Chapter 11

Becoming Lean

In This Chapter

Tracing the history of craft and mass production

Tracing the history of craft and mass production

Examining the principles and tools of lean businesses

Examining the principles and tools of lean businesses

Explaining push systems, pull systems, and the customer interface

Explaining push systems, pull systems, and the customer interface

Most doctors advocate lean human bodies and point out the health benefits of high-functioning physical activity, including extended life and improved quality of life compared to the heavier alternative. This is true in body and also in business.

The lean philosophy centers on doing more with less by eliminating waste and producing only the products that customers demand. The lean approach to business has changed manufacturing throughout the world, and it applies to all aspects of business.

In this chapter, we describe the concept of lean from a business perspective. We explore the principles of lean and offer a brief history of how businesses came to embrace the lean approach. We also present useful tools for becoming lean.

Evolving to Lean

The techniques described in this chapter that have become known as lean manufacturing dramatically changed manufacturing industries. The concepts and techniques that the Japanese implemented to save their failing industries after World War II revolutionized manufacturing everywhere and had a profound effect on the world economy. In this section, we explore the evolution to lean. Why did businesses need it and how did the lean revolution begin?

Mastering the craft

The human race has always made things. Even back in the Stone Age, cave dwellers made spears and other tools they needed to survive. The Egyptians managed large-scale projects when building the Pyramids and created ornamental artifacts they placed in the tombs. The Romans constructed viaducts, paved roads for their chariots, and also produced elaborate furnishings and decorations to adorn their homes.

In the beginning, humans made only what they needed to survive and usually made everything on their own. As societies developed, some people started to specialize in a particular field, such as blacksmithing. Craft production is the term often associated with the first manufacturing movement.

Craft production yielded one-of-a-kind products that were completely customized. Craftspeople made products for specific customers when they received an order. Craft workers were highly skilled, and the processes they used were very flexible; even when made by the same craftsperson, each piece varied slightly from the next. They used general-purpose tools, the facilities were usually small, and a business served its local market.

Craft production dominated until the mid-19th century, when several innovations emerged and paved the way to mass production. These innovations include interchangeable parts (one part can be swapped out for another), coal power, and the construction of the railroads.

Before interchangeable parts, mass production wasn’t possible. Eli Whitney, the American inventor of the cotton gin, was the first one to prove that it was possible to produce parts with enough precision to assure that parts could be interchanged from one product to the next. This made the division of labor not only possible but desirable, as companies could train workers on one specific task rather than requiring them to have the skills to complete all the process steps.

Prior to the mid-1800s, the establishment of large-scale industries was impossible because a reliable energy source was lacking. The availability of coal and steam power after 1840 opened the door to the creation of factories that were large enough to mass-produce products. Coal and the steam it produced offered an inexpensive and reliable means to fuel production.

Even with a reliable energy source and the interchangeable parts necessary for standardizing products, mass production wasn’t feasible until people found a way to get raw materials to the production site and then move finished products out to a large market. The massive railroad building that started in earnest in the 1830s provided the transportation solution, and the construction of the railways and rail cars provided a large demand for railroad-related mass-produced products. The railroads needed mass production and mass production needed the railroads. It was a marriage made in heaven.

Producing in mass

The availability of interchangeable parts, an inexpensive energy source, and reliable transportation provided the foundation for mass manufacturing, but it wasn’t until Henry Ford integrated the moving assembly line that true mass production began.

Ford realized that, to be most profitable, speed was of upmost importance. He needed to produce more product from the resources he had available. His moving assembly line removed the waste associated with workers needing to go to the product to perform their task; the product came to workers! And by controlling the speed of the line, Ford controlled how fast an employee worked, removing timing variability from the process. This emphasis on reducing processing time and eliminating waste is still at the heart of all modern operations improvement initiatives.

The Ford production system embodied the following characteristics:

Standardized product: The Ford plant in Highland Park, Michigan, made one automobile, the Model T, using identical parts with no customization. Ford held firm to his policy of producing identical products and is well-known for his famous quote: “The customer can have any color as long as it’s black.” (Black spray paint was the only color that dried fast enough to keep the line moving at Ford’s ideal pace.)

Standardized product: The Ford plant in Highland Park, Michigan, made one automobile, the Model T, using identical parts with no customization. Ford held firm to his policy of producing identical products and is well-known for his famous quote: “The customer can have any color as long as it’s black.” (Black spray paint was the only color that dried fast enough to keep the line moving at Ford’s ideal pace.)

