18

CHAPTER

Top Load Automatic Washers

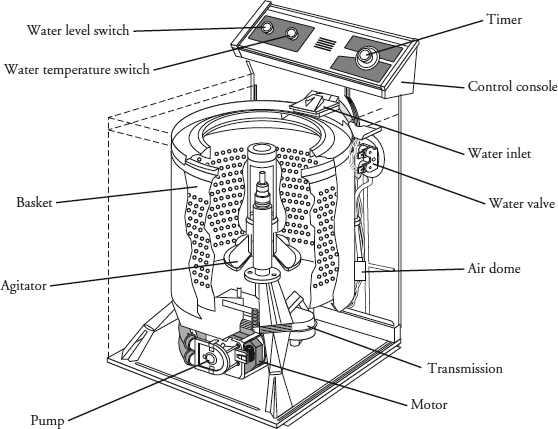

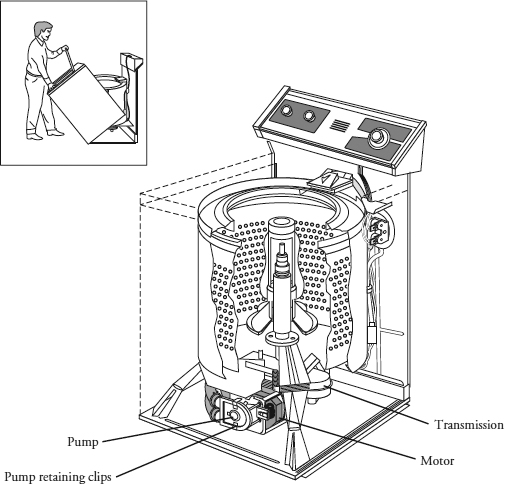

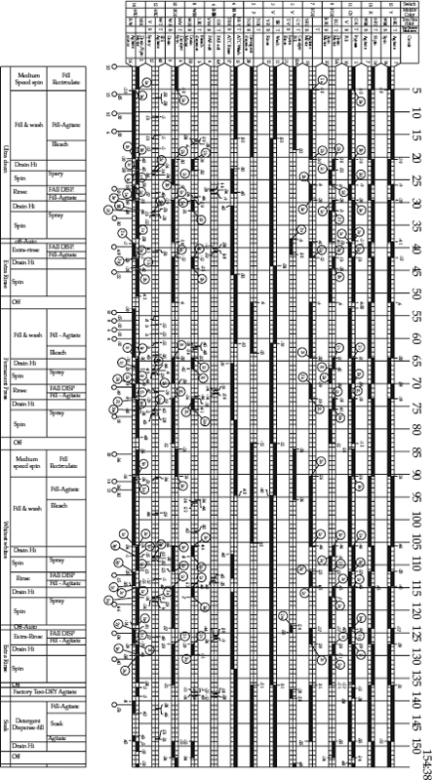

The automatic washer is a complex electromechanical machine, and Figure 18-1 is used as an example only. The actual construction and features of the washer you are servicing might vary, depending on brand and model. The automatic washer performs various cycles to clean clothes. There are times when a washer fails to operate properly. Don’t let its complexity intimidate you. This chapter will provide the basics needed to diagnose and repair the washing machine. On electronic models, you may need to have the service manual and the technical data sheet (located inside the control panel) present to perform the diagnostic test/service modes.

FIGURE 18-1 A typical top load automatic washer.

Principles of Operation

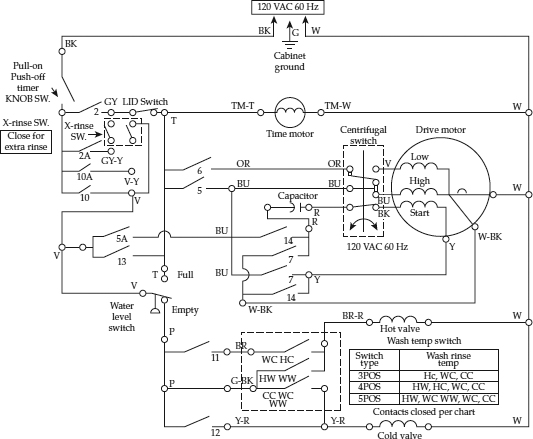

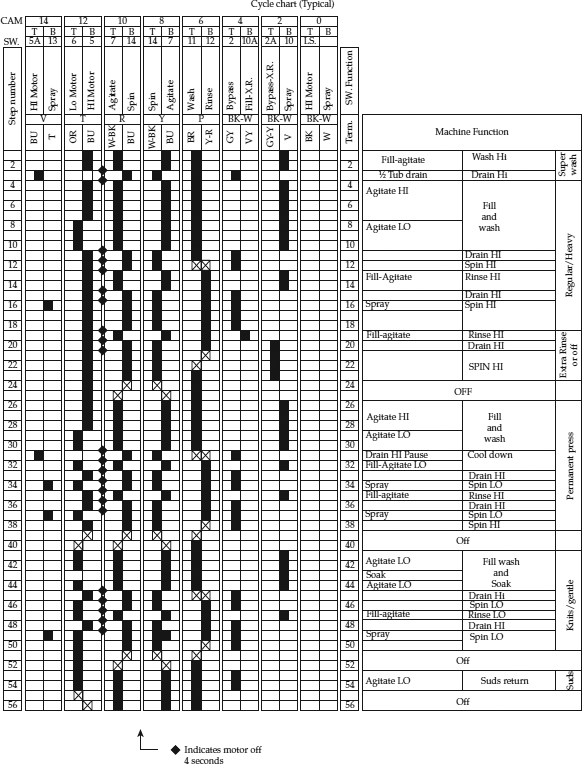

The clothes are placed evenly into the washer basket, making sure that the washer is not overloaded and that the proper cycle is selected. The user then adds detergent to the washer (see the use and care instructions), and then the user activates the washer through the timer. The internal switches of the timer distribute the electricity to activate the other components in the washing machine during a given time period, designated by the internal cam of the timer.

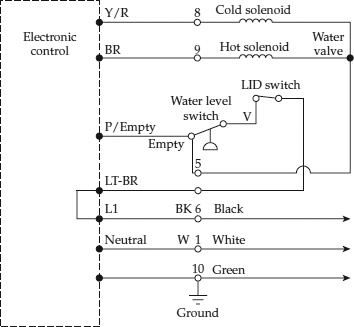

The water enters the tub through the water fill hoses, the water inlet valve, and water inlet hose. Hot, warm, or cold water is selected by the user via the water temperature selector switch, located on the console panel. On some models, the water temperature selection is controlled by the timer.

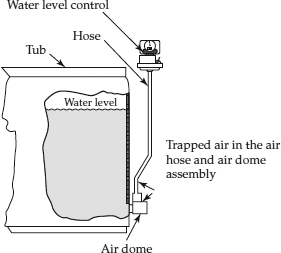

The amount of water that fills the tub is controlled by the water level control (pressure switch). The water level control offers a choice of water levels, depending on the amount of clothing being washed. As the water level rises in the tub, it forces air through the air dome and up the plastic tube to the water level control. The pressure that is exerted on the water level control’s diaphragm will trip the water level switch from empty to full, supplying electricity to the washer drive motor, and thus operating the transmission.

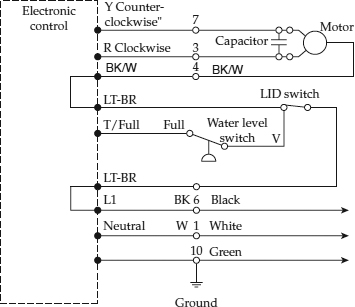

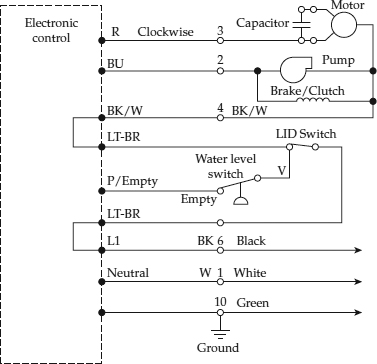

The transmission/gearbox is operated by the drive motor, either by belt drive or by direct drive, depending upon the model. Agitation is accomplished by the agitator, which is located in the center of the basket and which is driven by the transmission/gearbox. The agitator turns clockwise and counterclockwise, creating a water motion that moves the clothes within the basket.

When the washer goes into the drain mode, the agitator will stop agitating, and the water leaves the bottom of the tub through the water pump, to be pumped into the drain. The water pump may operate by belt drive, by direct motor drive, or by an electric motor.

A final deep rinse cycle (the tub fills to the selected water level and begins to agitate) will be introduced to wash off any remaining residue of soap or dirt.

The timer will now select the spin cycle, and the washer will then go into the spin mode. In the spin mode, the washer spins the clothes, removing most of the water from the clothing by centrifugal force. Some models use brief sprays of water to remove any residue of soap or dirt remaining on the clothes in the spin cycle.

Functions and Cycles

The removal of soil from clothing and fabrics is accomplished by a combination of mechanical and chemical processes:

• Mechanical process Soil is removed by agitating and by forcing the detergent through the clothing.

• Chemical process The detergent used will dissolve and loosen the soil in the clothing. As the washing machine operates through its cycles, it is aided by hot, soft water, which increases the chemical processes of the detergent being used.

Top load washing machines perform four basic functions, which are modified and put together in different ways to create the various cycles. The four functions are:

• Fill

• Agitate

• Drain

• Spin

Safety First

Any person who cannot use basic tools or follow written instructions should not attempt to install, maintain, or repair any top load automatic washers. Any improper installation, preventive maintenance, or repairs could create a risk of personal injury or property damage.

If you do not fully understand the installation, preventive maintenance, or repair procedures in this chapter, or if you doubt your ability to complete the task on the top load automatic washer, please call your service manager.

The following precautions should also be followed:

• Never bypass or disconnect any part or device (originally designed into the washer) as a temporary repair.

• Always reconnect all ground wires, and be sure that they are secure.

• Be careful of moving parts and sharp edges.

Before continuing, take a moment to refresh your memory of the safety procedures in Chapter 2.

Automatic Washers in General

Much of the troubleshooting information in this chapter covers top load automatic washers in general, rather than specific models, in order to present a broad overview of service techniques. The pictures and illustrations that are used in this chapter are for demonstration purposes only, to clarify the description of how to service washing machines, and in no way reflect a particular brand’s reliability.

