As I sit on a train gliding through the countryside, moving more quickly than the cars I can see on a nearby motorway, I wonder to myself how the passenger experience has changed over the years. Trains are an established part of our lives. Whatever we may think about them as they go by, they are not new to us. However, when the railways were first built, the impact of trains on the surrounding countryside was immense.

The train I am travelling in is a thoroughly modern ‘Pendolino’, and there is an unbroken, if somewhat complex, lineage between this train and the very first passenger trains. The Pendolino is closely related to the highly advanced but infamous public failure, the APT (Advanced Passenger Train). The APT was an attempt to improve the speeds achieved by the Intercity 125 trains that still run today. This quest for improving train speeds has led to many of the innovations on the railway and has directly impacted on the passengers over the decades.

The speed of the APT was increased through the deployment of a controversial tilting mechanism, but after a series of problems and a loss of financial and political support, the APT project was soon abandoned. The patents for the tilting mechanism were sold to the railway division of FIAT in Italy, who were working on their own set of tilting trains. These patents were used to improve the designs and eventually the Italian Pendolino was born.

The Pendolino trains have received their fair share of criticism, much of it relating to the passenger experience. The seats are crammed in and there is little room to spread out. If you are lucky enough to get a seat that is near one of the few windows on board, the view is limited and there is nowhere comfortable to rest your arm. Many of these restrictions on passengers are derived from high-speed rail safety regulations, which particularly apply when trains cross one another in a tunnel. I wonder what the views of a Victorian traveller aboard a Pendolino might have been, if their only other experience of rail travel had been aboard one of Britain’s first passenger trains?

The first recorded steam-powered device was the aeolipile, created in the first century AD, but it was in Britain during the eighteenth century that true advancements in steam power were made. Beginning with Thomas Savery’s steam pump in 1689, improvements were steadily made in the technology and steam became inseparable from the industrial revolution. As steam power was harnessed to create rotary motion and engines became lighter and more powerful, the idea of using a mobile steam engine that ran on rails became a reality.

“THE BENEFITS TO PEOPLE WHO TRAVELLED BY STEAM RAILWAY WERE THAT THIS METHOD OF TRAVEL WAS BOTH CHEAPER AND FASTER.”

As with any new technology, it took time to work out how to make passenger trains profitable. The Stockton and Darlington railway (1825) had one passenger carriage named ‘Experiment’ and although it was pulled by a steam engine during special ceremonies and the like, it was usually pulled by horse. Horse-drawn railways were not new, as the rails allowed the horse to pull a much heavier load. This could just as easily be people as goods. One such example is the short-lived Swansea to Mumbles horse-drawn passenger railway of 1807.

The Liverpool and Manchester Railway is considered by many to be the first true steam-hauled public railway service, featuring compartmentalized coaches and a proper timetable. The design of this railway’s coaches influenced many others, and early passenger travel on the steam railways began. The benefits to people who travelled by steam railway were that this method of travel was both cheaper and faster. The drawback was that, at times, it could be very uncomfortable. The movement of the train itself could cause discomfort, and driving wind and rain often added to the misery of the passengers. Sometimes, during or after heavy downpours, water would slosh around the bottom of the carriages and soot, smoke and cinders from the engine would find their way into passengers’ eyes or down their collars. However, this was the way of the future – and nothing was going to stop the railways.

BUILDING THE PERMANENT WAY

Once it became apparent that the railways were the way forward, several companies formed and many railways were built. Not all came to fruition and not all were successful, but the one thing that all the companies had in common was that they needed someone to construct the track, known as the ‘permanent way’. That someone was the ‘navvy’.

The word ‘navvy’ is an abbreviation of ‘navigator’ and is synonymous with the construction of the British railways. By the end of the nineteenth century, one in every hundred people in the UK was a navvy. The work of navvies – labourers, essentially – is often equated with large historical building projects, such as the great pyramid at Giza. However, it is much harder to envision the scale of the railway navvies’ work compared with that involved in a single-site construction project. Additionally, whereas an individual monument will often show evidence of an associated workers’ village, the very nature of the permanent way meant that the transient camps that navvies established left little or no remaining trace on the landscape.

NAVVY CAMP

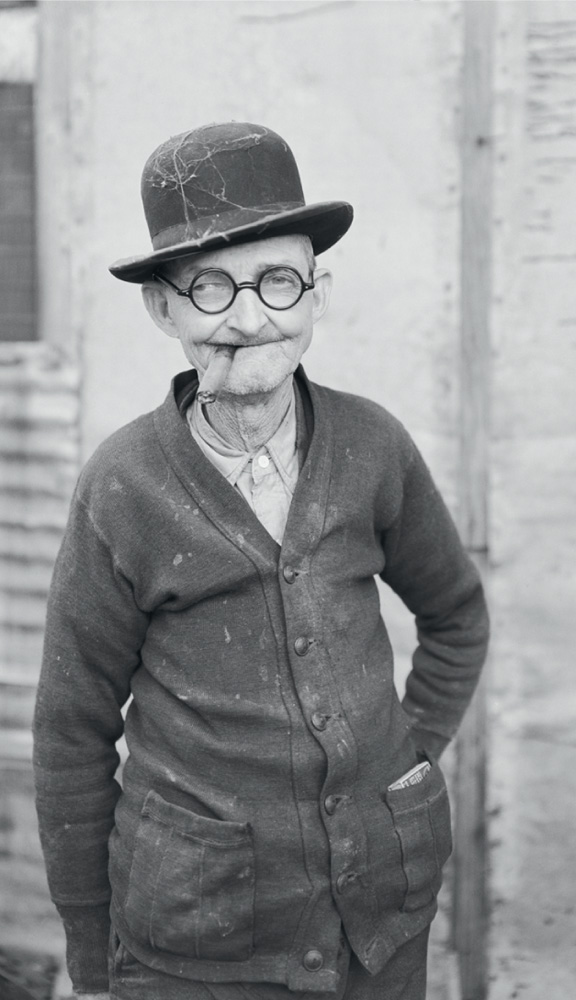

In order to better understand how navvies lived and worked, we travelled to Herefordshire, where Colin Richards had erected a navvy camp based on a nineteenth-century photograph. Stepping into the camp was like going back in time. We had certainly picked the day for it, as we had had a relatively mild winter but this was the first truly cold day. The night before temperatures had dropped as low as minus ten degrees, and during the day they never got above freezing. The surrounding countryside looked magical, with trees covered in a heavy frost, but it was so cold that even the smallest leaves hanging directly above the blacksmith’s forge never thawed out.

My father used to say to me that ‘any fool can be cold and wet’. I have spent much of my life outdoors and have always heeded these words, but the one part of my body that I find the hardest to keep warm is my feet, especially when I am wearing hobnail boots. The metal studs seem to conduct the cold and no amount of socks ever seem to help.

We met Colin Richards next to the still. He was brewing up a carrot whisky and we had a glass as we talked about health and safety. The nineteenth-century navvies were relatively well paid when compared with farm labourers or factory workers, but they had to work very hard. They had a reputation for playing hard, too. It is a common misconception that the navvies were Irish. Although some navvies who worked on the railways came from Ireland, they represented only about ten per cent of the total number of men who worked on the permanent way.

“THE WORK OF NAVVIES – LABOURERS, ESSENTIALLY – IS OFTEN EQUATED WITH LARGE HISTORICAL BUILDING PROJECTS, SUCH AS THE GREAT PYRAMID AT GIZA.”

Many of the navvies were local men, but the promise of good money also attracted seasonal workers, who often came from the farms that the railways disrupted. However, many workers were dedicated, full-time navvies who operated in groups known as gangs and followed the work around the countryside. These groups started out pretty small, but grew in size as the demand for railways increased.

Many established communities feared the arrival of the navvies, as they passed through villages and towns constructing the permanent way. They had no roots and were often viewed as having no religion. Their rough lifestyle, combined with a disposable income, meant that the local innkeepers were generally kept happy. However, the navvies had a reputation for fighting, and tensions between rival gangs competing for work were often settled in a bar room brawl.

Anyone who has ever visited Camden in north London has probably noticed the sheer amount of urban infrastructure there that is associated with the railways. Camden was at one time quite a rural area, but the railways quickly changed that. The district lies in spitting distance of three of Britain’s largest train stations: King’s Cross, Euston and St Pancras. It also proudly boasts the Camden roundhouse, one of the oldest railway buildings to survive, and is criss-crossed by sidings, main lines and the underground.

To build all of this, navvies had to be in the area for a long time. Thus, in order to prevent trouble and to avoid injuries from fighting that might prevent a gang from working, multiple pubs were constructed to segregate the different nationalities. The four pubs in question were the Edinburgh castle, the Dublin castle, the Windsor castle (no longer a pub) and the Pembroke castle.

