Chapter 5

Designing Your Process to Match Your Product or Service

In This Chapter

Classifying processes and balancing costs

Classifying processes and balancing costs

Creating successful customer interfaces and back-office operations

Creating successful customer interfaces and back-office operations

Deciding between making to stock and making to order

Deciding between making to stock and making to order

Using certain design techniques for specific products

Using certain design techniques for specific products

When you’re designing processes to create a product or deliver your services, a good relationship between process and product makes your job as an operations manager easier. In other words, every aspect of a manufacturing process depends on the product you’re trying to create, and process design is a fundamental aspect of product development. Your product, whether it’s a widget or a service, drives process design, and your processes ultimately determine your costs and profit margins.

In this chapter, we classify processes along four dimensions and describe a concrete method for evaluating the costs associated with process design choices. We also explore the anatomy of manufacturing and service operations with a focus on how to design and exploit a process to get the most productivity out of it. We conclude with a description of the design for (DFX) terms that operations management leaders use regularly.

Considering Costs, Standardization, Volume, and Flexibility

Processes fall into four different categories based on the nature of their function. Some processes relate primarily to a product’s cost structure; others address the company’s product standardization needs, output volume, or production flexibility. In this section, we look at processes that focus on these types of business considerations and provide general guidelines on how to best select a process to meet the requirements of your product.

Before you dive into classifying a process, consider the nature of the product it’s intended to produce. After all, creating a unique item, such as an interstate highway bridge, is wildly different from producing a million bottles of contact-lens solution or thousands of socks in two different colors. Here are common process classifications, arranged according to fixed costs (lowest to highest):

Projects: These generally result in an output of one. Examples include constructing a building or catering a party. Although the result of a project is one deliverable, the process of creating the item can be duplicated with modifications for other projects. Flip to Chapter 14 for details on projects.

Projects: These generally result in an output of one. Examples include constructing a building or catering a party. Although the result of a project is one deliverable, the process of creating the item can be duplicated with modifications for other projects. Flip to Chapter 14 for details on projects.

Job shops: This type of process produces small batches of many different products. Each batch is usually customized to a specific customer order, and each product may require different steps and processing times. Examples of job shop products include a bakery that specializes in baking and decorating wedding cakes, each one customized for a bride, or a programmer that creates customized websites for his clients.

Job shops: This type of process produces small batches of many different products. Each batch is usually customized to a specific customer order, and each product may require different steps and processing times. Examples of job shop products include a bakery that specializes in baking and decorating wedding cakes, each one customized for a bride, or a programmer that creates customized websites for his clients.

Batch shops: These produce periodic batches of the same product. Batch shops can produce different products, but typically all the products they produce follow the same process flow. A facility producing shirts of different sizes and colors or a bakery preparing different flavors of cakes or types of cookies are examples of batch shops. These processes make one type of shirt or cookie in a batch and then switch to a different type, but all types follow the same flow.

Batch shops: These produce periodic batches of the same product. Batch shops can produce different products, but typically all the products they produce follow the same process flow. A facility producing shirts of different sizes and colors or a bakery preparing different flavors of cakes or types of cookies are examples of batch shops. These processes make one type of shirt or cookie in a batch and then switch to a different type, but all types follow the same flow.

Batch shops usually require some setup time — time required to prepare resources to produce a different type of product. Chapter 4 provides a detailed analysis of how to manage a batch shop process.

Flow lines: This type of process consists of essentially independent stations that produce the same or very similar parts. Each part follows the same process throughout the process. Output on a flow line is dictated by the bottleneck, or the slowest operation. For more on bottlenecks, see Chapters 2 and 3. The flow line is similar to the assembly line but the parts don’t move at a constant rate dictated by the line speed.

Flow lines: This type of process consists of essentially independent stations that produce the same or very similar parts. Each part follows the same process throughout the process. Output on a flow line is dictated by the bottleneck, or the slowest operation. For more on bottlenecks, see Chapters 2 and 3. The flow line is similar to the assembly line but the parts don’t move at a constant rate dictated by the line speed.

The terms flow lines and batch shop process are often erroneously used interchangeably.

The terms flow lines and batch shop process are often erroneously used interchangeably.