Location and Installation of the Top Load Automatic Washer

The following are some general principles that should be followed when performing the installation of a top load washing machine:

• Locate the washing machine where there is easy access to existing drain, water, and electrical lines.

• Be sure you observe all local codes and ordinances for the electrical and plumbing connections.

• The washing machine should be installed and leveled on a firm floor to minimize vibration during operation.

• Do not install the washing machine in an area where the temperature might be below freezing.

• To reduce the risk of a fire, never install a washing machine on any type of carpet.

• Always follow the installation instructions that are provided with every new washing machine model purchased.

Common Installation Problems

Top load automatic washer installations are not complicated. As a service technician, you will come across a top load washer that has not been installed according to the manufacturer’s installation instructions. The following sections describe some of the problems that you might run into and how to solve them.

When you arrive at a service call and the consumer tells you that the washer is full of water and it will not drain out, check for the following:

• The drain hose is kinked.

• The drain hose has a blockage.

• The drainpipe might be too small, not allowing for proper venting. The drainpipe must be a minimum of 1½ inches in diameter.

• The drainpipe and the drain hose were installed over six feet above the floor.

If the consumer tells you the washer will not fill up with water or very little water is entering the washer, check the following:

• The water faucets were never turned on or they were turned on only a little bit.

• There is a blockage in the water inlet screen. The consumer did not flush out the water lines before installing the hoses on the washer.

• When the washer is filling with water, the water is siphoning out through the drain line. The drainpipe is too low or the wrong size diameter. You might have to install a siphon break kit at the end of the drain hose.

When you arrive at the service call, you notice water on the floor. Check the following:

• The water hoses to the water inlet valve

• The water faucet might be leaking

• The drain hose is not connected properly to the washer

• The drain hose comes out of the drainpipe

• The drainpipe might have a blockage

• The household drain cannot handle the capacity of the discharge water

When the washer goes into the spin cycle, it will begin to vibrate and walk across the floor. Check the following:

• The feet or leveling legs on the washer are not set properly, causing the washer to teeter-totter.

• Is the washer level?

• Is the floor level?

• Check and see if the packing and shipping straps have been removed. Read the installation instructions on removing the packing straps.

• Are the clothes distributed evenly within the tub?

Water Supply

The water supply for an automatic top load washer should have a hot and cold faucet located within five to seven feet of the washer. The faucets should be a 3/4-inch threaded type to accept the fill hose connection.

The water pressure must be between 25 and 125 pounds per square inch for the washer to operate properly. The water coming out of the fill hoses should be equal in both pressure and in the volume of water to prevent unacceptable water temperature changes when entering and filling the washer.

The hot water supply to the washer should be between 130 and 150 degrees Fahrenheit. If the hot water temperature is below 70 degrees Fahrenheit, the clothes being washed will not clean properly and the detergent will not dissolve properly. You can check the temperature of the hot water by operating the washer in the fill mode with the water temperature setting on hot. Let the water run until it is as hot as possible, and then insert a thermometer into the stream of water. If the thermometer reading is below 130 degrees Fahrenheit, you will have to raise the water heater thermostat setting. The cold water temperature should be between 70 and 100 degrees Fahrenheit. When the washer is in its rinse stage, the cold water will prevent wrinkles from setting into the fabrics. Some fabric manufacturers require that their fabrics be washed in cold water, both to prevent shrinkage and to eliminate the possibility of destroying the fabric. When the user selects the warm fill, the temperature of the water should be 100 degrees Fahrenheit.

It is recommended that the consumer read the use and care manual before performing a wash. Most use and care manuals have a water temperature guide to assist the user in the proper selection of the water temperature.

Drain Requirements

The drain to which the washer’s drain hose is connected must be able to accept at least a 20- to 30-gallon-per-minute flow in order to remove the water from the tub. The standpipe should be at least 32 inches high and not exceed 60 inches in height. The internal diameter of the drain pipe should be a minimum of 1½ inches in order to provide an air gap around the drain hose and thus prevent the suction from siphoning the water out of the tub during the wash cycle.

Detergent

The kind and amount of detergent that is used is an important part of getting clothes clean. Some top load automatic washer models are designed to use HE (high efficiency) detergent while other models use regular detergent. Different brands of detergent contain different amounts of phosphorous, which works to soften the water and to boost the cleaning action. If the water is hard, you might need to recommend a detergent with a higher phosphorous content. If the water is soft, the user can use a low-phosphorous detergent.

Some areas restrict the phosphate content to 8 percent or less. This means that the user will have to increase the amount of detergent used in those areas where the water is hard. This is done by adding a certain extra amount of detergent manually to the wash cycle.

It is recommended that the consumer read the use and care manual before performing a wash. Most use and care manuals have a detergent guide to assist the user in the recommended amount of detergent to use.

Water hardness is measured in grains:

• 0 to 3 grains: soft water

• 4 to 9 grains: medium-hard water

• 10 to 15 grains: hard water

• Over 15 grains: very hard water

If you do not know the hardness of the water supply, contact the local water department.

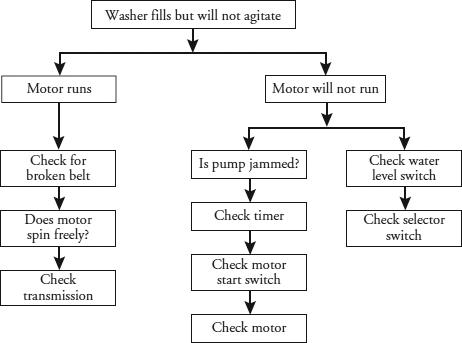

Step-by-Step Troubleshooting by Symptom Diagnosis

In the course of servicing an appliance, don’t overlook the simple things that might be causing the problem. Step-by-step troubleshooting by symptom diagnosis is based on diagnosing malfunctions, with their possible causes arranged into categories relating to the operation of the washer. This section is intended only to serve as a checklist to aid you in diagnosing a problem. Look at the symptom that best describes the problem that you are experiencing with the washer, and then proceed to correct the problem.

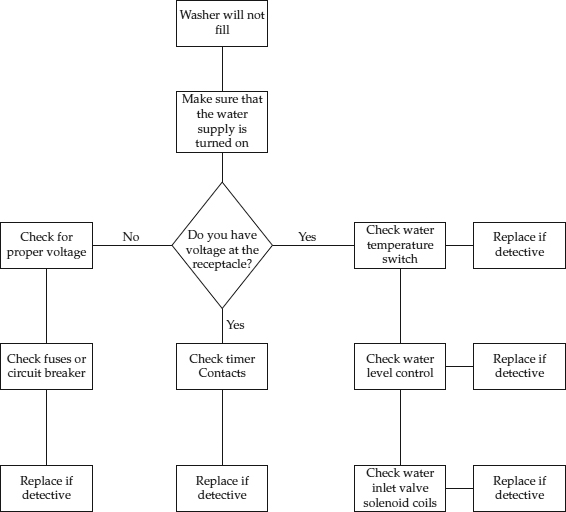

No Water Entering Washer

1. Is the washer plugged in?

2. Check for proper voltage at the wall receptacle.

3. Check the fuse or reset the circuit breaker.

4. Is the water supply turned on? The fill hoses should feel stiff.

5. Test the water temperature switch contacts for continuity.

6. Check for an open circuit in the timer contacts. On electronic models, run the test mode.

7. Check for loose wires to the water valve solenoid.

8. Check the entire wiring harness for loose connections.

9. Test water valve solenoid coils for continuity.

10. Check the water valve inlet strainer screens. Remove the fill hoses to inspect these filters.

11. Test the water level control switch for continuity.

12. Are the water supply hoses kinked?

13. Check water valves separately for fill.

14. Check for low water pressure at the washer and in the home.

15. Check for frozen pipes and washer fill hoses.

Motor Will Not Run

1. Check for proper voltage at the wall receptacle.

2. Is the washer plugged in? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit.

3. Check for a blown fuse or a tripped circuit breaker.

4. Check the line filter.

5. Check for a faulty timer. On electronic models, run the test mode and check the electronic control board.

6. On electronic models, check the motor drive board.

7. Are there any loose wires to the timer, motor, etc.?

8. Test the motor windings for continuity.

9. Test the thermal overload in the motor for continuity.

10. Test the water level control switch contacts for continuity.

11. Test the motor speed selector switch contacts for continuity.

12. Are there any open wires in the washer circuit?

13. Test the capacitor on the motor using a capacitor tester.

14. Check the centrifugal switch in the motor.

15. Check for continuity of the lid switch contacts. On some models, the lid must be closed before the motor will start.

16. On some models, check for a blown motor thermal fuse.

17. Check for obstructions in the drain pump.

18. On some models, turn the transmission pulley by hand in the agitation direction. If it is locked, replace the transmission.

Washer Will Not Agitate

1. Check fuse or circuit breaker. The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit.

2. On some models you may have to restart the cycle.

3. Check for a broken or worn belt.

4. Check the motor to the transmission drive coupling (direct-drive models).

5. Test the timer contacts for continuity. On electronic models, run the test mode.

6. Are there any loose wires within the wiring harness?

7. Are there any loose wires to the timer, motor, etc.?

8. Test the continuity of the motor windings.

9. Test the agitator solenoid on the transmission.

10. Check for loose pulleys on the transmission and motor.

11. Check the water level control switch.

12. Test for continuity of the start relay.

13. Test the capacitor on the motor using a capacitor tester

14. Check the centrifugal switch in the motor.

15. Test for continuity of the lid switch contacts.

16. Test for continuity of the speed selector switch.

17. Check the clutch assembly.

18. Check the transmission.

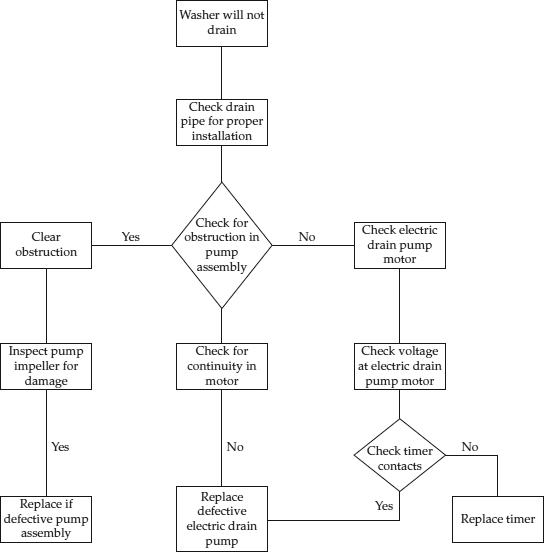

Water Will Not Drain

1. Check for a clogged drain connection.

2. In cold climates, check for frozen drain hose.

3. Inspect the pump for obstructions.

4. Check the drain hose and be sure it is not kinked.

5. Check the belt that goes to the pump.

6. Check for suds lock. If this happens, just add cold water and flush the suds out of the pump. (Suds lock is caused by too much soap remaining in the tub, pump, and the connecting hoses. This condition will prevent water from draining effectively.)