Dedicated equipment and tooling: Ford set out to automate as much of the process as possible. This was financially possible because the standardized product allowed high volumes of parts to be produced by machinery dedicated to the task. The long production life of the Model T allowed the equipment to be used over many years, thus spreading the investment cost. Between 1909 and 1927, more than 15 million Model Ts were sold, and all were produced on the same equipment. (Most of the customization on the automobile, if there was any, was added after assembly as add-ons.)

Dedicated equipment and tooling: Ford set out to automate as much of the process as possible. This was financially possible because the standardized product allowed high volumes of parts to be produced by machinery dedicated to the task. The long production life of the Model T allowed the equipment to be used over many years, thus spreading the investment cost. Between 1909 and 1927, more than 15 million Model Ts were sold, and all were produced on the same equipment. (Most of the customization on the automobile, if there was any, was added after assembly as add-ons.)

Standardized gauges: The use of interchangeable parts launched a rudimentary quality movement. In craft production, the craftsperson would adjust the parts on each assembly so that the parts would work together. Because this capability wasn’t possible on the moving assembly line, parts had to be more standardized and required much tighter measurement tolerance. Parts were inspected using go/no-go gauges, which were standardized and revealed whether the part was good or bad. This method allowed for quick evaluation of production quality.

Standardized gauges: The use of interchangeable parts launched a rudimentary quality movement. In craft production, the craftsperson would adjust the parts on each assembly so that the parts would work together. Because this capability wasn’t possible on the moving assembly line, parts had to be more standardized and required much tighter measurement tolerance. Parts were inspected using go/no-go gauges, which were standardized and revealed whether the part was good or bad. This method allowed for quick evaluation of production quality.

Simplified, easy-to-understand tasks: The moving assembly line required that each station take approximately the same amount of time to complete its task. The line needed to be balanced (each operation requiring the same amount of time), and it could move only as fast as the longest operation took. The emphasis on speed meant that tasks needed to be easy to understand and perform.

Simplified, easy-to-understand tasks: The moving assembly line required that each station take approximately the same amount of time to complete its task. The line needed to be balanced (each operation requiring the same amount of time), and it could move only as fast as the longest operation took. The emphasis on speed meant that tasks needed to be easy to understand and perform.

Unskilled workers: A worker on an assembly line performs the same limited tasks repetitively. This division of labor requires little training, and workers are interchangeable, just like parts. However, breaking down the process into a sequence of tasks and determining how long each task takes requires intimate knowledge of the process; this way of looking at the production process led to the creation of what would become known as industrial engineering.

Unskilled workers: A worker on an assembly line performs the same limited tasks repetitively. This division of labor requires little training, and workers are interchangeable, just like parts. However, breaking down the process into a sequence of tasks and determining how long each task takes requires intimate knowledge of the process; this way of looking at the production process led to the creation of what would become known as industrial engineering.

Vertical integration: The Ford River Rouge complex, which was completed in 1928, consisted of more than 90 buildings spanning 1.5 miles. The facility contained everything necessary to produce the Model A. It even had its own docks along the river where raw material was delivered, as well as its own railroad track for transportation within the complex, and an electrical plant produced energy for the plant on demand. This self-reliance is known as vertical integration, and it facilitated the rise of the Ford Motor Company and became the model for manufacturing industries in the decades that followed. This vertical integration was slowly replaced after World War II as companies became more reliant on other business to provide the items they needed.

Vertical integration: The Ford River Rouge complex, which was completed in 1928, consisted of more than 90 buildings spanning 1.5 miles. The facility contained everything necessary to produce the Model A. It even had its own docks along the river where raw material was delivered, as well as its own railroad track for transportation within the complex, and an electrical plant produced energy for the plant on demand. This self-reliance is known as vertical integration, and it facilitated the rise of the Ford Motor Company and became the model for manufacturing industries in the decades that followed. This vertical integration was slowly replaced after World War II as companies became more reliant on other business to provide the items they needed.

Continuous improvement: Despite mass production’s bad reputation as being inefficient and wasteful compared to the production concepts of lean manufacturing, Henry Ford was a master of efficiency and was always looking to improve his operations. He reduced the time required to produce a Model T from 12.5 hours to only 1.5 hours, and the price of the vehicle dropped from the original price of $850 in 1910 to $290 by the 1920s.