When navvies moved through towns or villages, they would generally stay in local lodgings. However, much of the urbanization we see associated with railway lines post-dates the lines being built. Indeed, much of the housing in Camden, especially around Primrose Hill, consists of cottages that were hastily erected in order to house railway workers.

Many of the navvies working on the permanent way would have found themselves effectively in the middle of nowhere, living in makeshift dwellings, and drinking homemade hooch, rather like Colin Richards’ carrot whisky. As we sipped from our glasses and the burn in our throats fended off the chill in the air, Colin gave each of us a bowler hat.

In the mid-nineteenth century, life was cheap and health and safety was in its infancy. Industrial accidents were commonplace and a navvy’s work was often dangerous, especially during the construction of tunnels or deep embankments. A navvy had to trust that the environment they were working in was as safe as possible. They also had to trust those around them – but ultimately they were responsible for their own safety.

The bowler hat was a popular choice of headgear amongst the Victorian working classes. The hat is believed to have been commissioned by Edward Coke (pronounced ‘Cook’), who approached the London hatters Locke & Co. Coke wanted a hat for his gamekeepers at Holkham Hall that could withstand a blow from low hanging branches when they were on horseback and, if tales are to be believed, a thump over the head from a poacher’s stick. The resulting stiff felt hat withstood Coke stamping on it twice and, satisfied with its strength, he replaced his gamekeepers’ previous headgear of choice – the top hat.

The bowler hat does have other names, such as the Billycock or the Derby. One thing that is certain: it has become an iconic piece of headwear. It is very similar to a modern hardhat. It has a rim that gives the eyes protection from either debris falling from above or from catching yourself on a protruding nail when turning your head. It keeps the rain off and is relatively hard. If I were a navvy and had the choice, I would definitely have worn a bowler hat.

During the twentieth century, the bowler became synonymous with gentlemen working in the city. It is part of the guards’ walkout uniform for officers, along with a pinstriped suit and a tightly furled umbrella. This has meant that the hat’s original working class origins have faded. Indeed, while wearing my own bowler hat at navy camp, I lost count of the number of people who, upon spying it, said to me ‘you must be the foreman’. My reply was to inform them that if they ever travelled to South America they should try and visit one of the indigenous ethnic groups known collectively as the Quechuas. British railway workers introduced the hat to the continent in the 1920s, and to this day many of the Quechua women still wear bowler hats.

SAW MILL

One of our first jobs at the navvy camp was tarring sleepers. However, before we could do that we had to make the sleepers in the first place. The railways were a new technology. No one knew how a train powered by steam would behave as it moved along rails. In the early days (the 1830s) it was thought that the track had to be rigid. It is easy to see how that idea could gain credence, as powerful, heavy but inefficient engines moved slowly along the permanent way.

Early sleepers were made out of stone, and to ensure maximum rigidity these sleepers were often concreted into position. The rails that made the track were initially quite short and simply spanned the gap between the rigid sleepers. Stone was a cheaper material than wood, but as the railway technology rapidly progressed and rails were made longer, it soon became apparent that something had to give – both literally and economically! Although it was more expensive, the plain fact was that wood offered the extra degree of flexibility that was required by several tons of train and freight moving at speed.

So, in time, the stone sleepers were removed and wooden ones took their place. As an interesting aside, the spire at St Walburge’s church in Preston is the third tallest spire in the UK after those of Salisbury and Norwich cathedrals (and the tallest spire of any parish church). It is constructed exclusively from the limestone sleepers that were removed from the Preston and Longridge Railway.

In 2007, road excavations uncovered a number of intact stone sleepers that were used as long ago as 1825 for the Stockton and Darlington railway. These were the very first sleepers to be laid down and weighed only 75lb, so that they could be carried by one person. However, they soon proved to be too flimsy and were quickly replaced by larger ones. Most of the 64,000 original sleepers were destroyed, but some were used in a retaining wall and it was these that were uncovered during the works for the Darlington Eastern Transport Corridor.

The sheer number of main lines, branch lines and sidings mean that the total number of railway sleepers in use in Britain is absolutely colossal. In the 1930s, at arguably the height of Britain’s railways in terms of infrastructure, the Great Western company owned an estimated 9,000 miles of track which equated to almost 20 million sleepers in use. However, sleepers, like rails, had to be replaced and during the same period the London, Midland and Scottish railway had an annual requirement of 1.25 million sleepers.

By the 1930s, sleeper production was big business, involving the mass importation of wood and extensive mechanical processing and treating. One hundred years earlier, it was a different story. Some early wooden sleepers were manufactured in the half round. This would mean harvesting young managed woodland, sawing the wood to length (which in the Victorian era was nine feet, becoming eight and a half feet in the twentieth century), and splitting the log in two. Splitting a log is a lot easier and quicker then sawing it, and if the tree has grown in relative shelter and the grain is straight, the split should result in a nice, flat face.

These half-round sleepers persisted for a while and crossed over with the uniform square-cut sleepers that are well known today. A type of wooden sleeper that was very short lived was the triangular sleeper, with the apex of the triangle driven down into the ballast stones. A triangle is the profile that one would achieve when splitting a tree with a much larger circumference into sleeper-sized chunks. The problem with split wood is that each face is unique and will be governed by the grain. Mass production requires order and uniformity. The nine-foot wooden sleeper with a square-cut end of ten by five inches was quickly adopted as standard.

The permanent way had to be as level as possible, as trains struggle with inclines and steep gradients are out of the question. The steepest sustained gradient on Britain’s railways, that does not employ a third rail for traction like a fell system, is Lickey Incline. At two miles long, it has a gradient of 1 in 37.7 or 2.65 per cent. Steam trains ascending this incline would often need bankers, which are other steam engines, to help them push their load uphill.

The creation of the permanent way involved building bridges, boring tunnels, digging cuttings and compiling embankments. As the navvies constructed the permanent way across a landscape that had not been significantly altered since the time of James I, they encountered many obstacles that either had to be avoided or demolished.

Often the navvies would have to remove trees that could be used as sleepers. Hardwoods such as oak were the most sought after for this purpose. At navvy camp, we felled an oak tree in order to cut it into sleepers. When felling a tree you must first look at the landscape and decide which way you want the tree to fall. You need to consider other trees and whether the branches will catch them as the felled tree falls down. The wind will always be a factor, and when we felled our oak, the wind speed was high. However, due to the size of the tree, we could fell it directly into the wind.

Once you have decided on the direction in which you want the tree to fall, you need to cut a notch known as a ‘gob’. I have always been taught, when felling with a two-man saw, to cut the horizontal bottom cut first. This is a very important cut and worth taking the time to get right, as this will determine the way in which the tree falls. It is essential to keep the saw level and have the perpendicular line formed by the cut to be in the direction you wish the tree to fall. Then, using a felling axe, the gob can be cut out by chopping down onto the cut you have made in the tree.

Once the gob has been created, a cut from the other side of the tree is made in order to fell it. It is important to establish lines of safety. Anywhere in front of the tree is a no-go area and directly behind the tree is also dangerous – both because a tree can fall the wrong way, but also because a tree when falling can kick backwards. The accepted safe paths are on each side of a tree at 120 degrees to the direction of the intended fall. The safest place to stand is behind the nearest big tree.

Cutting a tree down to make way for a railway is only half the story. The real problem is the stump. Victorian stumps were usually a lot higher than modern tree stumps, because of how a two-man saw was used. However, even if the stump was cut down to ground level, laying track over the top of it would only result in serious problems later on, when the stump rotted out or the tree tried to grow back (often from the roots).

In market gardening, tree stumps were often removed mechanically or by the use of an explosive such as stumping powder or dynamite. The navvies working on the permanent way were more likely to dig down into the ground around the stump, set a fire and smother the whole thing in leaf litter and earth. The result would be a clamp that would burn the remaining stump into charcoal. This could then be used as fuel for blacksmithing or simply for domestic fires. Although many trees were cut down to meet the demands of the railways, no part of the tree was ever wasted.

Once our tree was on the ground, we could get round to processing it. The first job is to remove the branches and is known as ‘snedding’. The trunk can then be cut into sections, with the objective of obtaining as many nine-foot sleepers as possible firmly in mind. To cut the trunk sections into sleepers, we used Britain’s only working water-powered saw mill, on the Gunton estate in Norfolk, just outside Cromer.

“IN MARKET GARDENING, TREE STUMPS WERE OFTEN REMOVED MECHANICALLY OR BY THE USE OF AN EXPLOSIVE SUCH AS STUMPING POWDER.”