7. On direct drive models, check the pump coupling. The pump and motor must be removed for a visual inspection of the coupling.

8. Check for air lock in the pump (air trapped inside the pump caused by debris).

9. Check to be sure that the motor is not running in the agitation direction.

10. Check the height of the drain.

11. Does the pump pulley turn freely?

12. On models with an electric drain pump motor, check for a blockage and also check the pump motor for continuity. Check for voltage at the drain pump motor.

Washer Will Not Spin

1. Check fuse or circuit breaker. The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit.

2. Check for a loose or broken belt.

3. Check for loose pulleys.

4. Check the clutch assembly.

5. Check for loose or broken wires in the washer circuit.

6. Test the continuity for a faulty lid switch assembly.

7. Test the continuity for a defective spin solenoid.

8. Check for a broken drive coupling (direct-drive models). The pump and motor must be removed for a visual inspection of the coupling.

9. Test the continuity of the water level control switch.

10. Test the continuity of the speed selector switch.

11. Test the continuity in the motor windings and the motor overload protector.

12. Test the timer contacts for continuity.

13. Check for clothing jammed between the inner basket and the outer tub.

14. Check all seals and mechanical linkages.

15. Check the transmission.

16. Check to be sure that the motor is running in the spin direction.

Washer Speed Too Slow

1. Check voltage at washer. The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit.

2. Check the spin selection. Make sure it was not selected.

3. Check the RPM of the tub in the spin cycle.

4. Check the drive belt.

5. Make sure the drain system in the home is functioning correctly.

6. Check for a kinked drain hose.

7. Check the tub seal. Is it binding?

8. Check the brake assembly for proper operation.

9. Look between the tubs for a foreign object binding the tubs.

10. Check the drain pump for a broken impeller.

Noisy Washer and/or Vibration/Walking Washer

1. Check for proper washer installation.

2. Check the leveling legs on the washer for proper adjustment and that they are locked into position.

3. Check that the rear legs stabilizer is locked into position.

4. Check to make sure that the pads are on the leveling legs.

5. Check flooring. The washer needs to be installed on a solid foundation.

6. On some models, check the belt.

7. Check the transmission, pulleys, and bearings.

8. Check the center tub seal.

9. Check the outer basket suspension.

10. Check for loose screws in the cabinet, front, and rear panels.

11. Check the base of the washer.

Wrong Water Temperature

1. Run the washer and verify the water temperatures.

2. Check that faucets are turned on fully.

3. Check hot water heater for a minimum of 120 degrees Fahrenheit at the tap.

4. Check hot water heater for capacity and recovery rate. May have to purge water prior to starting a cycle.

5. Check the inlet hoses. Are they reversed?

6. Check water valve, timer, or the automatic temperature control.

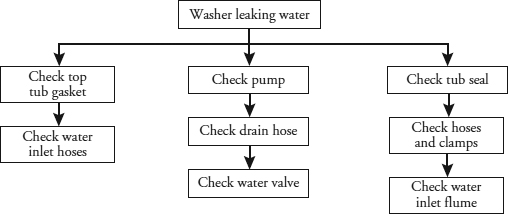

Washer Leaks Water

1. Check water inlet hoses.

2. Check water inlet hose connections.

3. Check drain hose installation.

4. Check tub seal.

5. Check all water hose connections in the washer.

6. Check for a cracked outer tub.

7. Check the water pump.

Common Washability Problems

If there are no mechanical problems with the washer’s operation and the complaints are that the washer does not clean the clothes properly, you have a washability problem. The next step should be to look at the cause that best describes the problem that the customer is experiencing with the washer. Then proceed to correct the problem. If necessary, instruct the user how to get better results from the automatic washer.

Stains on the Clothing

Stains on clothing can be caused by a number of different things. As the servicer, you will have to determine if it is caused by the washer’s components or from an external source. Many stains are blamed on leaking transmissions. This type of problem is related to the increasing use of synthetic fabrics and to the poor washing practices of the user. Many of these stains consist of cooking oil or grease and are not visible when they first occur during cooking or eating. The oil that is embedded in the clothing acts like glue, attracting dirt from the wash water. When the wash cycle is completed, the clothes come out dirty and spotted. If the transmission oil leaked into the wash water, there will be stains on all of the clothes in a random pattern. The color of transmission oil embedded into the clothing is usually a brownish-yellow stain. Transmission oil cannot be washed out of the clothes; a solvent is required to remove the stains.

The following are some stain-removal rules for clothing in general:

• Stains are easier to remove when they first appear on the clothing. If the stains are old, they might never come out of the clothing.

• Before attempting to remove any stain, you must know: what type of stain, what kind of fabric, and how old is the stain?

• Use only cold or warm water to remove stains. Hot water will set the stain permanently into the fabric.

• When bleach is recommended for the removal of the stain, use a bleach that is safe for the fabric. When using a chlorine bleach, always dilute it with water to prevent the bleach from destroying the fibers.

• Always test stain remover products on a hidden corner of the garment to see if the color remains in the fabric.

• When preparing to remove the stain from the fabric, face the stained area down on a paper towel or a white cloth. Then apply the stain remover to the back of the stain so that the stain will be forced off the fabric, instead of through the fabric.

• Some protein stains can be removed with an enzyme pre-soak or with meat tenderizer.

• When using dry-cleaning solvents, always use them in a well-ventilated room, away from flames and sources of ignition to prevent personal injury.

• Alcoholic beverage stains turn brown the longer they stay on the fabric. As soon as the stain appears on the fabric, start treating the stain immediately. Wash or soak the stain in cold water, and then wash the garment.

• To remove blood stains, rinse or soak the garment in cold water with an enzyme pre-soak product. You can use diluted chlorine bleach on white fabrics, if necessary. For colored fabrics, use a powdered oxygen-type bleach. Then wash the garment.

• To remove chewing gum, use ice on the stain to make the chewing gum hard. Then scrape most of it off the fabric. Next, use a nonflammable dry-cleaning solvent with a sponge to remove the excess chewing gum. Wash the garment.

• To remove coffee or chocolate stains, soak the garment in warm or cold water. Next, make a paste of detergent mixed with hot water, and brush it on the stain. Wash the garment.

• To remove a milk product stain, use a nonflammable dry-cleaning solvent with a sponge. Wash the garment.

• To remove antiperspirant and deodorant stains, wash the garment with laundry detergent in the hottest water that is safe for the fabric. If the stain remains on the fabric, place the stain face down on a white towel, and treat the stain with a paste of ammonia and a powdered oxygen-type bleach. Let the paste stay on the stain for 30 minutes, and then wash the garment in the hottest water that is safe for the fabric.

• To remove fruit stains, soak the stain in cool water. Do not use soap—it will set the stain. Wash the garment. If the stain remains, cover the stain with a paste made of a powdered oxygen-type bleach, a few drops of hot water, and a few drops of ammonia. Let the paste stay on the stain for about 15 to 30 minutes. Then wash the garment.

• To remove iron or rust stains, apply some lemon juice mixed with salt. Then place the garment in the sun. Alternatively, a commercial rust-removing solution can be used. Wash the garment.

Yellowing in Fabric

Some causes of yellowing in fabrics are:

• Poor body soil removal

• Clothes washed in water treated with a water softener

• Hard water or minerals in the water, such as iron

• Body oils released into the garment

• The water supply might pick up the color of decaying vegetation

To remove body oils, the user will have to increase the amount of detergent and use 150-degree Fahrenheit wash water. The user must also increase the frequency of using bleach in the wash.

To remove the yellowing from garments that are washed in water treated with a water softener, the user will have to decrease the amount of detergent used, approximately to the point that the decreased amount will not affect the soil removal process. The user must also increase the frequency of using bleach in the wash.

Hard water and minerals in the water can be treated with a water-conditioning apparatus. The user might have to drain the water heater and flush the tank. Never use chlorine bleach to remove hard water stains or iron stains.

To remove body oils from the garment, use a paste made of detergent and water. Let it stay on the fabric for 15 to 30 minutes. Then wash the garment.

To remove the yellowing caused by decaying vegetation, increase the amount of detergent, and bleach more often. White fabrics typically respond quite well to bleaching.

Fabric Softener Stains

Fabric softener stains are becoming more prevalent because it is now being recommended that some fabric softeners be used in the wash cycle, instead of the rinse cycle. These types of stains show up on synthetics as well as cotton fabrics. They can be removed from the fabric by pretreating the stain with liquid detergent and following the washing procedures listed in the use and care manual.

Lint

Lint is cotton fiber that has broken away from the cotton garment. Lint likes to attach itself to synthetic fabrics. When this happens, the user often thinks that the washer is not performing properly. Therefore, to solve the problem of lint on synthetic fabrics, the user must sort the items before washing the clothes. For example:

• The user must separate cottons from permanent press and knits.

• The user must separate light colors from dark colors.

Another cause of lint on clothes is overwashing. This causes the clothes to wear out faster. To correct the overwashing problem, use only one minute of wash time per pound of dry laundry with normal soil. Any more time than this is a waste, and it usually does not get the laundry cleaner.

If the drain cycle is excessive, this, too, will cause lint to remain on the garments.

Check for improper drain hose connections. For example:

• Drain hose is too long (over 10 feet)

• Drain hose is too high (over 5 feet)

• Drain hose is kinked

If excessive drain times still exist, check the following:

• Check the filter, located under the wash basket on most newer models.

• Check to be sure that the pump is operating properly.

• Check for any obstructions in the drain system.

• Check for any obstructions within the water circulatory system of the washer.

Automatic Washer Maintenance

The interior is normally self-cleaning. However, there are times when you might have to remove objects from the inner basket. Clean the control panel and outer cabinet with a soft damp cloth. Do not use any abrasive powders or cleaning pads. Clean and inspect the interior underneath the washer. Read the use and care manuals for the proper maintenance of the brands of washers you service.