Continuous improvement: Despite mass production’s bad reputation as being inefficient and wasteful compared to the production concepts of lean manufacturing, Henry Ford was a master of efficiency and was always looking to improve his operations. He reduced the time required to produce a Model T from 12.5 hours to only 1.5 hours, and the price of the vehicle dropped from the original price of $850 in 1910 to $290 by the 1920s.

The manufacturing model that Ford implemented was duplicated throughout the world, and it became the standard that powered the military machines of World War II and the consumer frenzy that followed.

After the war, America was left with excess manufacturing capacity that was no longer needed for the war effort. In addition, consumers who had survived the Great Depression and war rationing were ready to go on a buying spree. Using mass-production techniques, manufacturers started producing everything from underwear to appliances and every gadget imaginable.

This boom was also fueled by the shift of Americans to the suburbs. Neighborhoods sprung up throughout the country, many of which were centered around the growing number of manufacturing plants that were being built in what was once farm or vacant land. These newly built houses needed everything from refrigerators to TVs to washing machines. The move to suburban living also resulted in the need for families to have two cars; people could no longer walk to a shop to buy supplies and groceries.

Post-World War II conditions in America were the perfect environment for the growth of mass production: vast areas of undeveloped land, abundant natural resources, a growing population, and insatiable consumer demand. American manufacturers flourished. However, on the other side of the Pacific, the seeds for a major manufacturing paradigm shift were being planted.

Trimming the Fat

Lean means different things to different people. In essence, lean means doing more with less. It’s a philosophy for adding value to the customer while reducing waste from the process. From this philosophy, companies have developed and implemented a series of tools.

In this section, we examine the principles of lean and present the tools necessary for successful implementation.

Eliminating the waste

Eliminating waste, or muda as the Japanese call it, is the core of the lean approach to business. Waste exists in any process, and the goal of smart business is to identify it and get rid of it. For a detailed definition of the types of waste in a process, see Chapter 2.

The process flow diagram is a useful tool for identifying waste. The flow diagram is a visual representation of the process that you can use to identify those activities that don’t add value to the end product. These are the activities on which you want to focus your efforts.

1. Sort: Identify what’s necessary to do the job and get rid of the rest.

2. Set: Place the needed items in a convenient, easily accessible place.

3. Shine: Keep the work area clean and free of clutter.

4. Standardize: Organize all work areas in the same manner if possible.

5. Sustain: Establish procedures to keep the clutter clear and the workplace organized. Put everything back in its designated place when done with it.

Involving everyone

Everyone must be involved in a lean organization. Implementing and maintaining a lean environment requires a high level of training at all levels. In lean companies, decision-making is delegated to lower levels of the organizational chart. The workers are responsible for discovering issues and are empowered to take the appropriate action when problems are discovered.

Line workers in lean organizations are trained to have their eye on the big picture. They’re exposed to and learn the entire manufacturing process. This way, each employee knows what it takes to get the product to his station and the potential consequences to the next station of not doing his job correctly. This education puts employees in a better position to identify process errors and to diagnose the cause of those errors. The emphasis on understanding and training is critical for the successful implementation of lean. Workers cannot be expected to perform to the added demands of a lean work environment if they don’t have the skills required.

Leveling production

Heijunka is the Japanese term for production leveling. The goal of heijunka is to reduce batch size as much as possible while still meeting production volume targets. Heijunka facilitates just-in-time (JIT) production and significantly reduces all levels of inventory in a system. This contrasts with traditional production that tended to increase batch sizes to reduce downtime due to setups.

In Chapter 4, we describe the effect of batch sizing and setup times. In short, the longer it takes to change production from one model or product to the next, the larger the batch size needs to be. That’s why reducing setup times is a prime concern of lean organizations.

Here are some benefits of reducing the batch size:

Easily identified problems: Removing the clutter created by large batch sizes allows you to quickly identify problems such as machine breakdowns because subsequent operations will soon run out of inventory if the machine feeding them breaks down and there’s no inventory for it to work on.

Easily identified problems: Removing the clutter created by large batch sizes allows you to quickly identify problems such as machine breakdowns because subsequent operations will soon run out of inventory if the machine feeding them breaks down and there’s no inventory for it to work on.