Built in 1824, just before Britain’s railway bonanza, by the third Lord Suffield, the saw mill is a remarkable building housing a remarkable piece of kit. It was originally intended to be used as a processing plant for all of the estate’s timber, and just outside the doors of the building are the remnants of hastily poured concrete that represented the additional two circular saw pits made by the allies during the Second World War.

However, by the mid-1970s the building had completely fallen into disrepair. The thatch had started to rot, there had been a fire, and the two-and-a-half ton cast-iron flywheel had fallen from its mountings. The Norfolk county council, the local windmill trust and industrial archaeology society collectively drew up plans. With the help of the last remaining tenanted Harbord family member, Doris – and after her passing, the estate’s new owner Mr Kit Martin – the water-powered saw mill was saved.

When Alex and I first entered the building, he noted the recently thatched roof. Between the thatch and the rafters was a layer of woven reeds – known as ‘fleeking’ – that Alex commented upon. I told him that I had once lived in a thatched building and it too had been f-ing leaking…!

One of the notable aspects of the Gunton saw mill was just how dry the building was inside considering that there were two huge water wheels at the back. The sides of the building are wooden slatted panels that can be removed to increase light and more importantly to create an opening through which the tree trunk to be processed can be passed. I found the hardest aspect of the whole process to be moving the trunk from the yard outside to the saw bench. We used block and tackle, which through a series of pulleys gives the rope being pulled a mechanical advantage. We hauled the log in and got it set on the bench. After that, the saw mill did all the work.

The water power for the saw mill comes from a man-made lake that covers close to forty acres. We lifted the sluice gate and filled the headrace that channels the water onto the wheels inside. There are two wheels, one to drive our saw and one to power a grain crusher. They idly turn just on the water that leaks through the gaps. The benefit of this is that it stops the paddles of the wheel drying out and splitting and prevents an imbalance in the wheel between a wet and a dry side. A sluice gate for each wheel that regulates the flow of water is operated from inside. These effectively act as throttles for the wheels, but even when we fully opened the gates and had the wheels turning at full pelt, there was very little noise.

The wheels are ‘breast-shot’, which means that the water hits the paddles of the wheel at about the height of the axle and runs underneath the wheel. Early water wheels tended to be ‘undershot’ wheels, which sat on a stream or a river and utilized the kinetic energy. The most powerful water wheels are ‘overshot’ wheels, which use both the kinetic and gravitational potential energy of water flowing into them. Breast-shot wheels are found in places like Gunton, where the landscape does not naturally provide a height advantage. However, the funnelling of a huge millpond into a narrow millrace changes the pressure created by the weight of the water into velocity.

The saw itself was exactly the same as a pit saw, except instead of being worked by two people – one standing at the top and the other at the bottom – this saw was fitted to a large frame that moved up and down. We only had one saw in place, but when cutting planks it was possible to fix multiple saws at set distances. The key was to make sure that they were all exactly aligned.

As the saw moved up and down, the gearing designed by a clock maker could be engaged. Similar to an escapement mechanism in a pendulum clock, this periodically turns an axle attached to two pinion gears, which moved two racks attached to the underside of the frame upon which the log to be cut was chained. This moved the log through the saw a fraction of an inch at a time. As the log passed through the saw, the chains and the cross-struts of the frame were removed and re-attached so that the saw only cut the log. This was relatively straightforward, but nevertheless we set the saw at the lowest speed. I was told it was frightening when the saw was going at full pelt.

Just as with a pit saw, as the log went through we tapped thin wedges into the cut to open it up and stop the wood biting the saw. However, unlike a pit saw, we did not need to chalk a line for the cut. Instead, plumb bobs were used to eye up the cut of the saw, but once the log was strapped in their was no deviation to the cutting line. When a log is first put on the frame to be cut, it is strapped to a plank to give it some stability. Once a face has been cut, the log can be turned onto it and it becomes steady.

These water-powered frame saws were reasonably common throughout Europe and there were a number in Norfolk. However, pit saw workers did not welcome them, because they rendered many men redundant. They were also short lived, because circular saws took over and steam power followed by diesel and electricity became the power sources of choice. The mill at Gunton survived because of its position on an estate isolating it from the outside world and because it was never taken over commercially.

The last job we had to do was to jump down into the saw pit and empty out the saw dust. It was in no way strenuous and because it was all oak shavings the saw dust could be used for smoking meats. However, it was a dirty job, with dust getting everywhere. We wore paper hats that are made simply from sheets of broadsheet newspaper. These hats are easy to make, disposable and protect your hair from the dust that can be easily brushed off or rinsed off from other parts of your body.

These paper hats would have been a common sight in Victorian Britain and are very similar to the hats worn today by people involved in the food processing industry. Sir John Tenniel, the political cartoonist who illustrated Lewis Carroll’s Alice’s Adventures in Wonderland and Through the Looking Glass, depicts the carpenter wearing a paper hat in his illustration of the poem ‘The Walrus and the Carpenter’. Tenniel’s collective works are considered important to the study of that period’s social history. Mr Chip the carpenter in Happy Families also wears a paper hat, but it is thought – although he is not credited – that the Happy Families drawings were done by Tenniel.

As we took our oak sleepers back to the navvy camp, I wondered just how many sleepers the Gunton saw mill had produced for the railways. One of the problems with wooden sleepers is that they rot. The oak sleepers we had made were highly sought after, because hardwoods such as oak lasted a long time as did pitch pine, but many of the imported sleepers were made of softwoods that did not last long. The railways adopted a variety of different approaches to this problem.

One solution was ‘Kyanizing’ – a process initially patented in 1832 by its inventor and namesake, John Howard Kyan. Kyan, who at one point worked in a vinegar factory, developed a way of pickling wood in mercury chloride. The process gained a lot of public attention at the same time as the railways were battling their wood preservation issues.

Other companies would let sleepers just rot out and replace them when they needed to, but many covered them with substances such as coal tar or, like us today, bitumen. Bitumen is a hydrocarbon that sits between coal and oil. Its semi-solid state means that if you were to leave a block of bitumen – which breaks like glass when hit with a hammer – on the floor of your garage, it would eventually turn into a puddle shape. The largest known natural deposit of bitumen is in Canada in Alberta, which covers an area of 55,000 square miles – greater than the entire area of England.

However, the nineteenth-century British navvies who covered railway sleepers in natural bitumen may well have got their supplies from the tar tunnel in Ironbridge in Shropshire, before it dried up in 1847. This large bitumen deposit was first discovered in 1787, when a canal tunnel was being constructed near Coalport in the Ironbridge gorge. The focus of the project shifted from tunnel construction to bitumen mining and initially over 4,000 gallons of the material were collected each week. This soon tailed off, however, and by the 1820s only ten barrels of bitumen a year were being produced.

In order for us to apply the bitumen to the sleepers, we first had to break it up with a hammer. We then put it in a copper over a fire and heated it until it became liquid. The wood we were using was broken up pieces of floorboard, joists and lath. Much of the wood was covered in paint. This was similar to the wood the navvies used, because much of it came from houses that were demolished to make way for the railways.

The permanent way was constructed from point A to point B. Prior to any track being laid or any spades being put in the ground, teams of surveyors were sent out into the landscape to determine the best routes. Some wealthy landowners welcomed the railways, because they had either already invested in them or they saw their potential. However, many landowners were opposed to them. One such landowner was the Earl of Harborough, who objected to a railway proposed by George Stephenson passing through his estate, Stapleford Park.

The Earl had a financial interest in a nearby canal and believed the competition from the railway would have a negative effect. He refused to sell his land, the Midland Railway men refused to take ‘no’ for an answer, and skirmishes broke out involving almost 300 people. The dispute became known as the ‘Battle of Saxby’. The railway was eventually built, but it had to travel around Stapleford Park in a huge bend known as ‘Lord Harborough’s Curve’ (see box).

Railways had to respect rights of way and bridges, underpasses and crossings all had to be considered when dissecting an existing route. The railways also had to consider the welfare of animals as they passed through farmland. Much of the track needed to be enclosed with stock-proof fencing. (Interestingly, some of the fencing in the West Country was made out of Brunel’s old wide gauge rails, once the gauge had been standardized to a smaller width). George Stephenson did remark that an accident would ‘be the worse for the cow’, but a train hitting an animal would also have a detrimental effect on the engine.

LORD HARBOROUGH’S CURVE

For over twenty years, the words ‘Lord Harborough’s Curve’ were uttered in irritation by passengers travelling at a snail’s pace through part of the East Midlands. It was a phrase that continued in wider use to conjure up the intransigence of vested interests and carried much the same condemnatory connotation as the modern acronym, NIMBY (‘not in my back yard’). Lord Harborough was one of many aristocrats and wealthy landowners who tried to divert the new railway lines away from his estate. However, his personal conflict with the railway promoters caused more fuss than most.

