Wiring

In this chapter:

• Receptacle Wiring Configurations

• Hard-wired Smoke & CO Alarms

• Installing Motion-sensing Floodlights

• Troubleshooting Light Fixtures

• Repairing Fluorescent Lights

Wiring Tools

Wiring Tools

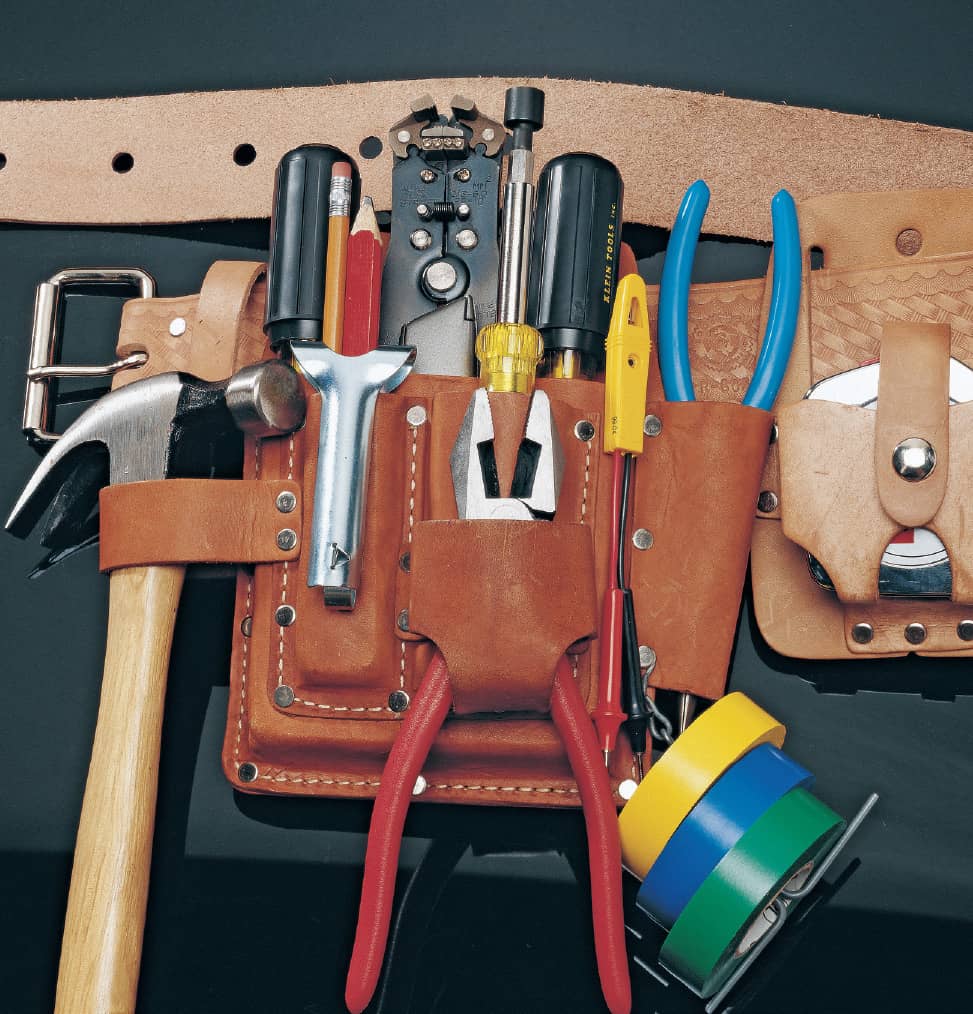

To complete the wiring projects shown in this book, you need a few specialty electrical tools as well as a collection of basic hand tools. As with any tool purchase, invest in quality products when you buy tools for electrical work. Keep your tools clean, and sharpen or replace any cutting tools that have dull edges.

The materials used for electrical wiring have changed dramatically in the last 20 years, making it much easier for homeowners to do their own electrical work. The following pages show how to work with the following components for your projects.

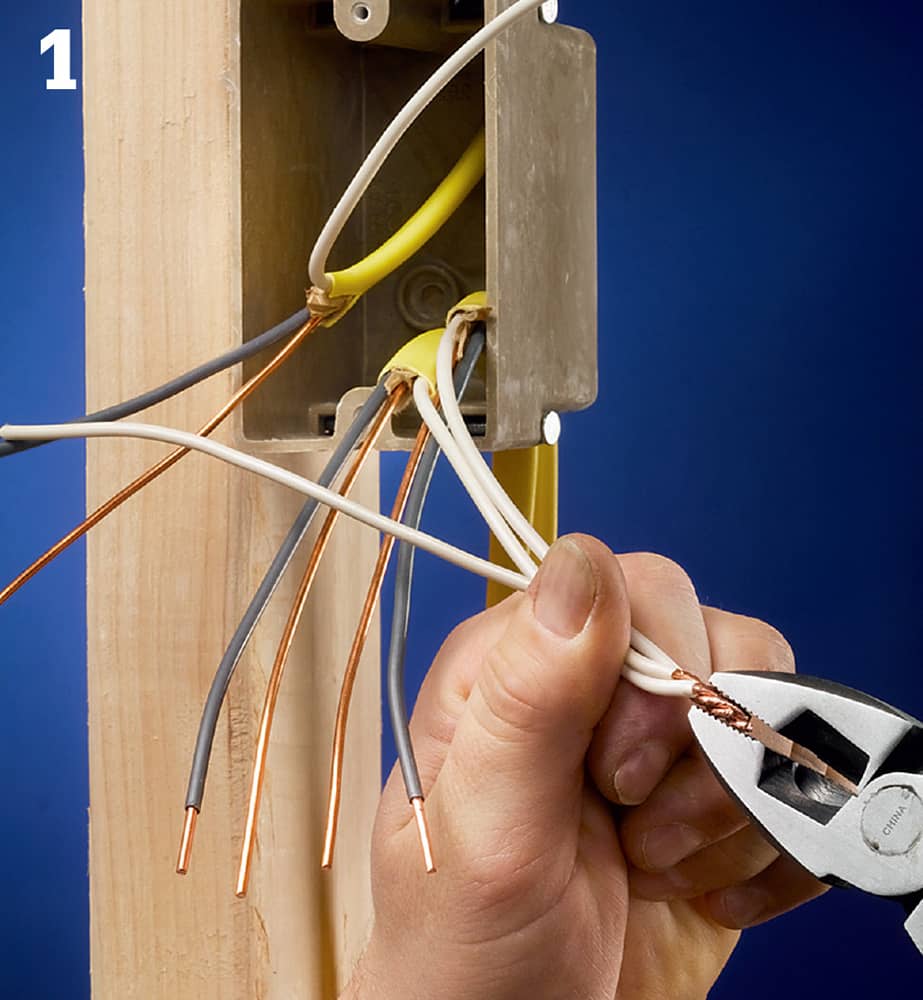

Hand tools you’ll need for home wiring projects include: Stud finder/laser level (A) for locating framing members and aligning electrical boxes; tape measure (B); a cable ripper (C) for scoring NM sheathing; standard (D) and Phillips (E) screwdrivers; a utility knife (F); side cutters (G) for cutting wires; channel-type pliers (H) for general gripping and crimping; linesman pliers (I) that combine side cutter and gripping jaws; needlenose pliers (J); wire strippers (K) for removing insulation from conductors.

Use a tool belt to keep frequently used tools within easy reach. Electrical tapes in a variety of colors are used for marking wires and for attaching cables to a fish tape.

A fish tape is useful for installing cables in finished wall cavities and for pulling wires through conduit. Products designed for lubrication reduce friction and make it easier to pull cables and wires.

Diagnostic tools for home wiring use include: A touchless circuit tester (A) to safely check wires for current and confirm that circuits are dead; a plug-in tester (B) to check receptacles for correct polarity, grounding, and circuit protection; a multimeter (C) to measure AC/DC voltage, AC/DC current, resistance, capacitance, frequency, and duty cycle (model shown is an auto-ranging digital multimeter with clamp-on jaws that measure through sheathing and wire insulation).

Wiring Safety

Wiring Safety

Safety should be the primary concern of anyone working with electricity. Although most household electrical repairs are simple and straightforward, always use caution and good judgment when working with electrical wiring or devices. Common sense can prevent accidents.

The basic rule of electrical safety is: Always turn off power to the area or device you are working on. At the main service panel, remove the fuse or shut off the circuit breaker that controls the circuit you are servicing. Then check to make sure the power is off by testing for power with a voltage tester. TIP: Test a live circuit with the voltage tester to verify that it is working before you rely on it. Restore power only when the repair or replacement project is complete.

Follow the safety tips shown on these pages. Never attempt an electrical project beyond your skill or confidence level.

Shut power OFF at the main service panel or the main fuse box before beginning any work.

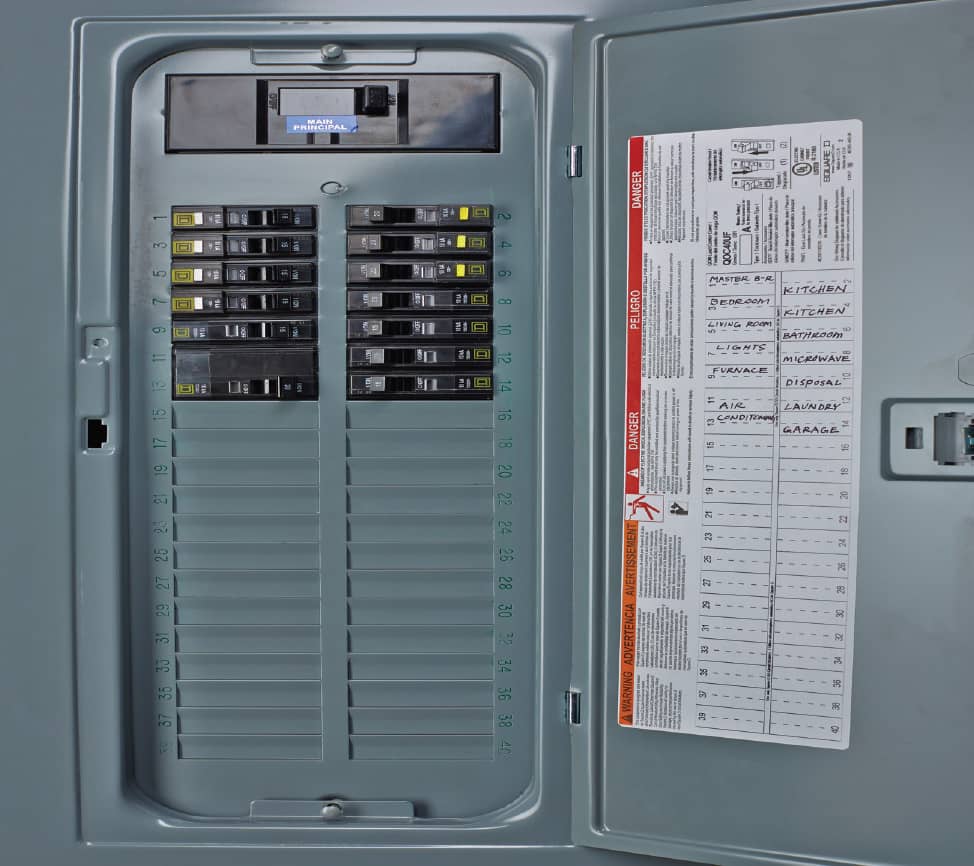

Create a circuit index and affix it to the inside of the door to your main service panel. Update it as needed.

Confirm power is OFF by testing at the outlet, switch, or fixture with a voltage tester.

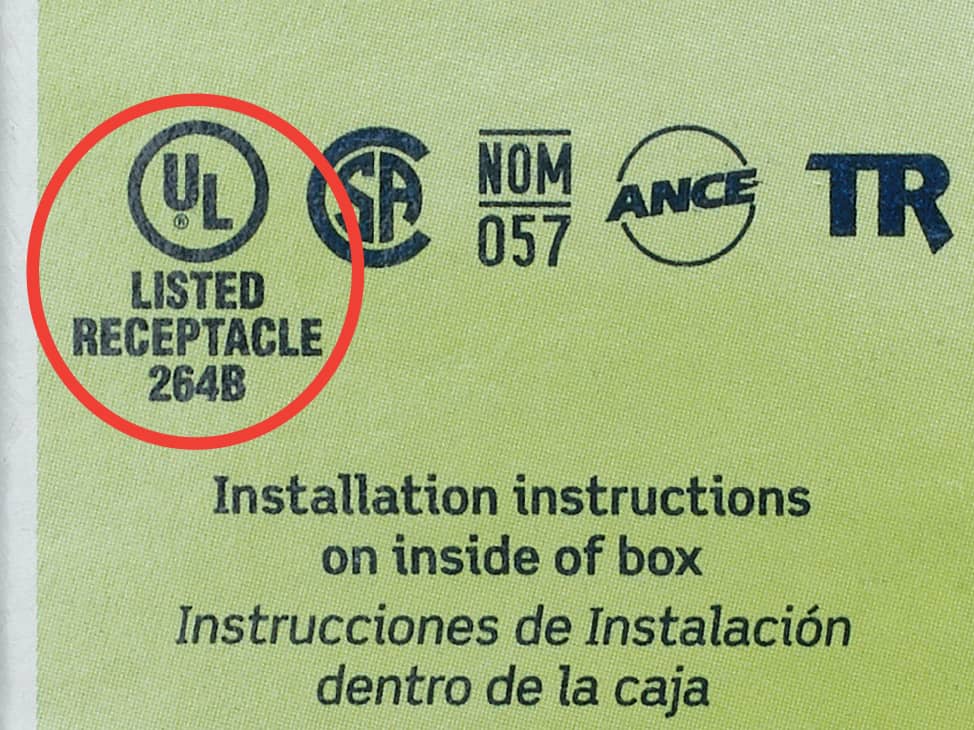

Use only UL-approved electrical parts or devices. These devices have been tested for safety by Underwriters Laboratories.

Wear rubber-soled shoes while working on electrical projects. On damp floors, stand on a rubber mat or dry wooden boards.

Use fiberglass or wood ladders when making routine household repairs near the service mast.

Extension cords are for temporary use only. Cords must be rated for the intended usage.

Breakers and fuses must be compatible with the panel manufacturer and match the circuit capacity.

Never alter the prongs of a plug to fit a receptacle. If possible, install a new grounded receptacle.

Do not penetrate walls or ceilings without first shutting off electrical power to the circuits that may be hidden.

Wire & Cable

Wire & Cable

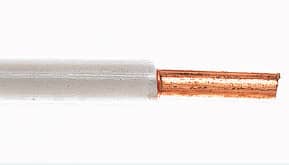

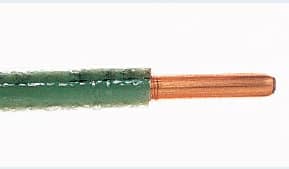

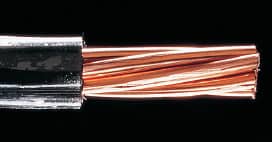

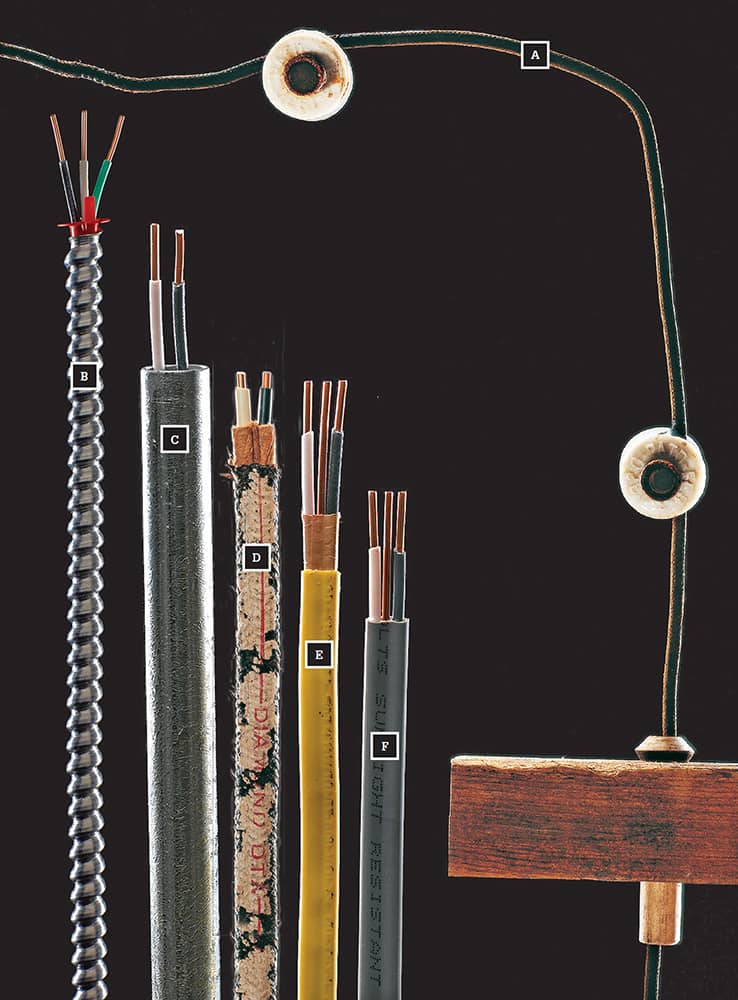

Wires are made of copper, aluminum, or aluminum covered with a thin layer of copper. Solid copper wires are the best conductors of electricity and are the most widely used. Aluminum and copper-covered aluminum wires require special installation techniques.

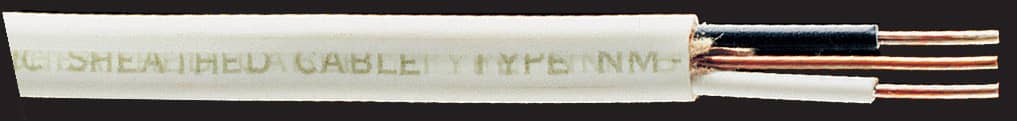

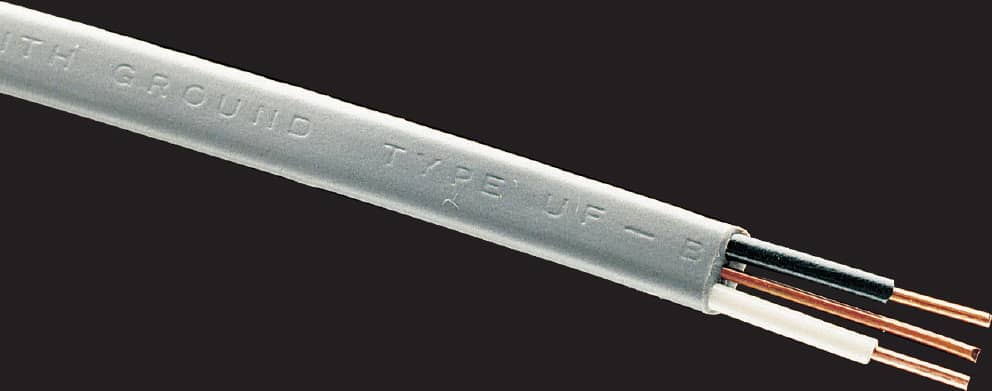

A group of two or more wires enclosed in a metal, rubber, or plastic sheath is called a cable (see photo, following page). The sheath protects the wires from damage. Conduit also protects wires, but it is not considered a cable.

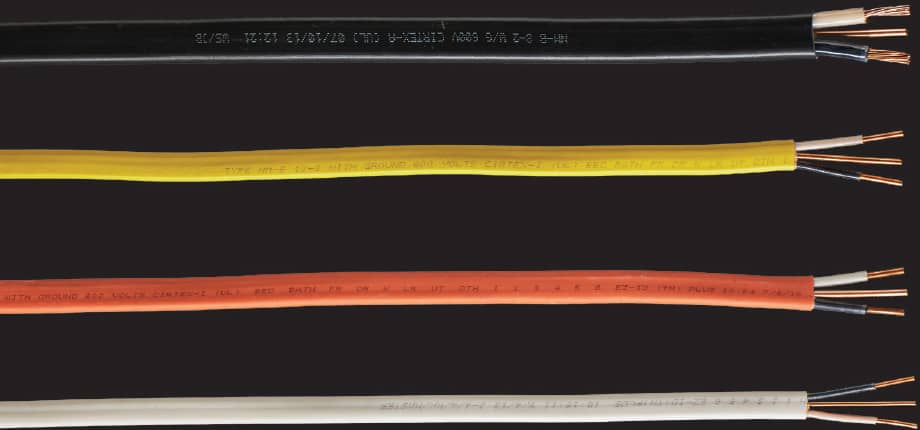

Individual wires are covered with rubber or plastic vinyl insulation. An exception is a bare copper grounding wire, which does not need an insulation cover. The insulation is color coded (see chart, below) to identify the wire as a hot wire, a neutral wire, or a grounding wire. New cable sheathing is also color coded to indicate the size of the wires inside. White means #14 wire, yellow means #12 wire, and red means #10 wire.

In most wiring systems installed after 1965, the wires and cables are insulated with plastic vinyl. This type of insulation is very durable and can last as long as the house itself.

Before 1965, wires and cables were insulated with rubber. Rubber insulation has a life expectancy of about 25 years. Old insulation that is cracked or damaged can be reinforced temporarily by wrapping the wire with plastic electrical tape. However, old wiring with cracked or damaged insulation should be inspected by a qualified electrician to make sure it is safe.

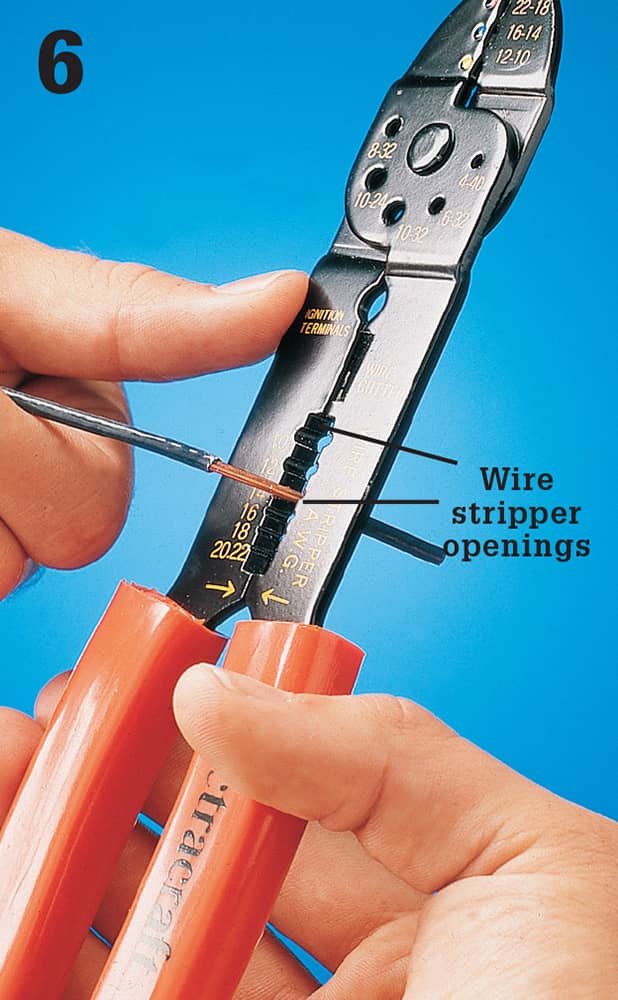

Wires must be large enough for the amperage rating of the circuit (see chart, below right). A wire that is too small can become dangerously hot. Wire sizes are categorized according to the American Wire Gauge (AWG) system. To check the size of a wire, use the wire stripper openings of a combination tool (see page 396) as a guide.

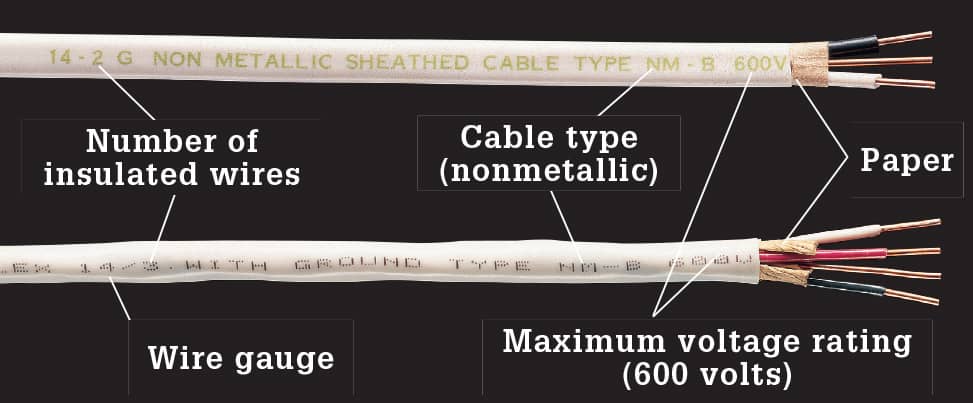

Reading NM (Nonmetallic) Cable

NM cable is labeled with the number of insulated wires it contains. The bare grounding wire is not counted. For example, a cable marked 14/2 G (or 14/2 WITH GROUND) contains two insulated 14-gauge wires, plus a bare copper grounding wire. Cable marked 14/3 WITH GROUND has three 14-gauge wires plus a grounding wire. NM cable also is stamped with a maximum voltage rating, as determined by Underwriters Laboratories (UL).

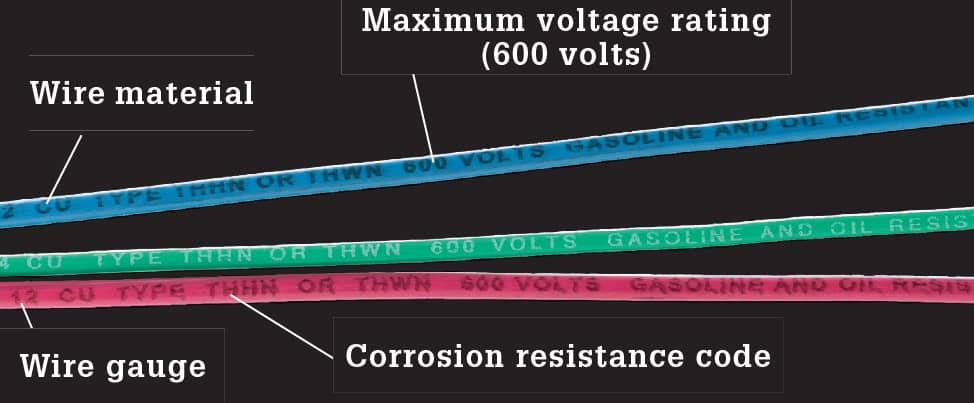

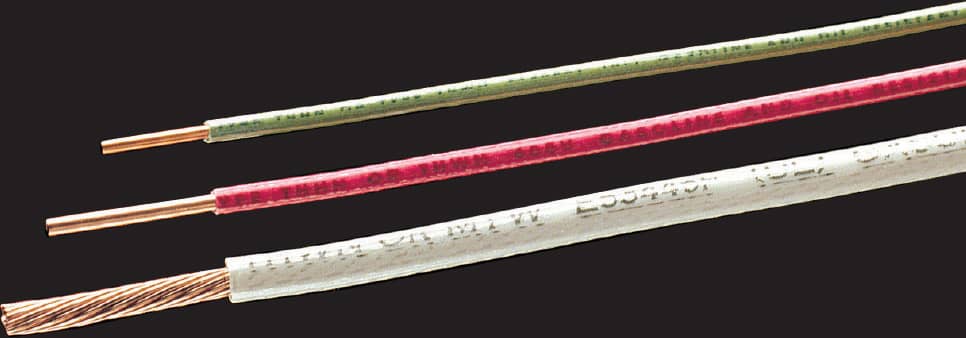

Reading Unsheathed, Individual Wire

Unsheathed, individual wires are used for conduit and raceway installations. Wire insulation is coded with letters to indicate resistance to moisture, heat, and gas or oil. Code requires certain letter combinations for certain applications. T indicates thermoplastic insulation. H stands for heat resistance, and two Hs indicate high resistance (up to 194° F). W denotes wire suitable for wet locations. Wire coded with an N is impervious to damage from oil or gas.

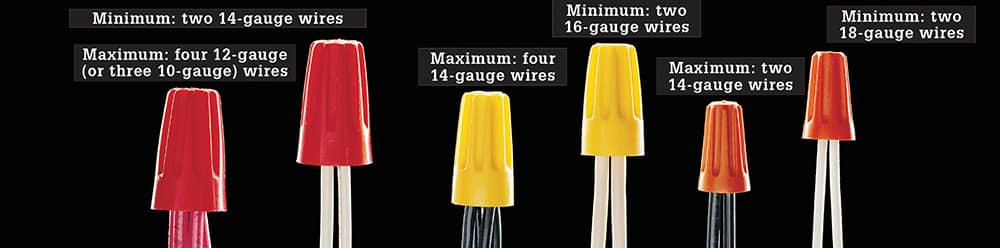

Use wire connectors rated for the wires you are connecting. Wire connectors are color-coded by size, but the coding scheme varies according to manufacturer. The wire connectors shown above come from one major manufacturer. To ensure safe connections, each connector is rated for both minimum and maximum wire capacity. These connectors can be used to connect both conducting wires and grounding wires. Green wire connectors are used only for grounding wires.