Improved quality and reduced waste: Small lot sizes allow you to discover quality problems quickly and prevent an operation from producing a large number of defective parts.

Improved quality and reduced waste: Small lot sizes allow you to discover quality problems quickly and prevent an operation from producing a large number of defective parts.

Less space requirements: With all the inventory eliminated, you need less production space. You can place operations closer together, which can enhance communication and process awareness.

Less space requirements: With all the inventory eliminated, you need less production space. You can place operations closer together, which can enhance communication and process awareness.

Reduced inventory: Small lot sizes reduce not only the amount of in-process inventory (WIP) but also the requirement for raw materials (RMI) and the amount of finished goods inventory (FGI).

Reduced inventory: Small lot sizes reduce not only the amount of in-process inventory (WIP) but also the requirement for raw materials (RMI) and the amount of finished goods inventory (FGI).

Reduced process flow time: Speed is a critical factor in a lean organization. Minimizing the batch size significantly reduces the wait time in the process. For a complete analysis on the effect of batch size on the process, see Chapter 4.

Reduced process flow time: Speed is a critical factor in a lean organization. Minimizing the batch size significantly reduces the wait time in the process. For a complete analysis on the effect of batch size on the process, see Chapter 4.

As Shigeo Shingo, a Japanese industrial engineer who was considered a leading expert on manufacturing practices during the lean revolution, discovered at Toyota, a major impediment to reducing batch sizes is the changeover time required to prepare the machinery for a different part. In Chapter 4, we point out that long setup times reduce active processing time and significantly reduce the capacity of the equipment because no parts are produced during the setup. Looking for a way to reduce the downtime, Shingo devised the single-minute exchange of die (SMED) method for changeovers. (Single minute doesn’t mean one minute but that the setup can be accomplished in less than ten minutes.)

SMED was first applied to change the dies on the stamping machines that shaped the metal of automobile body parts. These dies are very heavy, and the tolerances on the parts are less than a millimeter, making installation time-consuming because the machines need to be perfectly aligned. Although originally designed for die changes, the SMED method has applications for all types of machine setups. Here are the steps to SMED:

1. Observe the current methodology.

Document all the steps currently taken to accomplish the changeover. This can be in the form of a process flow diagram.

2. Separate the internal and external activities.

External activities are those activities that can be completed before the machine is shut down for the setup, and internal activities are those activities that can only be done when the machine is stopped.

3. Eliminate all non-value-added steps.

Are any steps in the process unnecessary?

4. Turn internal activities into external ones.

By taking activities off-line, you can reduce the time the equipment isn’t operating.

5. Simplify the internal activities.

For example, eliminate nuts, bolts, and screws, and replace them with clamps if a fastener is really needed. Use pins and jigs to simplify adjustments.

6. Simplify the external activities and make sure that they don’t delay any internal activities.

7. Document the new process and measure improvement.

8. Repeat the process.

Continuously reduce the setup time. You’ll likely need several cycles to get to a single digit setup time.

SMED reduced the time for die changes at Toyota to less than ten minutes per die, an improvement of over 40 times in most cases.

Embracing your supplier

One of the major characteristics of a lean company is the relationship it maintains with its suppliers. Lean organizations such as Toyota view their supply chain as an extension of the company, not as an adversary, as is common in traditionally managed companies.

For a healthy relationship with suppliers, follow these rules:

Minimize the number of suppliers. The smaller number is easier to manage and allows you to develop closer relationships.

Minimize the number of suppliers. The smaller number is easier to manage and allows you to develop closer relationships.

Establish long-term relationships. Long-term contracts provide assurance to suppliers that they’ll have revenue and allow them to focus on long-term improvements that will improve the product they produce for you.

Establish long-term relationships. Long-term contracts provide assurance to suppliers that they’ll have revenue and allow them to focus on long-term improvements that will improve the product they produce for you.

Establish clear expectations on cost, quality, and responsiveness. These expectations must be both clearly understood and obtainable.

Establish clear expectations on cost, quality, and responsiveness. These expectations must be both clearly understood and obtainable.

Share the risks and rewards. Provide incentives for improved supplier performance.

Share the risks and rewards. Provide incentives for improved supplier performance.

Develop effective lines of communication. Share operational information such as process times and demand forecasts. Provide an environment where suppliers are encouraged to inform you of potential problems so that you can be prepared to act and implement solutions.