Cleaning the Interior of the Top Load Automatic Washer

Every one to two months the interior of the washer will need to be cleaned. This periodic cleaning will remove any dirt, soil, mold, mildew, or bacteria residue that may remain in the washer as a result of washing the clothes. To clean and freshen the washer interior:

1. Add a cup of chlorine bleach in the bleach dispenser. On some models, pour the bleach in the wash water as the tub is filling with water.

2. Add ¼ cup of detergent to the tub or detergent dispenser.

3. Run the washer without clothes through a complete cycle using only hot water.

4. Repeat the process if necessary.

Repair Procedures

Each repair procedure is a complete inspection and repair process for a single washer component, containing the information you need to test a component that might be faulty and to replace it, if necessary.

Any person who cannot use basic tools should not attempt to install, maintain, or repair any top load washer. Any improper installation, preventative maintenance, or repairs will create a risk of personal injury, as well as property damage. Call the service manager if installation, preventative maintenance, or the repair procedure is not fully understood.

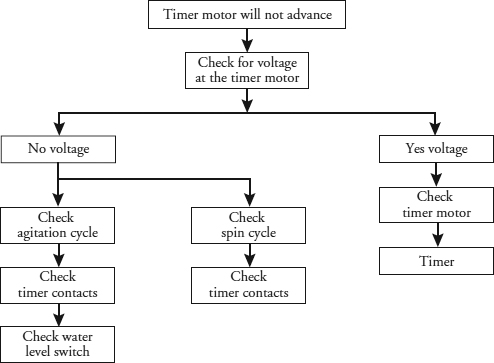

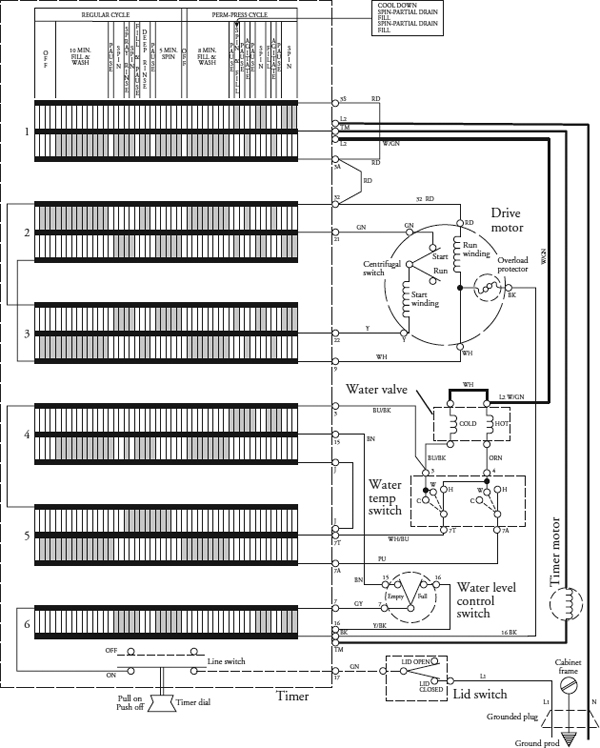

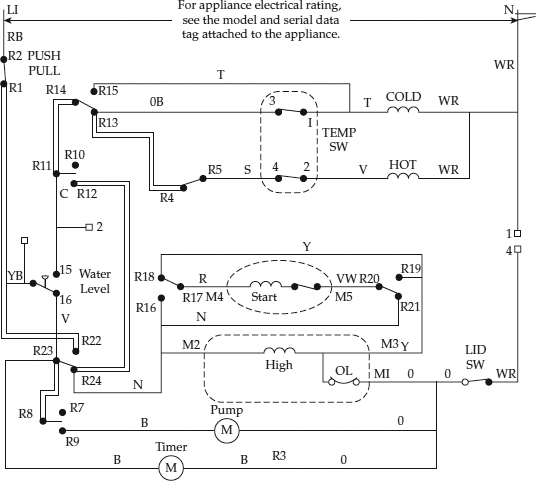

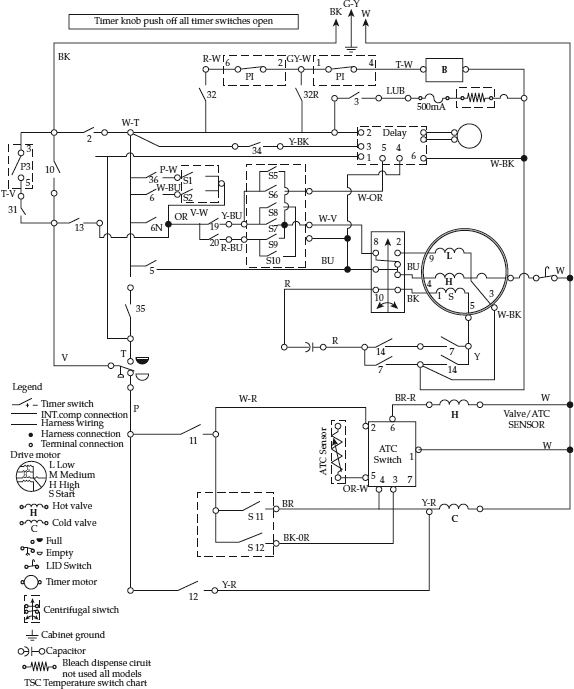

Washer Timer

The washer timer is an electromechanical component controlled by a synchronous motor in incremental advances. It controls and sequences the numerous steps and functions involved in each cycle.

The typical complaints associated with washing machine timer failure are:

• The cycle will not advance.

• The washer won’t run at all.

• The washer will not fill.

• The washer will not pump the water out.

• The washer will not shut off.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer through its cycles. Before you change the timer, check the other components controlled by the timer. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug out from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

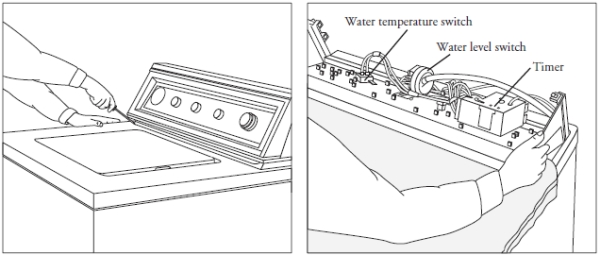

4. Remove the console panel to gain access. Begin by removing the screws from the console panel to gain access to the timer (Figure 18-2). Roll the console toward you. On some models, the console will roll upward.

FIGURE 18-2 Remove the screws that hold the control console. Fold over the console to gain access.

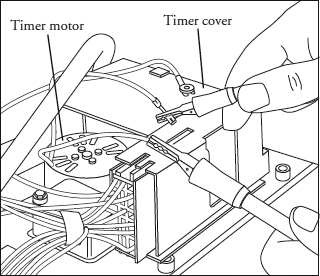

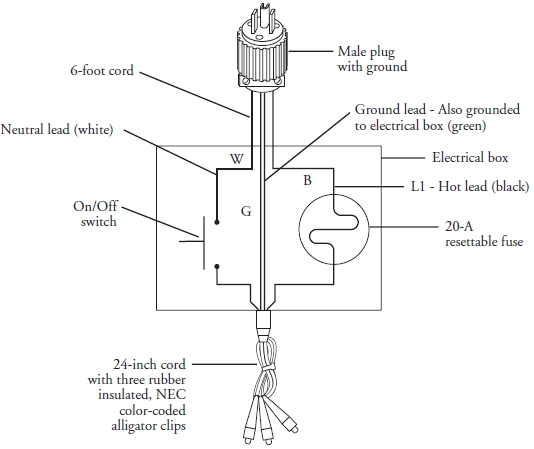

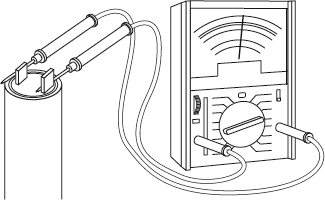

5. Test the timer. Remove the timer motor leads from the timer assembly. Test the timer motor by connecting the ohmmeter probes to the timer motor leads (Figure 18-3). Set the range on the ohmmeter to R x 100. The meter should indicate between 2000 and 3000 ohms. Next, test the timer switch contacts using the wiring diagram configuration for the affected cycle. Place the meter probe on each terminal being tested, and turn the timer knob. If the switch contact is good, your meter will read continuity. If the timer motor measures suitably, then connect a 120-volt, fused service cord (Figure 18-4) to the timer motor leads.

If the motor does not operate, replace the timer. If the timer motor runs but does not advance the cams, then the timer has internal defects and should be replaced.

FIGURE 18-3 Checking the washer timer motor.

FIGURE 18-4 120-volt fused service test cord.

NOTE Connect the ground (common) wire test lead to the console ground wire. Be cautious whenever you are working with “live” wires. Avoid any shock hazards.

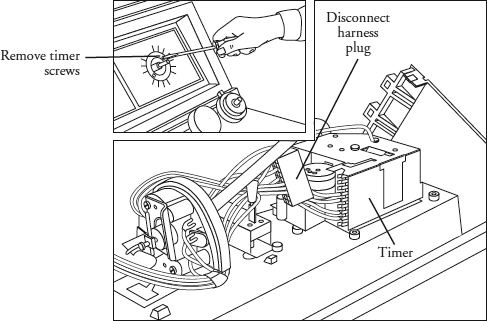

6. Remove the timer. To remove the timer, remove the timer mounting screws (Figure 18-5). Remove the wire lead terminals from the timer. Mark the wires as to their location on the timer. Some timers have a disconnect block instead of individual wires, which makes it easier to remove the timer wires.

Turn the timer knob counterclockwise to remove it from the timer shaft, and slide the indicator dial off the shaft.

FIGURE 18-5 Removing the timer.

7. Install a new timer. To install a new timer, just reverse the disassembly procedure, and reassemble. Replace the wires on the timer. Reinstall the console panel, and restore the electricity to the washer. Test the washing machine cycles.

Electronic Control Board and User Interface Controls

On some models the electronic control board and user interface controls replace the electromechanical timer and rotary selection switches.

The typical complaints associated with the electronic control board or the user interface controls are:

• The washer won’t run or power up.

• Unable to program the washer.

• The display board will not display anything.

• One or more key pads will not accept commands.