How to Strip NM Sheathing & Insulation

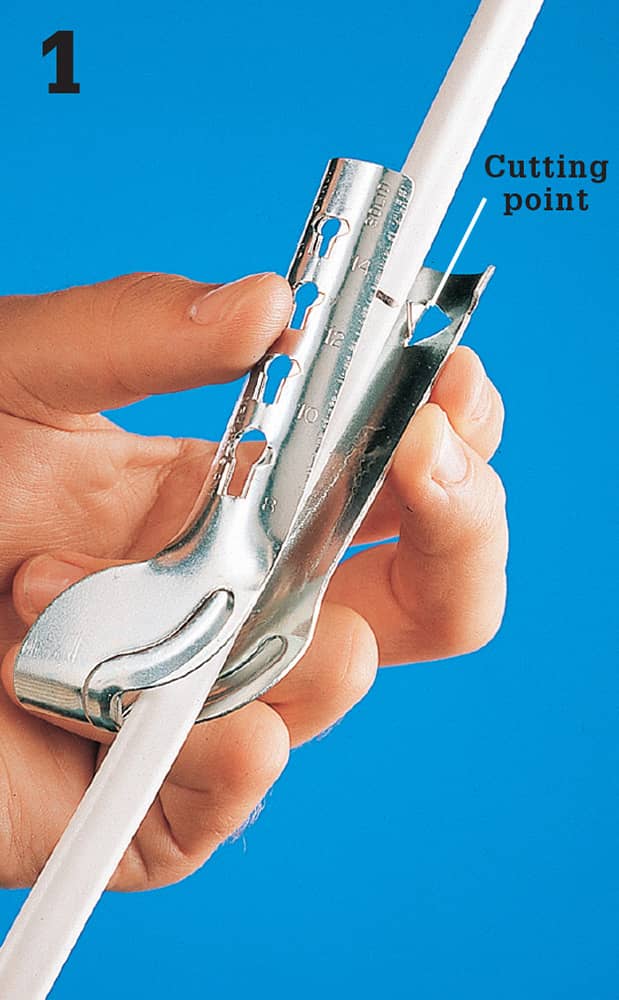

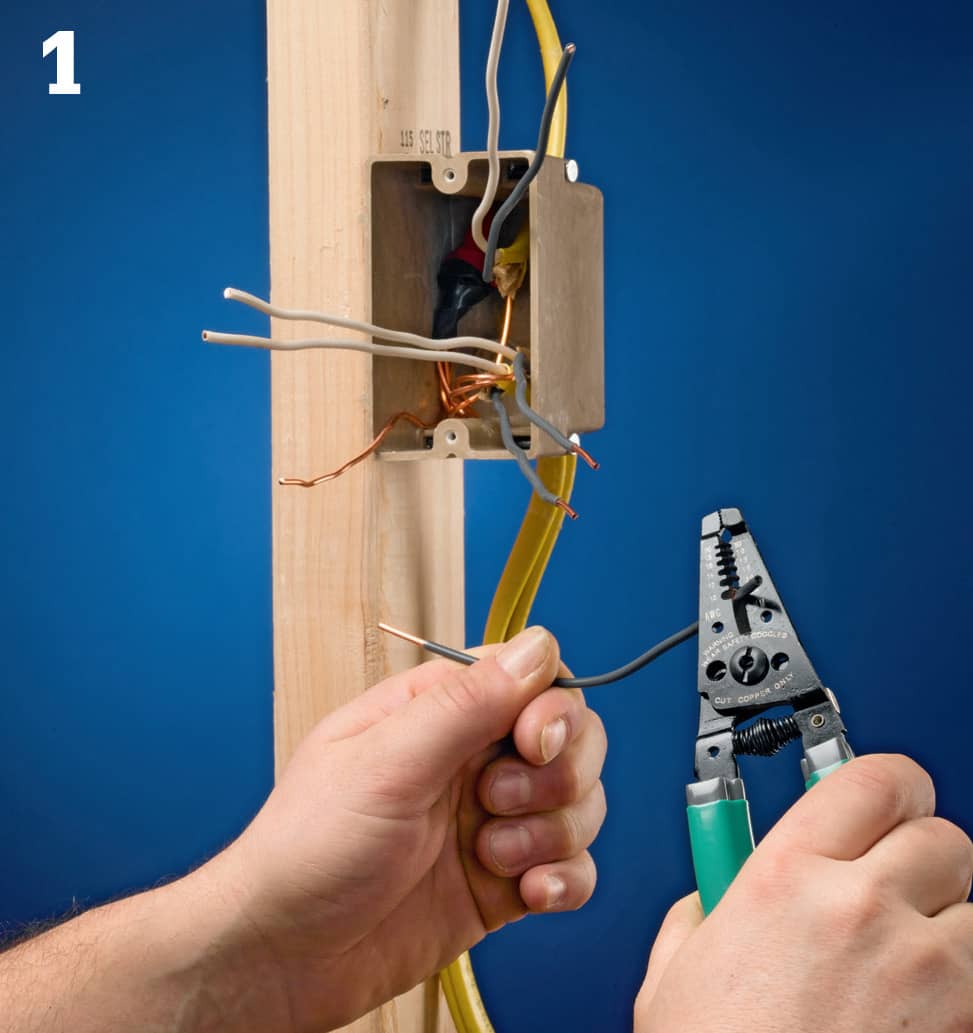

Measure and mark the cable 8 to 10" from the end. Slide the cable ripper onto the cable, and squeeze tool firmly to force the cutting point through the plastic sheathing.

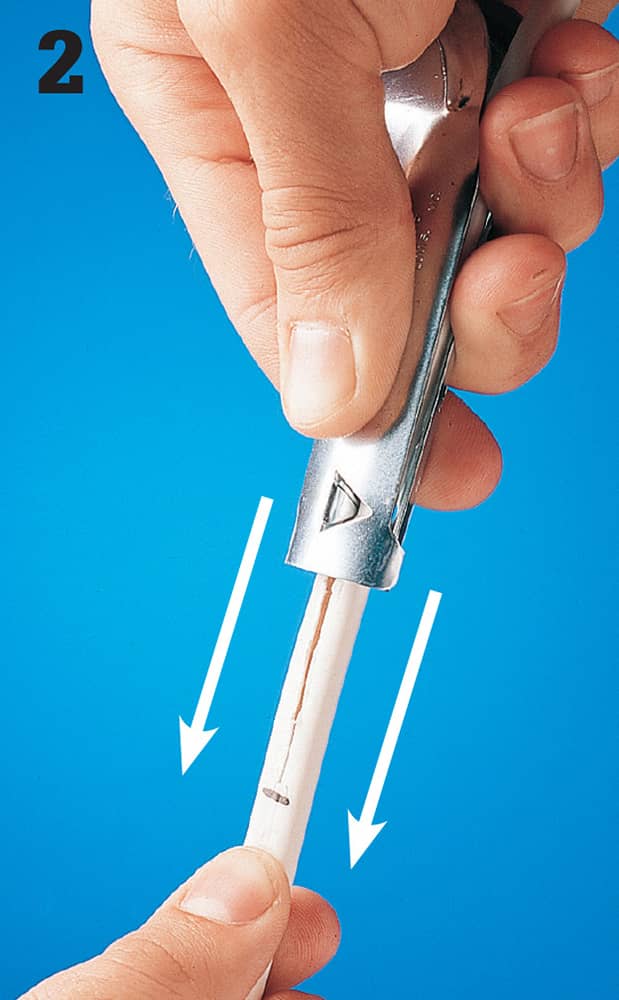

Grip the cable tightly with one hand, and pull the cable ripper toward the end of the cable to cut open the plastic sheathing.

Peel back the plastic sheathing and the paper wrapping from the individual wires.

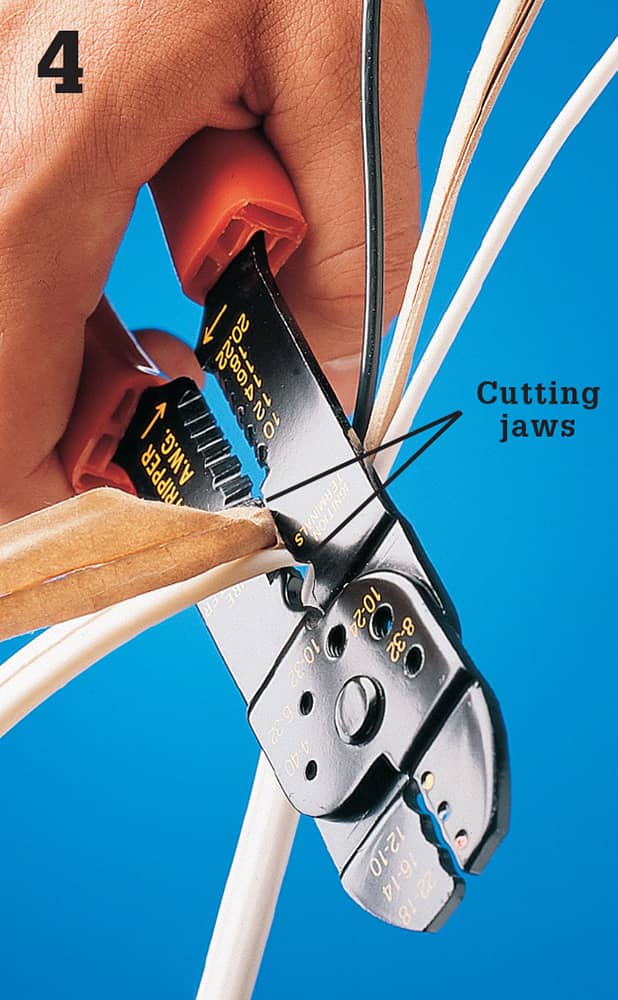

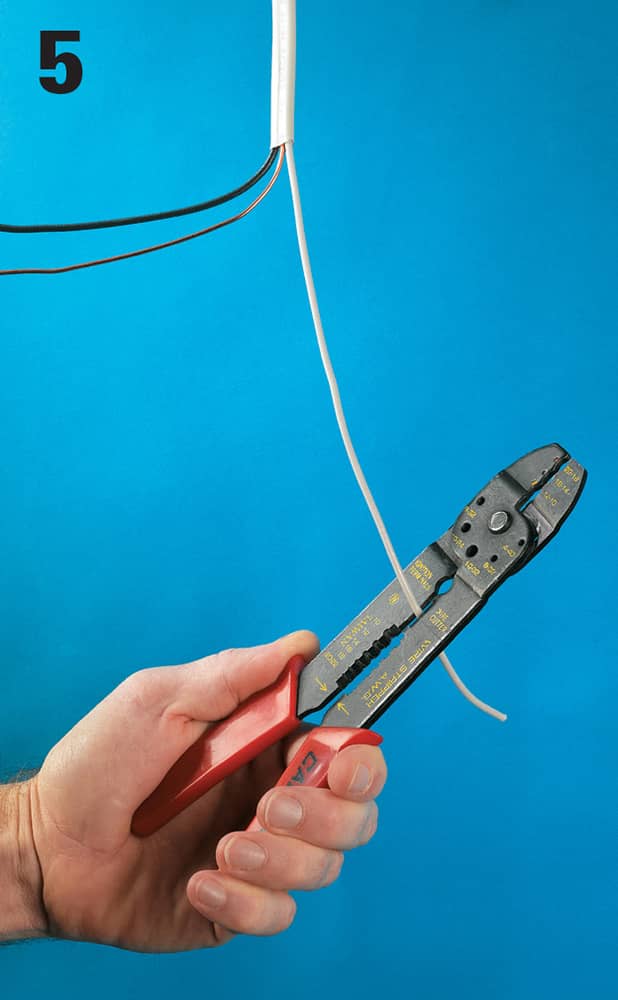

Cut away the excess plastic sheathing and paper wrapping using the cutting jaws of a combination tool.

Cut individual wires as needed using the cutting jaws of the combination tool. Leave a minimum of 3" of wire running past the edge of the box.

Strip insulation for each wire using the stripper openings. Choose the opening that matches the gauge of the wire, and take care not to nick or scratch the ends of the wires.

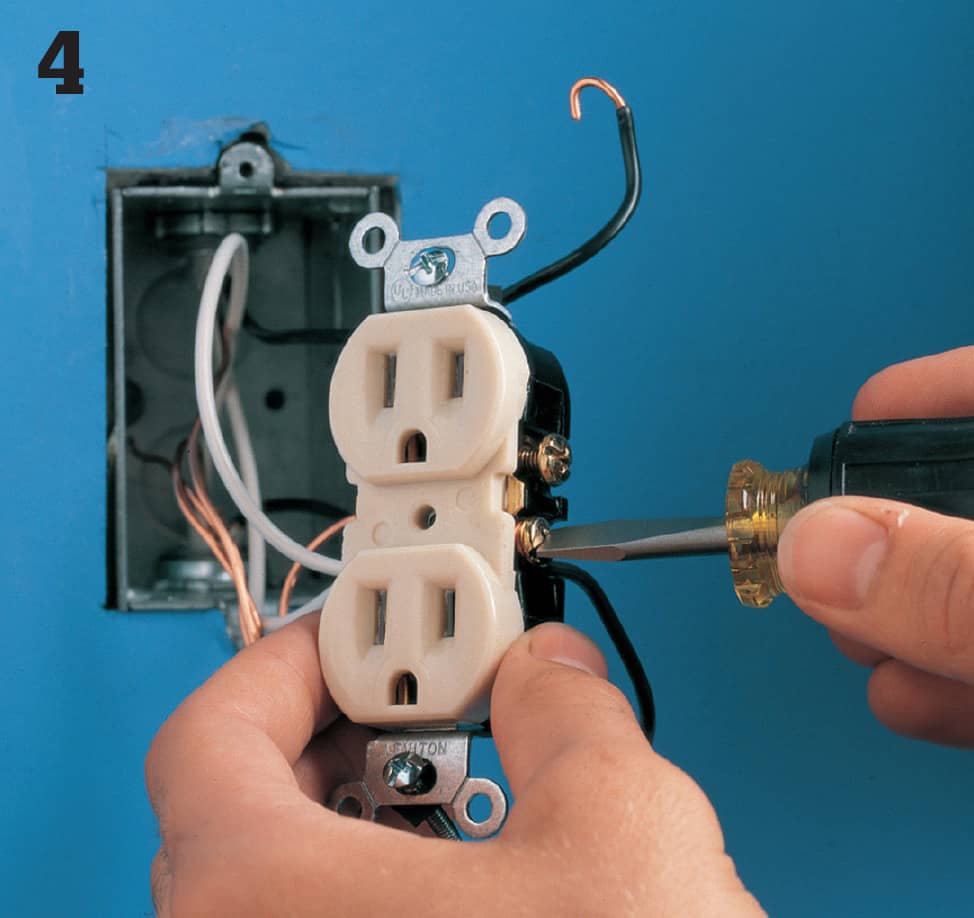

How to Connect Wires to Screw Terminals

Strip about 3/4" of insulation from each wire using a combination tool. Choose the stripper opening that matches the gauge of the wire, and then clamp the wire in the tool. Pull the wire firmly to remove plastic insulation.

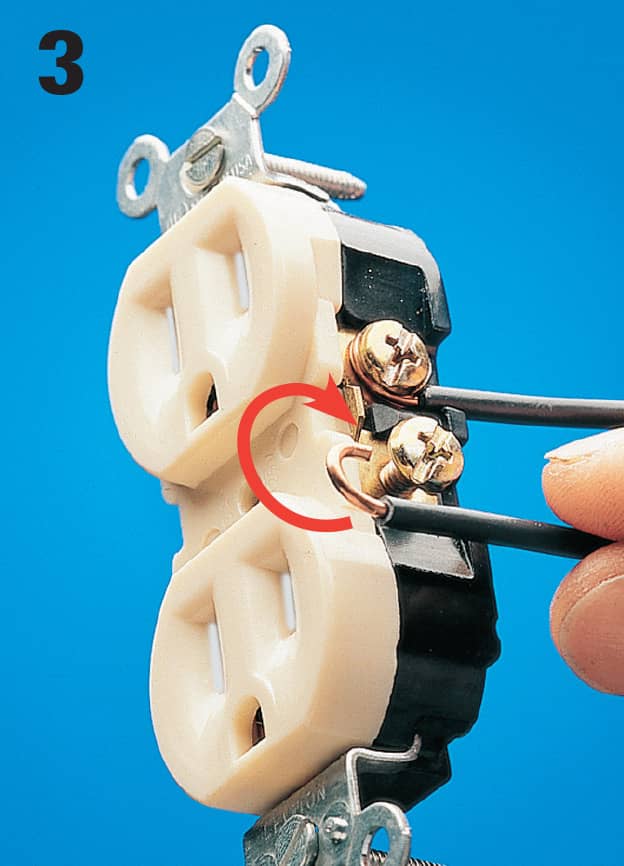

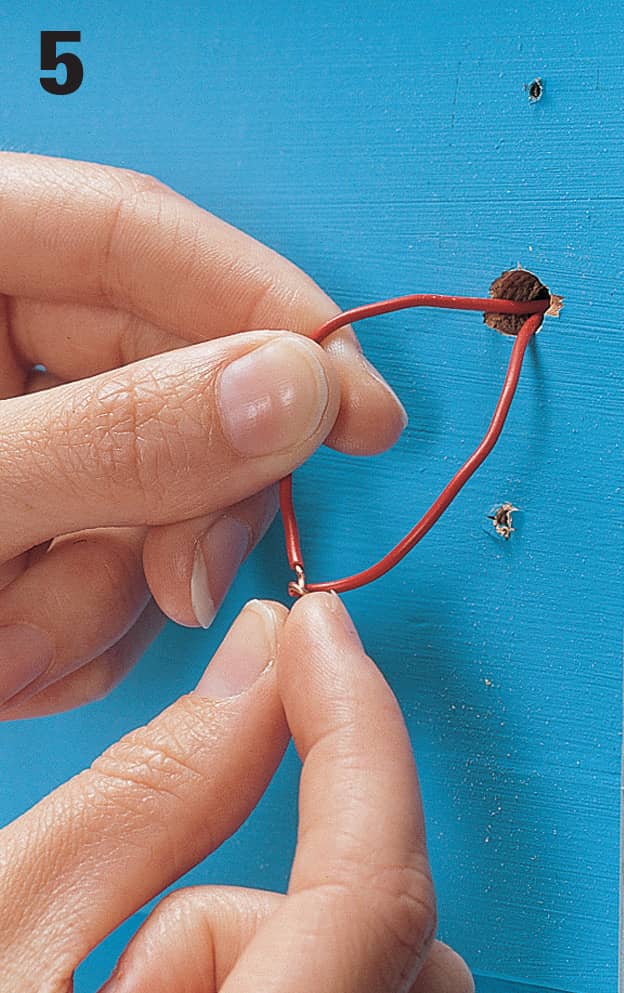

Form a C-shaped loop in the end of each wire using a needlenose pliers or the hole of the correct gauge in a pair of wire strippers. The wire should have no scratches or nicks.

Hook each wire around the screw terminal so it forms a clockwise loop. Tighten the screw firmly. Insulation should just touch head of screw. Never place the ends of two wires under a single screw terminal. Instead, use a pigtail wire (see page 399).

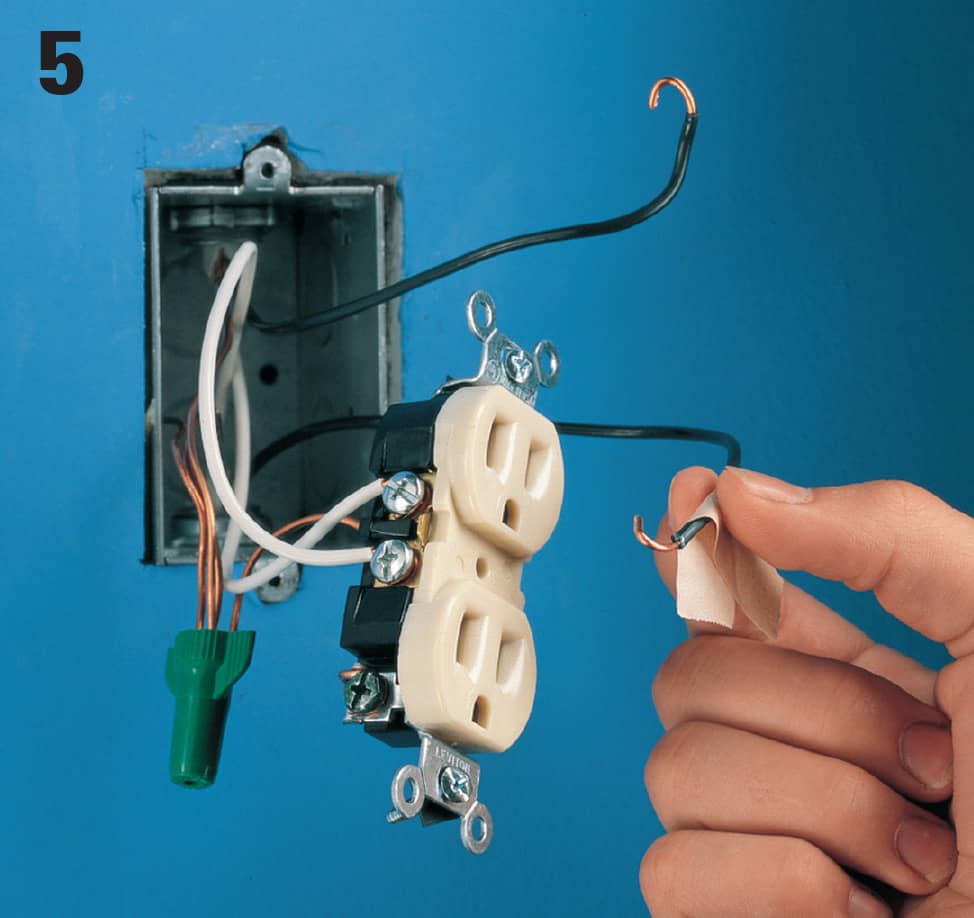

How to Join Wires with a Wire Connector

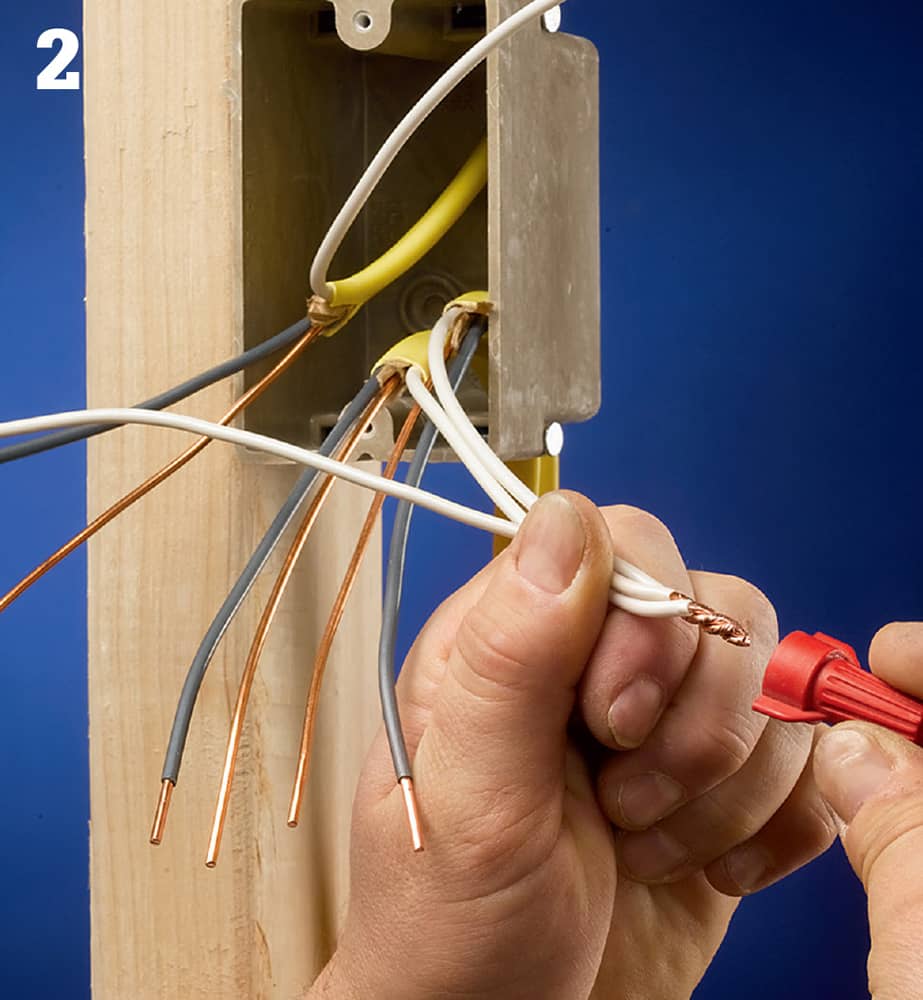

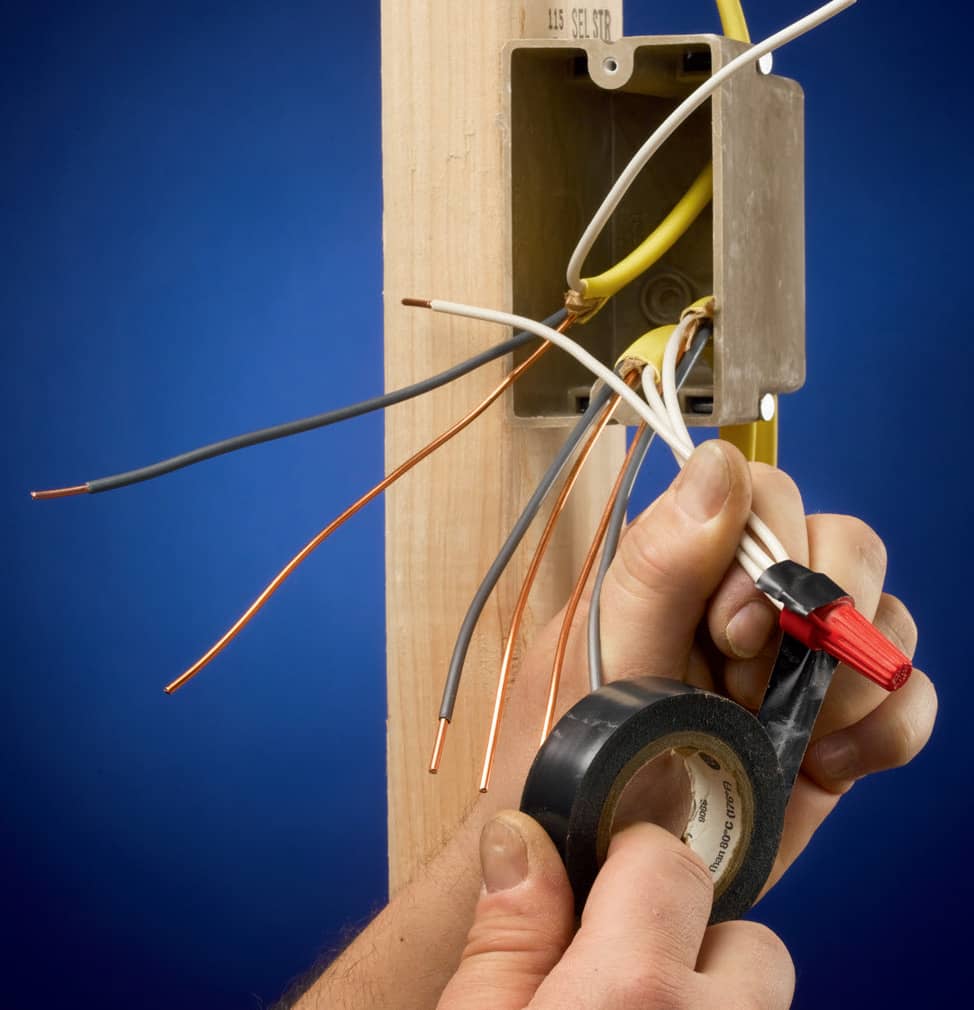

Ensure power is off and test for power. Grasp the wires to be joined in the jaws of a pair of linesman’s pliers. The ends of the wires should be flush and they should be parallel and touching. Rotate the pliers clockwise two or three turns to twist the wire ends together.