Develop effective lines of communication. Share operational information such as process times and demand forecasts. Provide an environment where suppliers are encouraged to inform you of potential problems so that you can be prepared to act and implement solutions.

Invest in supplier continuous improvement and development. When a supplier improves, either by increasing quality or reducing waste, this benefit is automatically passed on to you in an improved product. Lean manufacturers have been known to send their own employees into supplier facilities to help them increase quality and reduce costs.

Invest in supplier continuous improvement and development. When a supplier improves, either by increasing quality or reducing waste, this benefit is automatically passed on to you in an improved product. Lean manufacturers have been known to send their own employees into supplier facilities to help them increase quality and reduce costs.

Toyota embraced these supply chain principles. While researching his book The Machine That Changed the World, author Jim Womack found that the average number of suppliers for a Japanese plant was 170, compared to the average of 509 that supplied American plants. He also found that suppliers do benefit from multiyear contracts that allow them to focus on production rather than procurement.

For more information on how to create and manage a lean supply chain, see Chapter 10.

Focusing on quality

Quality is a pillar of any lean organization. Poor quality contributes significantly to the waste that lean companies strive to eliminate. In lean organizations, quality is the responsibility of everyone. Line workers are trained to detect poor quality, identify the causes of poor quality, and implement improvements. The quality process follows these steps:

1. Detect the abnormality.

Part of workers’ jobs is to identify poor quality as it occurs.

2. Stop the process.

Line employees have the power and are expected to stop the line.

3. Fix or correct the immediate condition.

Action is required to put in place a quick fix so that production can resume as quickly as possible.

4. Investigate the root cause and solve the problem.

You must implement a permanent solution to replace the quick fix of Step 3.

A radical concept found in truly lean organizations such as Toyota is the ability of workers to stop the production line when a quality issue is identified. The worker pulls an andon cord, which stops the line and sends a signal to an andon board that notifies management and other workers where the problem is.

This ability to stop the line can also be programmed into the equipment itself. Jidoka, sometimes referred to as autonomation, meaning automation with human intelligence, enables a machine to detect when a defect occurs and allows the equipment to stop the line automatically. For example, if a machine jams, the machine will not only shut itself down but also stop the entire line. The andon board then lights up, signaling for help at the machine. This eliminates the need to have an operator at each machine.

The first priority after you detect a defect is to implement a quick fix so that production can resume. This may involve the addition of another step in the process, such as manual machine adjustments or inspecting parts.

A common excuse for this behavior is that people are too busy with other things, and the fix is working. This firefighting, as it’s often referred to, is what a lean organization is trying to eliminate.

The best way to correct a mistake, of course, is to prevent it from happening in the first place. This is why lean firms embrace poke-yoke, which means “preventing mistakes.” Lean organizations focus on designing a simple process and training workers to function in the process. Always remember to simplify.

Implementing continuous improvement

Kaizen is the Japanese word for continuous improvement. It applies not only to quality but to everything one does in life. Any process can be improved, and your primary mission should be to improve it.

The primary difference is that kaizen (often called a kaizen event) focuses on making quick improvements with a series of changes to the exiting process, while methodologies such as Six Sigma place a greater emphasis on large-scale projects that often require an arsenal of tools.

Producing Just in Time

Push and pull systems are two common types of production control strategies. In this section, we define these production strategies and point out the difference between them with regards to the customer interface. We also cover the conditions for implementing a pull system.

Knowing when to work

A process is made up of several operations. Each operation has a particular task to perform, and as one operation completes its task, the part is moved on to the next operation in the process until a finished product is made. As an operations manager, you must decide how to release raw material into the process and how this material, the work-in-progress (WIP), will flow through the production facility.

Push and pull are two possible production strategies for moving material through the manufacturing facility. (We get to what triggers material to be released into the process a bit later.) Find out more on the inventory effects in Chapter 8.

Defining push

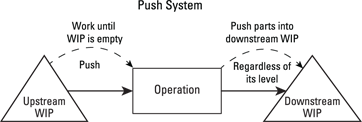

In a push system, work-in-process is pushed to the next operation as soon as it’s completed. The operation works as long as it has parts to process. A push system controls the thruput (what is actually produced) of the system and isn’t concerned with level of the WIP. If the operation has inventory to work on, it will work.

Figure 11-1 shows how a push system works. As long as the upstream WIP has inventory, the operation will continue to produce, regardless of the inventory levels in the downstream WIP.