• Unusual display readouts and/or error codes

To prevent electrostatic discharge (ESD) from damaging expensive electronic components, follow the steps in Chapters 6 and 11.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer. Turn off the electricity to the appliance and wait for two minutes before turning it back on. If a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is there electricity to the washer? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug out of the wall receptacle. Or disconnect the electricity at the fuse panel or circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position the panel in such a way so that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

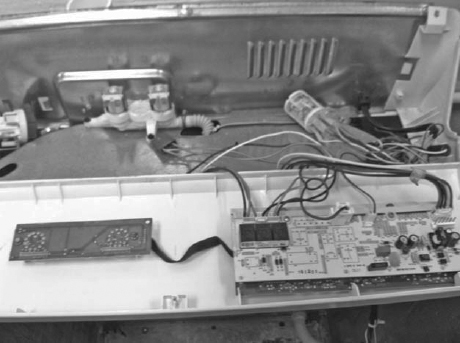

4. Remove the console panel to gain access. Begin by removing the screws from the washer console to gain access to the electronic control board. On top-loading models, the console will roll upward or toward you after removing the console screws (Figure 18-6).

FIGURE 18-6 A view of the control panel parts for a top load automatic washer.

5. Test the electronic control board and user interface controls. If you are able to run the washer diagnostic test mode, check the different functions of the washer. Use the technical data sheet for the model you are servicing to locate the test points from the wiring schematic. Check all wiring connections and wiring. Using the technical data sheet, you can test the electronic control board or user interface controls and input and output voltages. On some models, fuses are soldered to the printed circuit board (PCB). These fuses must be tested first before condemning the component.

6. Remove the electronic control board and user interface controls. To remove the defective component, remove the screws that secure the board to the control panel or washer frame. On some models you may have to lift a tab and turn the control to remove it. Disconnect the connectors from the electronic control board or user interface control.

7. Install the new component. To install a new electronic control board or user interface control, read the data sheet that comes with the part for the proper installation process and just reverse the disassembly procedure and reassemble. Reinstall the console panel, and restore the electricity to the washer. Make sure that the washer is not in the service mode. Test the washer operation.

Water Temperature Selector Switch

The water temperature selector switch will allow the user to choose different water temperatures for the specific wash cycle.

The typical complaints associated with the water temperature selector switch are:

• Inability to select a different water temperature.

• The consumer inadvertently selected the wrong water temperature.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by trying to select different water temperatures. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Is there any physical damage to the component? Are the fill hoses connected to the hot and cold water supply correctly? Be sure that both the hot and cold water faucets are turned on. The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug out of the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

4. Remove the console panel to gain access. Begin by removing the console panel to gain access to the water temperature selector switch (see Figure 18-3).

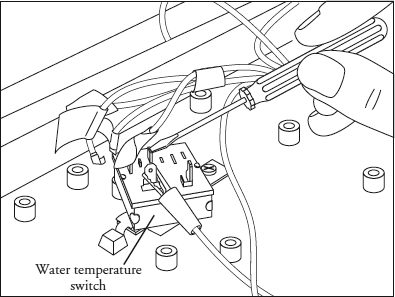

5. Test the water temperature selector switch. To test the water temperature selector switch, remove all wires from the switch. Label the wires.

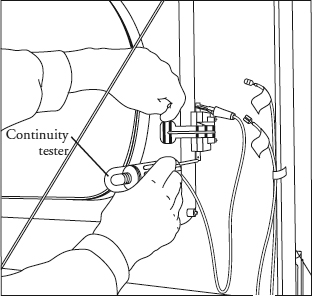

Remember, you will have to identify the wires according to the wiring diagram in order to reinstall them onto the water temperature selector switch properly. Take your ohmmeter and check for continuity on the switch contacts. Press or turn on the switch that coincides with the terminals that are being checked (Figure 18-7). At this point, you have to use the wiring diagram to identify the switch contacts.

FIGURE 18-7 Checking the water temperature switch.

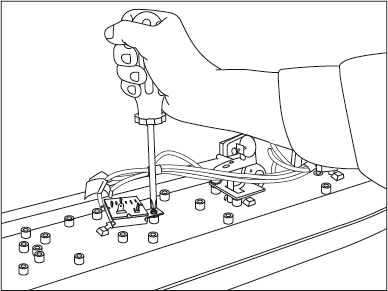

6. Remove the water temperature selector switch. To remove the water temperature selector switch, remove the screws that hold the component to the console panel (Figure 18-8).

FIGURE 18-8 Removing the water temperature switch.

7. Reinstall the water temperature selector switch. To reinstall the water temperature selector switch, just reverse the disassembly procedure, and reassemble.

NOTE You will have to identify the wires according to the wiring diagram in order to reinstall them onto the water temperature selector switch properly. Reinstall the console panel, and restore the electricity to the washer. Test the washing machine water temperature cycles.

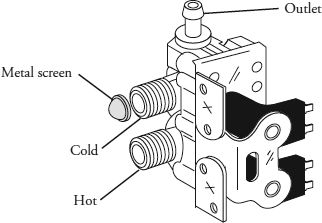

Water Valve

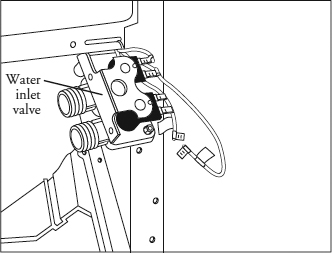

The water inlet valve controls the flow of water into the washer, and is solenoid-operated (Figure 18-9). When it is energized, water in the supply line will pass through the valve body and into the washer.

FIGURE 18-9 A typical water valve used in automatic top load washers.

The typical complaints associated with water valve failure are:

• The washer will not fill with water.

• The washer overfills and leaks onto the floor.

• When the washer is off, water still enters the tub.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer through its cycles. Listen carefully, and you will hear whether the water is entering the washer. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.) Is the water turned on? Both water faucets must be turned all the way counterclockwise.

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

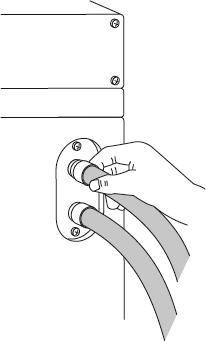

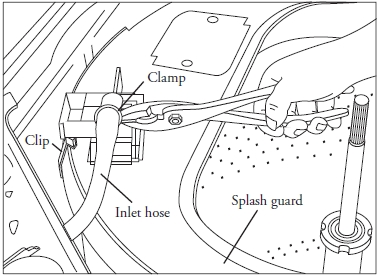

4. Gain access to the water valve. Turn off the water supply to the washer water valve. To access the water valve, the rear panel must be removed. (On some models, to access the water valve, you will gain access through the control panel.) Disconnect the fill hoses from the inlet end of the water valve (Figure 18-10). Next, remove the screws that hold the water valve to the chassis of the washer (Figure 18-11).

FIGURE 18-10 Turn off the water supply, and remove the fill hoses.

FIGURE 18-11 Remove the wires from the solenoid coil.

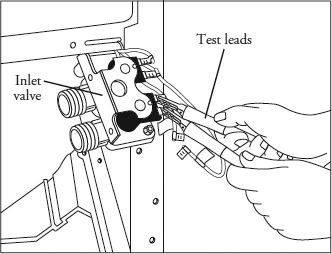

5. Test the water valve. In order to check the solenoid coils on the water valve, remove the wire leads (label them) that connect to the coils from the wire harness (see Figure 18-11). These are slide-on terminal connectors attached to the ends of the wire. Just pull them off. Set the ohmmeter on R x 100, and attach the probes to the terminals of one of the solenoid coils (see Figure 18-12). The meter should read between 500 and 2000 ohms. Repeat this test for the second solenoid coil.

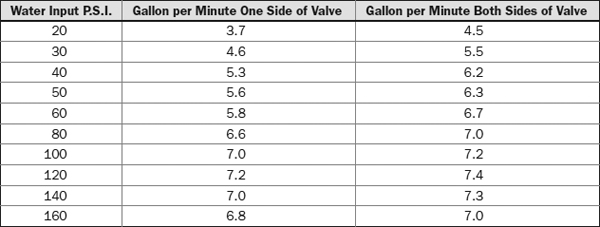

FIGURE 18-12 Attaching test leads to the solenoid coil on the water valve.

To test the fill rate of the water valve, just reverse the disassembly procedure, and reassemble the water valve. The rear panel does not have to be reinstalled for this test. Attach the 120-volt fused service cord—including the ground wire test lead to the cabinet ground (see Figure 18-4)—to the water valve solenoid coil (see Figure 18-12). Then energize the solenoid coil to allow water to enter the tub and to check the flow rate of the water valve (Table 18-1). This step is repeated for each solenoid coil. If, when you energize the water valve, no water enters the washer tub, replace the water valve. If the water valve checks correctly, check the timer and the wiring harness.

TABLE 18-1 Water Fill Rate for a Typical Water Value

6. Remove the water valve. To remove the water valve, follow the instructions in step 4. Remove the water outlet hose from the water valve.

7. Install a new water valve. To install the new water valve, just reverse the disassembly procedure, and reassemble. Reconnect the wire leads to the solenoid coils. After the installation of the new valve, turn on the water supply and check for water leaks. If none are found, reinstall the rear panel and restore the electricity to the washer. Set the timer and the water temperature control settings to operate the washer through its cycles.

Washer Motor (Older Models)

The typical complaints associated with motor failure are:

• Fuse is blown or the circuit breaker trips.

• Washer fills up with water but the motor will not run.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer through its cycles. Listen carefully, and you will hear if there are any unusual noises or if the circuit breaker trips. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

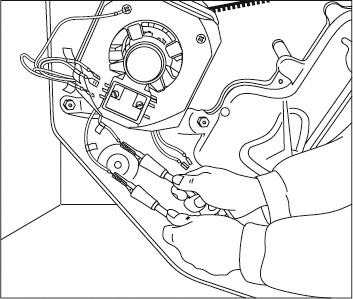

4. Gain access to the motor. To access the motor, the back panel must be removed (Figure 18-13). The back panel is held on with screws. Remove the screws and remove the panel.

FIGURE 18-13 Removing the screws that hold the back panel.

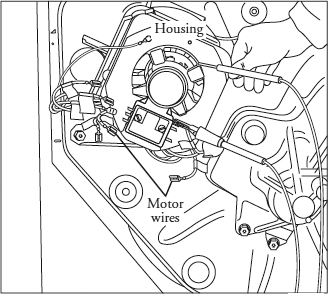

5. Disconnect the motor wire leads. Disconnect the motor wire leads from the wiring harness. Set the ohmmeter on R x 1, and attach the probes to the motor lead wires (Figure 18-14). Refer to the wiring diagram for the common, start, and run motor winding leads identification. Test these for continuity, from the common wire lead to the run winding. Then test for continuity from the common wire lead to the start winding. Next, test for continuity from the start winding to the run winding. To test for a grounded winding in the motor, take the ohmmeter probes and test from each motor wire lead to the motor housing (Figure 18-15). The ohmmeter will indicate continuity if the windings are grounded. If the motor has no continuity between the motor windings, replace the motor. If the motor checks out okay, check the timer and motor relay (if the model that you are repairing has one).