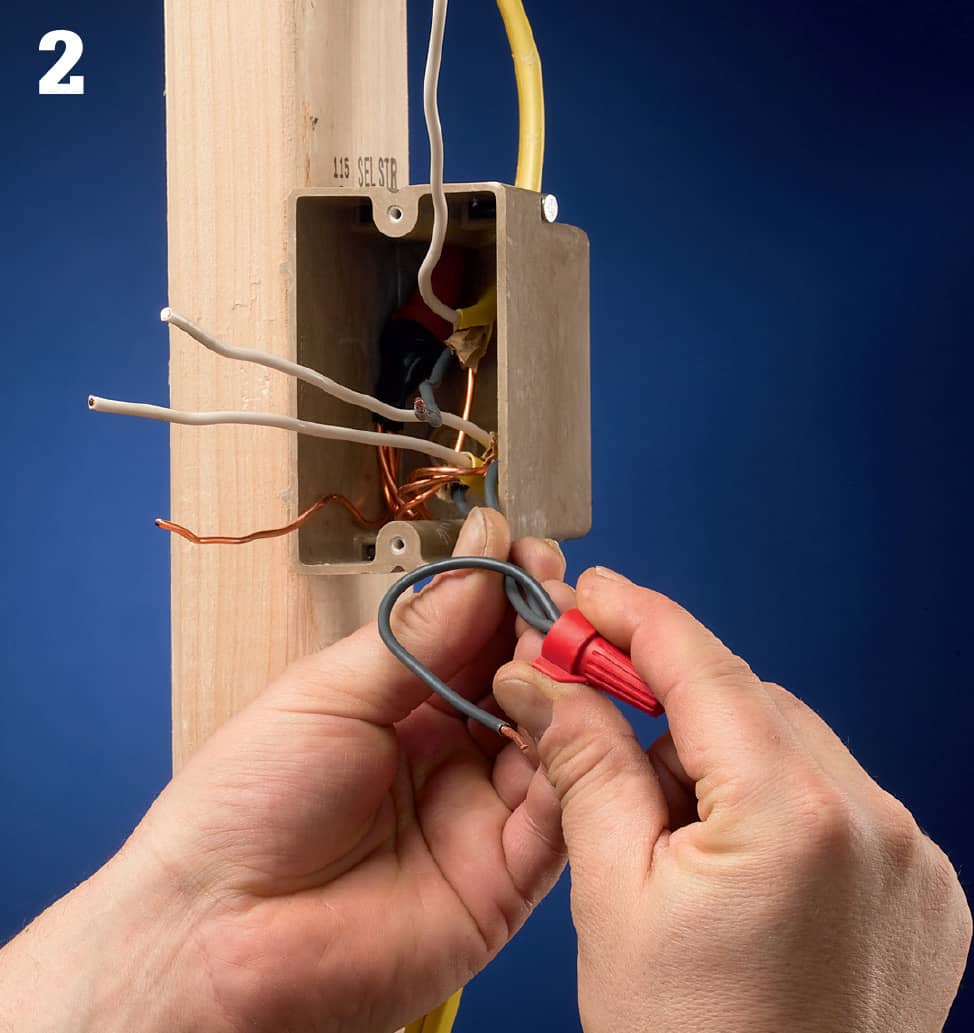

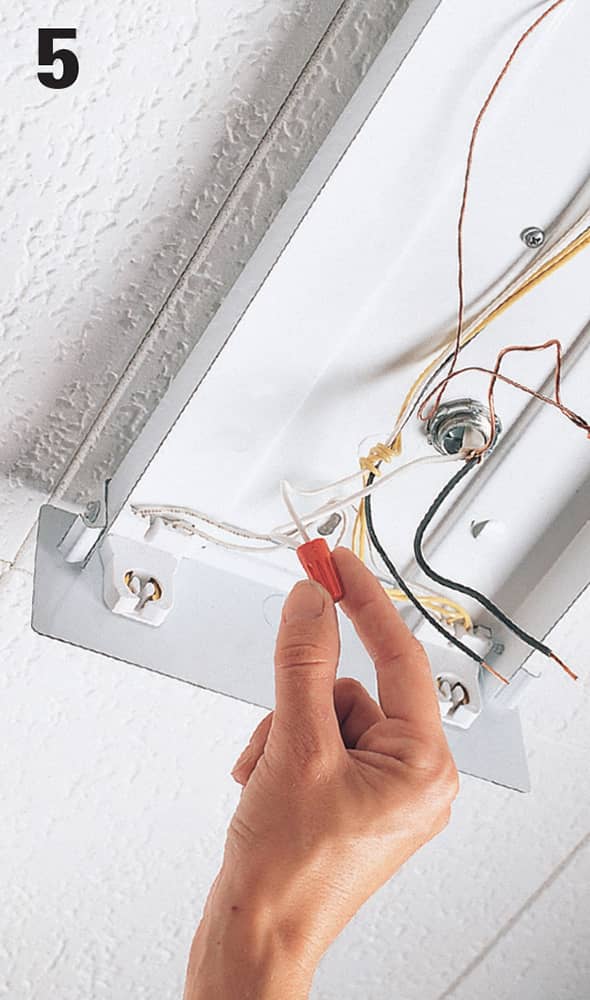

Twist a wire connector over the ends of the wires. Make sure the connector is the right size (see page 395). Hand-twist the connector as far onto the wires as you can. There should be no bare wire exposed beneath the collar of the connector.

OPTION: Reinforce the joint by wrapping it with electrician’s tape. By code, you cannot bind the wire joint with tape only, but it can be used as insurance. Few professional electricians use tape for purposes other than tagging wires for identification.

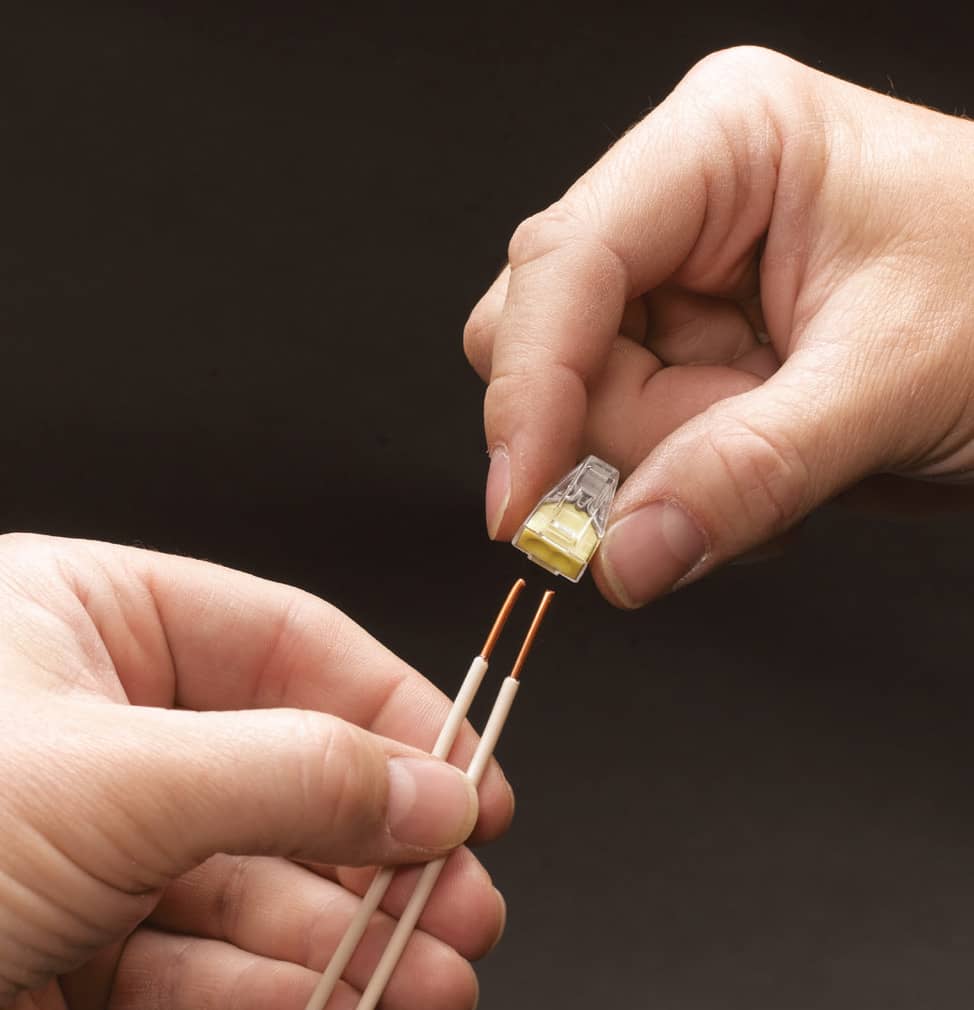

OPTION: Strip 3/4" of insulation off the ends of the wires to be joined, and insert each wire into a push-in connector. Gently tug on each wire to make sure it is secure.

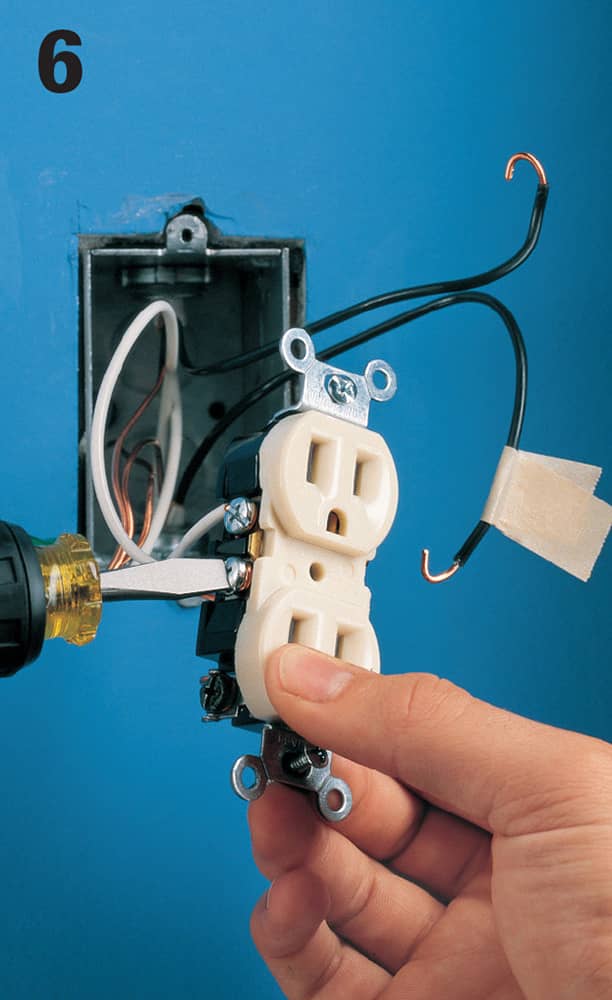

How to Pigtail Wires

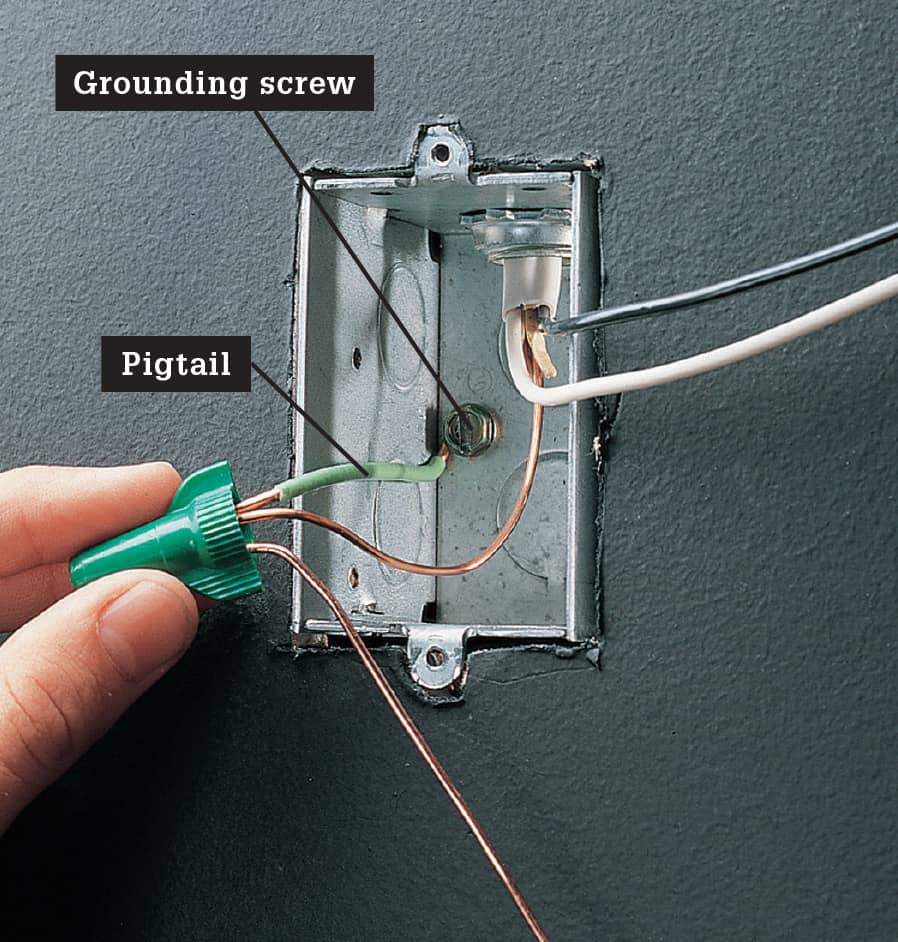

Cut a 6" length from a piece of insulated wire the same gauge and color as the wires it will be joining. Strip 3/4" of insulation from each end of the insulated wire. NOTE: Pigtailing is done mainly to avoid connecting multiple wires to one terminal, which is a code violation.

Join one end of the pigtail to the wires that will share the connection using a wire nut.

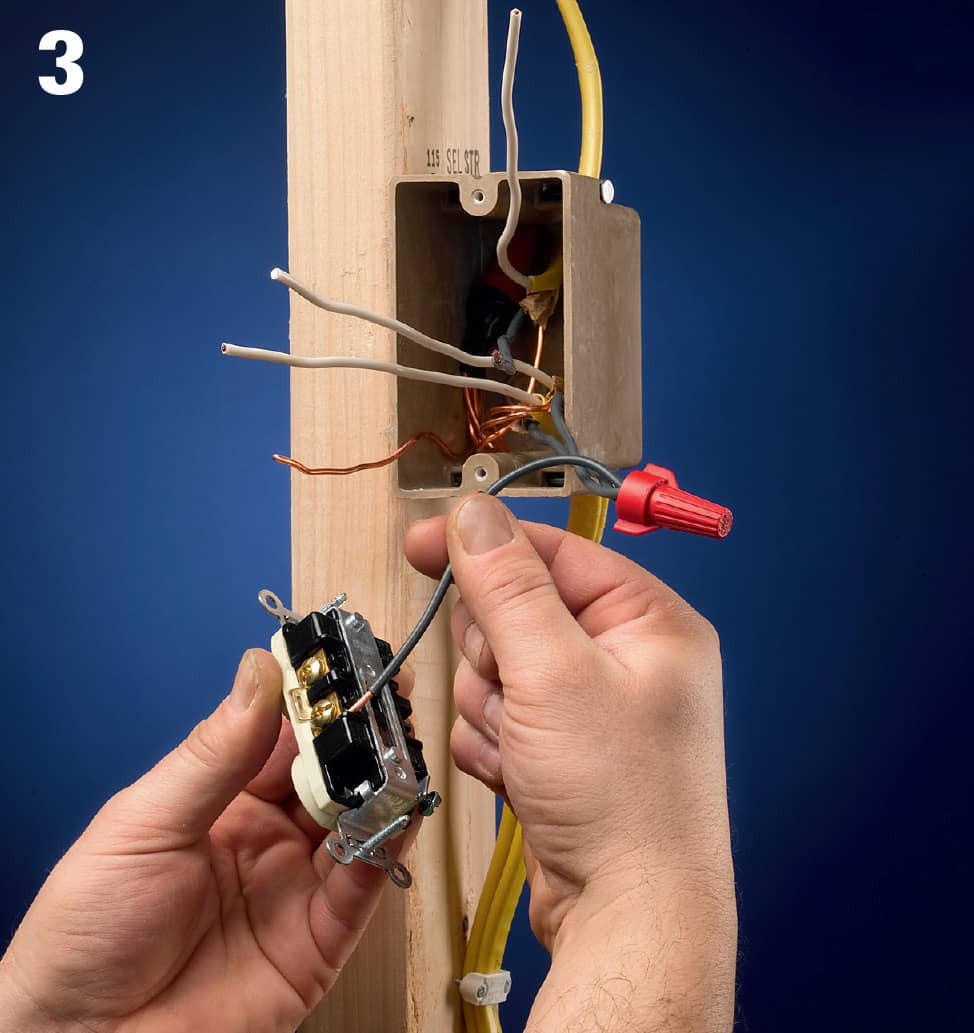

Connect the pigtail to the appropriate terminal on the receptacle or switch. Fold the wires neatly and press the fitting into the box.

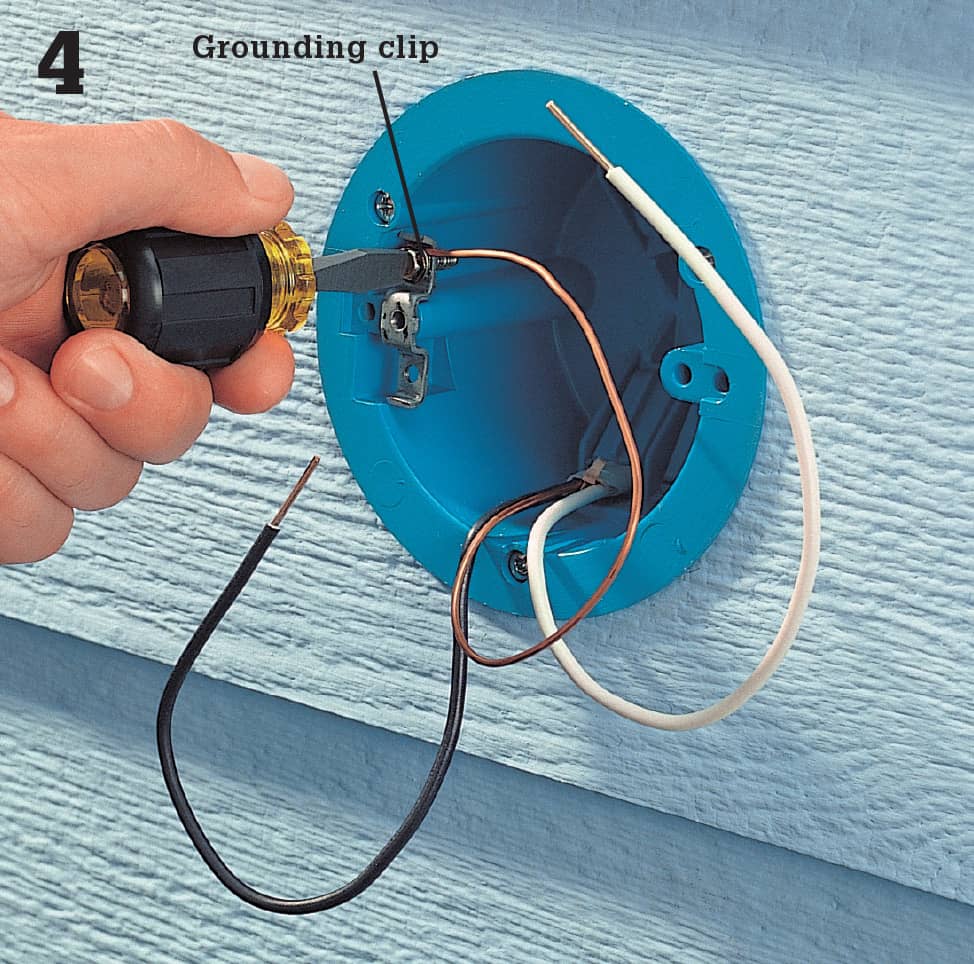

ALTERNATIVE: If you are pigtailing to a grounding screw or grounding clip in a metal box, you may find it easier to attach one end of the wire to the grounding screw before you attach the other end to the other wires.

Electrical Boxes

Electrical Boxes

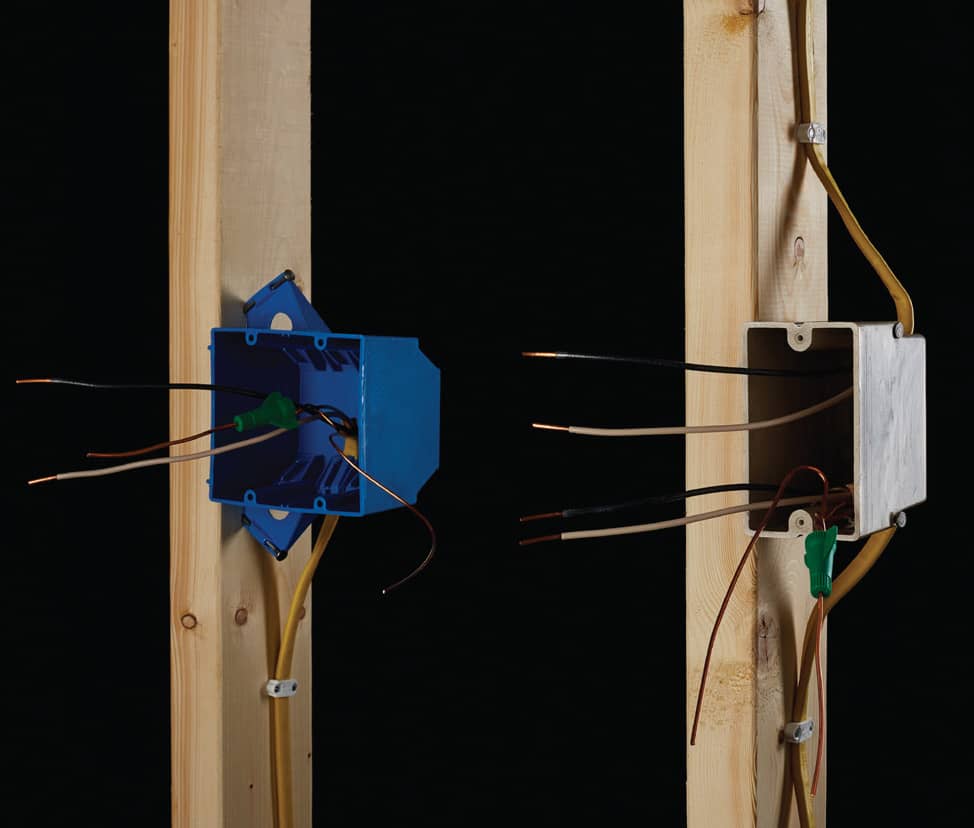

The National Electrical Code requires that wire connections and cable splices be contained inside an approved metal or plastic box. The box shields framing members and other flammable materials from electrical sparks and protects people from being shocked.

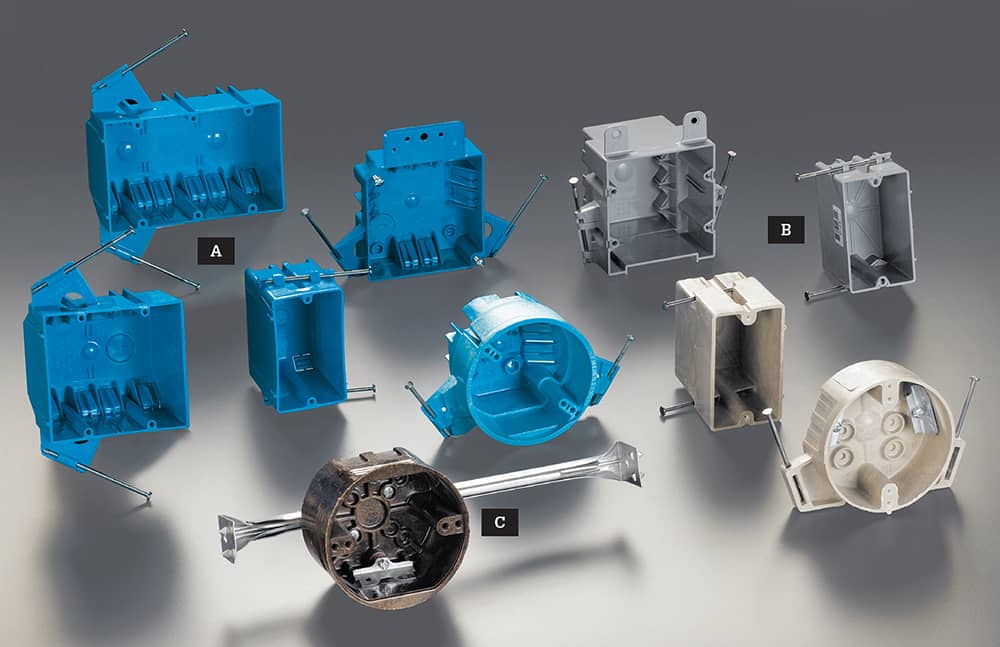

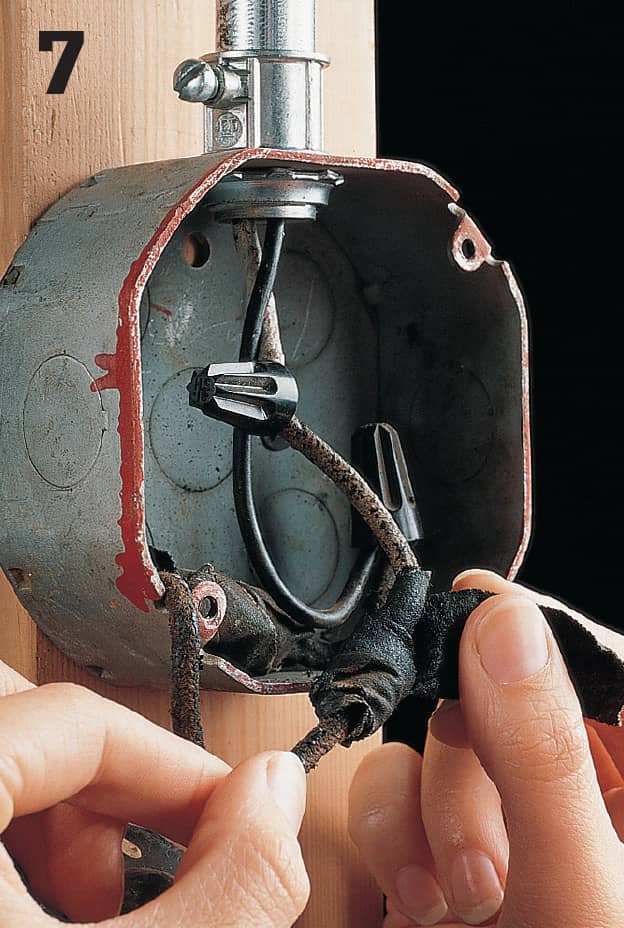

Electrical boxes come in several shapes. Rectangular and square boxes are used for switches and receptacles. Rectangular (2 × 3") boxes are used for single switches or duplex receptacles. Square (4 × 4") boxes are used any time it is convenient for two switches or receptacles to be wired, or “ganged,” in one box. Octagonal electrical boxes contain wire connections for ceiling fixtures.

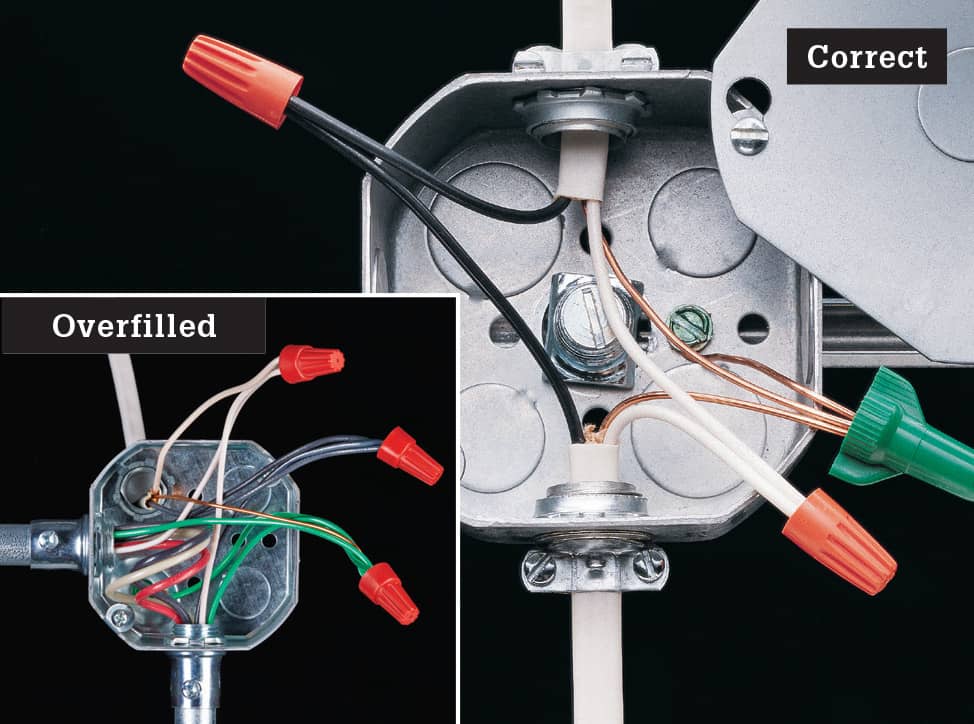

Electrical boxes are available in different depths. A box must be deep enough so a switch or receptacle can be removed or installed easily without crimping and damaging the circuit wires. The box must also be large enough to safely dissipate the heat from wires, switches, and receptacles. This is an important fire safety rule. Replace an undersized box with a larger box using the Electrical Box Fill Chart (right) as a guide. In addition to the maximum box fill allowed by the chart, the area of all wires, taps, and splices should not exceed 75% of the box area. The NEC also says that all electrical boxes must remain accessible. Never cover an electrical box with drywall, paneling, or wallcoverings.

Octagonal boxes usually contain wire connections for ceiling fixtures. Because the ceiling fixture attaches directly to the box, the box should be anchored firmly to a framing member. A properly installed octagonal box can support a ceiling fixture weighing up to 35 pounds. Any box must be covered with a tightly fitting cover plate, and the box must not have open knockouts. Do not overfill the box (inset).

