huge proportion of India’s milk fails to conform to health and safety standards. A Reuters report in January 2012 summarised that out of 33 Indian states, non-fat adulterants were found in all the milk samples from West Bengal, Orissa and Jharkhand. The problem appeared particularly acute in New Delhi with anything up to 70 per cent of the milk samples reported as ‘tainted’. The western state of Goa and the eastern state of Puducherry reportedly conformed to the standards, with ‘no indication of adulteration of their milk’.

Maneka Gandhi writing on www.mathrubhumi.com pointed out that the FSSAI offers various explanations as to why foreign chemicals were detected in so many of the milks tested. Where detergents were detected, this is explained by contamination from washed hands and failure to rinse out vessels. Formalin (or formaldehyde) is used as a preservative but its addition is illegal. Urea is reportedly added to avoid curdling during transport. The Delhi Food Safety Authority acknowledged the presence of skimmed milk powder, saying ‘this is not hazardous to health, it’s just reconstituted milk’. The situation is complicated by the fact that surplus milk produced at some times of the year is turned into milk powder, which is regularly mixed into fresh milk when shortages arise. Around 50 per cent of the milk sold in Delhi in the summer is reconstituted – perfectly sensible, but there are concerns that this is not declared on the packaging. There are other additions that can be logically explained if the milk is reconstituted, but there is also evidence of more extreme fakes – namely, the actual fabrication of milk.

In a perverse way, the idea of fabricating milk is not so far removed from making infant formula with mostly non-milk ingredients. But when reduced to its ingredient list and recipe, the production of this type of fake milk sounds horrific. The technology currently used to make India’s fake milk is reported to have been invented by milkmen of Kurukshetra (Haryana) around the turn of the millennium. It seems that the recipe was so successful that it spread very fast, and the practice now appears to exist all over India. Commonly reported recipes for fake milk require easily accessed ingredients such as urea, caustic soda, cheap cooking oil as a substitute for milk fat, sugar, water, powdered milk, and detergents such as hair shampoo. The first step is to emulsify the cheap oil, such as soy, in water using the detergent, to produce a white frothy solution. The oil also helps to create a mixture with a smooth texture. Caustic soda is then added to neutralise the acidity and prevent the mixtures from turning sour during transport. Urea is added in place of the milk solids-not-fat (SNF) (the caseins, lactose, whey proteins and minerals). Other reported ingredients include hydrogen peroxide, formalin, glucose, ammonium sulphate and various whitening agents. The cost of preparing synthetic milk is around 5 Indian rupees per litre (£0.05 per litre; $0.04 per pint) and it is sold for up to 30 Indian rupees per litre (£0.30 per litre; $0.22 per pint). The motive is pretty clear: pure profit with scant regard for human well-being. The Delhi Health Department estimates 100,000 litres (211,338 pints) of synthetic milk and 30 tonnes of thickened milk (khoya) are being manufactured every day in the city.

The recipe for fake milk sounds more like one of the examples from Accum’s Treatise from nineteenth-century London, but this is no crude fake. In its own way, the recipe is ingenious. The fraudsters are fully familiar with the crude testing systems that exist within the village milk cooperatives, so they have chosen the ingredients that go into the synthetic milk wisely in order to fool the test. The fat and SNF percentage is similar to real milk and blending in powdered milk disguises the taste.

There are surprisingly few reports of any adverse health impact from drinking this type of fake milk. The dilution of milk with water obviously reduces its nutritional value, while the use of contaminated water would clearly pose health risks. A study undertaken by the Indian Council of Medical Research concludes that detergents in milk cause poisoning and gastrointestinal problems. One very troubling report indicates six children dying and more than 60 falling ill after drinking adulterated milk in a state school in eastern India. The matter has clearly raised huge public concern in India, with the lack of proper monitoring appearing to be at the root of the problem. The results of the FSSAI’s survey led to an affidavit being filed in response to a notice issued on Public Interest Litigation (PIL) by a group of public citizens led by Swami Achyutanand Tirth of Uttarakhand seeking to check the sale of adulterated milk and various dairy products. Notices have also been issued to Haryana, Rajasthan, Uttar Pradesh, Uttarakhand and Delhi on PIL ‘alleging that synthetic milk and adulterated milk and milk products are prepared using urea, detergent, refined oil, caustic soda and white paint, which according to studies are “very hazardous” to human life and can cause serious diseases like cancer’. At the time of writing this chapter, we await developments – but we should probably not hold out too much hope for an imminent resolution.