FIGURE 18-14 Checking the motor windings for continuity.

FIGURE 18-15 Checking the motor for ground.

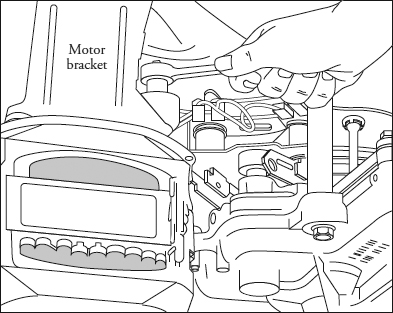

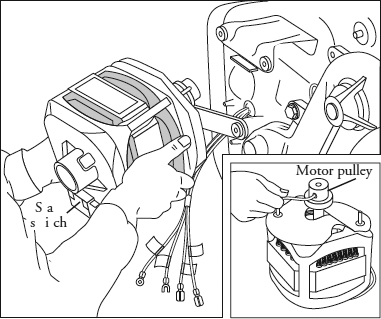

6. Remove the motor. To remove this type of motor, you must first loosen the two nuts that hold the motor support bracket (Figure 18-16). Then slide the assembly to disengage the belt from the pulley. Next, remove the four nuts that hold the motor to the motor support bracket (Figure 18-17). Remove the motor from the washer. Remember to remove any remaining wires from the motor and label them. Remove the pulley from the motor after loosening the set screw.

FIGURE 18-16 Removing the bolts that hold the motor on the bracket.

FIGURE 18-17 Removing the motor and then removing the pulley.

7. Install the new motor. To install the new motor, just reverse the disassembly procedure, and reassemble. To adjust the belt, refer to the “drive belt” section of this chapter (step 5). Restore the electricity to the washer, and test the motor. If the motor is working, reinstall the back panel.

Washer Motor (Direct-Drive Models)

The typical complaints associated with motor failure are:

• Fuse is blown or the circuit breaker trips.

• Washer fills up with water but the motor will not run.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer through its cycles. Listen carefully and you will hear if there are any unusual noises or if the circuit breaker trips. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

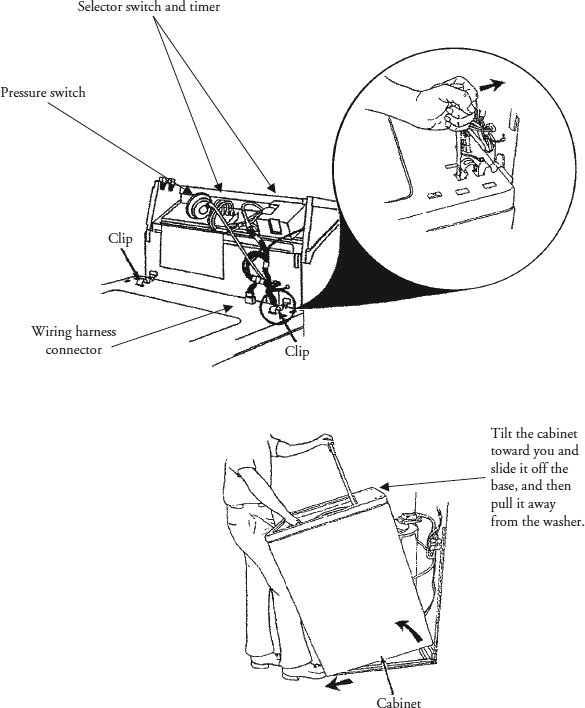

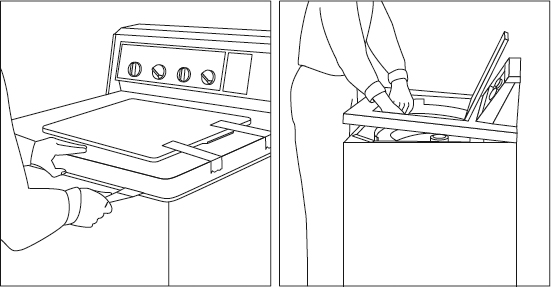

4. Gain access to the motor. To access the motor, you must first remove the cabinet from the washing machine (Figure 18-18). Remove the two screws that secure the control console to the cabinet. Tilt the control panel upward. Next, insert a flat-blade screwdriver in the cabinet retaining clip and push forward to remove it. Remove the wiring harness connector and ground wire. Finally, remove the cabinet as shown in Figure 18-18.

FIGURE 18-18 Removing the outer cabinet on a direct-drive automatic washer.

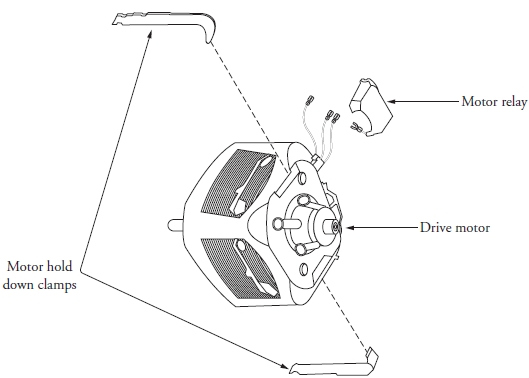

5. Test the drive motor. To test the drive motor, disconnect the wire connector from the motor relay. Refer to the wiring diagram for the motor protector; common; start, low, and high speed; and motor winding leads identification. Set your ohmmeter on the R x 1 scale and place your ohmmeter probes on the start winding. The meter should read around 7 ohms. Next test the high and low speed windings—the resistance should be between 1 and 3 ohms. Now test the motor overload protector—the reading should be zero ohms. After testing the motor, spin the motor shaft; it should spin freely. To test for a grounded winding in the motor, take the ohmmeter probes and test from each motor wire lead to the motor housing. The ohmmeter will indicate continuity if the windings are grounded. If the motor has no continuity between the motor windings, replace the motor. If the motor checks out okay, check the timer and motor relay.

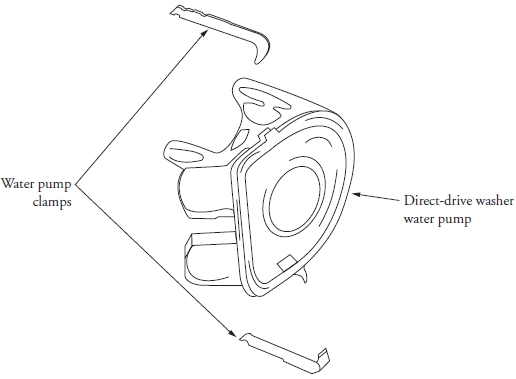

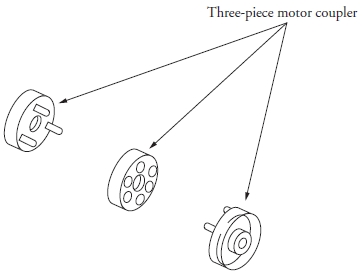

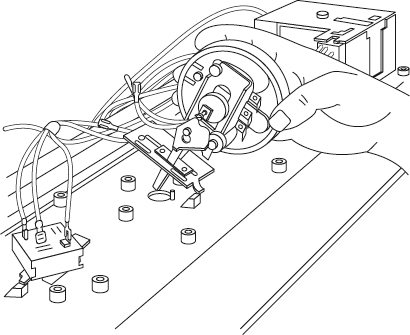

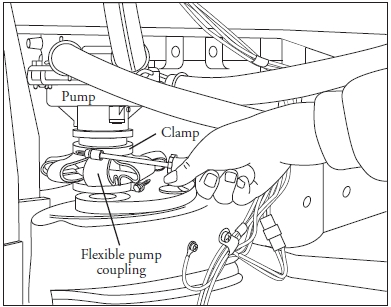

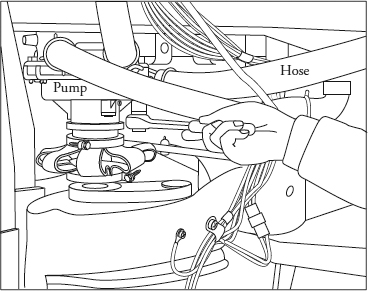

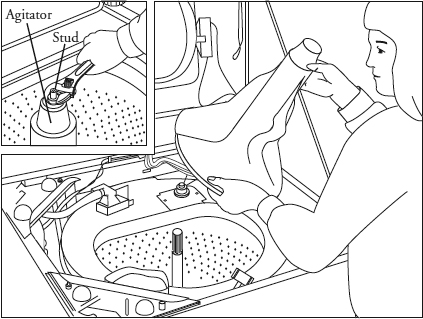

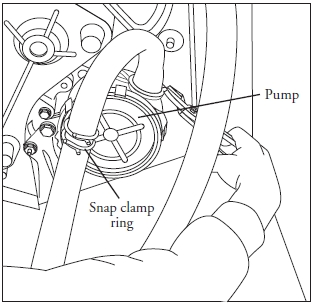

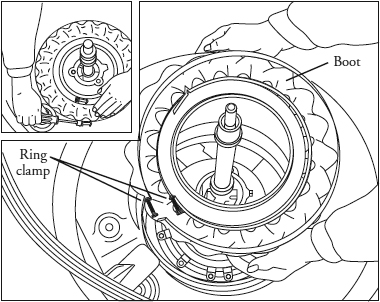

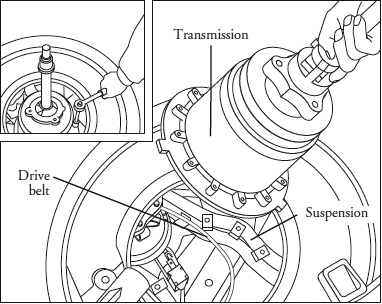

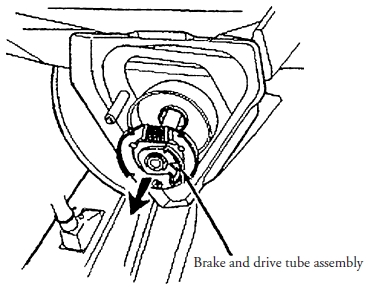

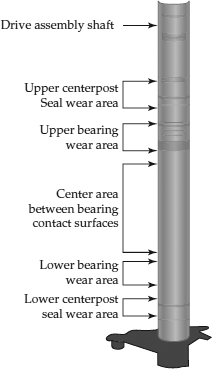

6. Remove the motor. To remove the motor, you must first remove the water pump and the motor coupler. Before removing the pump, make sure that most of the water is removed from the tub. Use a pinch-off tool to restrict the water lines at the pump hoses. Next, proceed to remove the water pump by removing the clamps that hold the pump in place (Figure 18-19). Remove the three-piece motor coupler (Figure 18-20). Finally, remove the clamps that secure the motor to the gearcase (Figure 18-21). Pull the motor toward you to remove it from the washer.