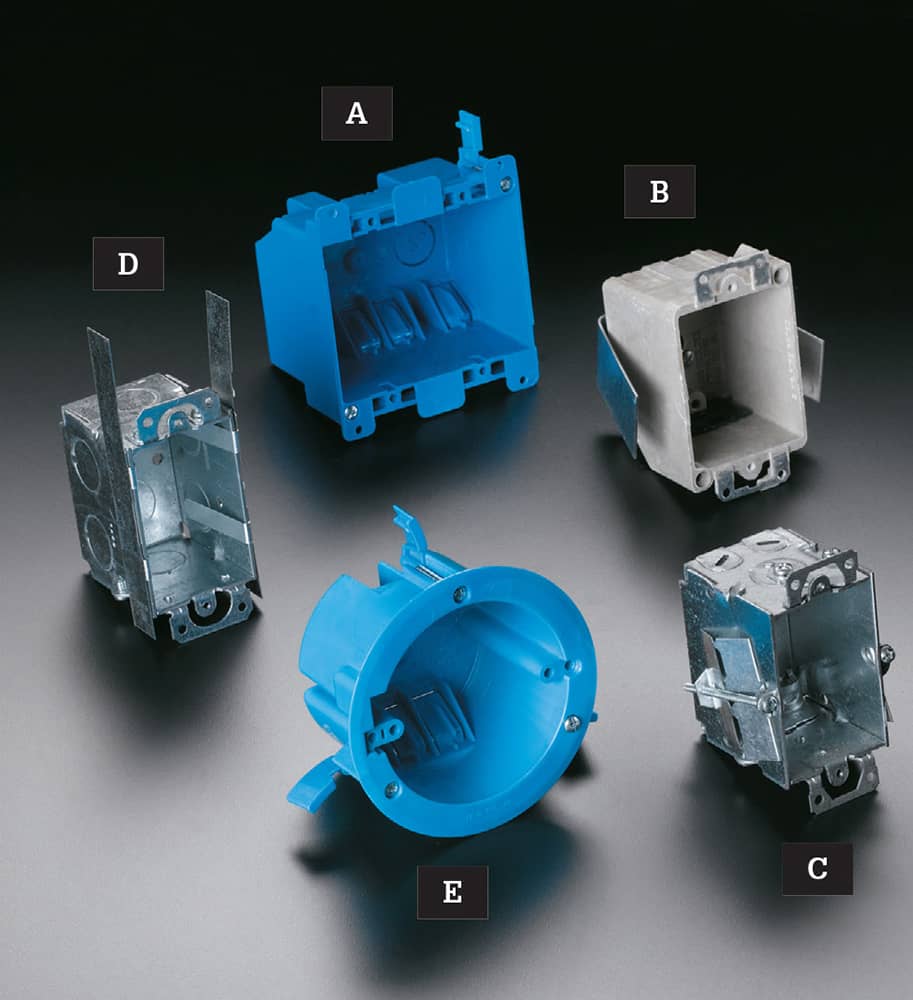

Common Electrical Boxes

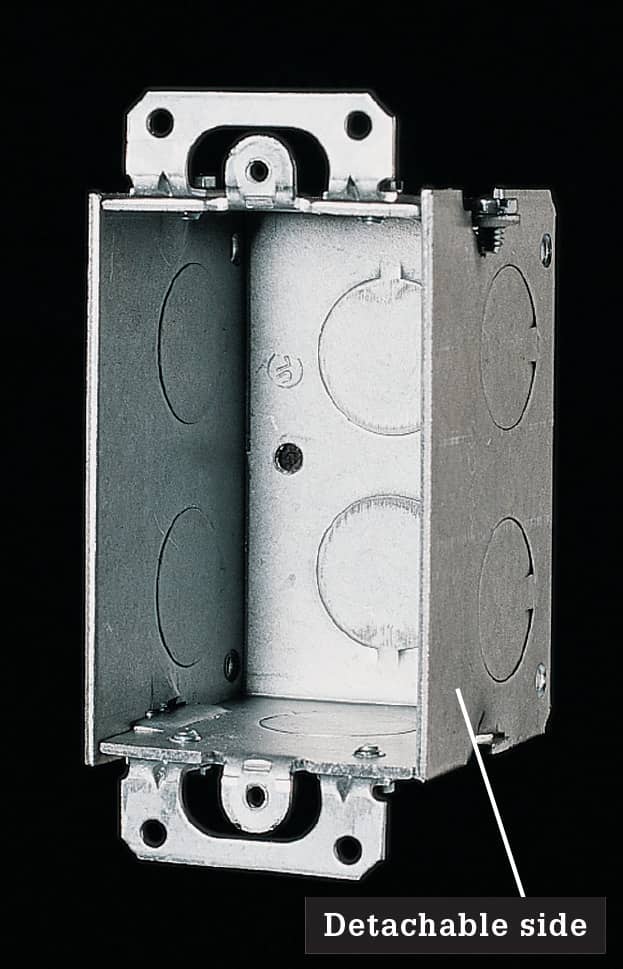

Rectangular boxes are used with wall switches and duplex receptacles. Single-size rectangular boxes (shown above) may have detachable sides that allow them to be ganged together to form double-size boxes.

Square 4 × 4" boxes are large enough for most wiring applications. They are used for cable splices and ganged receptacles or switches. To install one switch or receptacle in a square box, use an adapter cover.

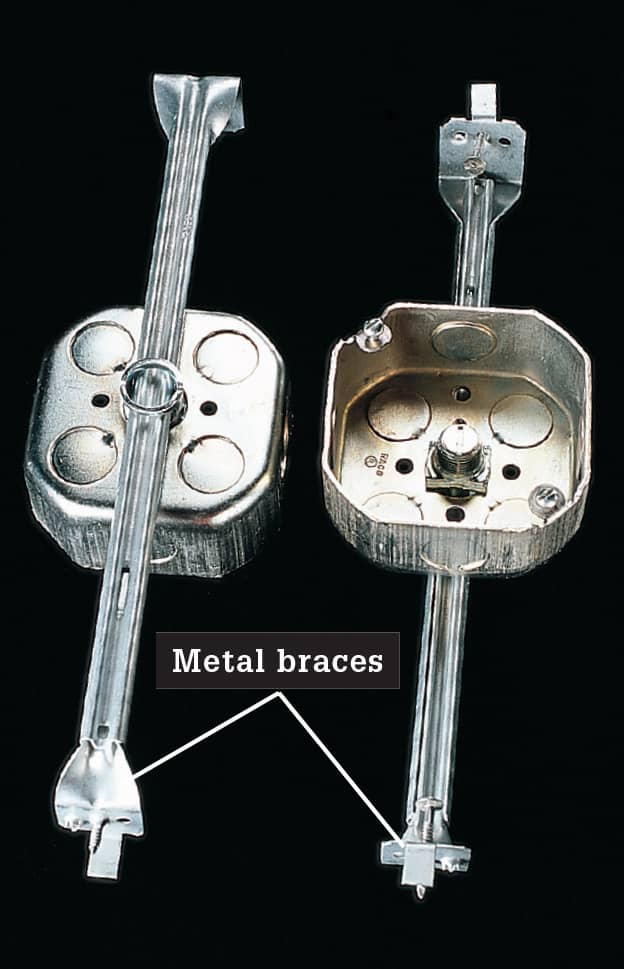

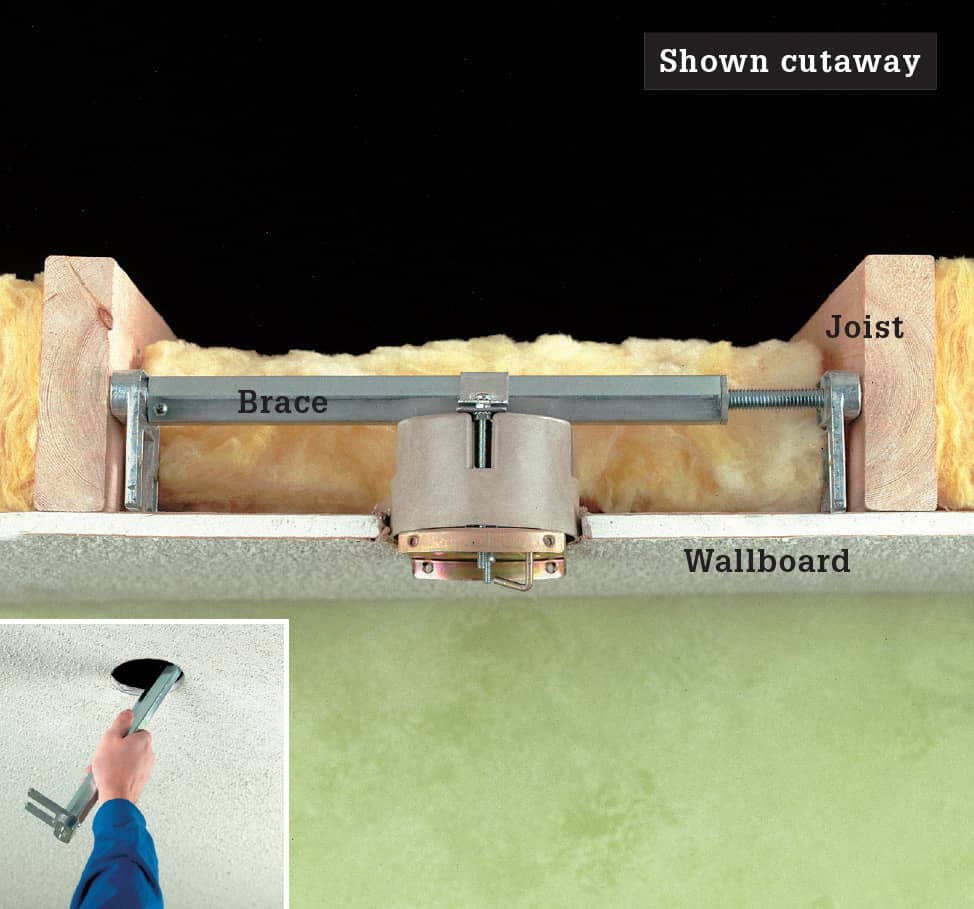

Braced octagonal boxes fit between ceiling joists. The metal braces extend to fit any joist spacing and are nailed or screwed to framing members.

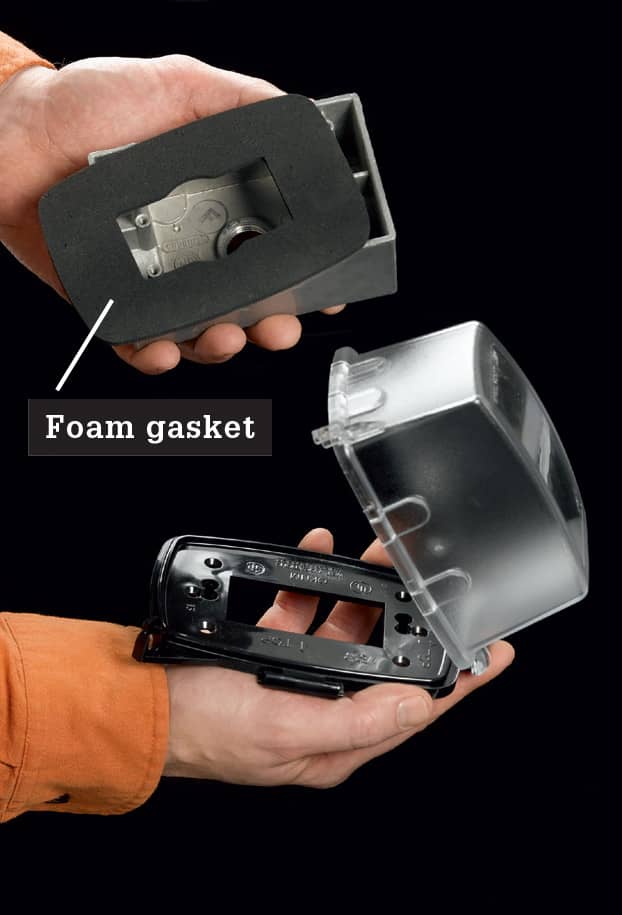

Outdoor boxes have sealed seams and foam gaskets to guard a switch or receptacle against moisture. Corrosion-resistant coatings protect all metal parts. Code-compliant models include a watertight hood that protects even when the outlet is in use.

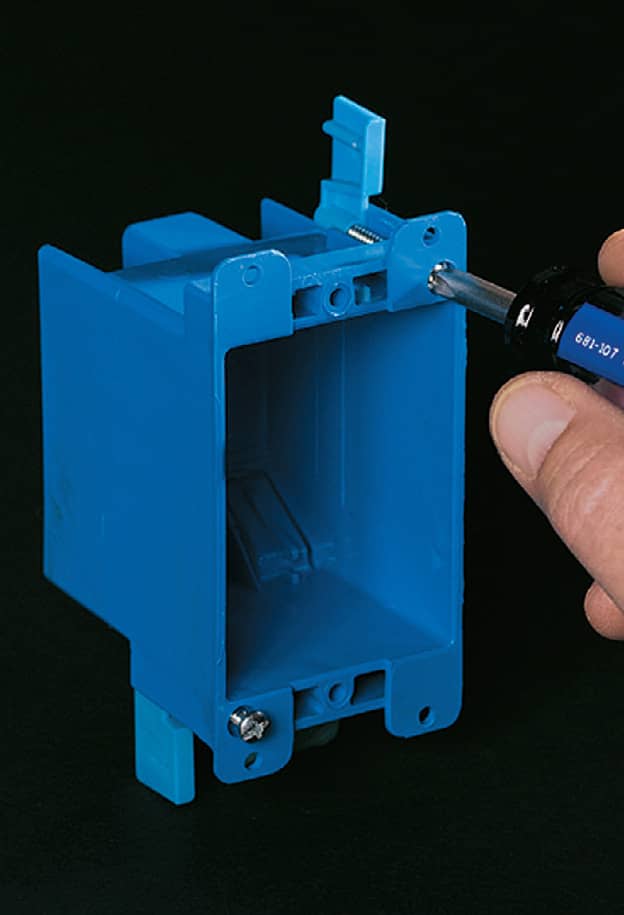

Old work boxes can be installed to upgrade older boxes or to allow you to add new additional receptacles and switches. One type (above) has built-in clamps that tighten against the inside of a wall and hold the box in place.

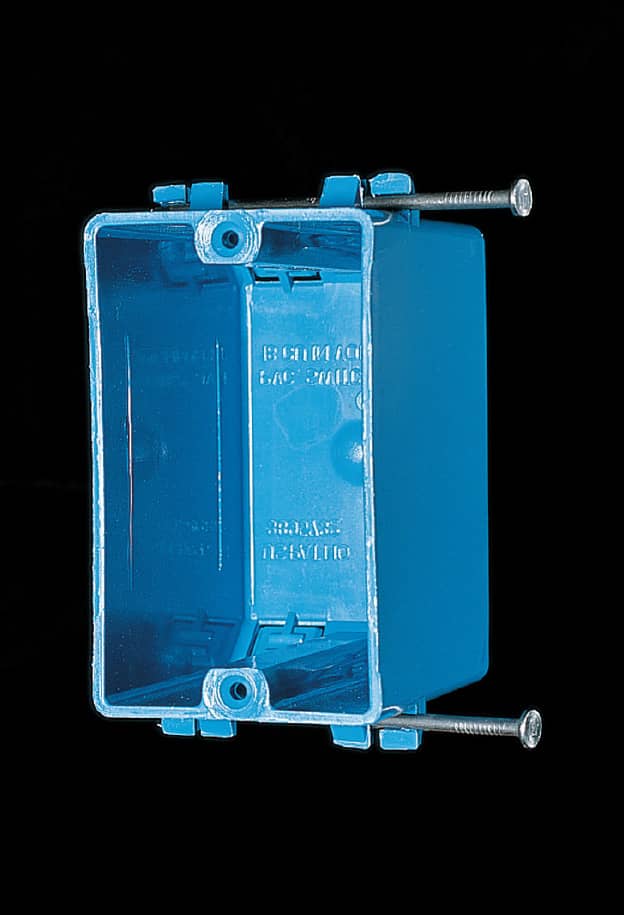

Plastic boxes are common in new construction. The box may include preattached nails for anchoring it to framing members. Wall switches must have grounding screws if installed in plastic boxes.

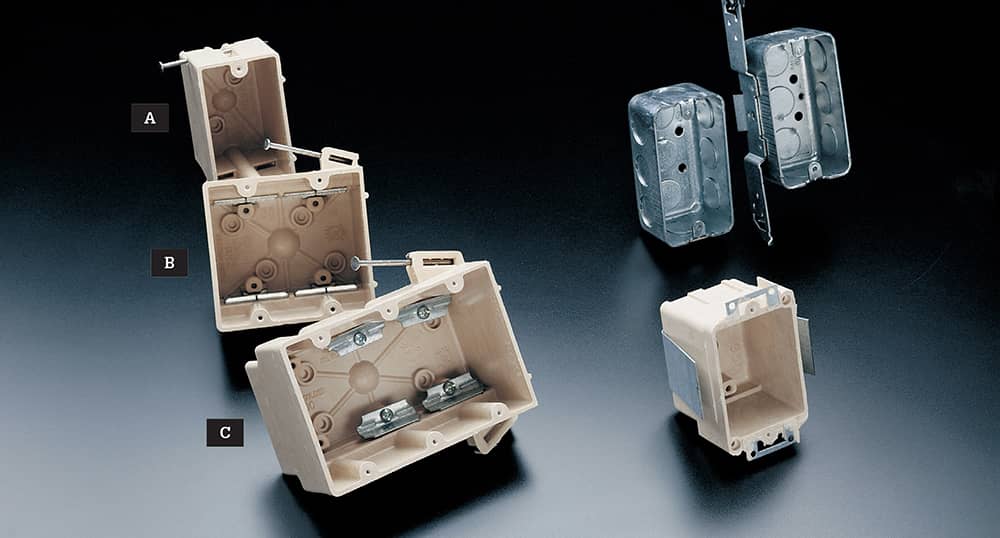

Plastic boxes 3 1/2"-deep with preattached mounting nails are used for any wiring project protected by finished walls. Common styles include single-gang (A), double-gang (B), and triple-gang (C). Double-gang and triple-gang boxes require internal cable clamps. Metal boxes should be used for exposed indoor wiring, such as conduit installations in an unfinished basement. Metal boxes also can be used for wiring that will be covered by finished walls. Plastic retrofit boxes are used when a new switch or receptacle must fit inside a finished wall. Use internal cable clamps.

Additional electrical boxes include cast aluminum box (A) for use with outdoor fixtures, including receptacles that are wired through metal conduit (these must have in-use covers if they house receptacles); old work ceiling box (B) used for light fixtures; light-duty ceiling fan box (C) with brace that spans ceiling joists; heavy-duty retrofit ceiling fan box (D) designed for retrofit; PVC box (E) for use with PVC conduit in indoor or outdoor setting; and vapor-proof ceiling box with foam gasket (F).

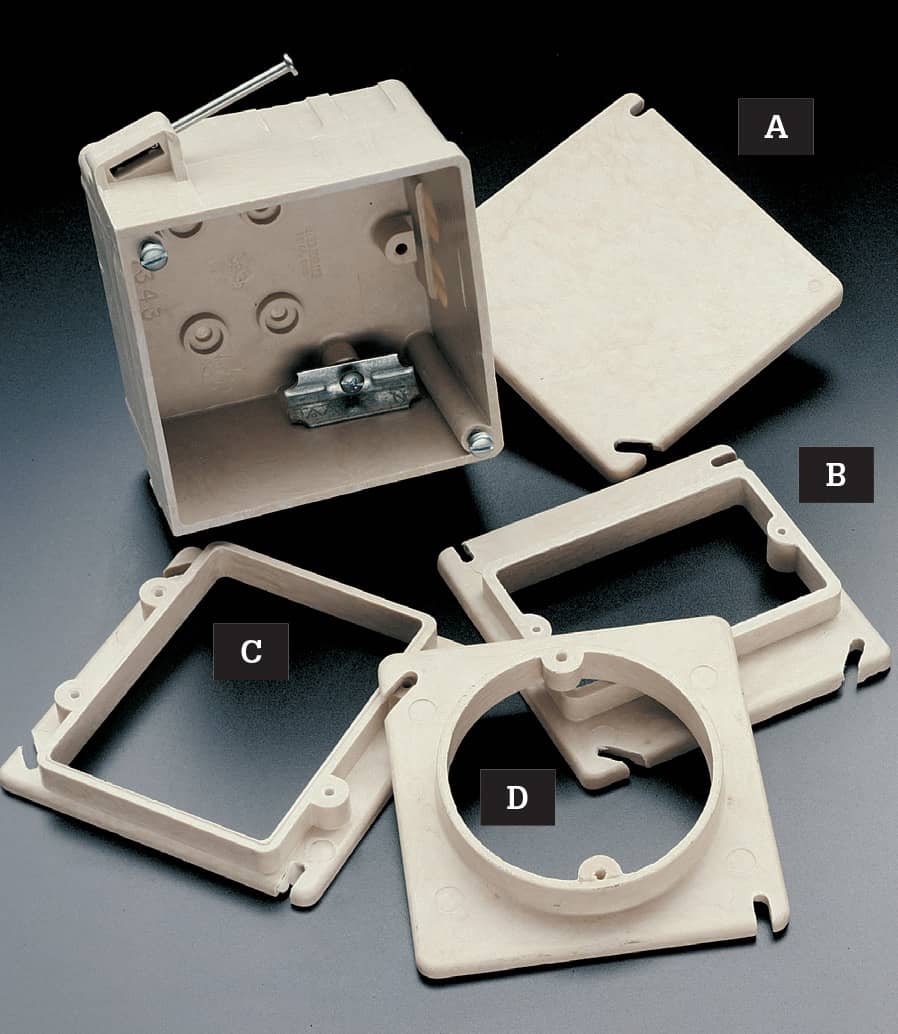

Nonmetallic Boxes

Nonmetallic electrical boxes have taken over much of the do-it-yourself market. Most are sold prefitted with installation hardware—from metal wings to 10d common nails attached at the perfect angle for a nail-in box. The bulk of the nonmetallic boxes sold today are inexpensive blue PVC. You can also purchase heavier-duty fiberglass or thermoset plastic models that provide a nonmetallic option for installing heavier fixtures such as ceiling fans and chandeliers.

In addition to cost and availability, nonmetallic boxes hold a big advantage over metal boxes in that their resistance to conducting electricity will prevent a sparking short circuit if a hot wire contacts the box. Nonmetallic boxes generally are not approved for exposed areas, where they may be susceptible to damage. Their lack of rigidity also allows them to compress or distort, which can reduce the interior capacity beyond code minimums or make outlets difficult to attach.

Low cost is the primary reason that blue PVC nail-in boxes are so popular. Not only are they inexpensive, they also feature built-in cable clamps so you may not need to buy extra hardware to install them. The standard PVC nail-in box is prefitted with a pair of 10d common nails for attaching to exposed wall studs. These boxes, often called handy boxes, are too small to be of much use (see fill chart, page 400).

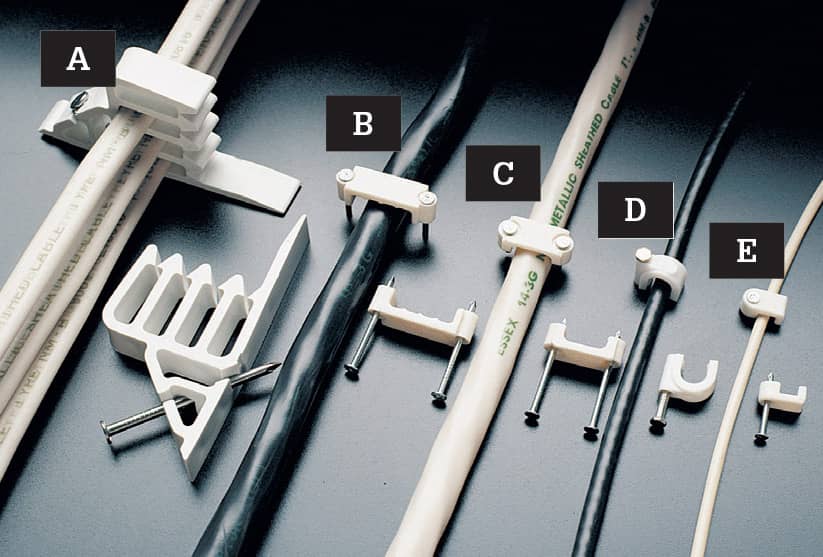

Nonmetallic boxes for home use include: Single-gang, double-gang, triple gang, and quad boxes (A); thermoset and fiberglass boxes for heavier duty (B); and round fixture boxes (C) for ceiling installation (nail-in and with integral metal bracket).

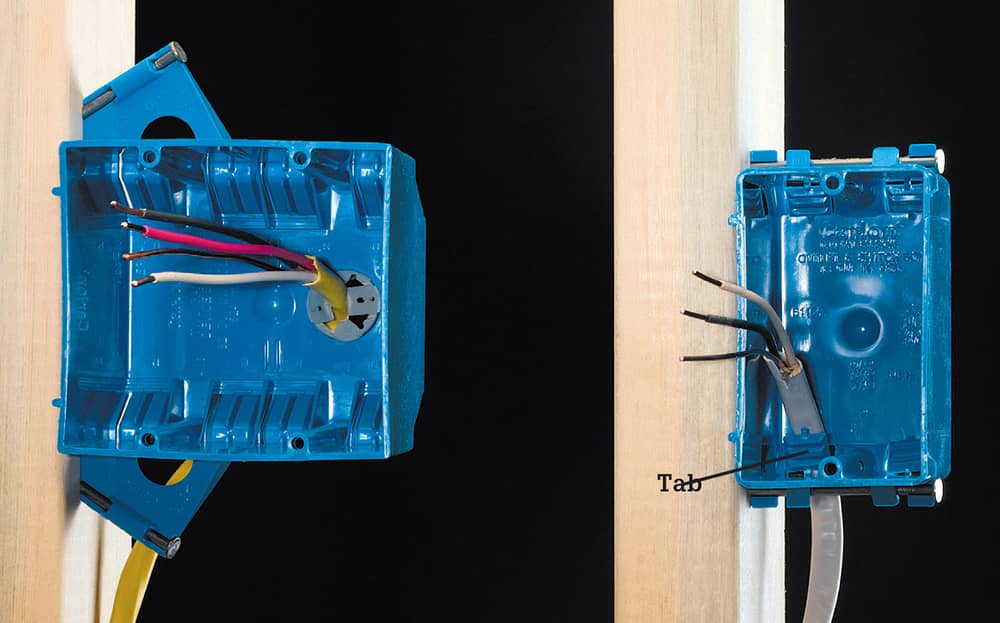

Working With Nonmetallic Boxes

Do not break off the tabs that cover cable entry holes in plastic boxes. These are not knockouts as you would find in metal boxes. In single-gang boxes (right), the pressure from the tab is sufficient to secure the cable as long as it enters with sheathing intact and is stapled no more than 8" from the box. On larger boxes (left), you will find traditional knockouts intended to be used with plastic cable clamps that resemble metal cable clamps. Use these for heavier gauge cable and cable with more than three wires.

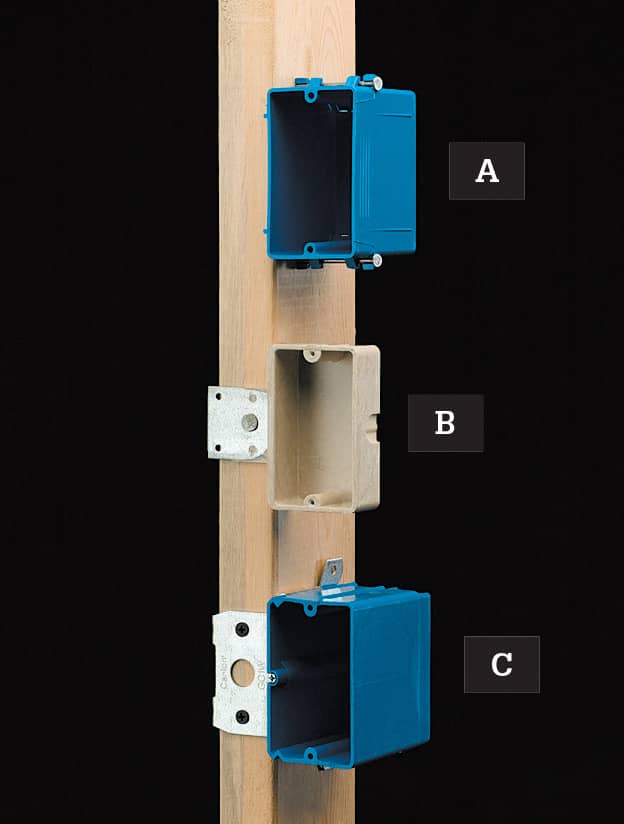

Nail-in boxes (A) are prefitted with 10d nails that are attached perpendicular to the face of single-gang boxes and at an inward angle for better gripping power on larger boxes. Side-mount boxes (B) feature a nailing plate that is attached to the front of the stud to automatically create the correct setback; adjustable side-mount boxes (C) are installed the same way but can be moved on the bracket.

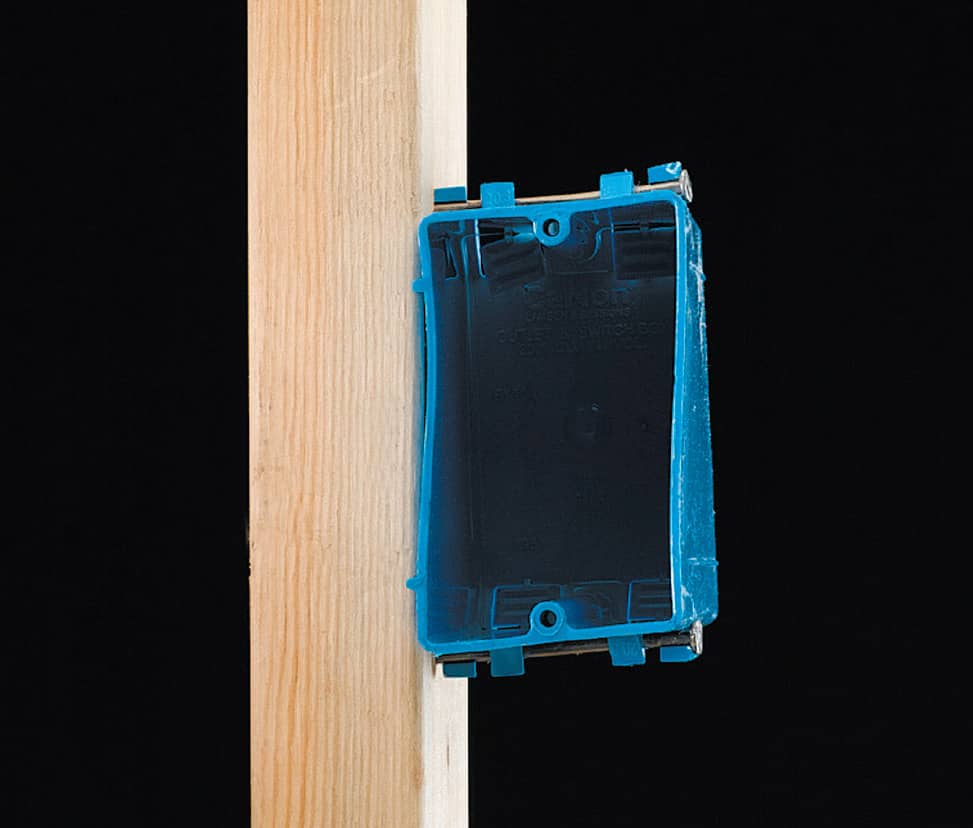

Distortion can occur in nonmetallic boxes when nails or other fasteners are overdriven or installed at improper angles, or when the semiflexible boxes are compressed into improperly sized or shaped openings. This can reduce the box capacity and prevent devices and faceplates from fitting.