Lord Harborough owned a very nice, landscaped park around his main residence, located between Leicester and Peterborough. The trees planted by his ancestors had matured and formed pleasing avenues and copses. Thirty years previously, Harborough had invested heavily in a canal which passed through this park quietly and unobtrusively, providing for all his estate transport needs and generating a healthy income. The prospect of a railway with all the attendant dirt and noise (and early railways were exceedingly noisy in comparison to modern ones, due to the short sections of jointed track and loose coupling of wagons) right through the middle of his park, close to the house and in competition with his interest in his commercial canal was not a welcome one.

Standing in Stapleford Hall (now a luxury hotel) and looking out across the park, you can see his point. You probably would not fancy the tranquillity of the area being shattered by an early railway, either. If you are one of those people who is going to be affected by the proposed HS2 railway line, you will have a fairly clear idea of what motivated Lord Harborough to dig in his heels.

In order to build a line across the countryside, a railway company had to obtain an act of parliament that allowed them to compulsorarily purchase the land. For pretty much the first time in history, an aristocratic landowner did not have final say over his land. However, in order to get an act through parliament, the railway promoters had to present evidence of a feasible route, and for this they needed a survey of the land. Lord Harborough refused the surveyors access, and with just twenty-four days to get the work done, the pressure was on.

Word went out to local gamekeepers and estate workers that surveyors were to be kept off the land. Bands of thugs and even a prizefighter were hired from the local pubs to assist in the defence of the estate. Meanwhile, the surveyors hired their own ‘guards’ as they attempted to gain access, legally or otherwise. Things came to a head after several smaller confrontations upon the towpath of the canal in what the local press called ‘The Battle of Saxby’. Pushing became shoving, punches were thrown, equipment was broken and men fell into Lord Harborough’s canal.

Nevertheless, these bouts of rough stuff could not stop the surveyors. They sneaked into the estate over the next few days and got just enough measurements in order to make their case. Lord Harborough settled for a very considerable compensation settlement (and maybe that is what he was really after all along) and a binding agreement to hide the railway in a tunnel as it passed across his estate.

However, this was not quite the end of the story. The tunnel was constructed in what was geologically completely unsuitable land and collapsed during construction, taking many of Lord Harborough’s precious trees with it. Instead, the railway was eventually built in a ridiculously tight curve, following the boundary wall of Stapleford Park, which forced trains to slow down to a crawl for this section of their journey. Lord Stapleford’s view along with his peace and quiet were preserved at the expense of everyone else’s convenience. That remained the case until his death, when his heir proved only too willing to sell the railway a slice of the park at a big, fat profit, so that they could smooth off the corner with a new section of straighter track.

All in all, land purchases and compensation payments have been estimated to have cost the various railway companies something in the region of four times the contemporary value of the land. The more direct the route they insisted upon, the greater the need for surveying speed – and the more the railways were willing to simply buy their way out of trouble with landowners.

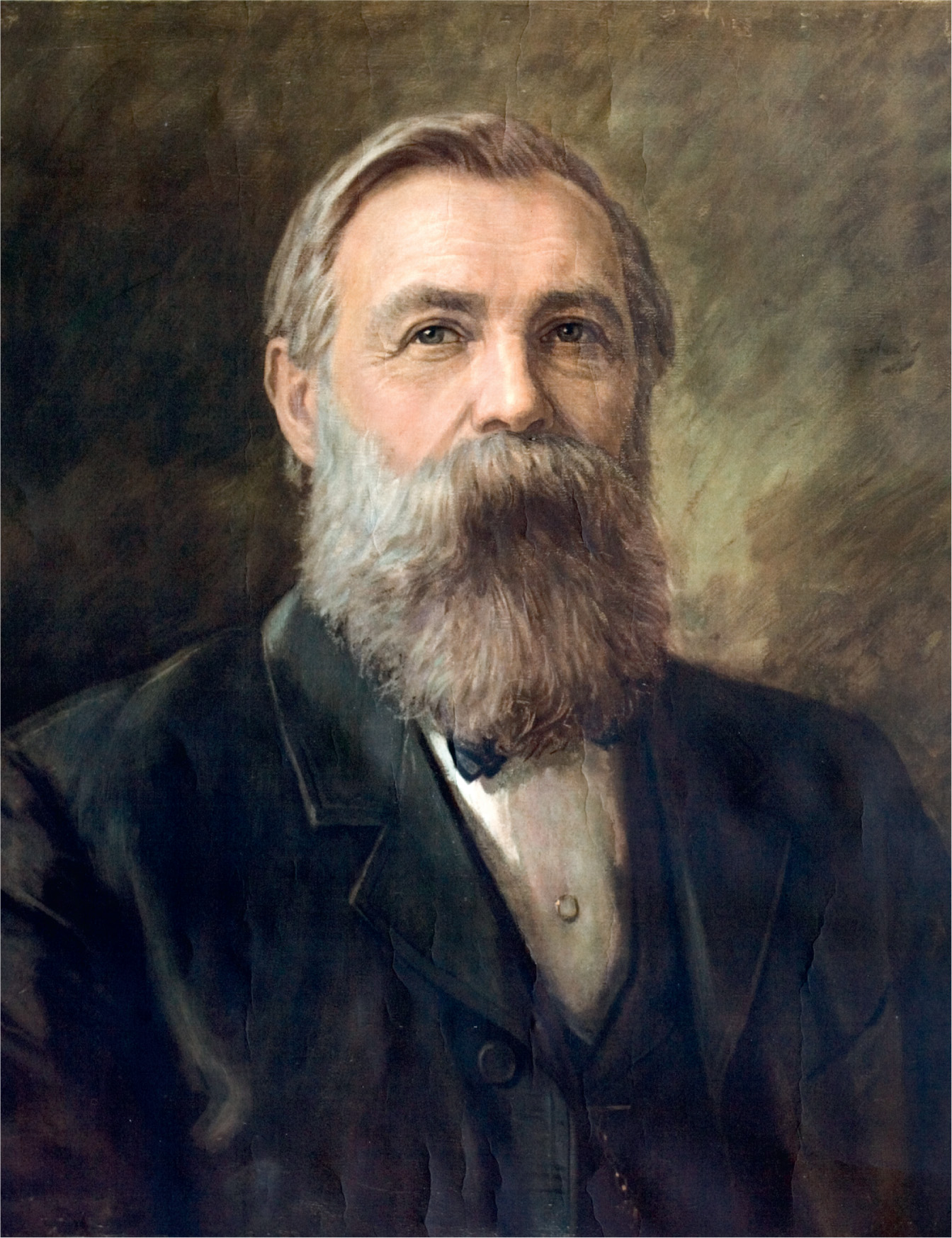

The same could not be said for tenants – particularly poor urban tenants who frequently found themselves out on the street with little warning and no compensation as the railways punched their way through working class housing and into the centre of Britain’s towns and cities. With no alternative housing on offer, many poorer people who were affected had to crowd ever more tightly into already insanitary overcrowded slums. Nor was there any compensation for those who now found their doors, yards and windows a matter of feet from passing trains. Working class districts were carved up by viaducts, embankments and cuttings, to be peered into by passing passengers. Passengers who included men like Friedrich Engels and Karl Marx, who were formulating new ideas about society, economics and history based upon what they saw of British industrial urban life. The railways both created many of our nation’s worst slums and displayed them to middle class view, prompting social reformers of many political hues to action.

Often farmers had to be paid compensation for the loss and alteration of their land. At the farm at Acton Scott where we lived for a year filming Victorian Farm, there was a building called Cray Barn adjacent to the now disused branch line. The villagers still proudly remember the night that the Royal train parked up on that very stretch of line. The line cuts the farmer’s grazing effectively in two, and Cray Barn was built by the railway as a location where he could over-winter his cattle, so that he did not have to bring the herd to the other side of the tracks and back to the main farm.

Many railways often travelled through slums on the edges of cities. The railways cutting through these slums often gave many people their first glimpse of working class living conditions that had largely been created by the industrial revolution. It was a period of huge social change and with it social reform and commentary, such as the 1845 publication The Condition of the Working Class in England, by the German social scientist Friedrich Engels.

The slum dwellings in cities that were in the way of proposed railways were often easier to demolish than the newly emerging suburbs. However, they were also harder to cut through than a country estate, due to the presence of multiple property owners. I lived in a house in London that was in a Georgian terrace. The part of the terrace I was in had been demolished in order for a cut and cover tunnel to be built. The houses had then been rebuilt to a Victorian floor plan and a lesser quality, but with a Georgian exterior. All of these houses and slums would have yielded a large quantity of pre-cut wood that was perfect for lighting the many fires needed to build the railways.