Assembly lines: These produce discrete parts flowing at controlled rates through a well-defined process. The line moves the parts to the resources, and each resource must complete its task before the line moves on. This requires a balanced line, meaning that each operation completes its task in a similar amount of time. The line moves at the speed of the slowest operation, or bottleneck. Automobile production is the classic example of an assembly line. Check out Chapters 2 and 3 for more on bottlenecks and balancing a process.

Assembly lines: These produce discrete parts flowing at controlled rates through a well-defined process. The line moves the parts to the resources, and each resource must complete its task before the line moves on. This requires a balanced line, meaning that each operation completes its task in a similar amount of time. The line moves at the speed of the slowest operation, or bottleneck. Automobile production is the classic example of an assembly line. Check out Chapters 2 and 3 for more on bottlenecks and balancing a process.

Continuous flow processes: As the name implies, these processes produce items continuously, usually in a highly automated process. Examples include chemical plants, refineries, and electric generation facilities. A continuous flow process may have to run 24/7 because starting and stopping it is often difficult.

Continuous flow processes: As the name implies, these processes produce items continuously, usually in a highly automated process. Examples include chemical plants, refineries, and electric generation facilities. A continuous flow process may have to run 24/7 because starting and stopping it is often difficult.

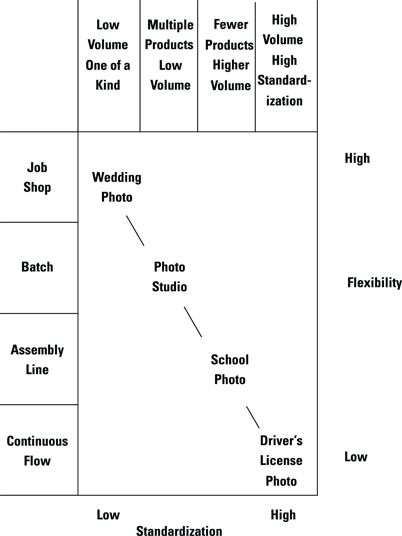

Figures Figure 5-1 and Figure 5-2 illustrate where each process falls on the standardization, volume, and flexibility matrix for both products and services. Figure 5-1 shows how different products vary along these metrics, and Figure 5-2 shows how services differ on the dimensions.

Illustration by Wiley, Composition Services Graphics

Figure 5-1: The product process matrix.

Illustration by Wiley, Composition Services Graphics

Figure 5-2: The service process matrix.

Balancing operating costs

Each process has its own operating cost structure that determines two important factors:

Cost of the units produced at various volumes of production

Cost of the units produced at various volumes of production

Minimum production volume at which the process becomes profitable

Minimum production volume at which the process becomes profitable

Operating costs are either fixed or variable:

Fixed costs (FC) are independent of unit volume produced. Examples include rent, mortgage payments, property taxes, insurance, capital equipment, and certain administrative and overhead expenses.

Fixed costs (FC) are independent of unit volume produced. Examples include rent, mortgage payments, property taxes, insurance, capital equipment, and certain administrative and overhead expenses.

Variable costs (VC) are dependent on unit volume produced, meaning they vary directly with volume. Examples include power to run equipment, material and labor (because these costs change depending on how much of them you use), and a wide range of other considerations, such as quantity discounts when purchasing material.

Variable costs (VC) are dependent on unit volume produced, meaning they vary directly with volume. Examples include power to run equipment, material and labor (because these costs change depending on how much of them you use), and a wide range of other considerations, such as quantity discounts when purchasing material.

An automated process usually has a higher investment in fixed cost assets like sophisticated machinery than a small manual process, which is more likely to have a higher proportion of a variable cost like labor. But the division between fixed and variable costs can be fuzzy sometimes. For example, union contracts often require that a certain employment level be maintained. In this case, you can’t consider labor costs as variable. Similarly, some maintenance must be performed routinely on equipment, regardless of volume produced. So the operations manager must designate operating costs as fixed or variable according to the operations’ circumstances and often according to company accounting practices.

Finding the right balance between fixed and variable costs can be difficult. Automating a process to reduce the number of employees you need to pay for manual labor requires significant upfront investment and usually reduces the amount of customization you can offer on the product. A variable cost structure requires more labor, but well-trained people power is better at accommodating customization.