Formula fraud

There is nothing more distressing than the sight and sound of a hungry baby in need of their feed. And there is no question that mother’s breast is best. However, not all mothers are able to breastfeed their babies. The historical solution to this was wet nursing, which was a safe and effective alternative to breastfeeding that probably dates back to the very origins of our species. However, throughout the industrial period, society’s negative view of the practice combined with the development of bottle feeding using artificial formulas resulted in the demise of wet nursing. An historical alternative to wet nursing would have been to substitute the mother’s milk with that of other animals, but we now know that giving babies cow’s milk too early can be very damaging owing to the differences in chemical composition between cow’s and human milk. The earliest attempts to produce artificial replacements for mother’s milk began in the mid-1800s. In 1865, using knowledge emerging about the composition of human milk, the chemist Justus von Liebig developed, patented and marketed an infant food, comprising cow’s milk, wheat and malt flour, plus potassium bicarbonate. It was considered the perfect infant food. Though it was far from perfect, it was a start and in the years that followed various other formulas were developed and their compositions modified as more detailed knowledge became available about the nutritional needs of newborns and the chemistry of human milk.

Numerous commercial baby formulas now exist; however, their composition is strictly regulated. The recommendations for infant formula compositions are laid down in the Codex Alimentarius. The document is 21 pages long and includes recommendations for special infant formula compositions required for certain medical disorders. The recommended formulation is based on the premise: ‘Only products that comply with the criteria laid down in the provisions of this section of this Standard would be accepted for marketing as infant formula. No product other than infant formula may be marketed or otherwise represented as suitable for satisfying by itself the nutritional requirements of normal healthy infants during the first months of life.’ The standard is regularly updated as new knowledge is obtained and is currently the globally accepted standard for infant formula.

We are at our most vulnerable as newborn babies, reliant on our parents for absolutely everything, especially our first food. Whatever a mother’s reasons for choosing to feed her baby formula, it has probably been a considered decision, and she is trusting that after 150 years of research there is now a replacement for mother’s milk specifically designed to meet the baby’s nutritional needs. It is a juncture in life when both mother and infant are exposed. And for this reason, it seems all the more incredible that people have sunk so low as to produce counterfeit baby milk that has resulted in fatalities and had life-changing health impacts.

On 29 April 2004, the New York Times reported that hundreds of parents in Fuyang in central China had unwittingly bought a counterfeit baby formula, in which nutritional supplements had been replaced with starch or sugar. The result was that babies manifested what local residents called ‘big head disease’. The babies readily ate the formula – of course, as there was nothing else – initially displaying fat cheeks that the parents took to be a sign of good health. However, due to the low protein and nutrient content of the feed, the rest of the body failed to develop properly. The body’s coping mechanism in times of deprivation is to direct resources to the brain and vital organs at the expense of other body parts. The 200 babies displaying these awful symptoms were terribly malnourished, with 13 eventually dying. The scandal was reported on Chinese state television on 19 April, and the next day Prime Minister Wen Jiabao sent a special investigation team into the region. At least 22 people who were involved in making and selling the formula were arrested. It appeared the problem extended outside the Fuyang region, with sick babies also being reported in Beijing and Guangzhou. A spot check of baby formula in stores in Guangdong province revealed that 33 per cent of brands failed to meet the national standard. Some brands tested in Fuyang had less than 1 per cent protein when the national standard is around 12 per cent.

The New York Times report stated that ‘Investigators blamed illegal manufacturers throughout China for the problem and reported that 45 brands sold in Fuyang and elsewhere were substandard.’ Sadly, it appeared that ‘reports of the problem had been percolating in Fuyang for almost a year without any significant action being taken’. The most desperate aspect of this case is that the companies producing the low-cost baby food took advantage of the parents’ poverty; they had no alternative but to purchase the cheaper brands because they were as low as half the price of the premium Nestlé baby formula. They never imagined of course that they were putting their babies’ lives at risk. The scandal really hit home, bringing calls for greater regulation in a country renowned for producing counterfeit products. Nearly 10 years later, in March 2013, the China Food and Drug Administration (CFDA) was formed. This is a ministerial-level agency similar to the US FDA, which should streamline regulation processes for food and drug safety. Sadly, it came too late for the victims of the Fuyang baby formula fraud.

Just when you thought things really couldn’t get any worse, another infant formula scandal broke. This time, the counterfeiters plumbed new depths of depravity, serving on the Chinese people a particularly inhumane and damaging food scam. The case, known as the Chinese Melamine Scandal, was a pure greed-motivated fraud perpetrated by individuals with a detailed knowledge of testing methods and seemingly no regard for the health impacts on potential consumers. The precise details of the impacts of this terrible fraud are difficult to establish with any certainty, but the Chinese have reported that the incident affected around 300,000 people, with 6 infant deaths and more than 50,000 babies hospitalised.16

The scandal broke on 16 July 2008, after 16 infants in Gansu province, fed infant formula milk, were diagnosed with kidney stones. Analyses of the kidney stones using HPLC and infrared spectroscopy showed they contained crystals of melamine and a melamine-related compound, cyanuric acid. There is no reason why these substances should have been present in the bodies of these infants. Melamine is an industrial chemical manufactured in huge amounts for the production of the melamine formaldehyde resins in commonly occurring plastic coatings, familiar to us in laminates, kitchenware and adhesives. Cyanuric acid, together with ammeline and ammelide, are by-products of melamine production.17

A WHO report confirms that on their own, none of these substances are toxic and we are normally exposed to them in very low amounts through a food’s contact with packaging. Under normal circumstances, these substances are eliminated from the body rapidly with no ill effects. However, tests on animals have shown that when melamine and cyanuric acid are consumed together, as they were in the infant formula, they are highly toxic, and can be fatal. The two substances combine to form insoluble melamine cyanurate crystals, which accumulate in the kidney causing blockage and degeneration.