FIGURE 18-19 The direct-drive water pump.

FIGURE 18-20 The three-piece motor coupler.

FIGURE 18-21 The drive motor and relay.

7. Install the new motor. To install the new motor, just reverse the disassembly procedure, and reassemble. Restore the electricity to the washer, and test the motor. If the motor is working, reinstall the cabinet.

Front Serviceable Washer

The typical complaints associated with motor, clutch, and belt failure are:

• Fuse is blown or the circuit breaker trips.

• Washer fills up with water, but the motor will not run.

• Motor runs, but washer will not agitate or spin.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer through its cycles. Listen carefully and you will hear if there are any unusual noises or if the circuit breaker trips. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

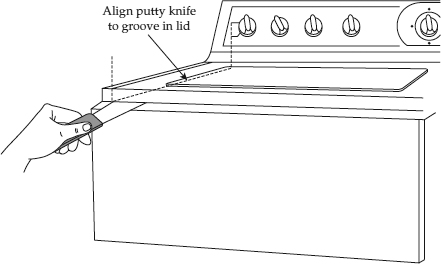

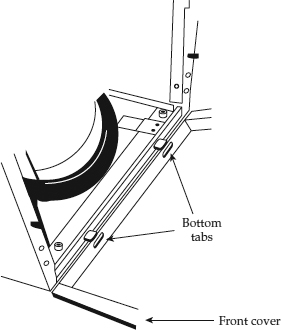

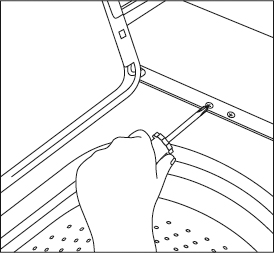

4. Gain access to the motor. To access the motor, you must first remove the front panel. Locate the two spring clips between the top cover and the front cover (Figure 18-22). Insert the putty knife and push in to release the spring clips on both sides. Pull the front panel toward you (Figure 18-23) and remove it from the bottom tabs. Next, remove the two ¼-inch hex screws from the top panel support brackets (left and right sides). Pull the top cover and lid assembly toward you and up enough to clear the locking tabs in the rear (Figure 18-24). Do not pull too much, because you have to remove the bleach hose and the lid switch. Do not cut the lid switch wires; just depress the tab from under the lid switch and remove the lid switch from the top cover. With the top and front panels removed, you now have access to the motor located on the bottom in the front of the cabinet (Figure 18-25).

FIGURE 18-22 Locate the spring clips on the left and right side, and press in to release the front panel.

FIGURE 18-23 To remove the front cover, lift it off the bottom tabs.

FIGURE 18-24 To remove the top and lid assembly, (1) lift up about 2 inches and (2) pull toward you and remove from locking tabs.

FIGURE 18-25 With the front panel removed, you now have access to the motor and clutch assembly, drain pump motor, and belt.

5. Disconnect the motor wire leads. Disconnect the motor wire leads from the motor. Set the ohmmeter on R x 1, and attach the probes to the motor lead wires. Refer to the wiring diagram for the common, start, and run motor winding leads identification. Test these for continuity, from the common wire lead to the run winding. Then test for continuity from the common wire lead to the start winding. Next, test for continuity from the start winding to the run winding. To test for a grounded winding in the motor, take the ohmmeter probes and test from each motor wire lead to the motor housing. The ohmmeter will indicate continuity if the windings are grounded. If the motor has no continuity between the motor windings, replace the motor.

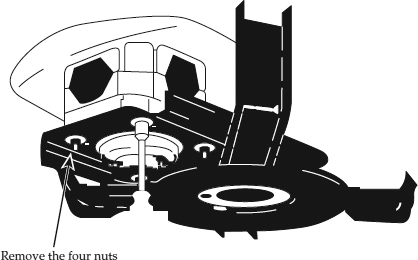

6. Remove the motor. Loosen the four 3/8-inch mounting nuts that hold the motor in place (Figure 18-26). Slide the motor inward and remove the belt. Next, remove the four 3/8-inch nuts. Rotate the transmission to a position that allows you to remove the motor from the platform.

FIGURE 18-26 To remove the motor, remove the four 3/8-inch nuts from the motor.

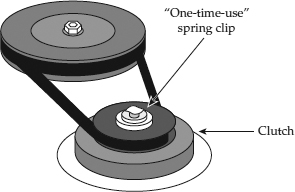

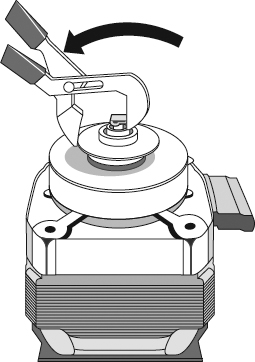

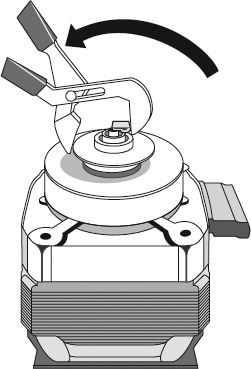

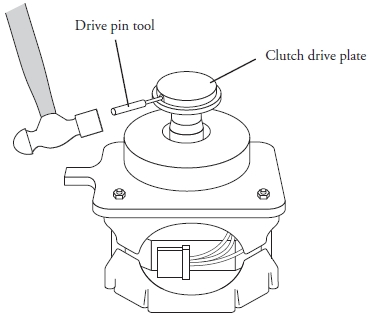

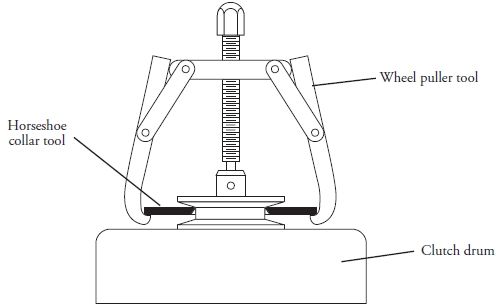

7. Remove the clutch. After removing the motor, turn it upright to access the clutch. Remove the one-time-use spring clip from the clutch with pliers (Figures 18-27 and 18-28).

FIGURE 18-27 The “one-time-use” spring clip is located on the clutch assembly. It must be replaced with a new one.

FIGURE 18-28 Squeeze and rotate the pliers to remove the spring clip.

8. Install the new motor and clutch. To install the new motor and clutch, just reverse the disassembly procedure, and reassemble (Figure 18-29). Restore the electricity to the washer, and test the motor and clutch assembly. If the motor is working, reinstall the cabinet top and front panels.

FIGURE 18-29 Squeeze and rotate the pliers to reinstall the new spring clip.

Capacitor

A capacitor is a device that stores electricity to provide an electrical boost for motor starting. Most high-torque motors need a capacitor connected in series with the start winding circuit to produce the desired rotation under a heavy starting load.

The typical complaints associated with capacitor failure are:

• Fuse is blown or the circuit breaker trips.

• Washer motor will not run.

• Motor has a burning smell.

• Motor will try to start and then shuts off.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer. Listen carefully and you will hear if there are any unusual noises or if the circuit breaker trips. If you smell something burning, immediately turn off the washer and pull the plug. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

4. Gain access to the capacitor. Some models have the capacitor mounted on the motor, and some are mounted to the cabinet interior in the rear of the machine. Access might be achieved through the front or rear panel, depending on which model you are working on. Do not touch the capacitor until it’s discharged.

WARNING A capacitor will hold a charge indefinitely, even when it is not currently in use. A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done.

5. Test capacitors. Before testing the capacitor, it must be discharged. Use a screwdriver with an insulated handle to discharge the capacitor by shorting it across both terminals. Remove the wire leads, one at a time, with needle-nose pliers. Set the ohmmeter on the highest scale and then place one probe on one terminal and the other probe on the other terminal (Figure 18-30). Observe the meter action. While the capacitor is charging, the ohmmeter will read nearly zero ohms for a short period of time. Then the ohmmeter reading will slowly begin to return toward infinity. If the ohmmeter reading deflects to zero and does not return to infinity, the capacitor is shorted and should be replaced. If the ohmmeter reading remains at infinity and does not dip toward zero, the capacitor is open and should be replaced.

FIGURE 18-30 Placing ohmmeter test leads on the capacitor terminals.

Another way to test a capacitor is to attach a capacitor tester to it and test the microfarad reading. It should be within +/− 10 percent of the capacitor rating that is stamped on the side of the capacitor. By using a capacitor tester, you will be able to test for a weak capacitor even if it tests out okay with an ohmmeter.

6. Remove the capacitor. Remove the capacitor from its mounting bracket.

7. Install a new capacitor. To install the new capacitor, just reverse the disassembly procedure, and reassemble. Note: A capacitor is rated by its working voltage (WV or WVac) and by its storage capacity in microfarads (µF). Always replace a capacitor with one that has the same voltage rating and the same (or up to 10 percent greater) microfarad rating.

Drive Belt

The typical complaints associated with belt failure are:

• Washer will not agitate.

• Washer will not spin.

• Washer motor spins freely.

• There is a smell of something burning.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer in the spin cycle. Listen carefully and you will hear and see if the inner basket is turning or if the circuit breaker trips. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug out from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

4. Gain access to the belt. You must gain access to the belt—whether by removing the back or the front panel, tilting the washer, or laying it onto its back—depending on which model washer you are working on. The back panel (or the front panel) is usually held on with two screws. Remove the screws, and remove the panel.