When making fixed versus variable process design decisions, you need to know how to calculate the impact of these choices on the bottom line.

Assuming you sell everything you produce for a fixed price per unit (R), total revenue (TR) is equal to R · Q. Figure 5-3 illustrates the relationship among volume, costs, and revenue. The difference between the TR and TC curves represents the profit (or loss) of the process.

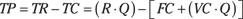

Total profit (TP) is simply your total revenue minus your total costs:

Figure 5-3: Relationship of cost to volume.

Your cost structure determines your break-even point (BEP), or break-even production quantity. This is the production volume at which your total revenue and total costs are the same. Every unit you produce above this BEP results in a profit.

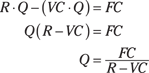

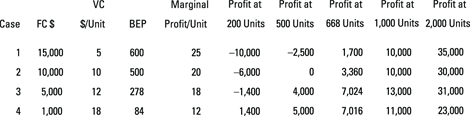

Solve for Q to determine your break-even point:

So the break-even quantity Q is determined by dividing the fixed costs FC by the marginal profit generated by one unit of production (R – VC).

How do you use this equation to guide your process decisions?

The first thing you may notice is that your BEP — the quantity Q — increases with your fixed costs. If you’re uncertain about your expected sales volume, you probably want to choose a process that limits the amount of money you must invest in fixed costs. This means trying to secure short-term rental agreements rather than purchasing facilities and capital equipment. You may also want to utilize manual labor rather than automating the process with expensive machinery.

On the other hand, by transferring the fixed cost to a variable cost, you may reduce the contribution margin of each unit sold. The contribution margin is the price you sell the product for minus the variable cost per unit (R – VC). If you have a high variable cost per unit, you receive less profit per unit sold after you reach your BEP. You may want to consider making an investment in fixed assets to automate your process if you expect higher volumes.

Consider a firm that must make a decision on purchasing equipment for producing highlander kilts. The firm has four options, each with different fixed and variable costs. Assuming that the firm plans to sell the kilts for $30 each, Figure 5-3 shows the combinations, the resulting BEP, and the expected profit at different sales levels.

Illustration by Wiley, Composition Services Graphics

Figure 5-4: Comparison of fixed and variable cost scenarios.

What case you choose depends on how sure you are of your expected demand and your organization’s risk tolerance (how willing you are to gamble on high demand). Case 4 guarantees a profit at any sales level above 84 units, and you exceed the profits of any of the alternatives until sales exceed 668 units. Case 3 results in a greater profit after sales exceed 668 units. Figure 5-4 shows that as sales expectations grow, you want to invest in more FC and reduce your VC per unit. Case 1 is the most profitable if your demand exceeds 1,000 units.

Blurring the lines: Making standardized stuff customizable

At first sight, standardization and customization may appear to be an either/or decision. If you want to produce customized products for your customer, you may assume that you need to give up the benefits of standardization, such as economies of scale and reduced inventory (see Chapter 8 for details on standardization using component commonality). However, with proper product and process design, you can produce customized products and still take advantage of the benefits related to standardization.

For example, consider a fast-food hamburger chain that promises customized sandwiches for each customer. It uses the same basic processes that other chains use, but it uses a postponement strategy — a process that uses common components and delays assembly until the customer order is received (known as made to order, which we describe later in the chapter). If you’re wondering how a postponement strategy works and benefits the business, see Chapter 8.

With proper process design, you may also be able to increase the variety of the deliverables you produce, at little additional cost, which may also increase your customer satisfaction. You just need to consider such flexibility when you design your facility layout and purchase equipment.

Improving Face-to-Face and Back-Office Operations

For many people, the term operations conjures images of factories and smokestacks or some other kind of manufacturing scenario. But successful businesses in the service industry also rely on efficient processes for creating customer deliverables.

There are big differences between manufacturing-based companies and service-based businesses. For starters, hotels, airlines, restaurants, theaters, and other service-based organizations can’t store finished products when their capacity exceeds demand; manufacturers can. This makes the management of demand variability quite different for the two types of businesses.