Sadly, this type of toxicity had been seen the year before, in 2007, in cats and dogs in the US. The outbreak was traced to the consumption of pet foods made with wheat gluten and rice protein concentrate supplied by a Chinese company. The outbreak affected thousands of pets, causing an unknown number of deaths of cats and dogs. There was no alternative but to withdraw thousands of pet products from stores. It was clear that melamine had been intentionally added to pet food ingredients to artificially increase their measured protein content. But melamine is not a protein.

This was where the fraudsters showed their expert knowledge: though melamine is not a protein, it could fool the test for protein. The quick and simple test for protein is the Kjeldahl assay, which determines the total nitrogen in a sample by treating it with sulphuric acid and measuring, with a simple titration, the amount of ammonia released. Another test, the Dumas combustion method, works on similar principles and is equally lacking in specificity. These are routine tests used to determine the total amount of protein in foods and the fraudsters clearly knew this because neither of these tests is designed to distinguish between protein and non-protein nitrogen. So, because every molecule of melamine contains six atoms of nitrogen, adding a small amount of melamine to milk significantly increases the amount of nitrogen detected by these tests. The result is an erroneously high protein estimate. Hence, such tests made the pet food and the infant formula appear to have the necessary protein content, when in fact it wasn’t protein at all.

As to where in the supply chain the melamine was added to the infant formula is not at all clear. It has been suggested that the melamine used in the fraud may not have been the highest grade product since this would have been expensive and free from the cyanuric acid. A cheaper impure by-product may have been used, which would account for the renal toxicity seen in both the humans and the animals. No matter what the mechanism for the introduction of the melamine into the baby formula, investigations showed that the fraud was widespread and ultimately extremely damaging, not only to the vulnerable victims, but to the entire Chinese dairy industry from top to bottom. Inevitably, the real victims, the less wealthy Chinese parents of newborns, were left wondering what food they could trust to give their babies. Ironically wet nursing was reportedly on the increase.

The BBC provides a timeline18 of the Chinese melamine scandal – the first deaths and arrests, the increasing tally of sick babies, discoveries of more melamine-laden products (pet food and eggs), nationwide alerts and bans on Chinese-made food products, bankruptcy and, finally, death sentences. It reveals the full horrors and impacts of this terrible episode – let’s hope the world never sees the likes of this again.

Such frauds, which are thankfully rare, have profound effects on any food industry at all levels in the supply chain, including innocent farmers. The producers that use the adulterated foodstuff suffer economic losses, as do the outlets for named products or brands, owing to the loss of public confidence, which can take years to recover. The obvious reaction to such a scandal is to demand increased food testing. However, the melamine scandal highlights the impossible position that the protection agencies are placed in when they need to test for an unknown or totally unexpected criminal activity. Whether it is an as yet unrecognised adulterant chemical or adulteration practice – analytical science simply doesn’t work this way. As we saw from Chapter 2, analysts need to have some idea of what they’re looking for and pose the questions accordingly.

Comprehensive testing to ensure ultimate food quality and safety is the unrealistic ‘Holy Grail’ of food fraud forensics. As we have mentioned before, foods are chemically highly complex and we simply can’t analyse for everything, especially for substances that have yet to be recognised as threats. The situation is quite different once a particular fraudulent practice or adulterant chemical has been identified – then testing can be harmonised internationally, with the most appropriate analytical methods being recommended and purity criteria defined. A horizon-scanning approach aimed at predicting the next big food fraud is on the agenda of the protection agencies but this type of preemptive approach will never be fully effective – the food cheats are working equally hard on their side.

Indeed, who would ever have predicted that hydrolysed protein reportedly made from ... wait for it ... scrap leather would be added to milk! This was reported in 2011 by the Hong Kong government’s Centre for Food Safety (CFS), which had been conducting regular testing on milk and milk products. Apart from this being bizarre in the extreme, the practice could be highly damaging to health owing to metallic contaminants used in the manufacture of leather, which could be transferred with the hydrolysed protein. The CFS is monitoring milk extensively to ensure that any sales in Hong Kong comply with the legal standards and are fit for human consumption. The tests for this abhorrent activity involve the use of ion exchange chromatography to detect chromium (derived from the tanning agent) and hydroxyproline (a characteristic leather protein amino acid).19

The more we have learned about food adulteration, the more it seems like the worst sort of practical joke – taking advantage of trusting people. Yet, as with practical jokers, the acts expose more about the criminal’s own character deficiencies than those of their supposedly gullible victims. What is especially dispiriting about the food cheats’ deceptions is that their trickery can affect unsuspecting consumers in life-changing ways.