The fumes were acrid and the cold was not our friend. I would take out a ladle full of bitumen, having first heated the metal ladle. I then poured it on each side of the sleeper in turn as Alex followed me with the brush to smooth it off. However, the sleepers were so cold that our workable window of fluid bitumen was not much more than one or two seconds.

When heated, bitumen is very flammable. We did manage to set fire to the brush, but this only made matters worse. However, we were pleased with the final result. It took us a few sleepers to get our eye in and perfect our technique, but soon we had a system that worked. As a child, I remember seeing sleepers covered with bitumen that were no longer on the railways. One of the benefits of bitumen is that it is semi-liquid, so any cracks that form when it is cold will heal when the sun comes out. This also allows the timber to breathe and the moisture to escape as it seasons in situ.

“THE FUMES WERE ACRID AND THE COLD WAS NOT OUR FRIEND. I WOULD TAKE OUT A LADLE FULL OF BITUMEN, HAVING FIRST HEATED THE METAL LADLE.”

The bitumen definitely kept the rain off, as any moisture that landed on the sleepers balled up into droplets. Most railway companies treated their sleepers themselves and, due to the vast numbers needed, the process became mechanized. The preferred treatment ended up being creosote. There are two types of creosote; one derived from wood tar that was often used in the preservation of foods and one derived from coal tar, used for the preservation of materials such as wood. They are chemically different. The creosote was forced into the sleepers under pressure and when the treatment was finished each sleeper would contain over ten litres of the stuff.

RENOWNED NAVVIES

We stepped into the living accommodation that Colin had built for a cup of tea. It was often the youngest navvy’s job to make the tea. Each navvy would have their own tea and sugar in a tin and the nipper would collect some from each person and make the brew. This ritual became known as ‘drumming up’, as the ‘tea pot’ was any metal vessel and was referred to as a drum. This expression was also used in the Glasgow shipyards.

There are plenty of accounts of navvies digging holes in the ground to sleep in or just lying down and sleeping rough wherever they could. The thought of this made Colin’s bunkhouse seem positively homely. Navvies lived on top of each other and many had their families with them. The camp they set up by the side of the railway lines they were building could often become insanitary, and outbreaks of dysentery or worse were common. In the short time we were sitting having tea, we could see condensation form on the tin roof and begin to run down over the bed.

The navvies, who also built the canals and worked on the docks, were almost a sub-working class. Despite paying them a good wage, many of the companies that employed the men took advantage. Rather than paying the navvies in money, they would pay them in goods or coupons to spend in the truck shop, which sold items at inflated prices. By the nineteenth century this practice had largely ceased, although navvies were still encouraged to spend their cash in the truck shops. Children born to navvies began work at a young age. One of the first jobs was ferrying tools back and forth and taking them to the blacksmith’s shop for sharpening. As the boys got older they became ‘fat-boys’, so named for the grease they smeared on the axles of carts and wagons.

Navvies from different parts of the country had different nicknames. Navvies from Wales were called ‘mountain-pecker’, those from Lancashire were called ‘Lanks’, but my favourite is the name given to navvies from Wiltshire. This was ‘moonrakers’, after the folk tale of how a group of Wiltshire men hid French brandy from customs officers in a village pond. When they tried to retrieve it at night and were caught by the custom officials, they explained their actions by saying they were trying to rake in the giant cheese that was in the pond. The officials, seeing the cheese in question was a reflection of the moon, deemed them yokels and let them be.

We could see the moon from where we were sitting, and Colin’s bed did look inviting – but we still had work to do. In order to attach the iron chairs, in which the rails sit, to the sleepers, we had to make coach bolts. The coach bolts that are used today are very similar to the early coach bolts used in the railways, except that the first coach bolts were all mass-produced by hand by teams of blacksmiths. They are relatively simple devices. A piece of iron is upset at one end. The resulting bulge is then squared off to form a nut. The shaft of the bolt is also squared off in the middle and then heated and twisted to form the screw. Finally, the end of the piece is drawn out to a point. The final result is a piece of iron, that although unique looks identical to every other one that has been made. This can then be hammered and twisted into the wooden sleeper below.

As the coach bolt fizzed in the ‘bosh’ of the sleeper, we thought about all those traditional crafts that had come together to build the railways. The railways unified the country, allowed for greater mobility and standardized time. Villages that had once been remote now found themselves linked to the outside world via a train to London – and then, if you had the money, a train on to Dover with a ticket for a paddle steamer. Village identity in Britain was truly unique. The varying regional styles of the simple tool the bill hook attest to that localized identity. Navvies travelling as they worked would have been acutely aware of the regional variations. They were also aware of the changes in soil and geological stratigraphy. There are even arguments proposed that the navvies were among the first to identify stratigraphy in an archaeological sense, as many would have been employed on antiquarian excavations.

“THE COACH BOLTS THAT ARE USED TODAY ARE VERY SIMILAR TO THE EARLY COACH BOLTS USED IN THE RAILWAYS AND MADE BY BLACKSMITHS.”

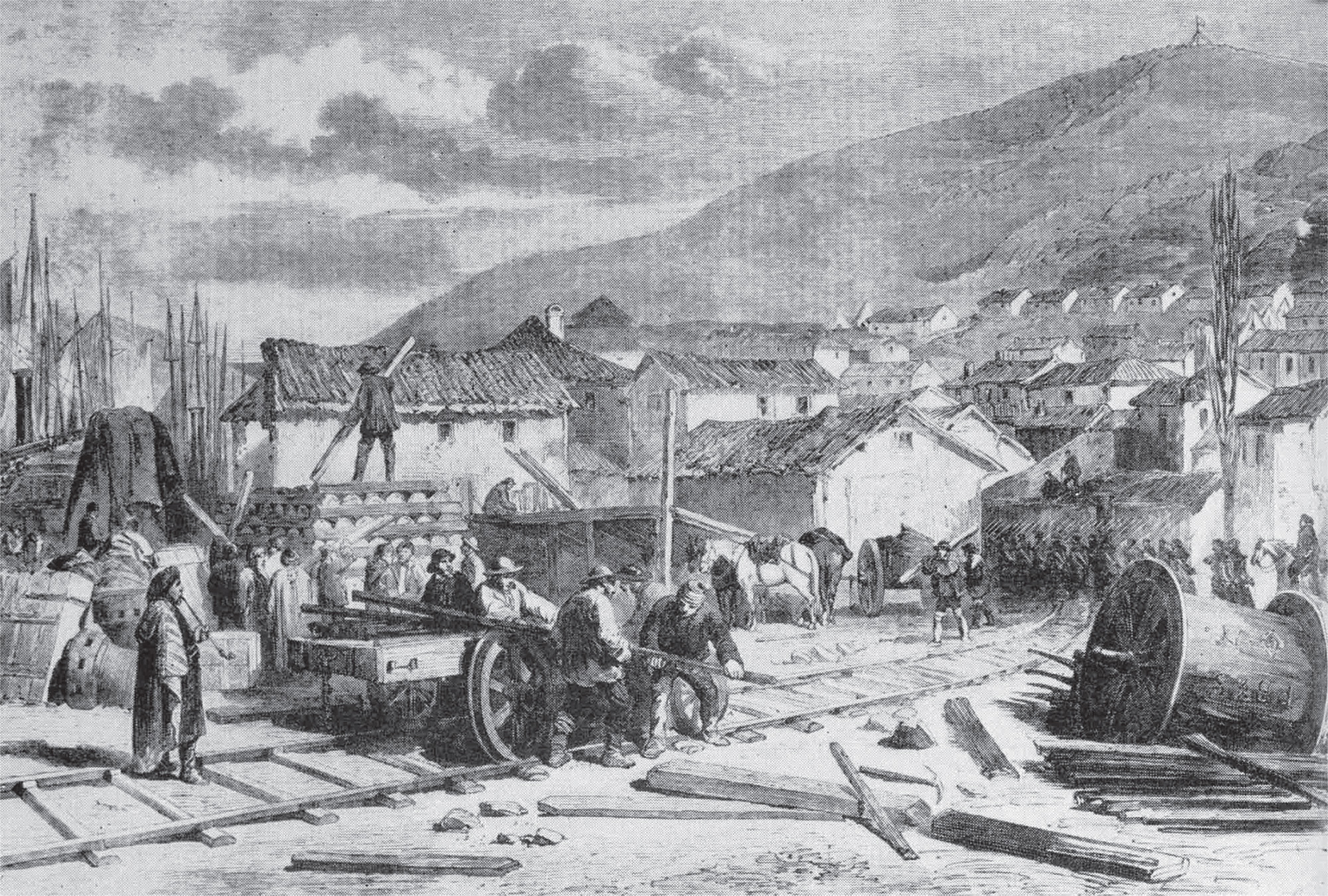

However, the railways would go some way in eroding the different regional identities of Britain. It was a period of huge change in the country. Even the navvies, who were perceived as godless and pursued by missions, were affected. The Times newspaper led the way in reaching mass circulation, using a steam-driven rotary press and adopting steam trains as a way of boosting readership. ‘The Thunderer’, as it was affectionately known, also introduced the practice of dispatching war correspondents. The reports by W. H. Russell on the Crimea War caused shock and outrage to the readers back home. The Crimea engraved images of the charge of the light brigade, Florence Nightingale, and balaclavas on the national consciousness. It was one of the first conflicts to deploy naval shells, telegraph wires and railways.