Illustration by Wiley, Composition Services Graphics

Figure 11-1: Example of a push system.

Defining pull

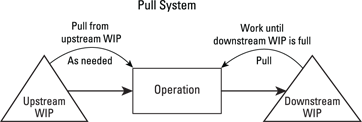

In a pull system, the operation pulls products only as they’re needed. The operation works only when the next station signals that it needs parts. A pull system in essence controls WIP and observes the throughput.

Figure 11-2 shows how a pull system works. Operation 1 works only until the downstream WIP is full. As Operation 2 takes parts from the WIP, Operation 1 works to replace them.

A kanban system can be used to establish the desirable inventory levels in the downstream WIP. A kanban system is in effect a scheduling system. The kanban system determines how much inventory is in the process and products are only produced as indicated by the kanban. For details on kanban, refer to the section Implementing pull later in this chapter.

Illustration by Wiley, Composition Services Graphics

Figure 11-2: Example of a pull system.

Differentiating the customer interface

It’s important to distinguish between a push and pull system and a make-to-order (MTO) or make-to-stock (MTS) system. MTO and MTS refer to the interface between the customer and the production system. In Chapter 5, we describe an MTO system and point out that it maintains no finished goods inventory (FGI). An MTO system produces only when a real customer order is received. Conversely, an MTS system generally produces to a forecast of demand and maintains an FGI for customer purchases.

Push and pull refer to how production in the facility is conducted. MTO and MTS can both use a pull or push system. Table 11-1 describes the steps to implement each of the four possible combinations:

An MTO system utilizes push.

An MTO system utilizes push.

An MTO system utilizes pull.

An MTO system utilizes pull.

An MTS system utilizes push.

An MTS system utilizes push.

An MTS system utilizes pull.

An MTS system utilizes pull.

Table 11-1 Implementing Customer Interface with Push and Pull

|

System |

Make to Order |

Make to Stock |

|

Push |

1. Customer order received 2. Production schedule developed 3. Raw material released into the facility based on production schedule 4. Parts pushed from operation to operation |

1. Demand forecast developed 2. Production schedule developed 3. Raw material released into the facility based on production schedule 4. Parts pushed from operation to operation |

|

Pull |

1. Customer order received 2. Raw material released into the system only when first operation needs parts 3. Parts pulled from operation to operation |

1. Demand forecast developed 2. Raw material released into the system only when first operation needs parts 3. Parts pulled from operation to operation |

Implementing pull

The key to implementing a pull system is to determine when the operation should work. In most cases, a pull system utilizes what’s called a kanban, which is a Japanese word meaning “signal.” Kanban isn’t an inventory control system but a scheduling system that determines when to produce and how much to produce. For details on other scheduling systems, flip to Chapter 9.

A kanban system uses a kanban card or other device (an empty bin, for example) to signal to the operation that it needs to produce. Figure 11-3 shows how a kanban system works.

Illustration by Wiley, Composition Services Graphics

Figure 11-3: Implementing kanban.

The downstream WIP contains four containers (K1, K2, K3, and K4) each containing the same part. When a container is removed by Operation 2, a card is placed in Operation 1’s production box. As soon as the card arrives, Operation 1 begins working to fill an empty container to bring the downstream WIP up to the preset level.

Setting the levels of the WIPs in a kanban system isn’t an easy task. It takes a lot of time and requires that you have intimate knowledge of the capacity of each operation in the system (see Chapter 2 for information on how to determine capacity levels) and the demand for the product.

In a kanban system, the levels of inventory, and thus the kanban, are set based on demand. To be successful, product demand needs to be relatively constant, and any variation (changes) in demand needs to be known. If demand isn’t stable, then the number of kanban in the system need constant monitoring and updating to adjust to increasing and decreasing demand.

To determine the number of kanban needed, you first need to determine how big your WIP should be. The total number of parts in any WIP is given by the following equation:

WIP Level = Demand during the lead time + Safety stock

For a detailed discussion of this equation, turn to Chapter 8. In summary, you should set the amount of inventory to the demand expected during the time required to produce the parts (lead time) plus some inventory (safety stock) required to accommodate for demand and lead time variability.