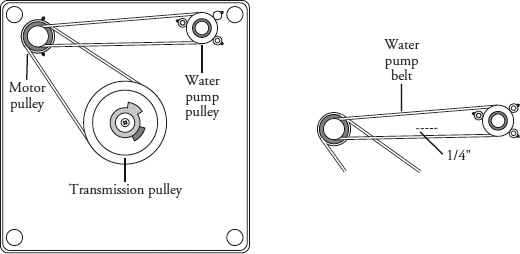

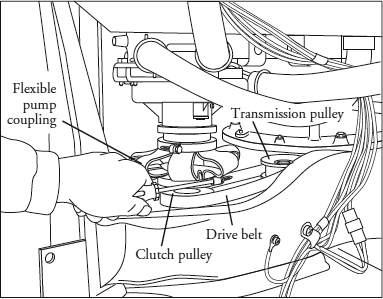

5. Adjust the belt. Before adjusting the belt, use your finger and press on the belt; it should only deflect about 1/4 inch. To adjust the belt (see Figure 18-16), loosen the motor bracket nut just enough to move the bracket. Take hold of the motor bracket, and pull against the belt just enough to take up the slack in it and to properly re-tension it. If you are unable to adjust the tension, or if the belt is worn, replace the belt. Some models have more than one belt: one is for the drive system that is attached to the motor and the transmission pulleys; the other belt is for the water pump. This belt is attached to the motor pulley and to the water pump pulley (Figure 18-31). To adjust the water pump belt in this type of washer, just loosen the pump mounting screws and adjust to obtain the correct tension, about 1/4-inch deflection. There are even some models that use a direct-drive system (which has no belts) to drive the motor, transmission, and pump (Figure 18-32). This type of washer has the motor and the water pump attached to the transmission with retaining clips.

FIGURE 18-31 View from underneath the washer base. Check belt defection.

FIGURE 18-32 The direct-drive washer has no belts.

Between the motor shaft and the transmission, there is a coupling. To replace this coupling, remove the retaining clips that secure the water pump and the motor. Install the new coupling, and reattach the motor and the water pump.

6. Replace the drive belt. To replace the drive belt on this type of washer, you must remove the flexible pump coupling (Figure 18-33). Next, loosen the motor bracket nuts, and slide the motor forward to take the tension off the belt. Then remove the belt from the motor pulley and the transmission pulley (Figure 18-34). Install the new belt on the transmission pulley and the clutch pulley. Be sure that the belt is in the pulley grooves. Next, adjust the belt tension, and tighten the motor bracket nuts. Reinstall the flexible pump coupling and clamps, making sure that the coupling is not twisted and that it is seated on the pump and clutch pulleys. The drive belt tension on this type of washer should be approximately 1/2 inch when deflected.

FIGURE 18-33 Loosening the screw on each clamp and removing the flexible coupling.

FIGURE 18-34 Sliding the belt over the motor pulley.

7. Test the washer. You are now ready to test the washer. Begin the wash cycle with a full load of laundry in the basket. Check the agitate and the spin cycles. If these check out okay, reinstall the outer panels. If not, readjust the belt tension.

Water Level Control

The water level control starts in the empty position. As the washer fills with water and the water level rises in the tub, it causes the air pressure in the tube and in the air dome to increase (Figure 18-35). The air pressure is transferred from the air hose to the water level control and against the diaphragm, which actuates the water level switch to the full position and agitation begins.

FIGURE 18-35 Water level control and air dome assembly.

The typical complaints associated with the water level control (pressure switch) are:

• Water is flowing over the top of the tub.

• Tub does not fill to the proper level selected.

• Washer will not agitate.

• Washer will not spin.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by trying to select different water levels when operating the washer through its cycles. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.) Is there any physical damage to the component? Is the plastic hose connected to the water level control and air dome? Check to be sure that the water is turned on all the way.

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

4. Remove the console panel to gain access. Begin by removing the console panel to gain access to the water level control (see Figure 18-2).

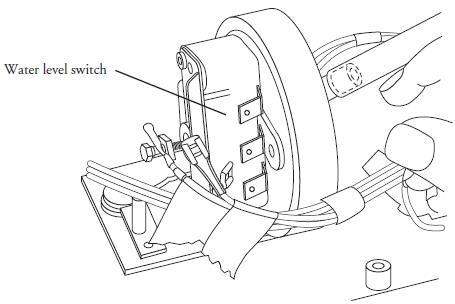

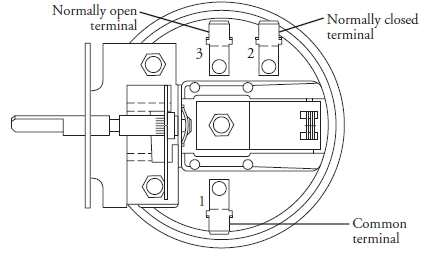

5. Test the water level control. To test the water level control switch, remove and label all of the wires from the switch (Figure 18-36). Remember, you will have to identify the wires according to the wiring diagram in order to reinstall them on the water level control switch properly. With the washer empty, use your ohmmeter (set on R x 1), and test it for continuity on the switch contacts numbered 1 and 2 (Figure 18-37). If you have continuity, this means that the water valve will be energized, allowing the water to enter the tub. Now test for continuity between contacts 1 and 3; the ohmmeter should read no continuity. Reconnect the wires to the water level switch.

FIGURE 18-36 Removing the wires from the water level control before checking continuity.

FIGURE 18-37 Adjustable water level control terminal identification for this model only.

Plug in the washer, and start the wash cycle. Let the console rest on top of the washing machine for this test. Be careful not to touch any live wires or to short them to the washer chassis while the test is being performed. As the water level rises in the tub, it forces air through the air dome and up the plastic tube to the water level control. The pressure that is exerted on the water level control’s diaphragm will trip the water level switch from empty to full, which will start the agitation cycle. When the agitation cycle begins, turn off the washer. Pull the power plug from the wall socket to ensure that power has been removed.

At this point, test for continuity again between the contacts numbered 1 and 2. The ohmmeter should read no continuity. Next, test for continuity between contacts numbered 1 and 3. The ohmmeter will read continuity. If the water level switch checks out, then check the plastic hose that goes from the air dome to the water level control. Ensure that there are no holes or cracks in the line. If the switch does not check out okay, replace it. Remember: Never blow into the water level control switch to activate it. Why? You might activate the switch, but it will not prove that the switch will activate (at lesser pressures) at the proper water level setting selected.

6. Remove the water level control. To remove the water level control, remove the wires and then remove the screws that hold the component to the console panel (Figure 18-38). Next, remove the plastic hose.

FIGURE 18-38 Disconnecting the wires and removing the screws that hold the control to the console.

7. Reinstall the water level control. To reinstall the water level control, just reverse the disassembly procedure, and reassemble. Remember, you will have to identify the wires according to the wiring diagram in order to properly reinstall them on the water level control.

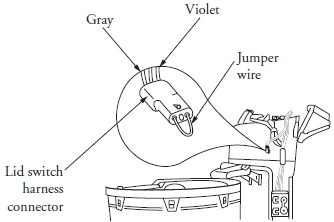

Lid Switch

On some models, the lid switch will pause the spin operation; on other models, it will pause the wash operations, except water fill. Once the washer cycle is started, the washer lid should remain closed until the end of the wash cycle. The lid switch is a safety device added to protect consumers from getting entangled within the washer. Never bypass this switch.

The typical complaints associated with the lid switch are:

• Washer will not spin.

• Washer will not agitate.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by closing the washer lid and turning the timer dial to start the spin cycle. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.) Is there any physical damage to the component?

3. Disconnect the electricity. Before working on the washer, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the washer plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel, you can position it in such a way that the wiring will not make contact with metal. This act will allow you to test the components without electrical mishaps.

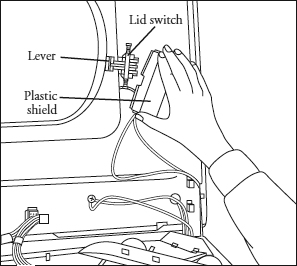

4. Gain access to the lid switch. If the washer’s top snaps in place, tape the lid shut. Use a putty knife to release the spring clips in each corner, and lift off the top. If the spring clips won’t release, open the lid, pull the top toward you, and lift (Figure 18-39). Raise the washer top to gain access to the lid switch (Figure 18-40).

FIGURE 18-39 Tape the lid closed. Then pry the top open and lift the top off.

FIGURE 18-40 Removing the plastic shield to gain access to the lid switch.

On some models, the top is held down with two screws that are secured from underneath the top. The front of the cabinet is secured in place with two screws; take them out and remove the front panel. Then remove the screws that hold the top in place. On other models, the top is part of the cabinet (Figure 18-41). To gain access to the switch, the cabinet will have to be removed as shown in Figure 18-18.

FIGURE 18-41 Remove the screws that hold the console and then remove the two clips that hold the cabinet in place and remove the cabinet.

5. Test the lid switch. To test the lid switch, remove the two wires from the switch (Figure 18-42). With a continuity tester, test for continuity between the two terminals of the switch while moving the lid switch lever. If the switch fails these tests, replace the switch.

FIGURE 18-42 Removing the wires to check for continuity of the switch.

6. Replace the lid switch. Remove the screws that hold the switch in place (Figure 18-43). Install the new switch, and connect the wires on the switch terminals. Then reconnect the electricity and test the washer.

FIGURE 18-43 Removing the two screws that hold the lid switch in place.

Water Pump

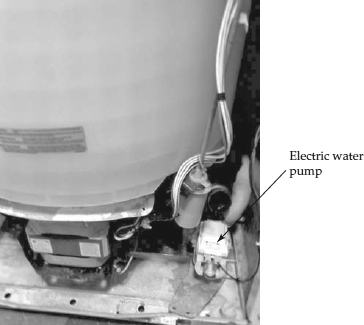

Two types of water pumps are used on automatic washers: mechanical (direct drive or belt driven; Figure 18-41) and electric (electric motor coupled to a pump; Figure 18-44). The water pump is used for draining the water from the washer.

FIGURE 18-44 Some models use an electric water pump to drain the water out of the tub.

The typical complaints associated with the water pump are:

• Washer will not drain the water out.

• It smells like something is burning.

• The water in the washer will not recirculate.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the washer. On electronic models, if a fault code appears, look up the code. If the washer will not power up, locate the technical data sheet behind the control panel for diagnostics information. On some models you will need the actual service manual for the model you are working on to properly diagnose the washer. The service manual will assist you in properly placing the washer in the service test mode for testing the washer functions.

2. Check for external factors. You must check for external factors not associated with the appliance. Is the appliance installed properly? Does the appliance have the correct voltage? The voltage at the receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)