Instead of classifying operations as manufacturing or service, we’d like you to view them as processes that have a direct interface with a customer (face-to-face operations) or processes that occur out of sight of the customer (back-office operations). Every business has several processes that fall under each category. How you design an operation depends on its particular function; each has its own set of design rules.

Throughout this book, we point out the fundamental differences that exist in primarily manufacturing and mainly service organizations. Here, we’re simply pointing out that manufacturing companies have many service elements and, likewise, service companies have many processes that resemble manufacturing operations.

Strengthening the customer interface

Any process that requires direct contact with the customer needs special attention. These face-to-face interactions reveal blemishes along with beauty marks to the customer. Examples of interface points include a customer entering a bank for service, a patient coming into a doctor’s office for an appointment, or a patron sitting down at a restaurant table. In all these situations, customers directly interface with your resources (employees and facilities).

Here are some guidelines for designing a customer interface:

Establish an easy service flow. How many times have you stood in a line, only to discover you were in the wrong line? Confusing processes are infuriating to customers, so you want to avoid them. Design a process that’s visible and clear from the customer’s perspective.

Establish an easy service flow. How many times have you stood in a line, only to discover you were in the wrong line? Confusing processes are infuriating to customers, so you want to avoid them. Design a process that’s visible and clear from the customer’s perspective.

One way to establish a clear process is to have these components:

One way to establish a clear process is to have these components:

• One point of entry

• Well-marked steps

• Personnel available to direct customers as needed

Minimize handoffs of customers. How many times have you been at a store and gone from employee to employee, trying to find someone to answer your question or solve your problem? When designing the customer interface, clear this hurdle to customer satisfaction by creating a step in the process that makes it easy for customers to be served at their convenience or a resource that can provide a quick and clear path through the process. Implementing this may require the use of flexible resources (resources that can perform multiple tasks in a process). See Chapter 3 for details on using flexible resources.

Minimize handoffs of customers. How many times have you been at a store and gone from employee to employee, trying to find someone to answer your question or solve your problem? When designing the customer interface, clear this hurdle to customer satisfaction by creating a step in the process that makes it easy for customers to be served at their convenience or a resource that can provide a quick and clear path through the process. Implementing this may require the use of flexible resources (resources that can perform multiple tasks in a process). See Chapter 3 for details on using flexible resources.

Minimize the movement of the customer through your process. The last thing you want is a customer roaming throughout your facility because she doesn’t know where to go. This increases the customer’s flow time and runs the risk that the customer may not end up at the next correct process step or, worse, may be exposed to those back-office processes that weren’t designed for customer eyes.

Minimize the movement of the customer through your process. The last thing you want is a customer roaming throughout your facility because she doesn’t know where to go. This increases the customer’s flow time and runs the risk that the customer may not end up at the next correct process step or, worse, may be exposed to those back-office processes that weren’t designed for customer eyes.

Maximize the customer’s comfort. If you must make your customers wait, make sure they do so in comfort. When designing your facility, be sure to balance service and waiting areas; make sure your waiting areas are comfortable. For more ideas on how to make a favorable impression on customers while they wait, turn to Chapter 7.

Maximize the customer’s comfort. If you must make your customers wait, make sure they do so in comfort. When designing your facility, be sure to balance service and waiting areas; make sure your waiting areas are comfortable. For more ideas on how to make a favorable impression on customers while they wait, turn to Chapter 7.

Keep customers in view. Designing a process in which your customer is always visible allows employees to make sure that the process is running as it should be and that customers aren’t deviating from the desired path. Visibility also aids in security and, especially in retail operations, deters theft.

Keep customers in view. Designing a process in which your customer is always visible allows employees to make sure that the process is running as it should be and that customers aren’t deviating from the desired path. Visibility also aids in security and, especially in retail operations, deters theft.

Capitalize on your space. You generally want to place your facilities where customer traffic is high, so that potential customers can see and easily enter your facility. Because of this, most face-to-face customer interaction occurs in locations where the facility cost per square foot is high relative to less congested areas. You want high traffic or sales volume to compensate for the cost of the location. Design processes to minimize space while maintaining these directives.

Capitalize on your space. You generally want to place your facilities where customer traffic is high, so that potential customers can see and easily enter your facility. Because of this, most face-to-face customer interaction occurs in locations where the facility cost per square foot is high relative to less congested areas. You want high traffic or sales volume to compensate for the cost of the location. Design processes to minimize space while maintaining these directives.