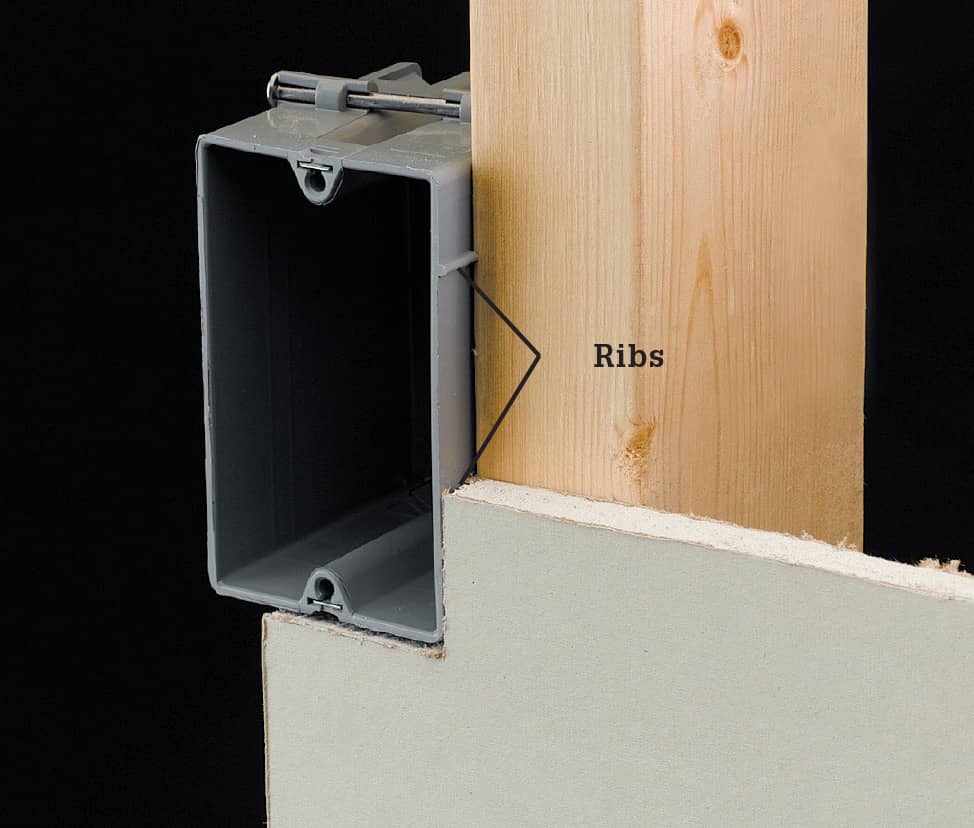

Integral ribs cast into many nonmetallic boxes are used to register the box against the wall studs so the front edges of the box will be flush with the wall surface after drywall is installed. Most are set for 1/2" drywall, but if your wall will be a different thickness you may be able to find a box with corresponding ribs. Otherwise, use a piece of the wallcovering material as a reference.

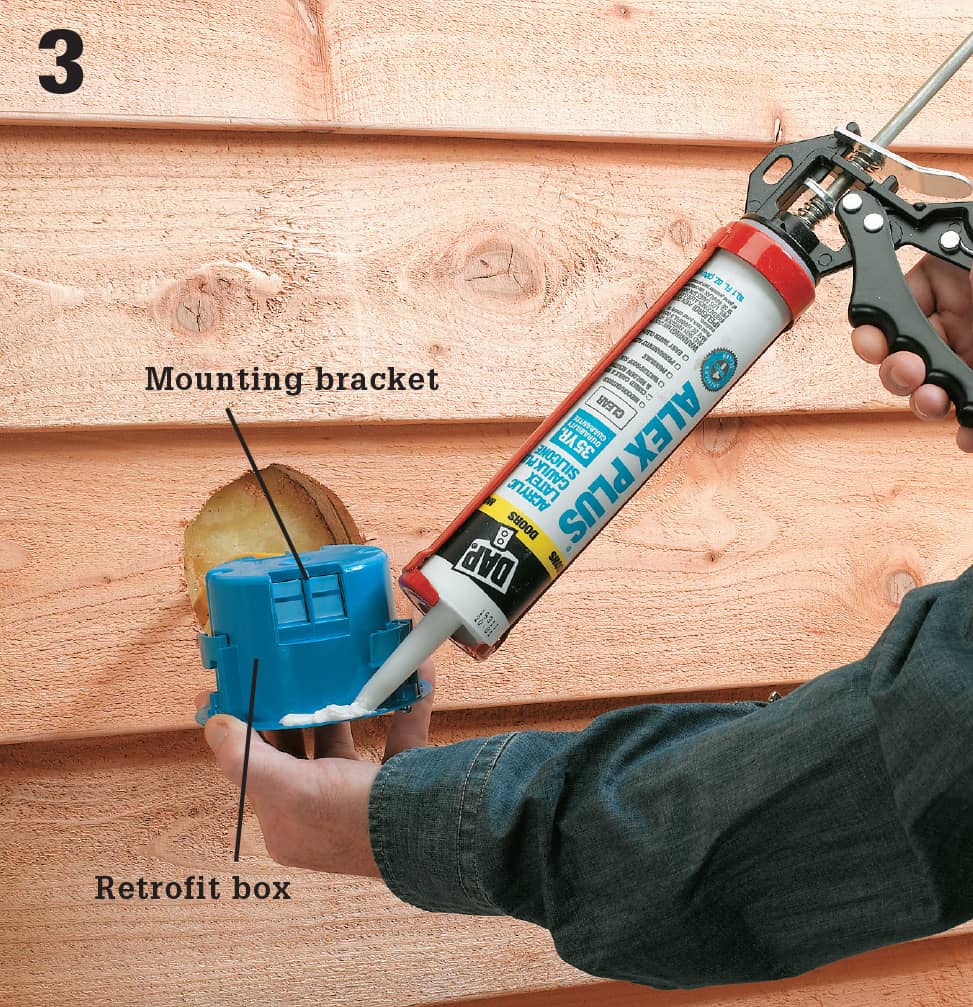

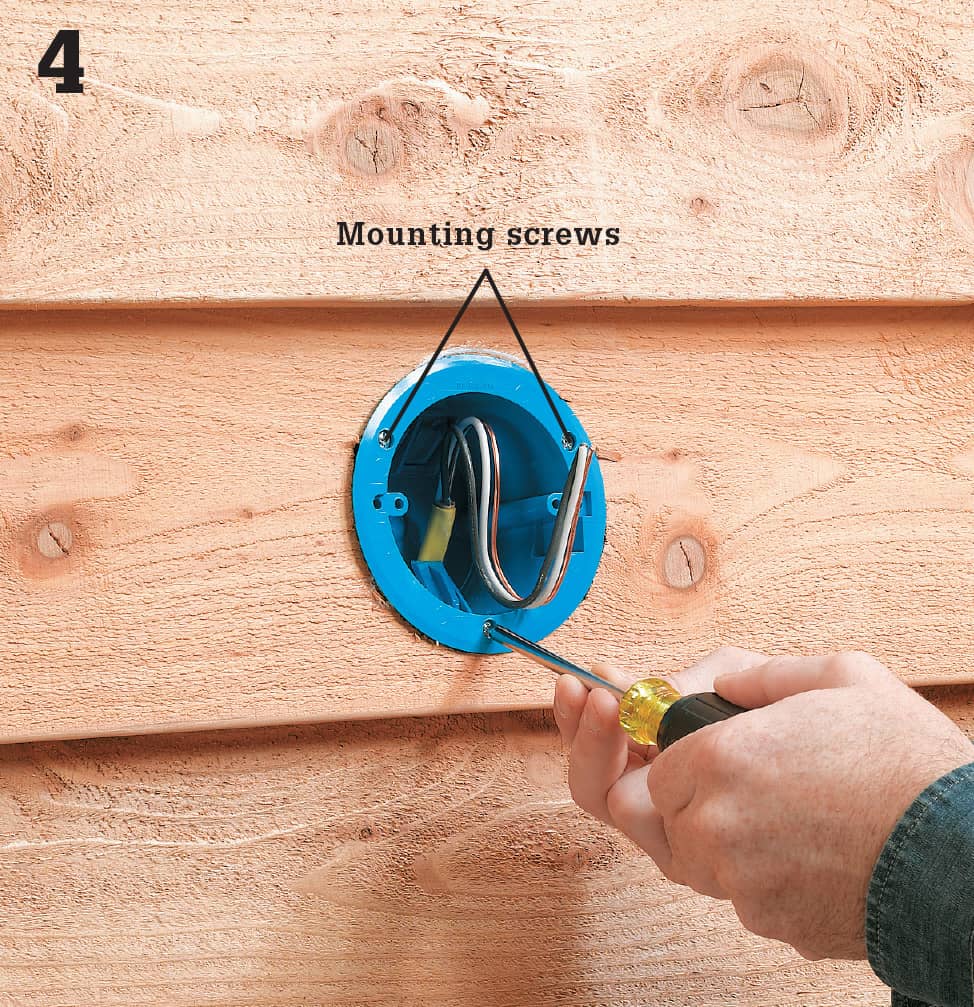

Installing Pop-in Retrofit Boxes

Attaching an electrical box to a wall stud during new construction is relatively easy. The task becomes complicated, however, when you’re working in finished walls during remodeling or repair. In most cases, it’s best to use an electronic stud finder, make a large cutout in the wall, and attach a new box directly to a framing member or bracing (and then replace and refinish the wall materials). But there are occasions when this isn’t possible or practical and you just need to retrofit an electrical box without making a large hole in the wall. You also may find that an older switch or receptacle box is too shallow to accommodate a new dimmer or GFCI safely. These situations call for a pop-in retrofit box (sometimes called an “old work” box).

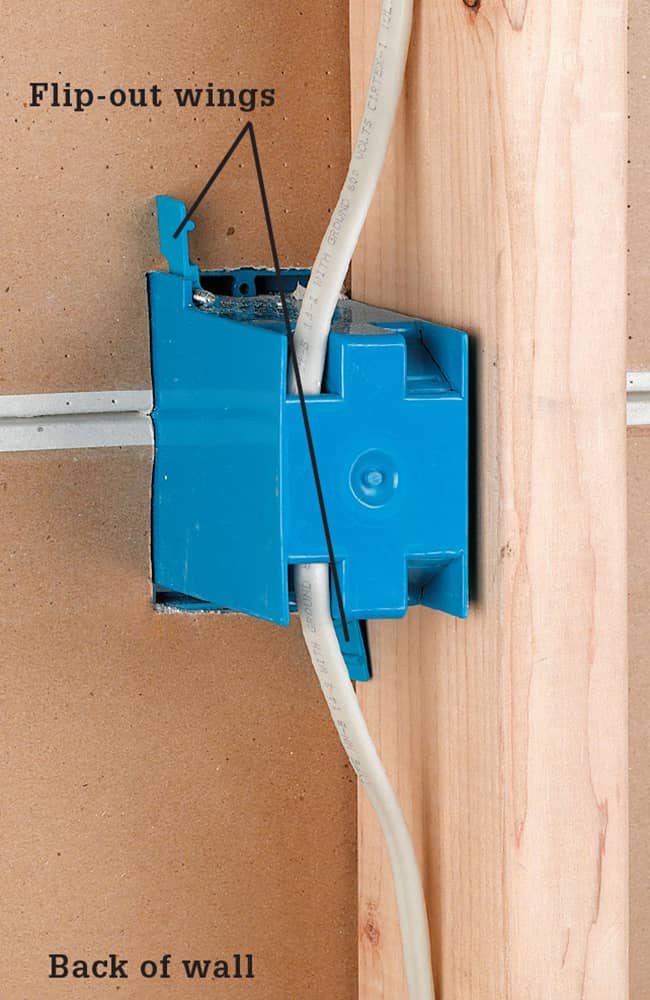

A pop-in box typically has wings, tabs, or brackets that are drawn tight against the wall surface on the wall cavity side, holding the box in place. It can be made either of metal or plastic.

Pop-in boxes for remodeling come in a variety of styles. For walls, they include plastic retrofit boxes with flip-out wings (A), metal or plastic boxes with compression tabs or brackets (B), metal retrofit boxes with flip-out wings (C), and metal boxes with bendable brackets, also known as F-straps, (D). For ceilings, plastic fixture boxes with flip-out wings (E) are available.

How to Replace an Electrical Box

To install a dimmer switch or GFCI receptacle, you may have to replace an old, overcrowded box. Shut off power and remove the old switch or receptacle. Identify the location of nails holding the box to the framing member and cut the nails with a hacksaw or reciprocating saw with a metal blade inserted between the box and the stud.

Bind the cable ends together and attach string in case they fall into the wall cavity when the old box is removed. Disconnect the cable clamps and slide the old box out. Install a new pop-in box (see next page).

How to Install a Pop-in Box

Use a template to trace a cutout for the box at the intended location. If no template is provided, press the pop-in box against the wall surface and trace its front edges (but not the tabs on the top and bottom).

Puncture the wallboard with the tip of a wallboard saw or by drilling a small hole inside the lines, and make the cutout for the box.

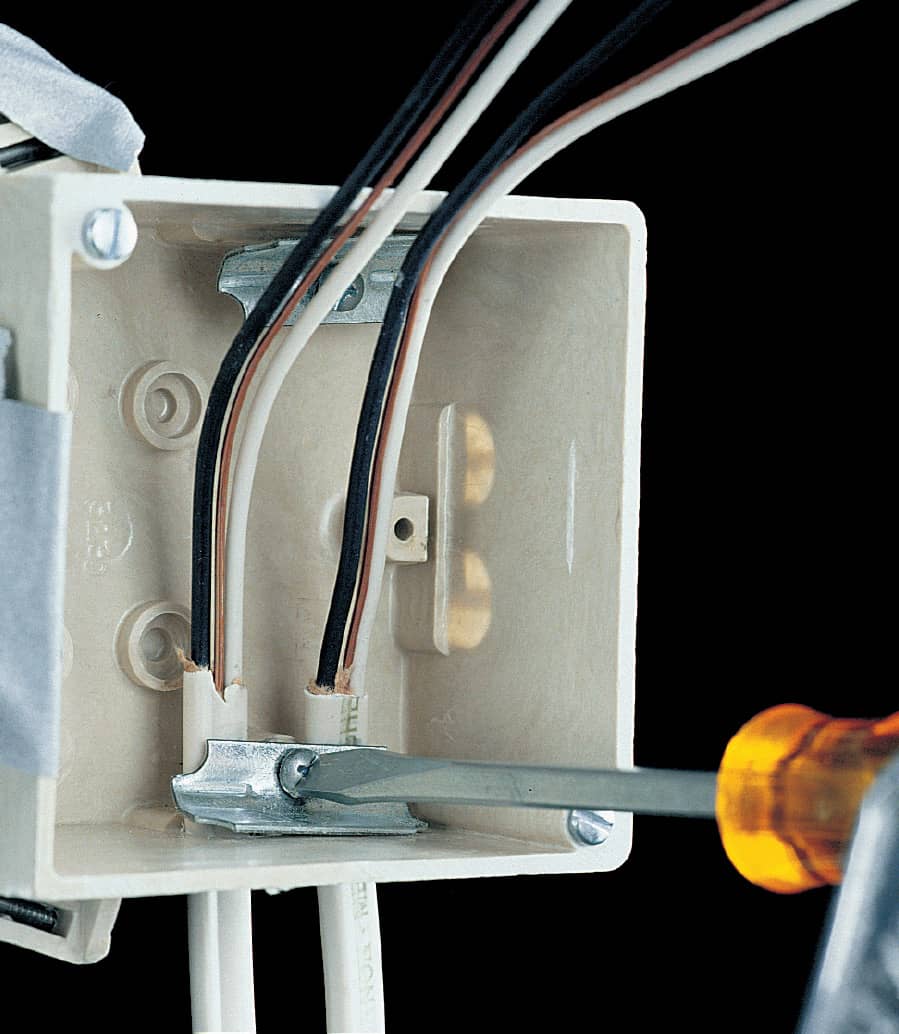

Pull NM cable through a knockout in the box (no cable clamp is required with a plastic box; just be sure not to break the pressure tab that holds the cable in place).

Insert the box into the cutout so the tabs are flush against the wall surface. Tighten the screws that cause the flip-out wings to pivot (below) until the box is held firmly in place. Connect the switch or receptacle that the box will house.

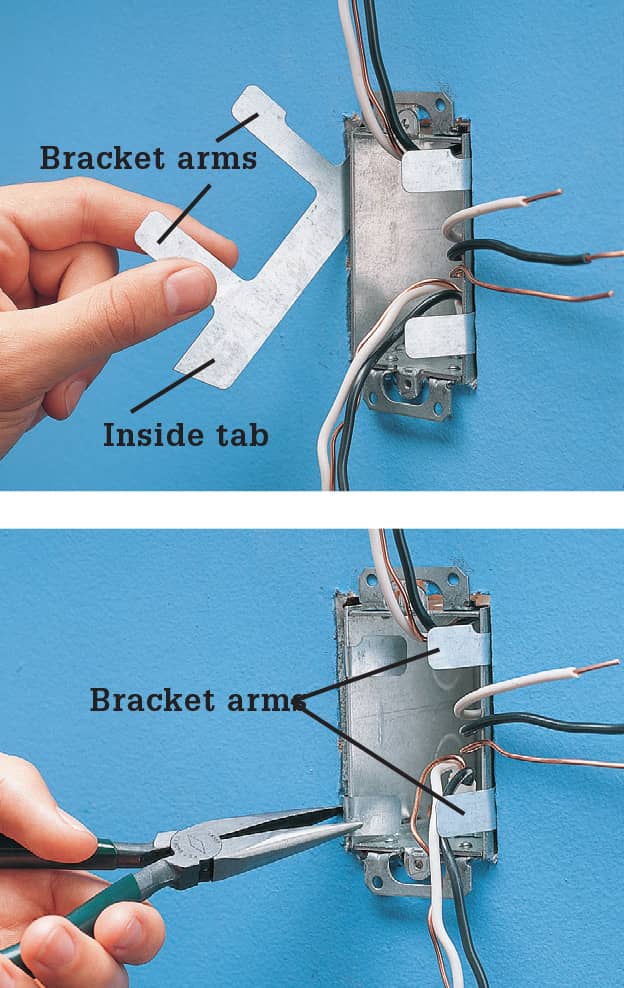

VARIATION: Feed cable into the new box and secure it in the opening after clamping the cables. With this pop-in box, bracket arms are inserted at the sides of the box (top) and then bent around the front edges to secure the box in the opening (bottom).

Electrical Panels

Electrical Panels

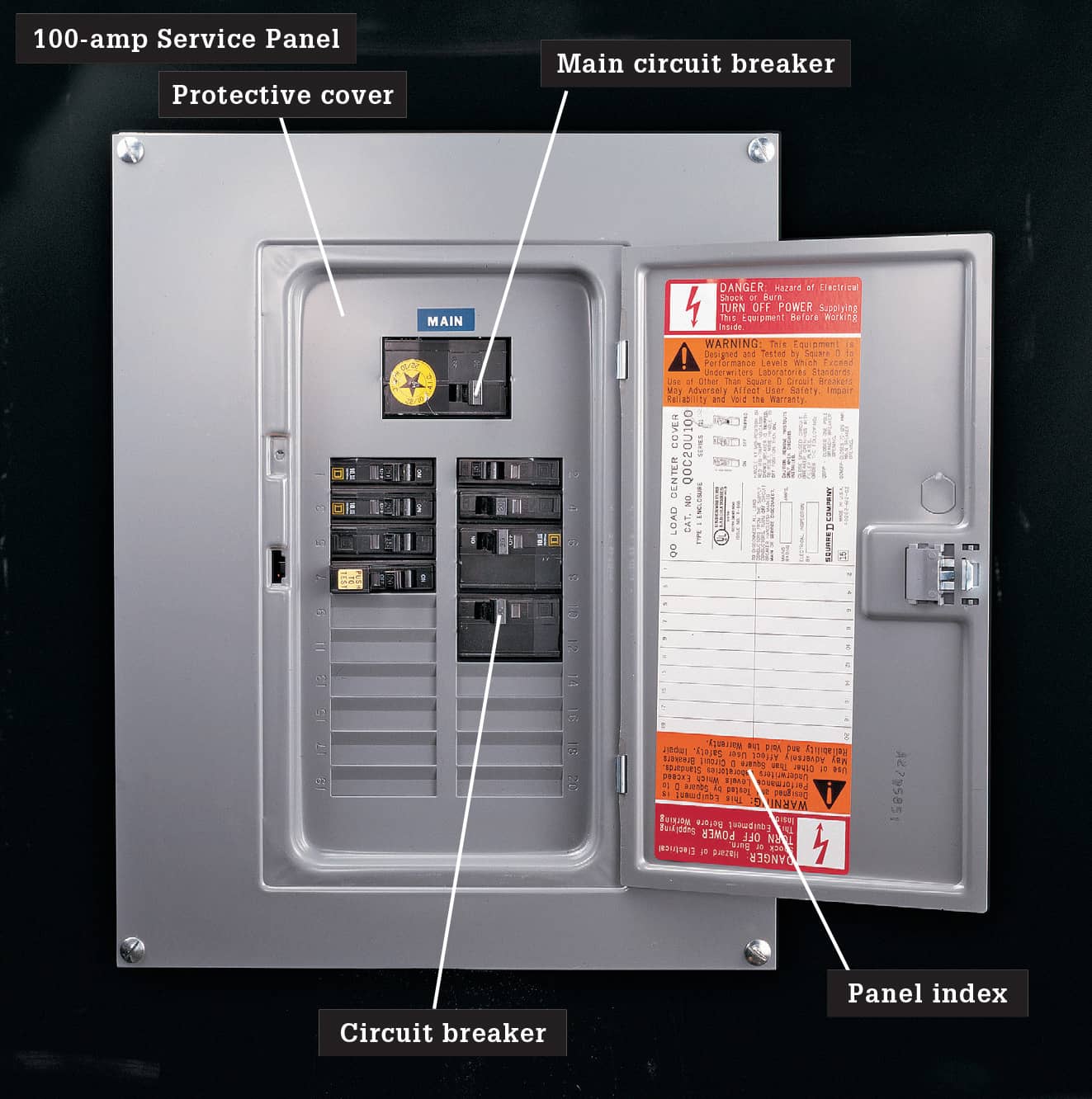

Every home has a main panel that distributes electrical current to the individual circuits. The main panel may be found in the basement, garage, utility area, or on an exterior wall and can be identified by its metal casing. Before making any repair to your electrical system, you must shut off power to the correct circuit at the main panel or at the subpanel where the circuit begins. Every circuit in every panel should be labeled (see page 390) so circuits can be identified easily.

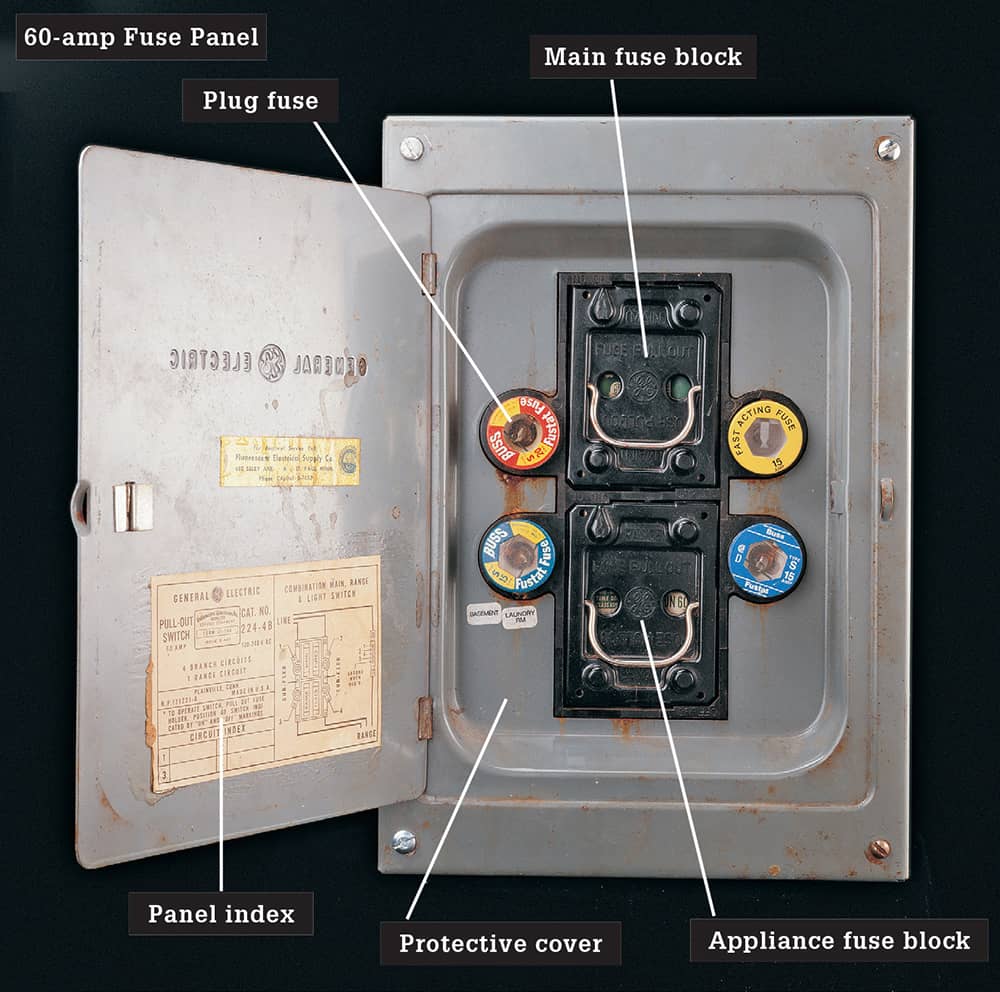

Panels vary in appearance, depending on the age of the system. Very old wiring may operate on 30-amp service that has only two circuits. New homes can have up to 400-amp service with 30 or more circuits. Find the size of the service by reading the amperage rating printed on the main fuse block or main circuit breakers.

Regardless of age, all panels have fuses or circuit breakers (see page 412) that protect each circuit from overloads. In general, older service panels use fuses, while newer panels use circuit breakers.

In addition to the main panel, your electrical system may have one or more subpanels that protect some of the circuits in the home. A subpanel has its own circuit breakers or fuses.

The subpanel resembles the main service panel but is usually smaller. It may be located near the main panel, or it may be found near the areas served by the new circuits. Garages and basements that have been updated often have their own subpanels. If your home has subpanels, make sure that their circuits are indexed correctly.

When handling fuses or circuit breakers, make sure the area around the panel is dry. Never remove the protective cover on the panel. After turning off a circuit to make electrical repairs, remember to always test the circuit for power before touching any wires.

The main panel is the heart of your wiring system. As our demand for household energy has increased, the panels have also grown in capacity. Today, a 200-amp panel is often installed in new construction. Many homebuilders are installing dual 200-amp panels to deliver 400 amps to larger houses. A pair of 200-amp panels is much cheaper than one 400-amp panel.

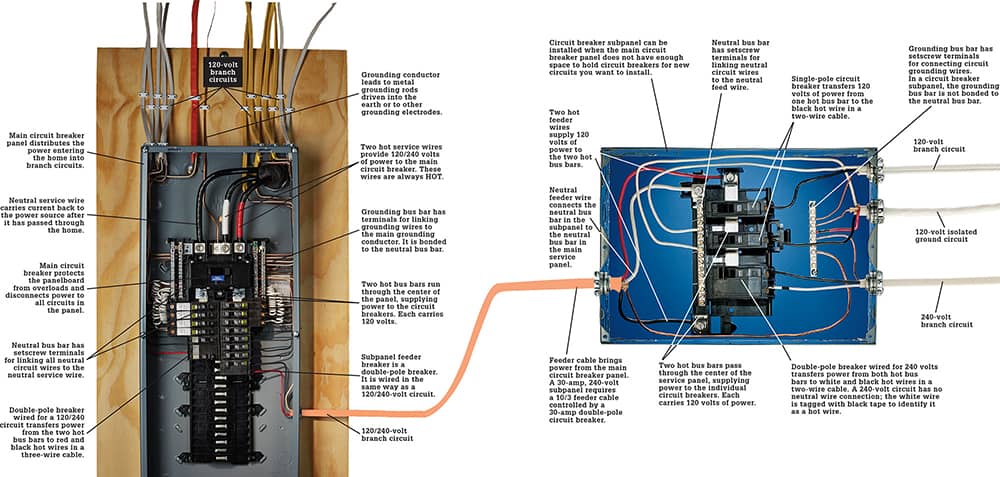

A circuit breaker panel providing 100 amps or more of current is common in wiring systems installed during the 1960s and later. A circuit breaker panel is housed in a gray metal cabinet that contains two rows of individual circuit breakers. You can determine service size by reading the amperage rating of the main circuit breakers. In systems rated 200 amps and below, the main breaker is often located in the main panel, but it may be in a separate cabinet located elsewhere.