To build the railway between Balaklava and Sebastopol Peto, the building contractors Brassey and Betts recruited huge gangs of navvies and took them to the Crimea. Reports appeared back home of how the navvies worked day and night through rain, hail and snow, laying the track at a fantastic rate. The Illustrated London News suggested one solution to the conflict was to send in the navvies in hand-to-hand combat. The public came to admire the navvies and many pictures of the period showed that the men departing were leaving behind families.

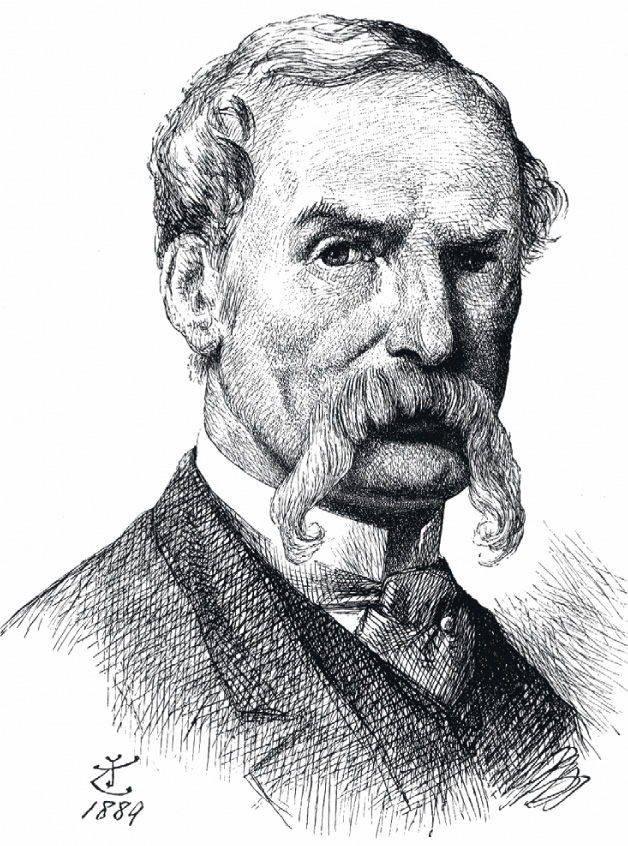

Thomas Brassey was one of the best contractors the navvies could work for. Brassey built some 6,500 miles of railway in total, which equates to one in twenty miles of track in the whole world. During his busiest periods, Brassey had over 100,000 men in his employ and he made strenuous efforts to look after them properly. He subsidized hospitals, tried to stagger work to cover periods of inactivity and unemployment, and banned the beer sellers and tommy (food) shops. The statistic that a navvy could move twenty tonnes of earth in a day is an often-quoted figure. It is upon the efforts of Brassey’s exceptional workforce that this figure is based.

STONE CRUSHING

As the navvies moved across the British landscape, they often encountered large rocks blocking their path. Moving such boulders requires a lot of effort and small stones were also needed as ballast. To deal with the problem, navvies employed the ancient technique of fire setting.

A technique that has been used in mining since prehistoric times, fire setting involves a fire being built in and around the rock that gradually heats the stone. While this happens, the first cracks begin to appear. When the rock is hot enough, the fire can be moved off and the rock can be rapidly doused in cold water. The resulting thermal shock causes the rock to fracture further. When we tried this technique, the results were astounding. The rock cracked into many pieces and when we struck it with the hammer it broke easily. Our earlier attempts to strike the rock with the hammer when it was cold did not even make a dent.

Ballast was essential for the railways. It is the crushed stone that the sleepers are bedded into. Ballast not only anchors the sleepers and the track in place – it helps spread the load on the rails and provides drainage to stop the sleepers rotting and the permanent way becoming waterlogged. This is very important, because insufficient ballast will result in problems with the ground and a possible destabilizing of the track.

As much as fire-cracked stones and clinker and slag from furnaces could be used as ballast, the demand by the railways for the material was so great that they had to turn to quarries. Initially, local stone was employed as ballast on the railways, but it was soon demonstrated that soft stones such as limestone began to round off and quickly wear away where they lay. One of the stones of choice was basalt, which is basically a Latin term meaning ‘very hard rock’. When basalt is crushed, the angular stones lock together when put in place.

We travelled to Blodwell stone quarry in north Wales, on the county border with Shropshire, where basalt stone for ballast was extracted up until the 1990s. Basalt is an igneous rock and is one of the most common rock types in the world. It was taken out of this quarry using rock drills driven by compressed air and explosives. A matrix of holes are drilled and explosives inserted, and then a face is blasted. The quarry was an impressive landscape, with a huge lake at its heart, surrounded by the manmade rock shelves known as ‘chairs’.

Rock drills made by the Holman brothers running off compressors became a staple of mining and large-scale quarrying in the nineteenth century. Compressed air generated by steam power also powered the winch we used to move the carts containing our large lumps of basalt up to the rock crusher. The winch had previously been used on a steam ship. To get the stone into the rock crusher, we used our shovels.

The rock crusher was powered by a static steam engine via a canvas belt. We had problems with the steam engine creeping forward and the tension in the belt changing, but it was nothing that was not easily fixed. The crusher itself was a fairly basic, relentless machine. It had funnel-shaped jaws that oscillated, moving the rock upwards as gravity fed it down. The jaws could be set to produce the desired size of ballast and the resulting crushed rocks fell into another wagon, ready to be wheeled off on the rails to the desired location on the permanent way.

After crushing our rock, I went to check on the meal we had made. If you are cooking over an open fire, a good way to prepare food, especially fish, is to wrap it in dock leaves or moss and then encase it in clay. This package can then be left in a fire to cook while you go off to do other things. The Victorian diet contained more calories than the recommended modern diet, but the Victorians were more physically active than we are today. Navvies would have needed even more calories to give them the energy required to carry out their strenuous work. Sometimes, when they were in isolated areas of Britain, navvies would have cooked whatever came to hand.

KEIGHLEY AND WORTH VALLEY RAILWAY

We had cut our sleepers, we had crushed our ballast and we had created our coach bolts. All that was left was to see how they were combined to create the permanent way. We travelled to the Keighley and Worth Valley Railway in West Yorkshire, where the preservation society were replacing some of the rails on their line.

The Keighley and Worth Valley Railway opened in 1867, with much of its funding coming from local mill owners who needed a railway to serve the textile industry in the area. It soon became part of the Midland Railway. Then, later on in 1923, when the grouping occurred, it became part of the London, Midland and Scottish Railway.

In 1948 when the railways were nationalized, the Keighley and Worth Valley Railway was run by British Rail. Then in 1962, when it was deemed unprofitable, it was finally closed. This was met by a lot of local opposition and a preservation group quickly formed. The group acquired the railway and it reopened in 1968, but even in the short time that the railway had been out of commission, it had decayed badly. Vandals had caused much damage and harsh weather had taken its toll on the exposed rolling stock and engines. The society got the railway up and running again and it is now quite unique in Britain. Most preserved railways are only part of a line that once existed, but the KAWVR offers the whole branch line as it was.

However, we were not in West Yorkshire to play with trains – we were there to help lay track. We met Keith and Margaret, who were getting the crane ready to be taken out to be used to move the rails. The crane was a thing of beauty. It was built in 1942 and acquired from British rail in 1982. It was still fully operational, so needed very little work to be done. The BR colours of blue and yellow had been changed back to the deep green of the London and North Eastern Railway, and the iron floor of the cab had been replaced, because the alkaline leeching out of the ash from the boiler had worn the metal paper-thin.

“THE KEIGHLEY AND WORTH VALLEY RAILWAY OPENED IN 1867, WITH MUCH OF ITS FUNDING COMING FROM LOCAL MILL OWNERS.”

THE FUTURE THAT MIGHT HAVE BEEN

In taking part in this project – examining how steam railways changed Britain – I have become acutely aware that a number of paths could have been taken and the best ideas did not always succeed.