Separate back-office processes from front-office processes. Make every effort to separate your face-to-face processes from the processes that, although they must occur to satisfy the customer, the customer isn’t directly involved in. Back-office processes include a restaurant kitchen, the loan approval process at a bank, and inventory storage spaces at big box stores. However, some companies expose traditional back-office processes as part of their business strategy, such as those restaurants that have open kitchens so the customer can observe the cooking or warehouse retailers that keep all inventory visible in an effort to keep costs down.

Separate back-office processes from front-office processes. Make every effort to separate your face-to-face processes from the processes that, although they must occur to satisfy the customer, the customer isn’t directly involved in. Back-office processes include a restaurant kitchen, the loan approval process at a bank, and inventory storage spaces at big box stores. However, some companies expose traditional back-office processes as part of their business strategy, such as those restaurants that have open kitchens so the customer can observe the cooking or warehouse retailers that keep all inventory visible in an effort to keep costs down.

Facility layout design is critical because the design may be duplicated in many facilities. Think about your favorite fast food joint. When entering, it’s often difficult to distinguish one facility from another across town or in a different state. The process and facility design of a chain restaurant is duplicated many times, so an inefficiency is magnified many times in each location.

Improving efficiencies behind the scenes

For the most part, anything that the customer doesn’t have to be directly involved in should be optimized only for business efficiency. When a customer takes a check to the bank for deposit, he’s unconcerned about how the money gets credited to his account — only that it does.

Design these processes with these guidelines:

Utilize a sequential flow pattern in the process. You want the material to flow through the process in sequence, from station to station. Facilities, especially in manufacturing, often utilize a U-shaped design. The process begins and ends at the front of the facility. This arrangement allows a manager to observe the process over a small, confined space, making it easy to control. This design also facilitates good communication among workers because they’re typically in close proximity to one another.

Utilize a sequential flow pattern in the process. You want the material to flow through the process in sequence, from station to station. Facilities, especially in manufacturing, often utilize a U-shaped design. The process begins and ends at the front of the facility. This arrangement allows a manager to observe the process over a small, confined space, making it easy to control. This design also facilitates good communication among workers because they’re typically in close proximity to one another.

Minimize backtracking of work in the process. Sending parts back in the process can create confusion because tracing the part in the process may become difficult; it can also impede the movement of other parts in the process. If material needs to backtrack, then maintain separate inboxes for the first-time material and returned material, or implement a marking system to distinguish the two.

Minimize backtracking of work in the process. Sending parts back in the process can create confusion because tracing the part in the process may become difficult; it can also impede the movement of other parts in the process. If material needs to backtrack, then maintain separate inboxes for the first-time material and returned material, or implement a marking system to distinguish the two.

Implement a predictable process. If possible, all parts should progress through the process in the same steps. Aim to remove any decisions on the operator’s part. If the process has decision points, then every part meeting the same criteria should go through the same predictable path.

Implement a predictable process. If possible, all parts should progress through the process in the same steps. Aim to remove any decisions on the operator’s part. If the process has decision points, then every part meeting the same criteria should go through the same predictable path.

Reduce material movement. Material movement is a non-value-added activity that takes time and can lead to parts getting lost or ending up at the wrong locations. In addition, unnecessary movement can create safety concerns, especially in cases where equipment is required to move parts from place to place.

Reduce material movement. Material movement is a non-value-added activity that takes time and can lead to parts getting lost or ending up at the wrong locations. In addition, unnecessary movement can create safety concerns, especially in cases where equipment is required to move parts from place to place.

Emphasize bottleneck management. A bottleneck is the operation that limits a system’s overall capacity (see Chapter 2). Design processes to maximize utilization of the bottleneck. Details on how to best exploit a bottleneck are in Chapter 3.

Emphasize bottleneck management. A bottleneck is the operation that limits a system’s overall capacity (see Chapter 2). Design processes to maximize utilization of the bottleneck. Details on how to best exploit a bottleneck are in Chapter 3.