Larger new homes may have 300- or 400-amp service. These systems usually have two main circuit breakers in the main panel and at least one subpanel.

A 100-amp service panel is now the minimum standard for all new housing. It is adequate for a medium-sized house with no more than three major electric appliances. However, larger houses with more electrical appliances require a service panel that provides 150 amps or more.

To shut off power to individual circuits in a circuit breaker panel, flip the lever on the appropriate circuit breaker to the OFF position. To shut off the power to the entire house, turn the main circuit breakers to the OFF position.

Some older homes may still have a 60-amp fuse panel. It usually is housed in a gray metal cabinet that contains four individual plug fuses, plus one or two pull-out fuse blocks that hold cartridge fuses. A 60-amp panel is considered undersized by current standards. The system should be upgraded for both convenience and safety. Insurance companies and mortgage lenders may require a complete electrical system upgrade before issuing a homeowner insurance policy or approving mortgage financing.

To shut off power to a circuit, carefully unscrew the plug fuse, touching only its insulated rim. To shut off power to the entire house, hold the handle of the main fuse block and pull sharply to remove it. Major appliance circuits are controlled with another cartridge fuse block. Shut off the appliance circuit by pulling out this fuse block.

Circuit Breaker Panels

The circuit breaker panel is the electrical distribution center for your home. It divides the current into branch circuits that are carried throughout the house. Each branch circuit is protected by a circuit breaker that protects the wires from dangerous current overloads. When installing new circuits, the last step is to connect the wires to new circuit breakers at the panel. Follow basic safety procedures and always shut off the main circuit breaker and test for power before touching any parts inside the panel. Never touch the service wire lugs. If unsure of your own skills, hire an electrician to make the final circuit connections. (If you have an older electrical service with fuses instead of circuit breakers, always have an electrician make these final hookups.)

If a circuit breaker panel does not have enough open slots for new full-size circuit breakers, you may be able to install 1/2-height (slimline) circuit breakers. Otherwise, you will need to install a subpanel.

Before installing any new wiring, evaluate your electrical service to make sure it provides enough current to support both the existing wiring and any new circuits. If your service does not provide enough current, you will need to upgrade to a higher amp rating panel with enough extra breaker slots for the new circuits you want to install.

Fuses & Circuit Breakers

Fuses and circuit breakers are safety devices designed to protect the electrical system from short circuits and overloads. Fuses and circuit breakers are located in the main service panel and in subpanels.

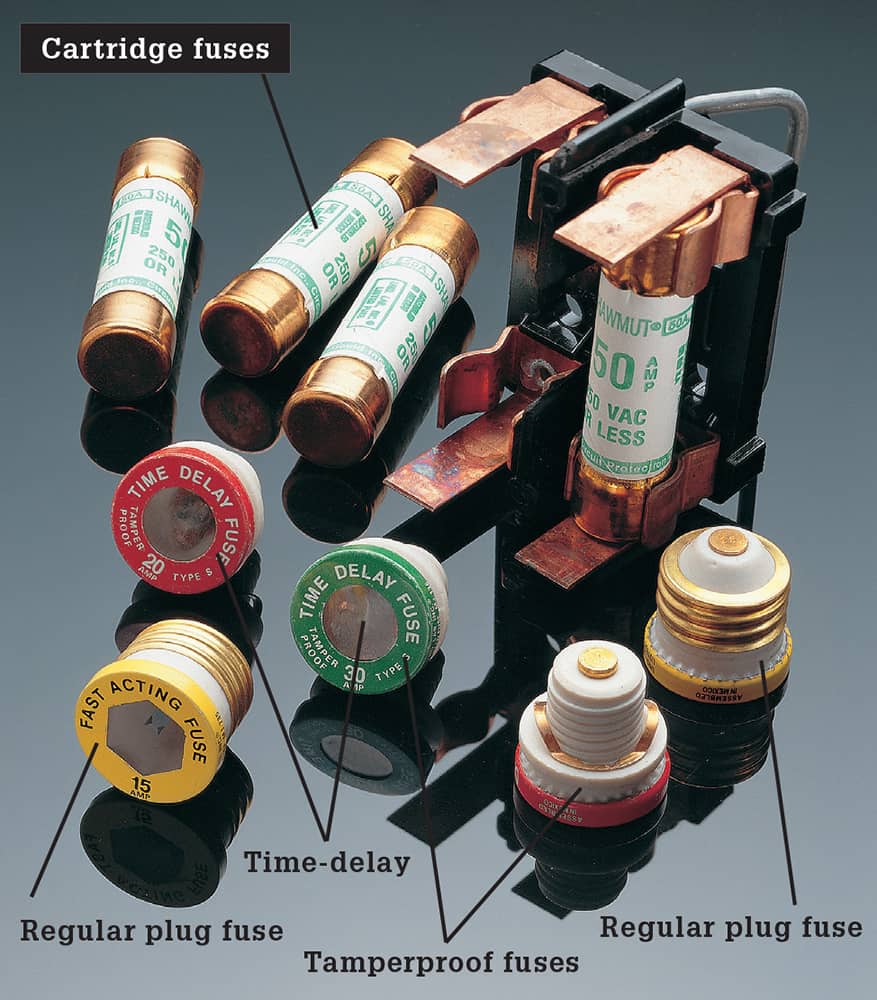

Most service panels installed before 1965 rely on fuses to protect individual circuits. Screw-in plug fuses protect 120-volt circuits that power lights and receptacles. Cartridge fuses protect 240-volt appliance circuits and the main shutoff of the service panel.

Inside each fuse is a current-carrying metal alloy ribbon. If a circuit is overloaded, the metal ribbon melts and stops the current flow. A fuse must match the amperage rating of the circuit. Never replace a fuse with one that has a larger amperage rating.

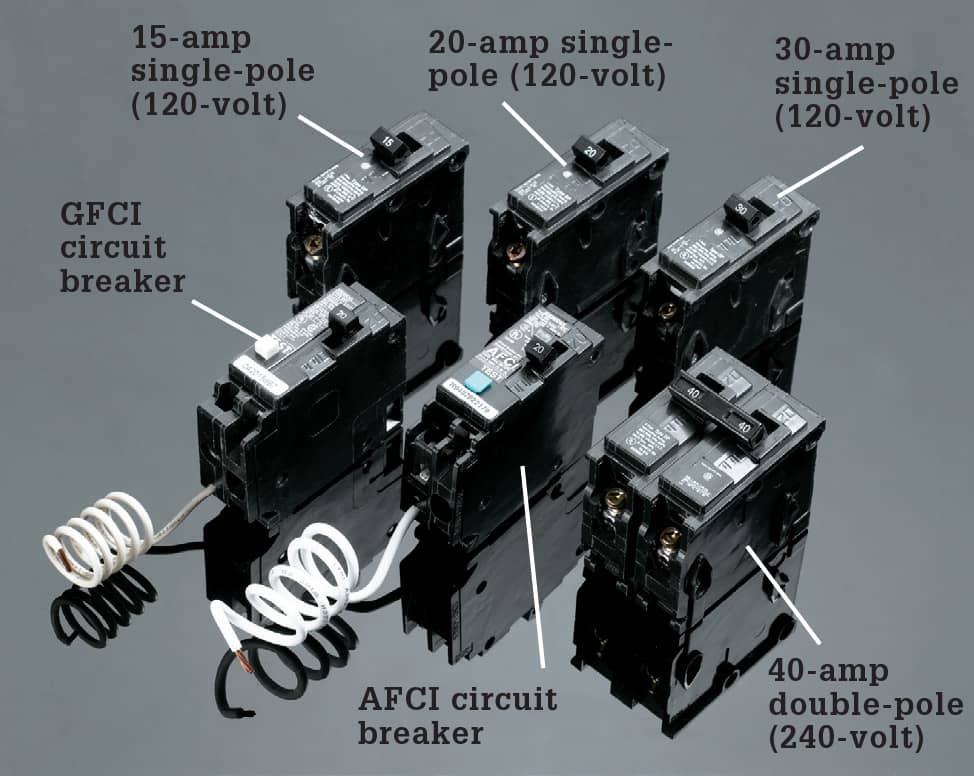

In most service panels installed after 1965, circuit breakers protect individual circuits. Single-pole circuit breakers protect 120-volt circuits, and double-pole circuit breakers protect 240-volt circuits. Amperage ratings for circuit breakers range from 15 to 100 amps.

Each circuit breaker has a permanent metal strip that heats up and bends when current passes through it. If a circuit is overloaded, the metal strip inside the breaker bends enough to “trip” the switch and stop the flow of power. Circuit breakers are listed to trip twice. After the second trip they weaken and tend to nuisance trip at lower currents. Replace breakers that have tripped more than twice—they may fail.

When a fuse blows or a circuit breaker trips, it is usually because there are too many light fixtures and plug-in appliances drawing power through the circuit. Move some of the plug-in appliances to another circuit, and then replace the fuse or reset the breaker. If the fuse blows or the breaker trips again immediately, there may be a short circuit in the system. Call a licensed electrician if you suspect a short circuit.

Old-style fuse boxes can accept modern “s” type fuses if you use an Edison adapter. Be sure to screw the fuse into the adapter first, and then screw the assembly into the socket.

Circuit breakers are found in the majority of panels installed since the 1960s. Single-pole breakers control 120-volt circuits. Double-pole breakers rated for 20 to 60 amps control 240-volt circuits. Ground-fault circuit interrupter (GFCI) provides protection from shocks. Arc-fault circuit interrupter (AFCI) breakers provide protection from fire-causing arcs for the entire circuit.

Fuses are used in older panels. Plug fuses usually control 120-volt circuits rated for 15, 20, or 30 amps. Tamper-proof plug fuses have threads that fit only matching sockets, making it impossible to install a wrong-sized fuse. Time-delay fuses absorb temporary heavy power loads without blowing. Cartridge fuses control 240-volt circuits and range from 30 to 100 amps.

How to Identify & Replace a Blown Plug Fuse

Locate the blown fuse at the panel. If the metal ribbon inside is cleanly melted (left), the circuit was overloaded. If window is discolored (right), there was a short circuit.

Unscrew the fuse, being careful to touch only the insulated rim of the fuse. Replace it with a fuse that has the same amperage rating.

How to Remove, Test & Replace a Cartridge Fuse

Remove cartridge fuses by gripping the handle of the fuse block and pulling sharply.

Remove the individual cartridge fuses from the block using a fuse puller.

Test each fuse using a continuity tester. If the tester glows, the fuse is good. If not, install a new fuse with the same amperage rating.

How to Reset a Circuit Breaker

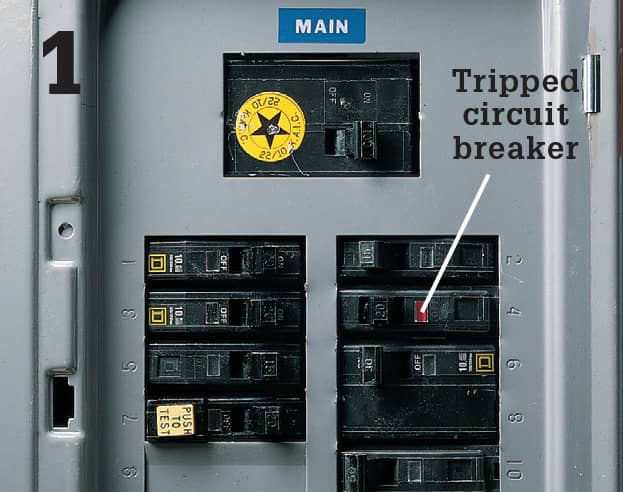

Open the service panel and locate the tripped breaker. The lever on the tripped breaker will be either in the OFF position or in a position between ON and OFF.

Reset the tripped circuit breaker by pressing the circuit breaker lever all the way to the OFF position and then pressing it to the ON position.

Test AFCI and GFCI circuit breakers by pushing the TEST button. The breaker should trip to the OFF position. If not, the breaker is faulty and must be replaced.

Connecting Circuit Breakers

The last step in a wiring project is connecting circuits at the breaker panel. After this is done, the work is ready for the final inspection.

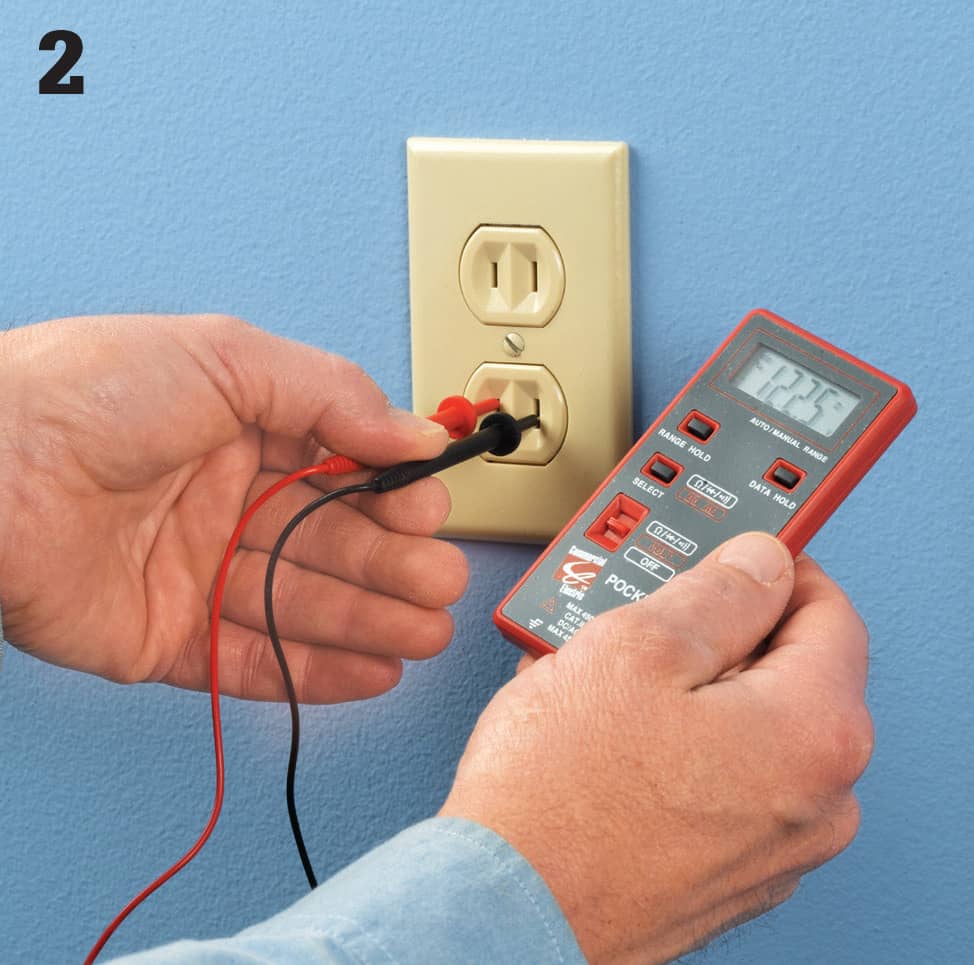

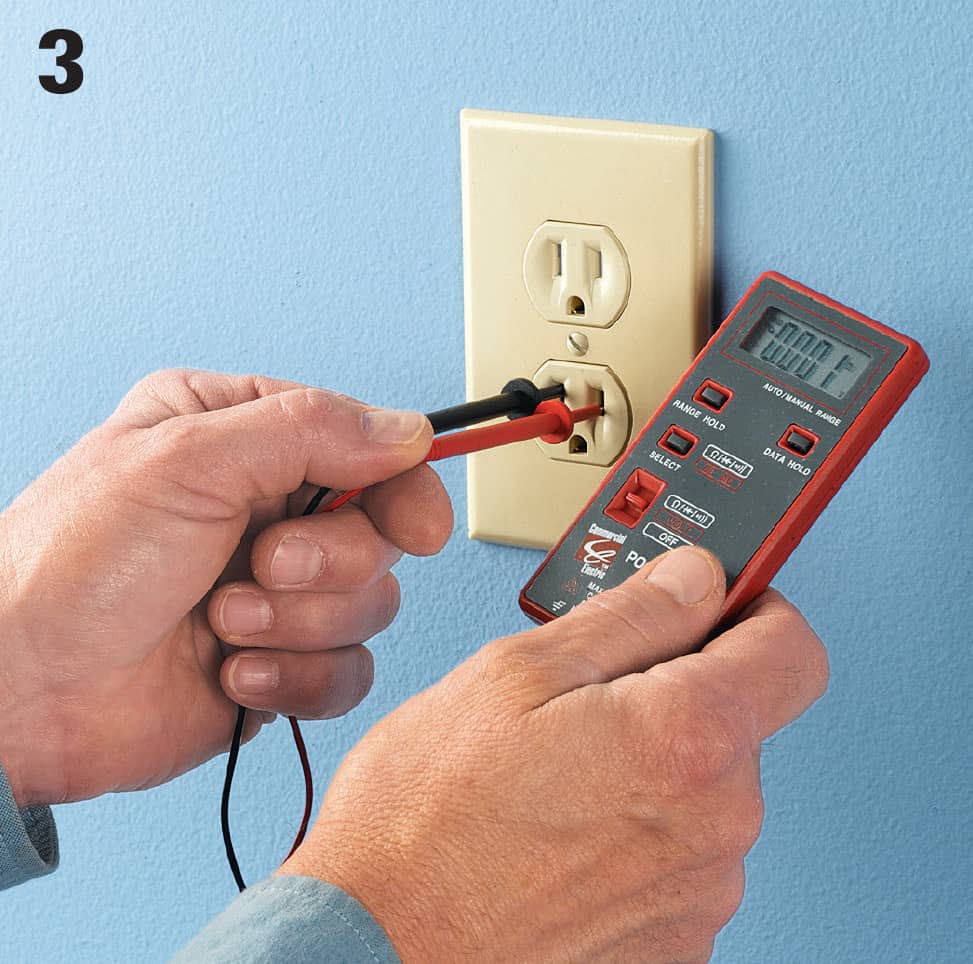

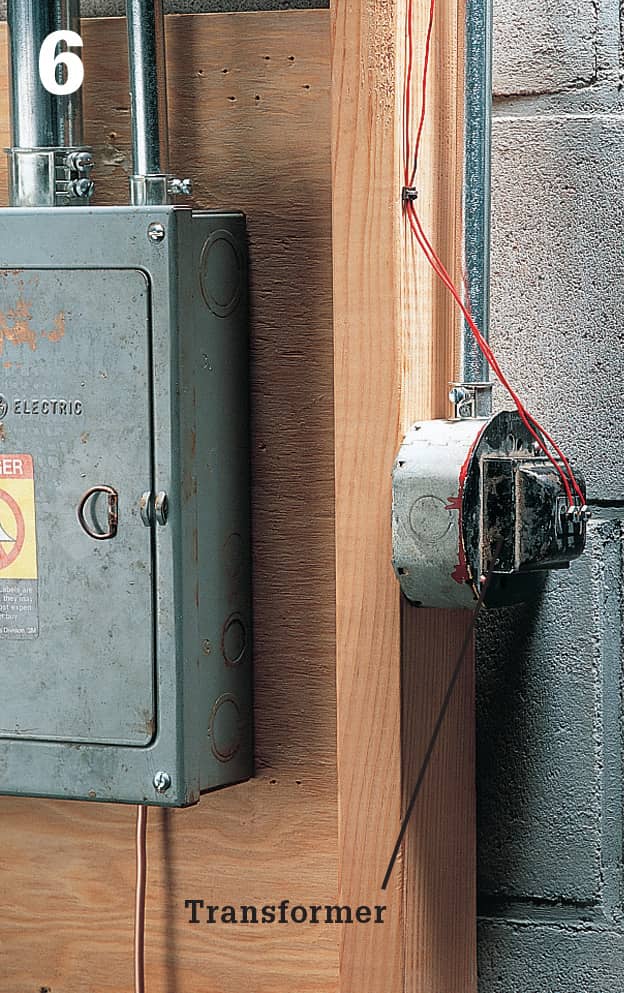

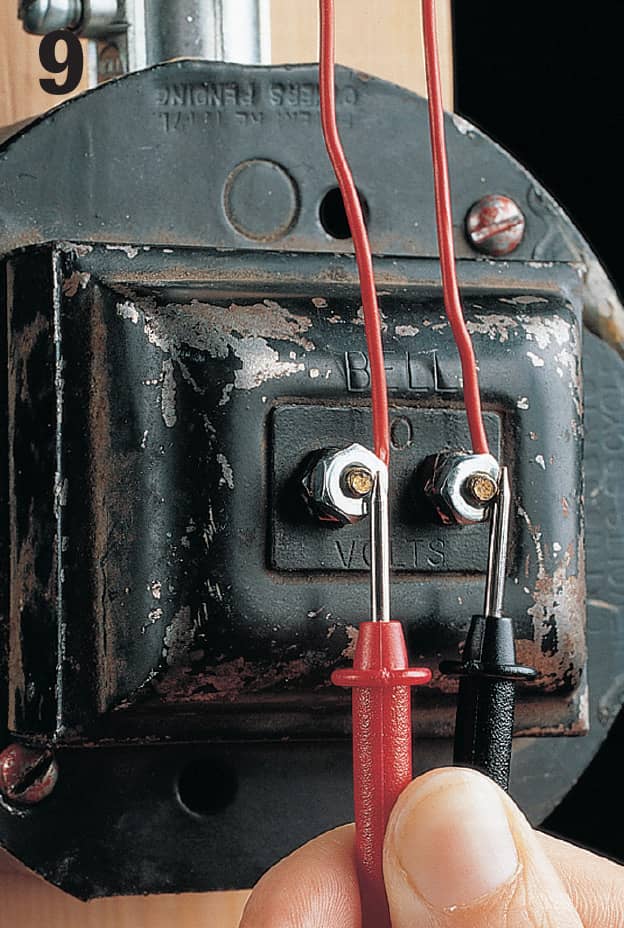

Circuits are connected at the main panel, if it has enough open slots, or at a circuit breaker subpanel (see pages 410 to 411). When working at a subpanel, make sure the feeder breaker at the main panel has been turned off, and test for power (see photo, right) before touching any parts in the subpanel.

Make sure the circuit breaker amperage does not exceed the ampacity of the circuit wires you are connecting to it. Also be aware that circuit breaker styles and installation techniques vary according to manufacturer. Use breakers made by the panel manufacturer. You should install AFCI circuit breakers for most 15- and 20-amp, 120-volt circuits inside the home.

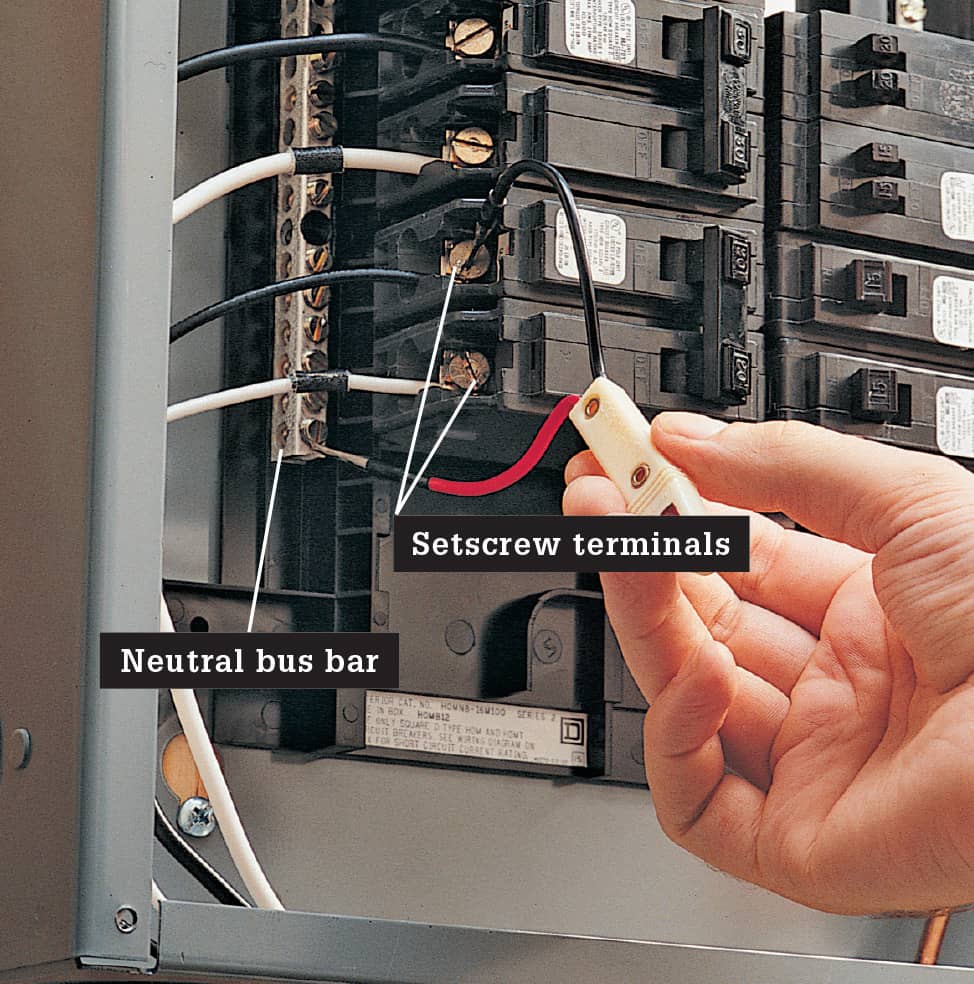

Test for current before touching any parts inside a circuit breaker panel. With the main breaker turned off but all other breakers turned on, touch one probe of a neon tester to the neutral bus bar, and touch the other probe to each setscrew on one of the double-pole breakers (not the main breaker). If the tester does not light for either setscrew, it is safe to work in the panel. NOTE: Touchless circuit testers are preferred in most situations where you are testing for current because they’re safer. But in some instances you’ll need a tester with individual probes to properly check for current.