Next, to determine the number of containers, divide the calculated WIP level by the number of parts each container will hold:

Knowing when to JIT

Pull systems aren’t always better than push systems. A well-executed push system (see Chapter 9) can be just as efficient as the best-run pull system. A pull system does work better in environments with the following characteristics:

A dedication to preventive maintenance: The low levels of inventory within the plant make each operation more susceptible to breakdowns anywhere in the system. If one operation experiences any unplanned downtime, then the operations before it quickly stop working because they don’t have any parts to replenish and the operations following soon run out of inventory to work on. A pull system ties each operation closely together. A preventive maintenance program can help eliminate these disruptions.

A dedication to preventive maintenance: The low levels of inventory within the plant make each operation more susceptible to breakdowns anywhere in the system. If one operation experiences any unplanned downtime, then the operations before it quickly stop working because they don’t have any parts to replenish and the operations following soon run out of inventory to work on. A pull system ties each operation closely together. A preventive maintenance program can help eliminate these disruptions.

A limited menu of product options: A pull system operates most efficiently when the number of product configurations is limited. Increased differentiation of product requires a kanban system for each different part used in the product, which increases the inventory levels.

A limited menu of product options: A pull system operates most efficiently when the number of product configurations is limited. Increased differentiation of product requires a kanban system for each different part used in the product, which increases the inventory levels.

A reliable supply chain: A lean supply chain is necessary for a firm to get the most out of its lean efforts. Because inventory is maintained at such low levels, any disruptions in the supply of parts can cripple production. Recently, after a devastating earthquake in Japan, the supply of parts for electronic and automotive products to assembly plants throughout the world was cut off, and all production came to a sudden halt. The stock of finished goods was quickly depleted, and customers experienced a shortage of goods.

A reliable supply chain: A lean supply chain is necessary for a firm to get the most out of its lean efforts. Because inventory is maintained at such low levels, any disruptions in the supply of parts can cripple production. Recently, after a devastating earthquake in Japan, the supply of parts for electronic and automotive products to assembly plants throughout the world was cut off, and all production came to a sudden halt. The stock of finished goods was quickly depleted, and customers experienced a shortage of goods.

A stable and smooth demand pattern: Because of the time required to set up the kanban in a pull system, it’s beneficial if demand is relatively predictable, with limited fluctuations.

A stable and smooth demand pattern: Because of the time required to set up the kanban in a pull system, it’s beneficial if demand is relatively predictable, with limited fluctuations.

Seeking the Silver Bullet

Despite what many operations management consultants may tell you, there’s no easy way to build an efficient organization. As continuous improvement implies, there is always work to be done.

We describe different operation management approaches in this book. In this chapter, we cover lean. In Chapter 12, we describe Total Quality Management (TQM), and in Chapter 13 we cover Six Sigma. Still, no operations management book would be complete without mentioning the theory of constraints, which is basically the art of managing based on your bottleneck. We cover that in Chapter 3. All these strategies share the intents of eliminating waste, reducing inventory levels, cutting flow times, and improving quality. These strategies are also not exclusive. Most lean companies also embrace the techniques offered by Six Sigma.

Whichever approach you choose to implement, success depends on the ability of your organization to stay focused and adhere to the principles of your approach. Many companies fail when they attempt to implement a strategy because they don’t follow the entire program and choose to implement only the easy parts. Some companies achieve success from the low-hanging fruit but give up when they actually have to get down to the hard work of redesigning the processes and changing the policies that they have utilized in the past to get results. As with dieting, getting started is easy; it’s finishing the plan and sticking with it until you hit your goal that’s usually difficult. And it’s even harder to maintain the results as a lean maintenance plan is required.

An organized work environment is essential for the identification, elimination, and prevention of waste. “A place for everything and everything in its place” is a philosophy of lean companies. Applying the

An organized work environment is essential for the identification, elimination, and prevention of waste. “A place for everything and everything in its place” is a philosophy of lean companies. Applying the  We use the terms

We use the terms  Because the quick fix usually adds some waste into the system, you don’t want it to become permanent. What separates lean organizations from those trying to be lean is a relentless effort to identify the root cause of quality problems and implement permanent solutions. Many companies get lazy, allowing the quick fix to become permanent.

Because the quick fix usually adds some waste into the system, you don’t want it to become permanent. What separates lean organizations from those trying to be lean is a relentless effort to identify the root cause of quality problems and implement permanent solutions. Many companies get lazy, allowing the quick fix to become permanent.