Minimize inventory. Inventory takes up space in your process, and you can reduce the size of your facility by reducing it. Some inventory is necessary to allow smooth operations, but too much can interfere with the smooth flow of material through the process (find more about inventory in Chapter 8).

Minimize inventory. Inventory takes up space in your process, and you can reduce the size of your facility by reducing it. Some inventory is necessary to allow smooth operations, but too much can interfere with the smooth flow of material through the process (find more about inventory in Chapter 8).

Create an open environment. An open environment allows everyone to see what’s going on in the process and simplifies the job of managing. It exposes problems in the process because there’s nowhere to hide. This applies to manufacturing operations and office environments. An open environment can also increase communication among employees because everyone can see the state of the operation.

Create an open environment. An open environment allows everyone to see what’s going on in the process and simplifies the job of managing. It exposes problems in the process because there’s nowhere to hide. This applies to manufacturing operations and office environments. An open environment can also increase communication among employees because everyone can see the state of the operation.

Maintain flexibility. A facility design should be flexible to allow for new conditions. If possible, you should be able to reconfigure the design to accommodate the introduction of new products or a change in the mix of products produced or processed at the facility.

Maintain flexibility. A facility design should be flexible to allow for new conditions. If possible, you should be able to reconfigure the design to accommodate the introduction of new products or a change in the mix of products produced or processed at the facility.

The processes that take place out of the sight of the customer are prime for taking advantage of economies of scale. In a bank, centralizing such things as the loan decision process is common, and in fast food restaurants, employees form the hamburger patties and cut the potatoes into French fries at a central location that supplies several restaurants.

Fulfilling Customer Demand: Making to Stock or Making to Order

How do you supply products to your customer? The product-customer interface typically follows one of two patterns: make to stock or make to order. In this section, we look at both.

Making to stock

In a make-to-stock (MTS) process, you produce products and place them in a finished goods inventory (FGI) until you receive a customer order. Most consumer goods manufacturers use this process. MTS works best in environments where customers want their product on demand or where the time it takes to produce the product (the lead time) is greater than the time the customer is willing to wait.

In an MTS process, the firm must forecast what it believes customer demand will be (see Chapter 6 for info on how to forecast). The company produces a certain volume of product based on the demand forecast. Ready-to-sell products wait in an FGI for the customer to buy.

You can probably appreciate the benefits of MTS. Think of a grocery store shelf. When you need milk, the last thing you want to do is go to the grocery store and find out that you need to order the milk and wait for Farmer Joe to milk the cow. Often, long lead times necessitate making products to a forecast.

Making to order

A make-to-order (MTO) process can be your best dream or your worst nightmare. In an MTO process, you only produce something when you have a customer order. MTO allows you to avoid all the risk associated with a bad forecast and to avoid being left holding FGI that no one wants to buy. You can provide a customized product — exactly what the customer wants. However, you must produce these products within a lead time acceptable to the customer. If you can’t deliver, the customer may cancel the order and/or never return to your company for future orders.

A variation of MTO is assemble to order (ATO). The postponement strategy used to minimize inventory (described in Chapter 8) is an example of ATO. In an ATO strategy, assembly of the final product is delayed as long as possible. This allows a firm to wait until a customer order is received but reduces the lead time because some of the process is already completed.

Many service processes can only operate using MTO. For example, you can’t process a mortgage loan application until a customer requests a loan. You can’t have an FGI of approved loan applications waiting for the customer. Chapter 7 goes into detail on how to build and manage capacity in these service operations.

A tale of two companies: Making either method work

Fortunately, most companies can be successful using either the MTS or the MTO process. They just have to design a process to take advantage of the positives and be prepared to negate the negatives of each.

Take two competing personal computer (PC) manufacturers. One utilizes MTS, while the other emerged in the market utilizing MTO. Both experienced success in the PC computer revolution.

The first company remained with the traditional model of MTS. It manufactured a few models of computers and sold them through major retailers. By utilizing a superior forecasting model, it was able to supply its sales outlets with the products customers were demanding. It designed its production process to mass-produce the models and took advantage of commonality and postponement to minimize inventory (see Chapter 8).