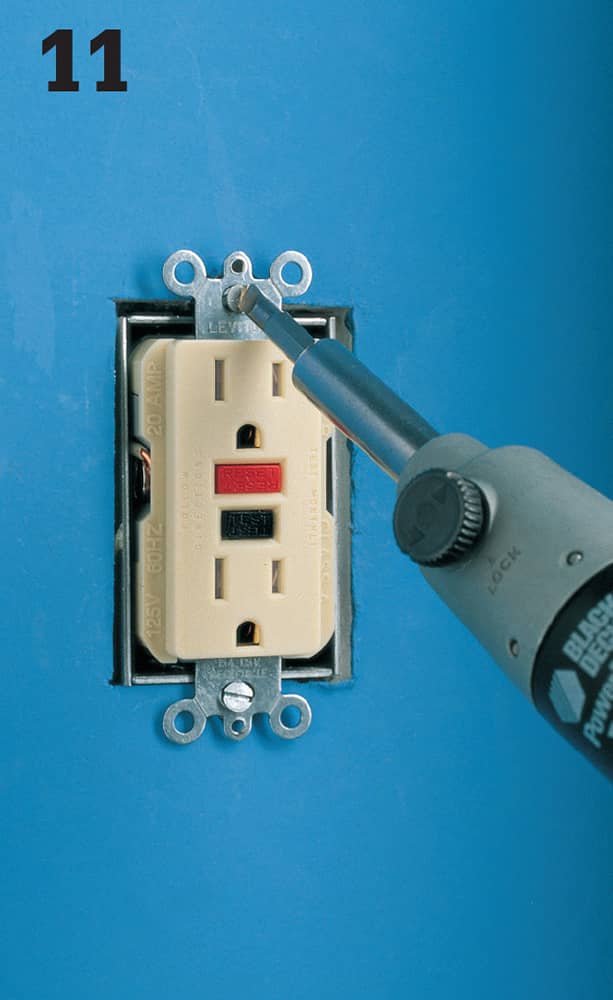

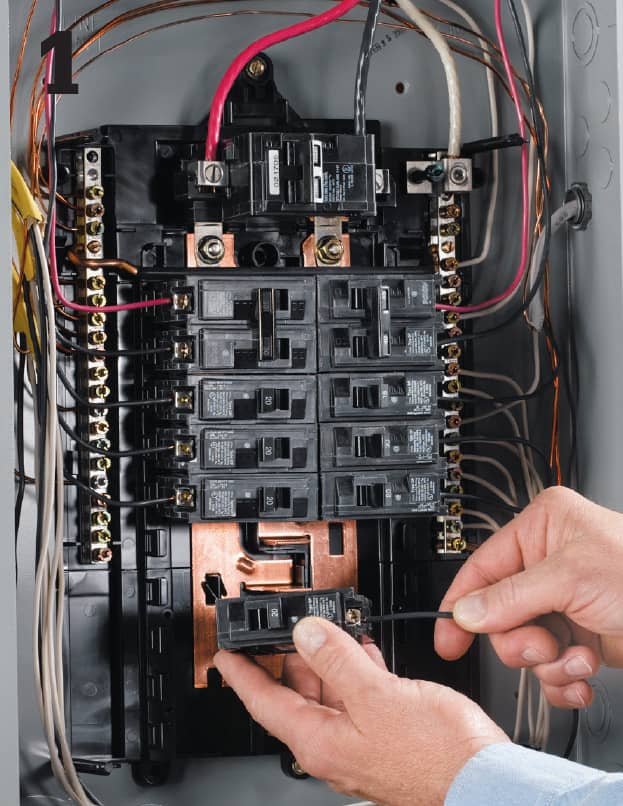

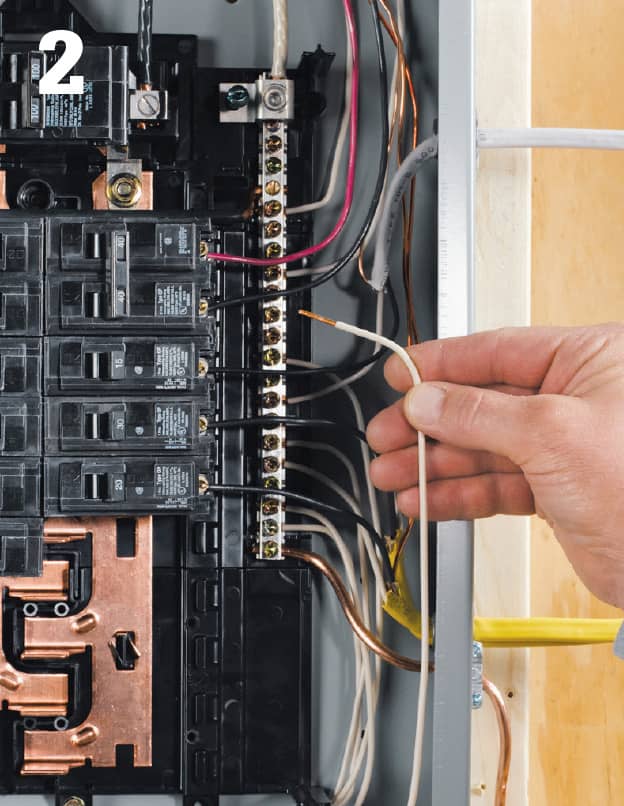

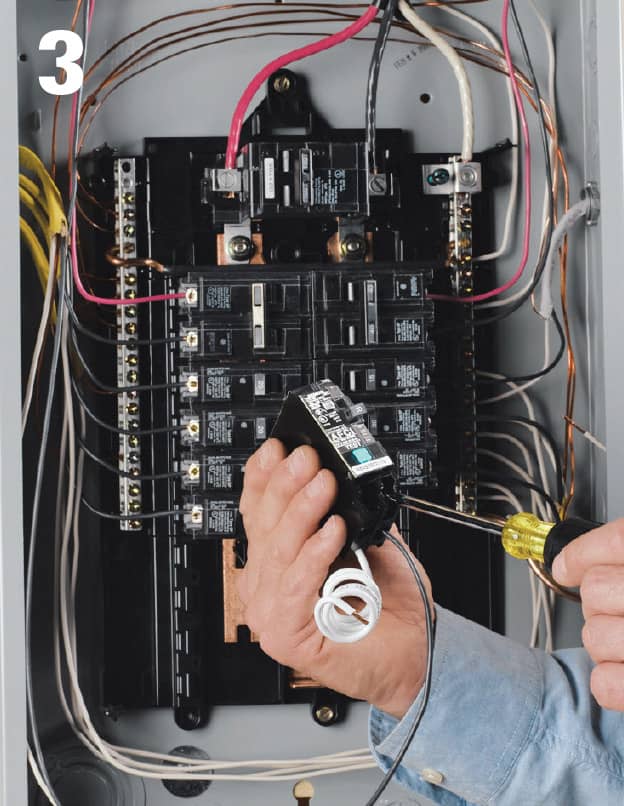

How to Connect Circuit Breakers

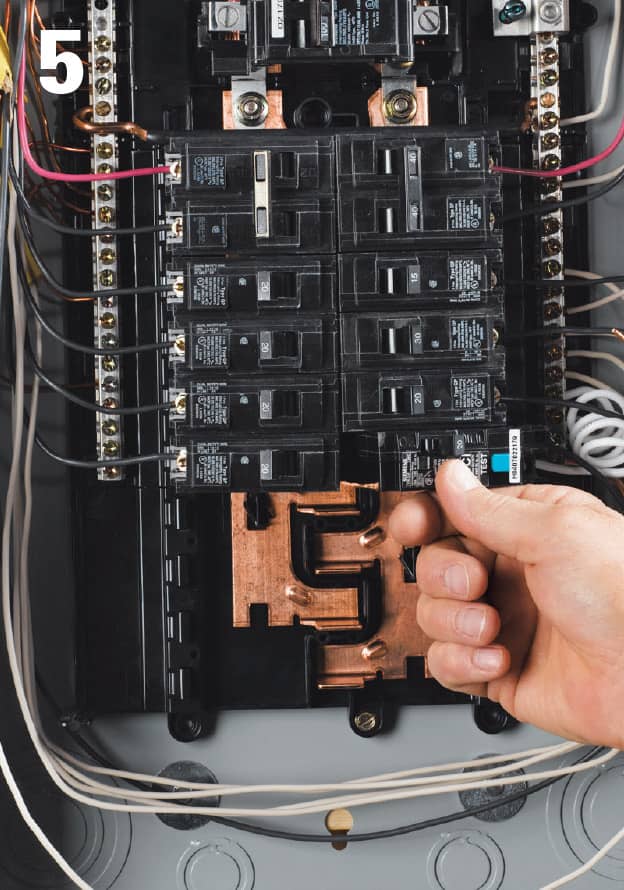

Shut off the main circuit breaker in the main circuit breaker panel (if you are working in a subpanel, shut off the feeder breaker in the main panel). Remove the panel cover plate, taking care not to touch the parts inside the panel. Test for power (photo, top).

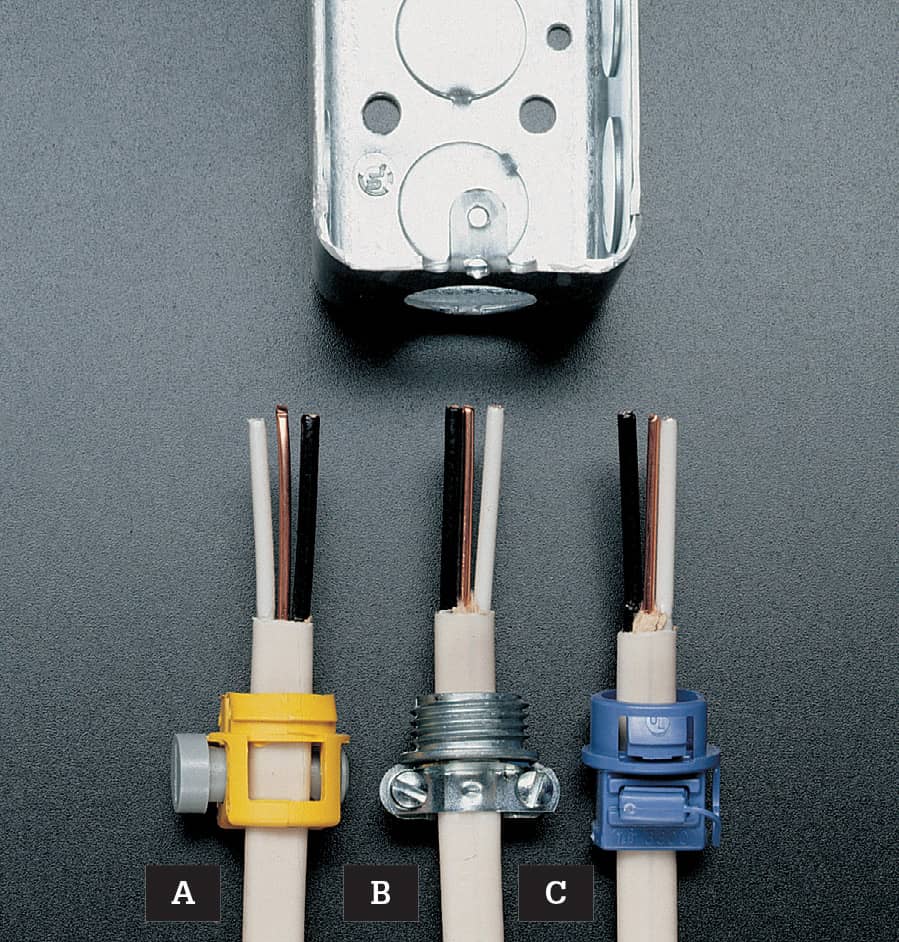

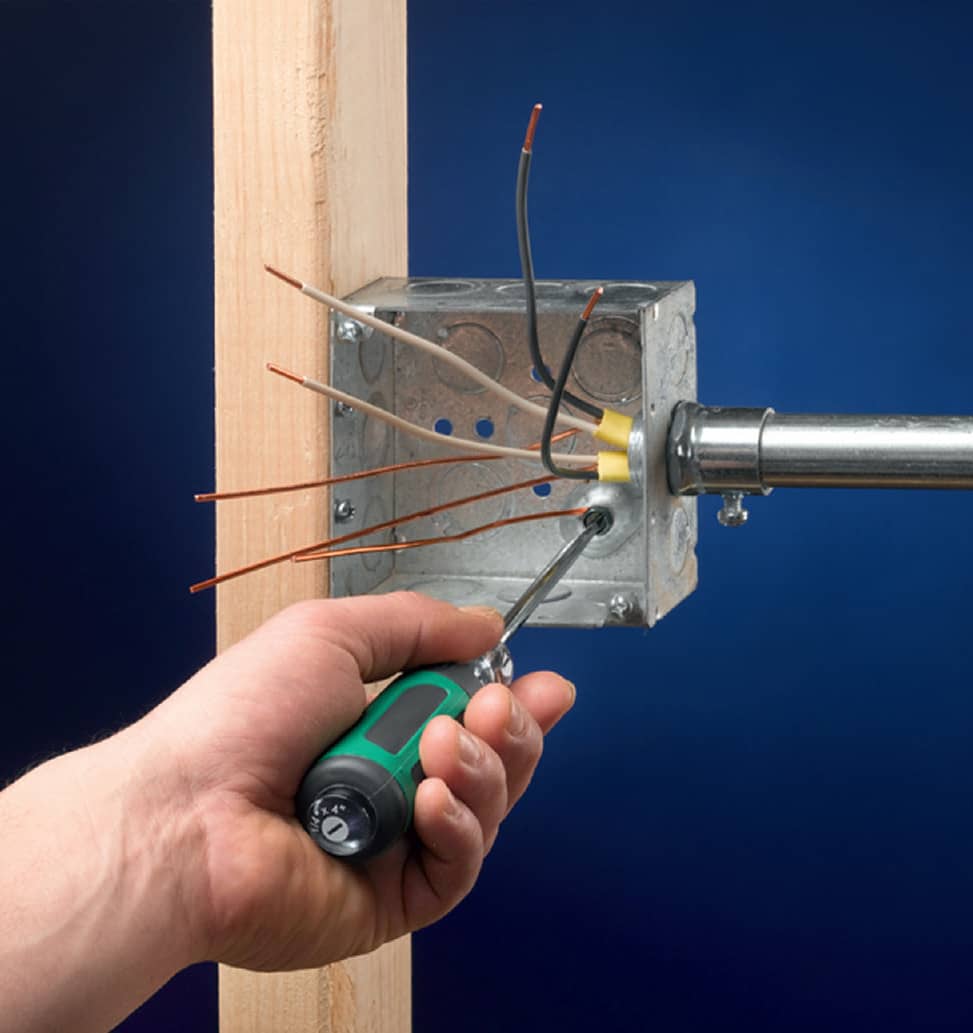

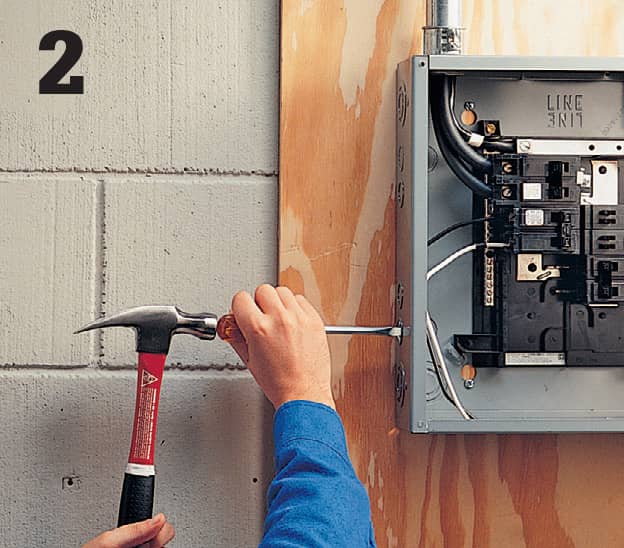

Open a knockout in the side of the circuit breaker panel using a screwdriver and hammer. Attach a cable clamp to the knockout.

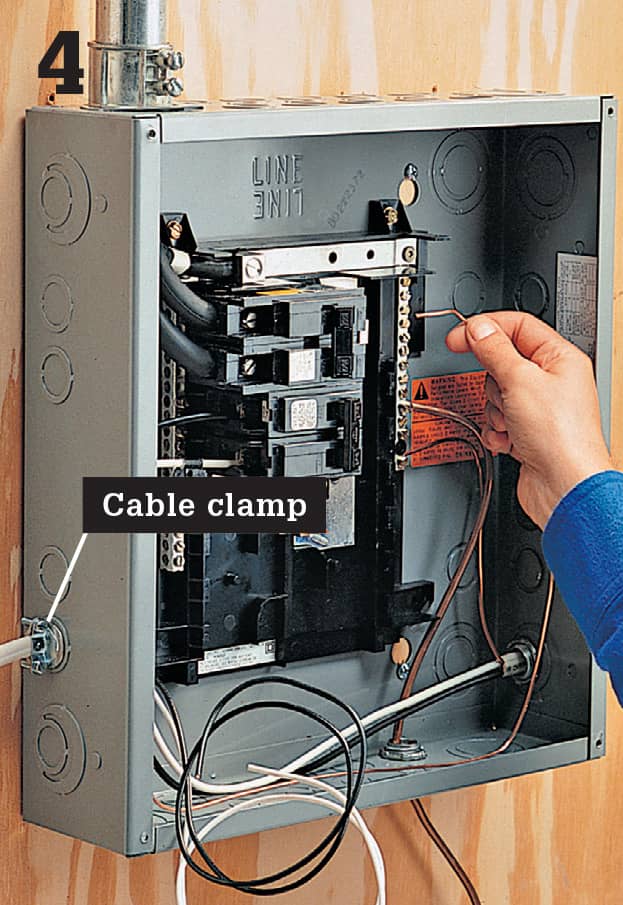

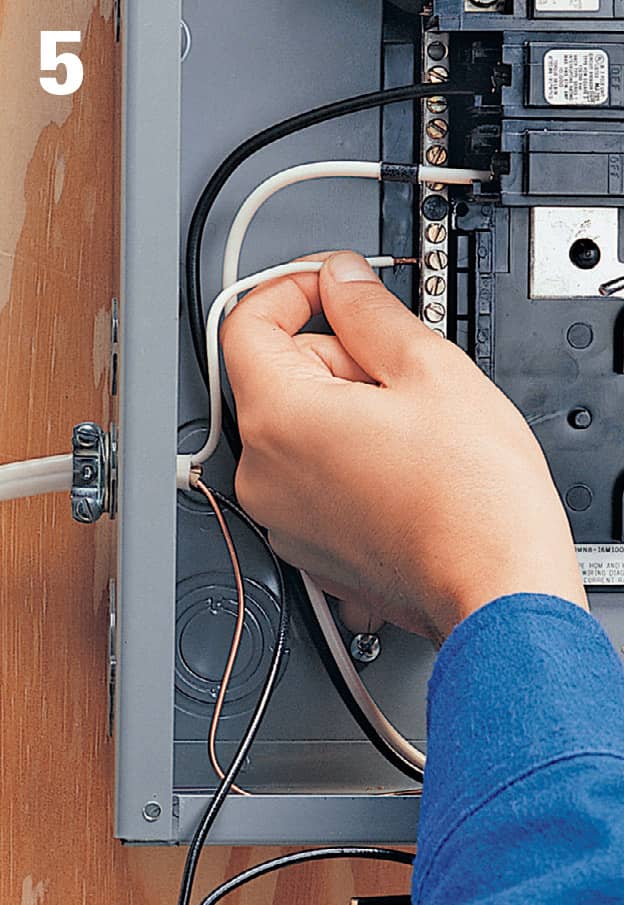

Hold the cable across the front of the panel near the knockout, and mark the sheathing about 1/2" inside the edge of the panel. Strip the cable from the marked line to the end using a cable ripper. (There should be 18" to 24" of excess cable.) Insert the cable through the clamp and into the service panel, and then tighten the clamp.

Bend the bare copper grounding wire around the inside edge of the panel to an open setscrew terminal on the grounding bus bar. Insert the wire into the opening on the bus bar, and tighten the setscrew. Fold excess wire around the inside edge of the panel.

For 120-volt circuits, bend the white circuit wire around the outside of the panel to an open setscrew terminal on the neutral bus bar. Clip away excess wire, and then strip 1/2" of insulation from the wire using a combination tool. Insert the wire into the terminal opening, and tighten the setscrew.

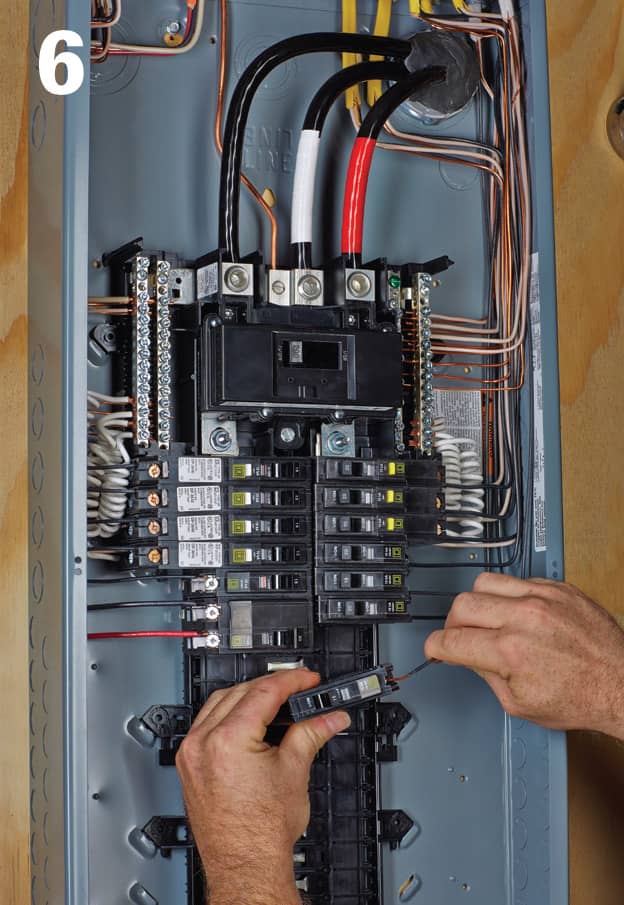

Strip 1/2" of insulation from the end of the black circuit wire. Insert the wire into the setscrew terminal on a new single-pole circuit breaker, and tighten the setscrew.

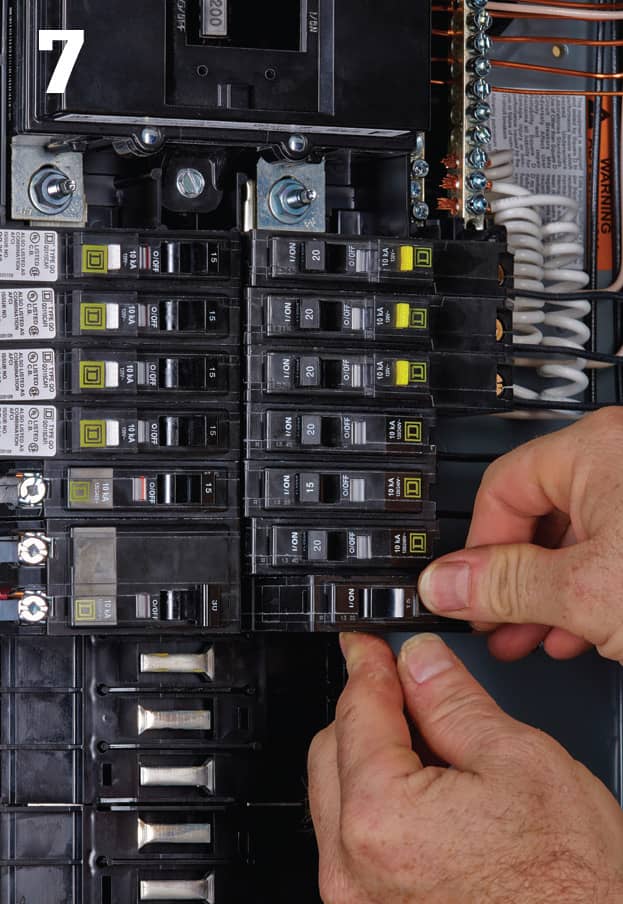

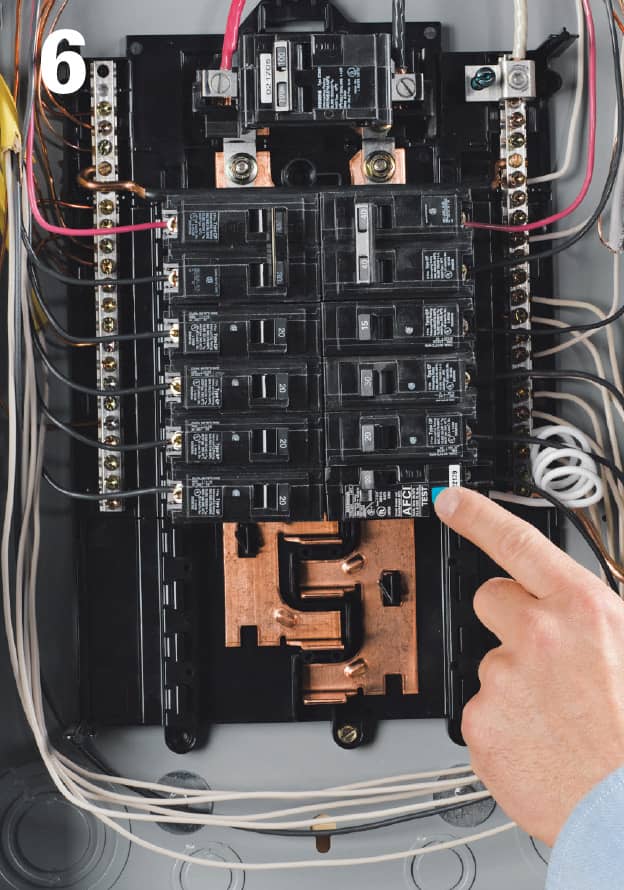

Slide one end of the circuit breaker onto the guide hook, and then press it firmly against the bus bar until it snaps into place. (Breaker installation may vary, depending on the manufacturer.) Fold excess black wire around the inside edge of the panel.

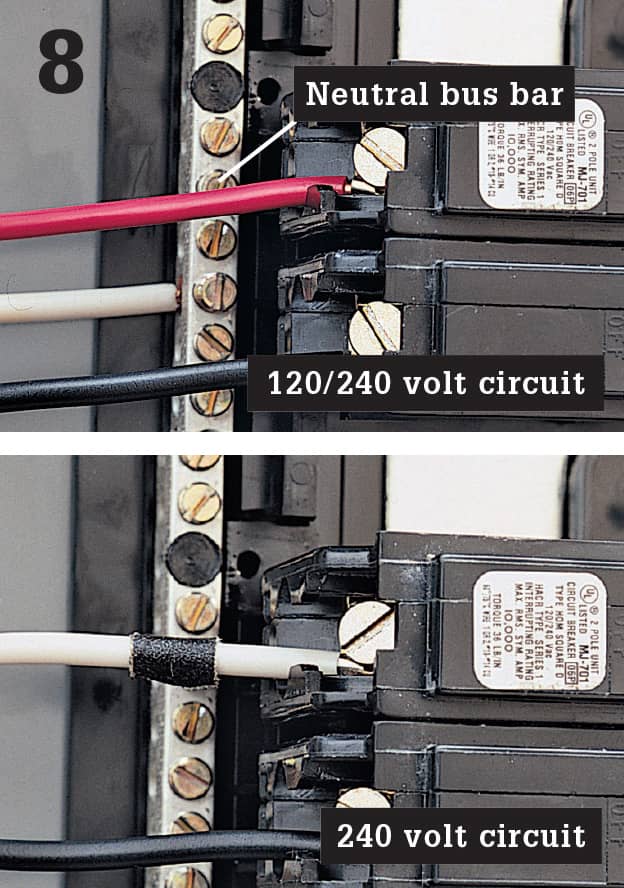

120/240-volt circuits (top): Connect red and black wires to the double-pole breaker. Connect white wire to the neutral bus bar, and the grounding wire to grounding bus bar. For 240-volt circuits (bottom), attach white and black wires to the double-pole breaker, tagging white wire with black tape. There is no neutral bus bar connection on this circuit.

Remove the appropriate breaker tab on the panel cover plate to make room for the new circuit breaker. A single-pole breaker requires one tab, while a double-pole breaker requires two tabs. Reattach the cover plate, and label the new circuit on the panel index.

Wall Switches

Wall Switches

An average wall switch is turned on and off more than 1,000 times each year. Because switches receive constant use, wire connections can loosen and switch parts gradually wear out. If a switch no longer operates smoothly, it must be replaced.

The methods for replacing a switch vary slightly, depending on the switch type and its location along an electrical circuit. When working on a switch, use the photographs on pages 418 to 429 to identify your switch type and its wiring configuration. Individual switch styles may vary from manufacturer to manufacturer, but the basic switch types are universal.

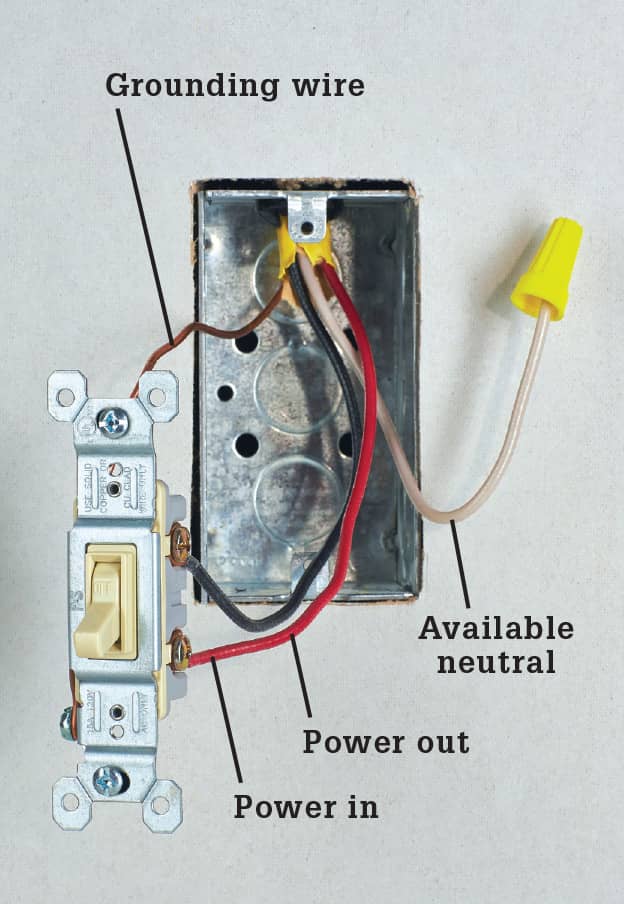

It is possible to replace most ordinary wall switches with a specialty switch, such as a timer switch or an electronic switch. When installing a specialty switch, make sure it is compatible with the wiring configuration and size of the switch box. Notice: Two changes in the NEC affect how new switch wiring should be installed. These changes do not affect existing switch wiring. The pictures and instructions in this book about replacing existing switches show wiring that does not comply with these new requirements. This is because you will probably see non-compliant wiring for many years to come. Pictures and instructions about installing new switch wiring show wiring that complies with these new requirements.

One change requires that a wire with white insulation should not supply current to a light or receptacle, even when the wire is marked as hot. A black or red colored wire should supply current to the device. A white colored wire, marked as hot, may supply current to the switch.