The railways were created and improved over such a short period of time that early locomotives or carriages soon gave way to newer versions. Many of the early examples of rolling stock were not kept in service – and why would they be? In archaeology, a challenge that often presents itself is how to deal with a lack of material culture. Contrarily, we have a very defined version of railway history, but it could have been so very different....

Atmospheric railways

Nature abhors a vacuum – and that is why vacuum brakes were so successful. It is also the reason why from 1836 onwards pneumatic tube systems were used in many offices and banks to send messages and items from one location to another. The use of differential air pressure as a form of propulsion on a greater scale has long been seen as a possibility, but ultimately has never become an effective reality. The idea first gained merit early on, when steam engines were too heavy to effectively travel by rail. To have a static engine generate a vacuum that could pull a train seemed a fitting idea.

Perhaps the most famous attempted application was that of the celebrated Victorian engineer Isambard Kingdom Brunel, who engineered the Great Western Railway. His railway, which had reached as far as Exeter, was broad gauge – evidence of which can still be seen today at stations such as Taunton, where there is a visible space between the standard gauge tracks. Continuing westwards, the landscape became quite challenging. Steam locomotives run very well on level track but struggle with elevations. The track that runs down through the West Country stretching down to Cornwall is slightly bumpy at best. However, atmospheric railways can cope with slopes a lot better, and Brunel’s ultimately aborted attempt at one was a fine early example of this technology.

George Medhurst was arguably the first to suggest the possibility of a commercial atmospheric railway, and many tried to make this a reality. However, the first commercially operated atmospheric railway was that found on the line to Dalkey, which was part of the Dublin and Kingston Railway. This was witnessed by many rail pioneers of the time and led Isambard kingdom Brunel to operate the South Devon railway as an atmospheric railway for a year. Despite the achievement of respectable speeds on the rails, sadly the innovation was ultimately not to be. It was a flawed system. Today, the putative concept of a vacuum system combined with magnetic levitation is still on the drawing board, with proponents advocating a new form of propulsion for entering space and the idea being part of the proposed hyperloop train.

Tracked hovercraft

At the very end of the age of steam, in the 1960s, a new transportation idea gained momentum. This was a hovercraft that ran on rails. Using hovercraft technology and an invention known as a ‘linear induction motor’, tracked hovercraft were set to become Britain’s answer to high speed travel.

For a short while, the proposed concept looked like a winner – but it lost investment and found itself positioned between the idea of Maglev trains (those employing magnetic levitation) and the development of the Advanced Passenger Train (see here). The remains of the project can be glimpsed by passengers on board the east coast line as they pass by Peterborough. What is left of the RTV (research test vehicle) 31 is exhibited near to the entrance of ‘Railworld’. RTV 31 clocked 104mph in 20mph headwinds on a one-mile section of track. At one time, it could have been the future....

The first thing we were given was a rag. Keith told us this was the most important thing and to always keep it to hand. Operating any steam machine is a dirty job and having a rag to wipe your hands upon is essential. The dirty rags covered in coal dust, oil and grease are then used to light the fire the next time the machine is used.

The crane was shunted out of the Victorian shed so that the fire could be lit. The shed still has all its original Victorian timbers supporting a stone-tiled roof and the fire risk is too great to light the fire indoors. It takes several hours to light a boiler and get it up to temperature. Often boilers of engines were never allowed to cool fully, so that the process was faster and the stress placed on the surrounding fabric was reduced.

We made sure that the water was topped up and the ash was raked out. We put a bed of coal on the grate and wood on top and then we placed a shovel of coal, wood and burning oil rags into the centre of the firebox. As the fire drew and the coal began to take light and the water temperature increased, we undertook the job of checking, oiling and greasing the crane. In the case of machinery such as this crane, you can never have too much lubricant. If there was any doubt that a grease point had been missed, we just added a bit more. Some of the moving parts had little reservoirs that fed thick oil into the works via wicks that worked using capillary action. Capillary action is a liquid’s ability to move up or along a narrow space and was first observed by Leonardo da Vinci in the sixteenth century.

Once the moving parts were oiled, the boiler was up to pressure and we were ready to move the crane. Not a simple task, as it turned out. We were in a siding and had to negotiate our way onto the branch line. The steam in the crane powers the derrick or arm of the crane up and down, turns the crane round and raises and lowers the winch. It can also power the crane itself, so that the crane can move up and down the rails. However, unlike a steam engine, the boiler cannot issue steam while making steam. This means that when travelling to and from a site where the crane is needed, it has to be moved by a locomotive.

We knew the locomotive that was going to pull us, we knew where the guard’s van was and we knew which flat bed we needed to take with us. More importantly, we knew the order the vehicles had to be in. Thus ensued a game of organize-that-train, as rolling stock that was not required was moved out of the way and vehicles that were required were moved to a suitable location.

Shunting would have happened on sidings in goods yards such as this on an almost continuous basis while the railways were in operation. Shunting can be very dangerous work and is quite physical. Indeed, to save fuel, many shunting yards were equipped with a windlass, so that wagons could be manually moved from siding to siding.

The section of track we were laying was to be located at the far end of the branch line. The term ‘permanent way’ (often abbreviated to ‘p-way’) was adopted in the early days of the railway to distinguish it from the temporary rails that many companies and navvies would lay to assist in the building of the tracks that would remain once work was finished. The network that was left comprised of sidings, branch lines and main lines. These were usually labelled ‘up’ and ‘down’ lines. The up line travels towards a major destination such as London or Edinburgh and the down line travels in the opposite direction. This is terminology that originated in mining, with carts going up to the mine or down to the port.

After an enjoyable journey along the line, we arrived at the section of track that needed replacing. A square red flag on two poles denoted the danger on the line where the rails had been removed. Once the gang had greeted us and our presence was known, the crane was moved along the other line into position. We were uncoupled from the rest of the train and we took off the locks that stopped the crane rotating unintentionally.

We made sure that the water in the boiler was topped up and the fire stoked and then we began work. The crane is now fitted with a modern electronic gauge to indicate safe working loads in relation to the angle and the rotation of the crane. The gauge does exactly the same job as the brass disc engraved with the same information. A needle that is attached to worm screws points to the relevant section as the crane moves, in order to alert the operator as to the precise load capacities that can be moved.

The rails that we had been tasked to put in place did not look very heavy from where I was sitting in the cab. However, they actually weighed around two and a half tons each. The thickness of the steel rails and the spacing of the sleepers dictate the speeds and weights of the trains that can use the railways. As trains travel over the rails, they begin to wear away. The loss in condition and the estimated wear rate is factored in to the quality and life expectancy of the rail. Rails that were used on main lines often saw a second lease of life on branch lines and then again in sidings, where the speeds were slower and the trains were lighter. The new rails we were putting on were actually second-hand, as they had previously been used elsewhere on Britain’s rail network.

The location we were working in proved to be quite challenging. The view from the crane is limited and it requires constant vigilance to see what is going on. Not only did Keith have to concentrate on moving the load, he had to be aware of obstacles such as the mile markers on the steep bank, the trees and a bridge. Margaret worked as his ‘banksman’, directing his movements with hand signals that most people working on building sites today would recognize.

The crane was very quiet. Unlike a diesel crane, which has a noisy engine, the only real noise was from the movement of the pistons and the winch. When the crane was stationary it was possible for Keith to speak quite clearly to Margaret on the ground. The work ebbs and flows, which gives the crane driver time to stoke the fire and build the steam ready to trundle up and down the track and raise and lower the crane.

As each rail was put in place, the crew would see it home. They wiggled it into position in the chairs and bolted it to the last rail laid, using a fishplate. A gap for expansion is left, but modern rails are now continuous and the way the steel is produced allows for expansion and contraction within the rail itself. The rails are cut up at the manufacturing point and re-welded in situ. The first welded rails were used in the 1920s in Germany. After the Hither Green rail crash in 1967, in which 49 people lost their lives, British Rail sped up the introduction of continuous welded rail on the mainline. The crash had been caused by a crack forming at the bolt hole on the fishplate, which had gone unnoticed and had become progressively worse. Cracks at bolt holes were a common problem.

The crew tapped home the keys that wedge the rail to the chairs. The navvies building the permanent way would have laid the track by hand, using bars, jacks and shovels. It would have been hard work and they needed to get it right. The crew at Keighley also made sure that the ballast was free of weeds and in sufficient supply to do its job. The importance of ballast spreading the load, giving adequate drainage and anchoring sleepers in place cannot be over emphasized. When ballast is first laid, the gaps between the rocks, devoid of any soil, is not an environment conducive to cultivation. However, soil from leaf litter and blown from the banks builds up over time, and soon a well-drained weed bed establishes itself. The oil, steam, ash and cinders that came out of the bottom of engines often took care of any new shoots of vegetation – but not always.