The competitor introduced an MTO process, producing a computer only when it received an order. This company could customize computers 100 percent. It was only able to accomplish this because of outstanding knowledge of its production lead times and a process that took minimal time to make a computer. The company used such techniques as implementing a batch size of 1 (see Chapter 3) and developing a responsive supply chain that could respond to unpredictable customer demand (see Chapter 10).

In addition, the MTO strategy only worked because of the modularity of the components that make up a computer. Modularity, or the ability to swap one component for another, allowed the manufacturer to use different components, such as the hard drive in the same interface, so hard drives of different sizes could be easily popped in during assembly.

The market had room for both strategies. The two different strategies were possible because the target customer for each company was slightly different. MTS customers wanted a computer that met their basic requirements; they didn’t care about what was under the hood. They also wanted technical assistance and/or home installation. The MTO company appealed to more sophisticated buyers who understood the differences in RAM space and computer chip speed and wanted an ability to customize what they thought was the ultimate machine. In addition, they needed limited customer support and didn’t mind waiting a few days to receive their computer.

Designing for X: Designing Products with Operations in Mind

A large part of a product’s cost to manufacture is determined by the product design itself. The design determines how many components make up the product and dictates how these components must work together to provide the product’s necessary functionality. This section describes the design techniques that successful firms use when developing products.

Long ago, product designers developed new products without any input from manufacturing engineers. This “throw it over the wall” approach often resulted in designs that were difficult to manufacture and that incurred higher-than-necessary production costs.

Most firms now participate in concurrent engineering, which brings product design and process design personnel together early in the design phase. This allows manufacturing to have input into the design and to make suggestions on how best to design a product that minimizes production costs. This meeting of the product and process design minds is commonly referred to as design for manufacturing (DFM).

The DFM revolution has led to the design for revolution. Following on the heels of DFM, every aspect of the product is considered in the design, and this generates a sea of DFXs — you fill in the X. Here are some examples:

Design for assembly (DFA): This is similar to DFM and focuses solely on how to design for ease of assembly and for reduced assembly time. Accomplish this by designing a product with few parts and by making the interface among the components simple, such as designing snap-together parts rather than parts that have to be bolted together.

Design for assembly (DFA): This is similar to DFM and focuses solely on how to design for ease of assembly and for reduced assembly time. Accomplish this by designing a product with few parts and by making the interface among the components simple, such as designing snap-together parts rather than parts that have to be bolted together.

Design for logistics (DFL): This involves designing a product for ease of transporting from manufacturing to the customer. With rising transportation costs, the importance of DFL is only increasing. Utilizing DFL, companies design and package products to minimize the space required to ship.

Design for logistics (DFL): This involves designing a product for ease of transporting from manufacturing to the customer. With rising transportation costs, the importance of DFL is only increasing. Utilizing DFL, companies design and package products to minimize the space required to ship.

Design for sustainability: Companies now design products with the product’s end of life in mind. Environmental concerns are forcing designers to consider how a product can be reused or recycled. Examples include designing an ink cartridge that can be easily refilled and incorporating biodegradable materials into the product.

Design for sustainability: Companies now design products with the product’s end of life in mind. Environmental concerns are forcing designers to consider how a product can be reused or recycled. Examples include designing an ink cartridge that can be easily refilled and incorporating biodegradable materials into the product.

Design for service: Throughout their life cycle, many products need to be serviced or repaired. Depending on how components are placed in the design, they can be easy or difficult to access when service is needed.

Design for service: Throughout their life cycle, many products need to be serviced or repaired. Depending on how components are placed in the design, they can be easy or difficult to access when service is needed.

Design for reliability/quality (DFR, DFQ): Quality doesn’t just happen, and it’s not solely the responsibility of manufacturing. DFQ recognizes that quality starts in the product’s design. For details on quality, check out Chapters 12 and 13.

Design for reliability/quality (DFR, DFQ): Quality doesn’t just happen, and it’s not solely the responsibility of manufacturing. DFQ recognizes that quality starts in the product’s design. For details on quality, check out Chapters 12 and 13.

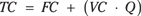

The total cost (TC) associated with a given volume of output is equal to the sum of the fixed cost (FC) and the variable cost per unit (VC) times volume produced (Q):

The total cost (TC) associated with a given volume of output is equal to the sum of the fixed cost (FC) and the variable cost per unit (VC) times volume produced (Q):