If plants took root in the ballast, they could interfere with the track and badly affect drainage. Even if the track was not flooded, if the ballast became waterlogged and then froze, it could actually distort the rails, as when water freezes its volume increases by as much as nine per cent. Until the 1930s, ballast was cleared of any vegetation by hand. After this time, weedkilling trains were employed to spray the ballast. The trains would be made up of old steam engine tenders, into which water and chemicals could be placed. The liquids would be piped to the back of the train, where a brake van had spray nozzles added. The pumps worked off the axles of the vans and the required mixture of weedkiller to water could be delivered at a force of about two bar.

As we headed back to the shed to put the crane away and dispose of our now filthy rags, I thought about all the people who both built and maintained the railways. All those countless men, women and children who lived and often died working on the very trackways that we now take for granted…

STATION ARCHITECTURE

The permanent way connects two destinations with a number of stops along the way – but how do people access trains? The railway, in terms of trains and track, came long before stations. Instead, buildings that already existed – such as cowsheds and wooden barns – were used as makeshift passenger pens. Sometimes engines were stored in these locations as well, and it was not uncommon for the barns to burn down. Public houses were also frequently used as places to gather passengers and issue tickets.

The term booking hall – which we still use today – is adopted from the old coaching practice of issuing tickets from a book. These tickets were handwritten and the process was laborious. A stationmaster and trained cabinet-maker named Thomas Edmondson introduced the Edmondson railway ticket in 1837 (see here). These pre-printed tickets were all uniquely numbered and were stamped by a machine upon issue. The system was adopted in 1842 with the introduction of the Railway Clearing House, which was a central body that could allocate a share in revenue from tickets issued for journeys that used more than one company’s line. The last Edmondson ticket was issued in 1990.

The first station to have two platforms that were distinctly for arrivals and departures was Euston station in London. All the stations along the London and Greenwich Railway are elevated, because the track was entirely built on arches. Stations had to be built to serve a function, and often their form reflected either the practicalities required to facilitate the movement of passengers or the limitations imposed by the surrounding terrain and landscape.

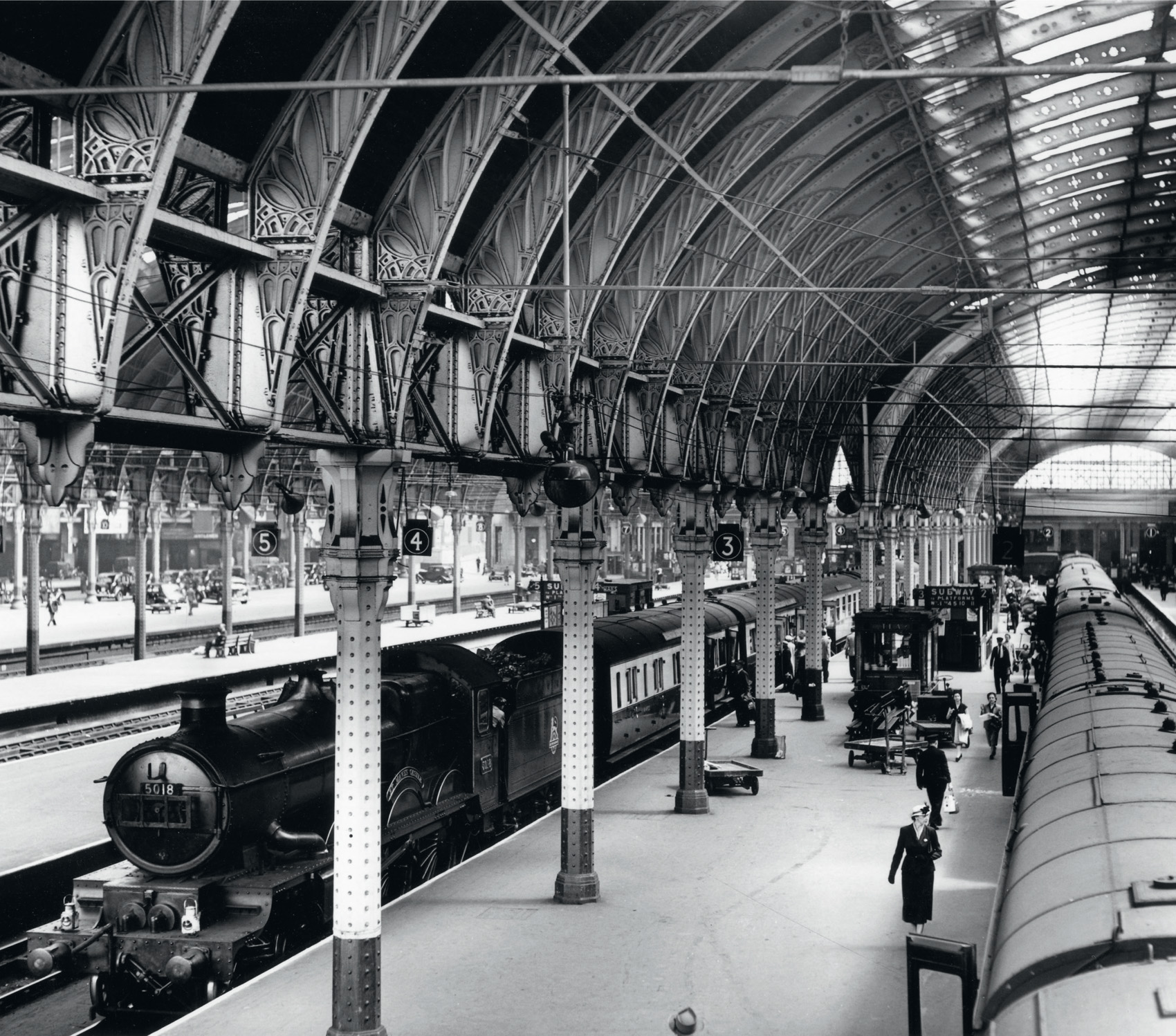

However, train companies realized quite quickly that their stations were beacons for their companies, as well as a statement to the passenger that they had arrived. Decorations were included in the cast iron that decorated these buildings, often doubling as practical items such as brackets. If you look at the Victorian ceiling of Paddington station, you will notice numerous stars and moons cut out of the iron, which serve both to lighten the material and provide anchor points.

An arched iron roof such as that found at Paddington station truly represents the best of Victorian engineering. Isambard Kingdom Brunel, who constructed Paddington with his associate, the architect Matthew Digby Wyatt, adopted the system for creating the roof from advancements that had been made by Joseph Paxton. Paxton was an architect and a gardener, and while working at Chatsworth House he designed and built a series of greenhouses, each more elaborate than the last. They were engineered to provide maximum light and their ridge and furrow roofs allowed for good drainage. In these structures he cultivated the Cavendish banana, which is now the most consumed type of banana in the world.

Paxton’s largest greenhouse was the Great Conservatory, which would act as a prototype for his most famous creation (other than the aforementioned banana) – the Crystal Palace. Crystal Palace was constructed in Hyde Park in 1851, from prefabricated cast iron and glass, before being moved to Sydenham, where it was destroyed by fire in 1936. This, along with Burton’s Palm house at Kew, opened the floodgates for station architecture.

Built in 1854, the same year as Paddington station, Birmingham New Street station held the record for the widest roof span at 64 metres. However, this would not last long. London, Glasgow and Belfast all saw stations with amazing arched roofs being built. Then, in 1868 St Pancras station was constructed – with a huge roof coming in at a staggering 74 metres. This roof was different – it had no struts or ties, because it used a latticed arch. When St Pancras was recently renovated, the colour of the underlying paint was discovered and reinstated – a beautiful sky blue.

St Pancras is also the proud possessor of another great example of Victorian station features – the grand entrance. Designed by Sir George Gilbert Scott and comprising of both booking hall and hotel, St Pancras is stunning in all its gothic revival glory. The arched windows are accentuated by red and white sunbursts and the building is constructed from all the main bedrocks that the railway’s permanent way traverses.

Another station that was given a fabulous entrance was Euston. However, sadly Euston station’s classic Doric arch was destroyed in the 1960s, prompting a campaign to save St Pancras from a similar fate. Once described as the ‘gateway to the north’, all that is left of the entrance today are the gatehouses – now bars – that are emblazoned with all the original destinations of the railway.

Although big engine halls were in vogue for terminus stations in the nineteenth century, they were hugely expensive, so lesser stations along the line had to settle instead for platform awnings. The awnings often featured an ornate wooden valance, which was a style that quickly spread throughout the world. However, from the very first stations to the most recent stations, collectively they represent a wealth of architectural styles. This is a constant reminder that the railways are always changing – and of the incalculable influence that they have had on a global scale.