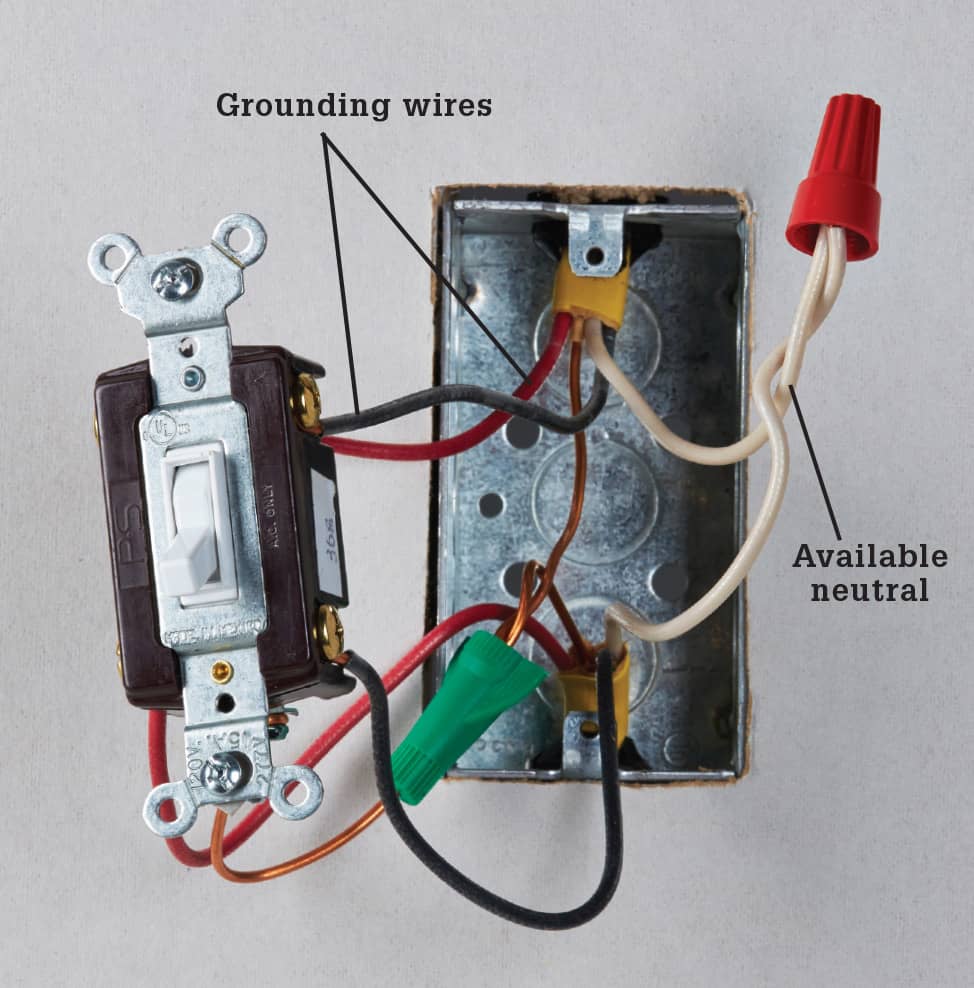

The other change requires that a neutral wire be available at switch boxes. An exception allows you to ignore this requirement if the switch box is accessible from above or below, such as from a basement, crawlspace, or attic. This new requirement is intended to allow easier installation of devices, such as intelligent switch controllers, that need power for controller operation.

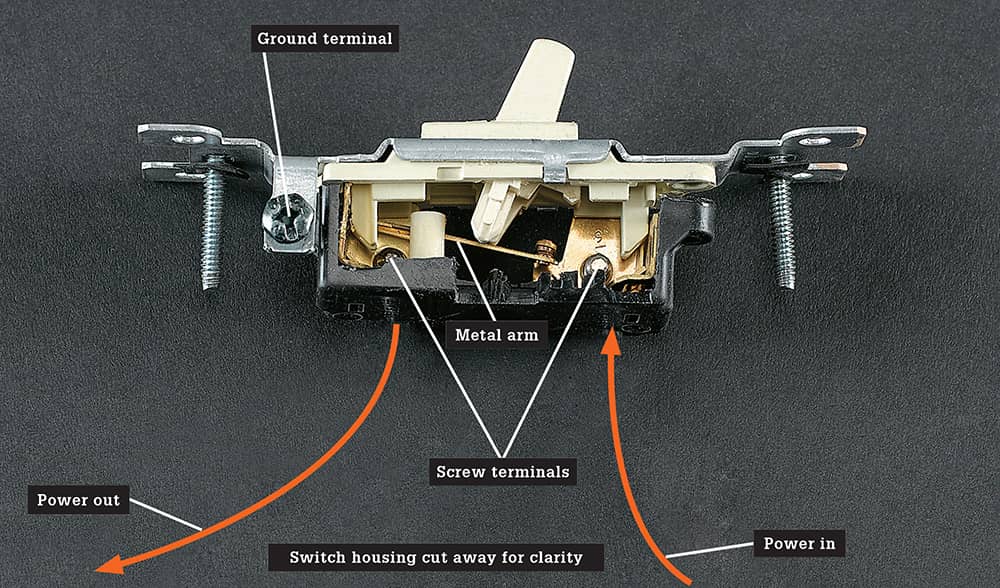

A typical wall switch has a movable metal arm that opens and closes the electrical circuit. When the switch is ON, the arm completes the circuit and power flows between the screw terminals and through the black hot wire to the light fixture. When the switch is OFF, the arm lifts away to interrupt the circuit, and no power flows. Switch problems can occur if the screw terminals are not tight or if the metal arm inside the switch wears out. NOTE: The switch above has had part of its housing removed so the interior workings can be seen. Switches or fixtures that are not in original condition should never be installed.

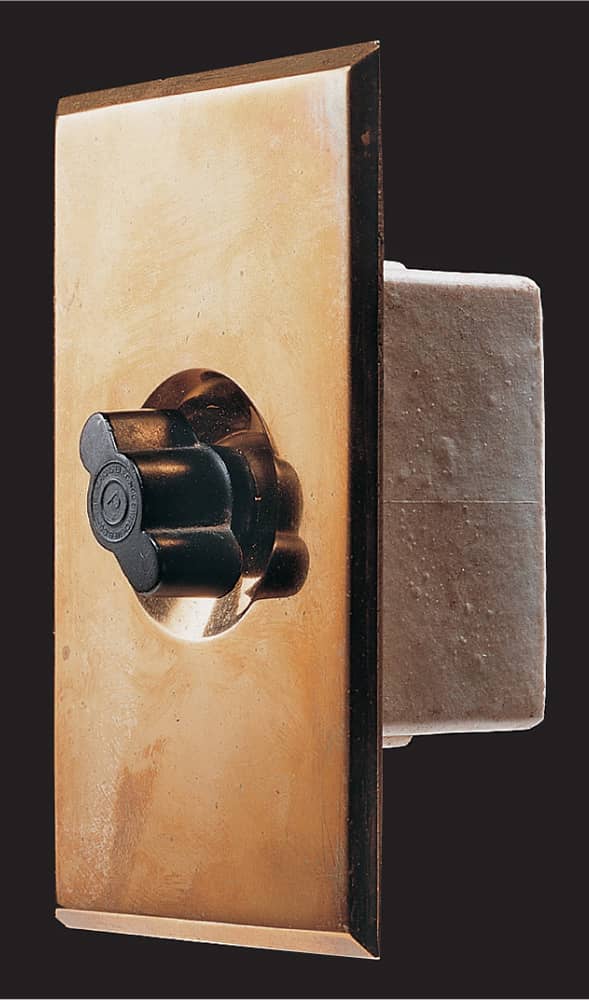

Rotary snap switches are found in many installations completed between 1900 and 1920. The handle is twisted clockwise to turn light on and off. The switch is enclosed in a ceramic housing.

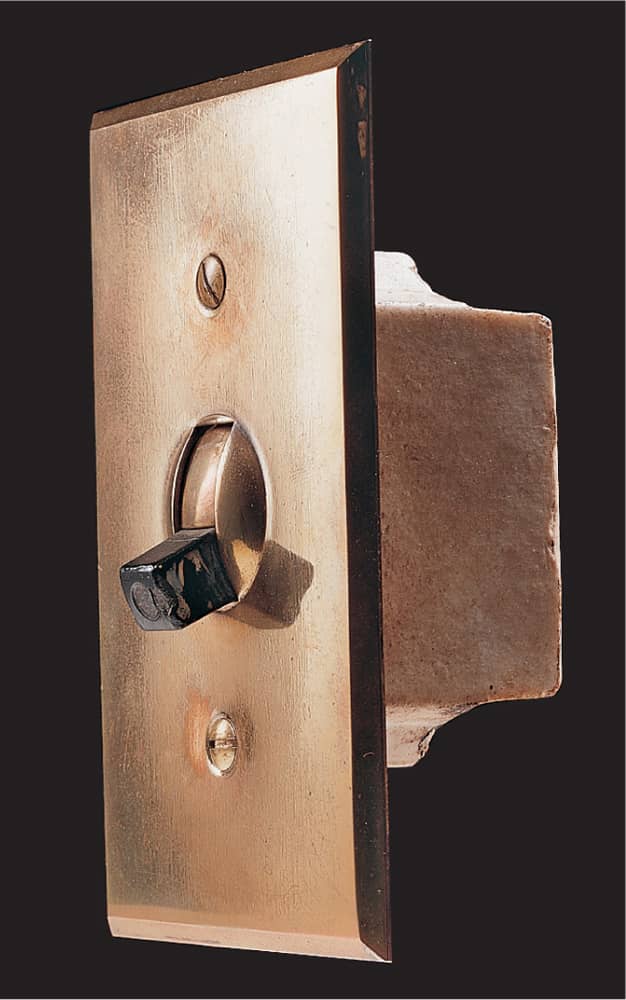

Push-button switches were widely used from 1920 until about 1940. Many switches of this type are still in operation. Reproductions of this switch type are available for restoration projects.

Toggle switches were improved during the 1950s and are now the most commonly used type. This switch type was the first to use a sealed plastic housing that protects the inner switch mechanism from dust and moisture.

Toggle switches were introduced in the 1930s. This early design has a switch mechanism that is mounted in a ceramic housing sealed with a layer of insulating paper.

Mercury switches became common in the early 1960s. They conduct electrical current by means of a sealed vial of mercury. No longer manufactured for home use, old mercury switches are considered a hazardous waste.

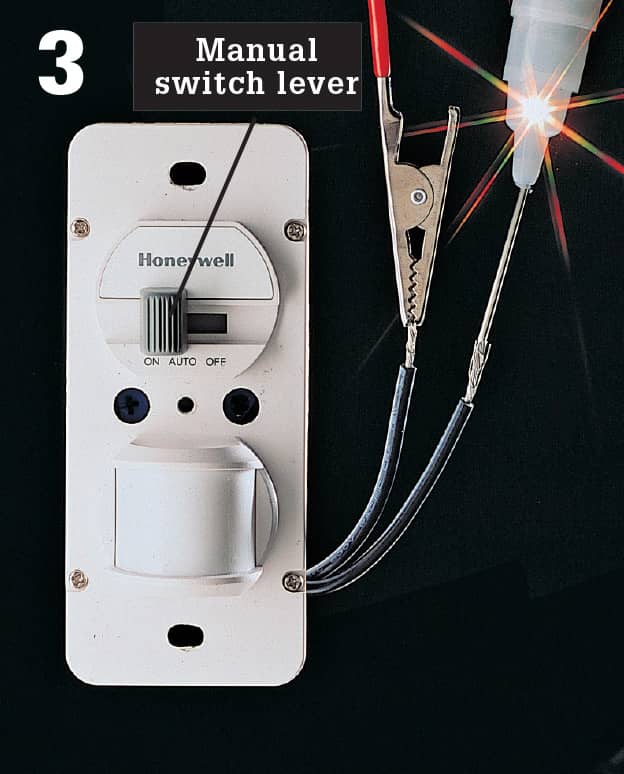

Electronic motion-sensor switches have an infrared eye that senses movement and automatically turns on lights when a person enters a room. Motion-sensor switches can provide added security against intruders.

Types of Wall Switches

Types of Wall Switches

Wall switches are available in three general types. To reconnect or replace a switch, it is important to identify its type.

Single-pole switches are used to control a set of lights from one location. Three-way switches are used to control a set of lights from two different locations and are always installed in pairs. Four-way switches are used in combination with a pair of three-way switches to control a set of lights from three or more locations.

Identify switch types by counting the terminals. Single-pole switches have two screw terminals, three-way switches have three screw terminals, and four-way switches have four. Most switches include a grounding screw terminal, which is identified by its green color.

When replacing a switch, choose a new switch that has the same number of screw terminals as the old one. The location of the screws on the switch body varies depending on the manufacturer, but these differences will not affect the switch operation.

Whenever possible, connect switches using the screw terminals rather than push-in fittings. Some specialty switches (pages 94 to 97) have wire leads instead of screw terminals. They are connected to circuit wires with wire connectors.

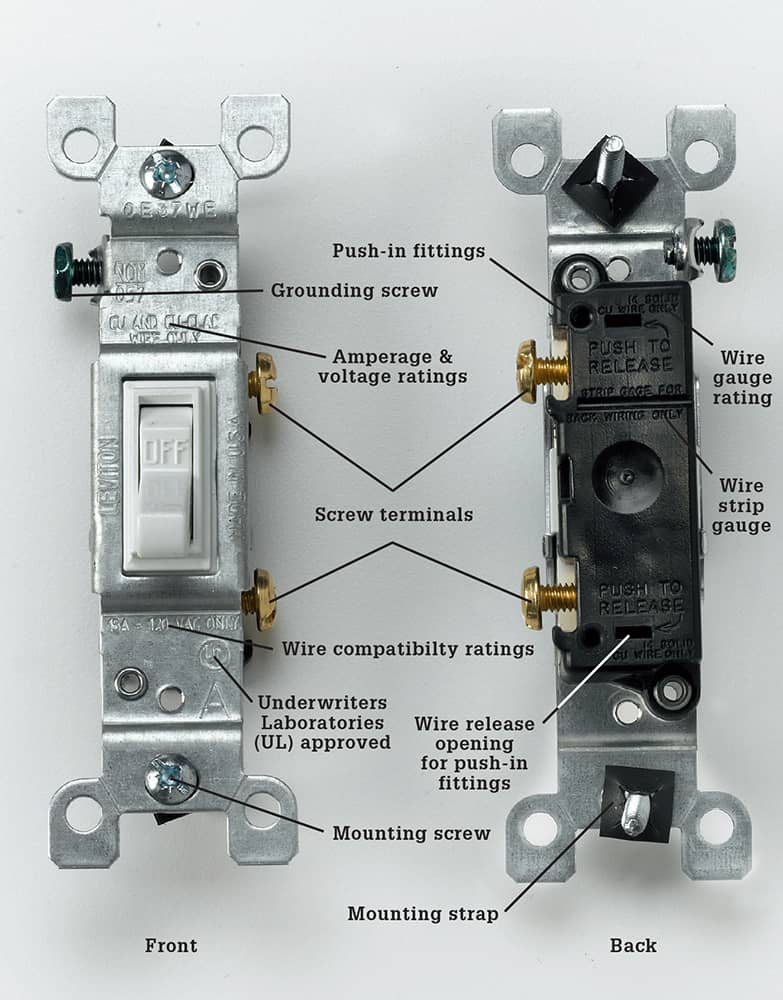

A wall switch is connected to circuit wires with screw terminals or with push-in fittings on the back of the switch. A switch may have a stamped strip gauge that indicates how much insulation must be stripped from the circuit wires to make the connections.

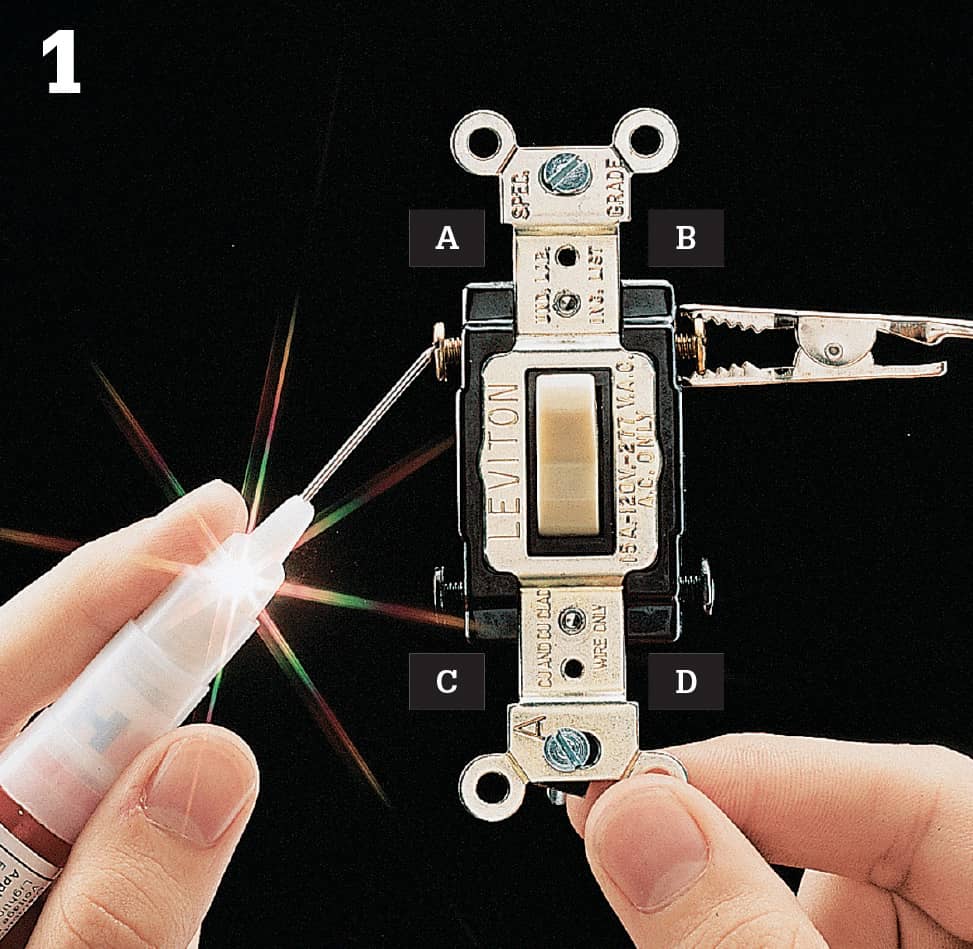

The switch body is attached to a metal mounting strap that allows it to be mounted in an electrical box. Several rating stamps are found on the strap and on the back of the switch. The abbreviation UL or UND. LAB. INC. LIST means that the switch meets the safety standards of the Underwriters Laboratories. Switches also are stamped with maximum voltage and amperage ratings. Standard wall switches are rated 15A or 125V. Voltage ratings of 110, 120, and 125 are considered to be identical for purposes of identification.

For standard wall switch installations, choose a switch that has a wire gauge rating of #12 or #14. For wire systems with solid-core copper wiring, use only switches marked COPPER, CU, or CO/ALR. For aluminum wiring, use only switches marked CO/ALR. Note that while CO/ALR switches and receptacles are approved by the National Electrical Code for use with aluminum wiring, the Consumer Products Safety Commission does not recommend using these. Switches and receptacles marked AL/CU can no longer be used with aluminum wiring, according to the National Electrical Code.

Single-Pole Wall Switches

A single-pole switch is the most common type of wall switch. It has ON-OFF markings on the switch lever and is used to control a set of lights, an appliance, or a receptacle from a single location. A single-pole switch has two screw terminals and a grounding screw. When installing a single-pole switch, check to make sure the ON marking shows when the switch lever is in the up position.

In a correctly wired single-pole switch, a hot circuit wire is attached to each screw terminal. However, the color and number of wires inside the switch box will vary, depending on the location of the switch along the electrical circuit.

If two cables enter the box, then the switch lies in the middle of the circuit. In this installation, both of the hot wires attached to the switch are black.

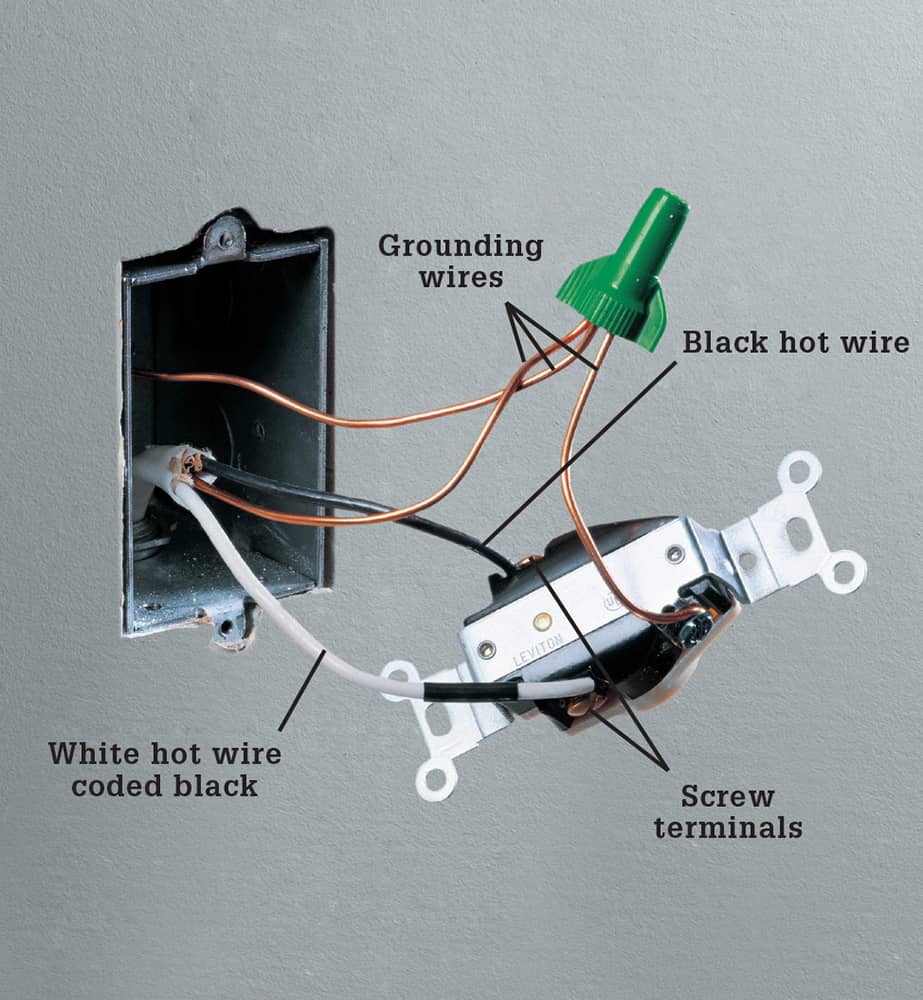

If only one cable enters the box, then the switch lies at the end of the circuit. In this installation (sometimes called a switch loop), one of the hot wires is black, but the other hot wire usually is white. A white hot wire should be coded with black tape or paint.

A single-pole switch is essentially an interruption in the black power supply wire that is opened or closed with the toggle. Single-pole switches are the simplest of all home wiring switches.

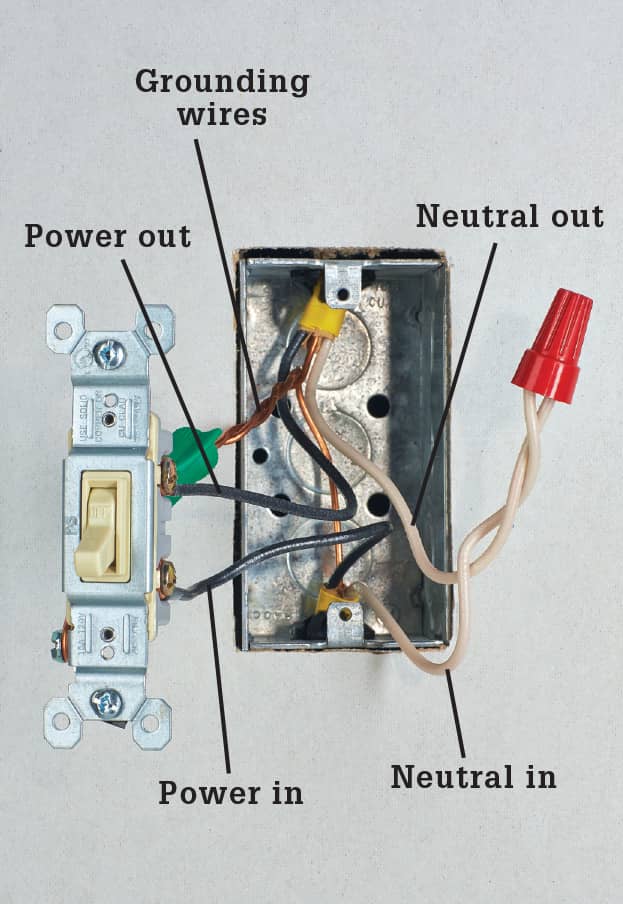

Typical Single-Pole Switch Installations

Two cables enter the box when a switch is located in the middle of a circuit. Each cable has a white and a black insulated wire, plus a bare copper grounding wire. The black wires are hot and are connected to the screw terminals on the switch. The white wires are neutral and are joined together with a wire connector. Grounding wires are pigtailed to the switch.

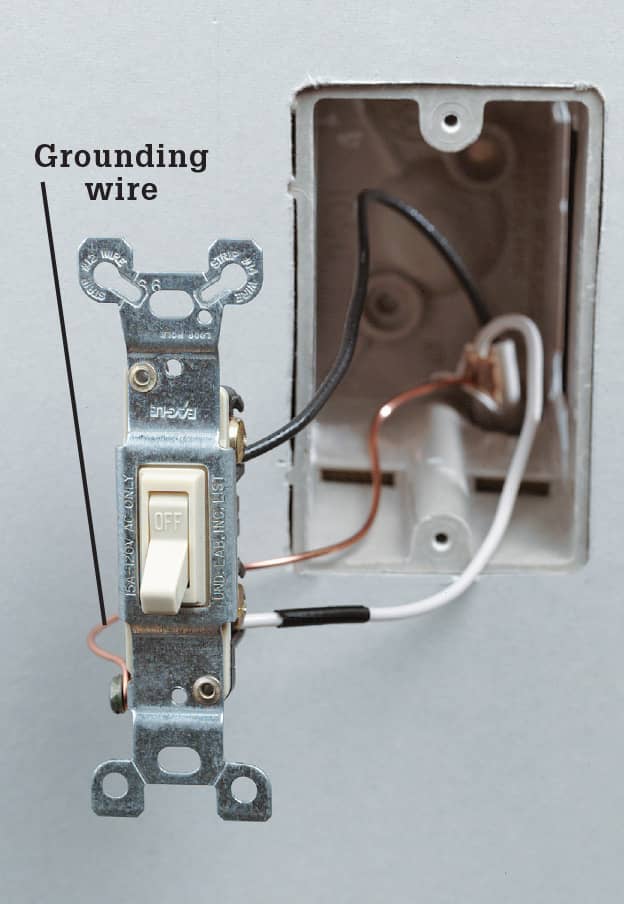

Old method: One cable enters the box when a switch is located at the end of a circuit. In this installation, both of the insulated wires are hot. The white wire should be labeled with black tape or paint to identify it as a hot wire. The grounding wire is connected to the switch grounding screw.

Code change: In new switch wiring, the white wire should not supply current to the switched device and a separate neutral wire should be available in the switch box.

Three-Way Wall Switches

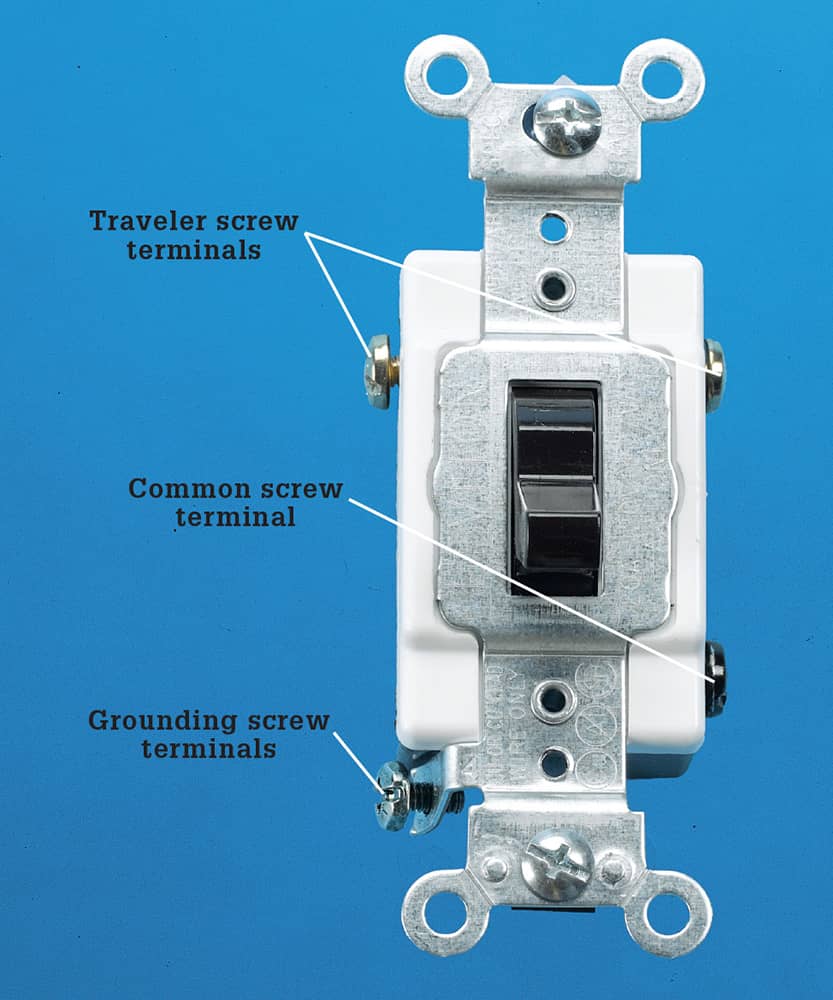

Three-way switches have three screw terminals and do not have ON-OFF markings. Three-way switches are always installed in pairs and are used to control a set of lights from two locations.

One of the screw terminals on a three-way switch is darker than the others. This screw is the common screw terminal. The position of the common screw terminal on the switch body may vary, depending on the manufacturer. Before disconnecting a three-way switch, always label the wire that is connected to the common screw terminal. It must be reconnected to the common screw terminal on the new switch.

The two lighter-colored screw terminals on a three-way switch are called the traveler screw terminals. The traveler terminals are interchangeable, so there is no need to label the wires attached to them.

Because three-way switches are installed in pairs, it sometimes is difficult to determine which of the switches is causing a problem. The switch that receives greater use is more likely to fail, but you may need to inspect both switches to find the source of the problem.

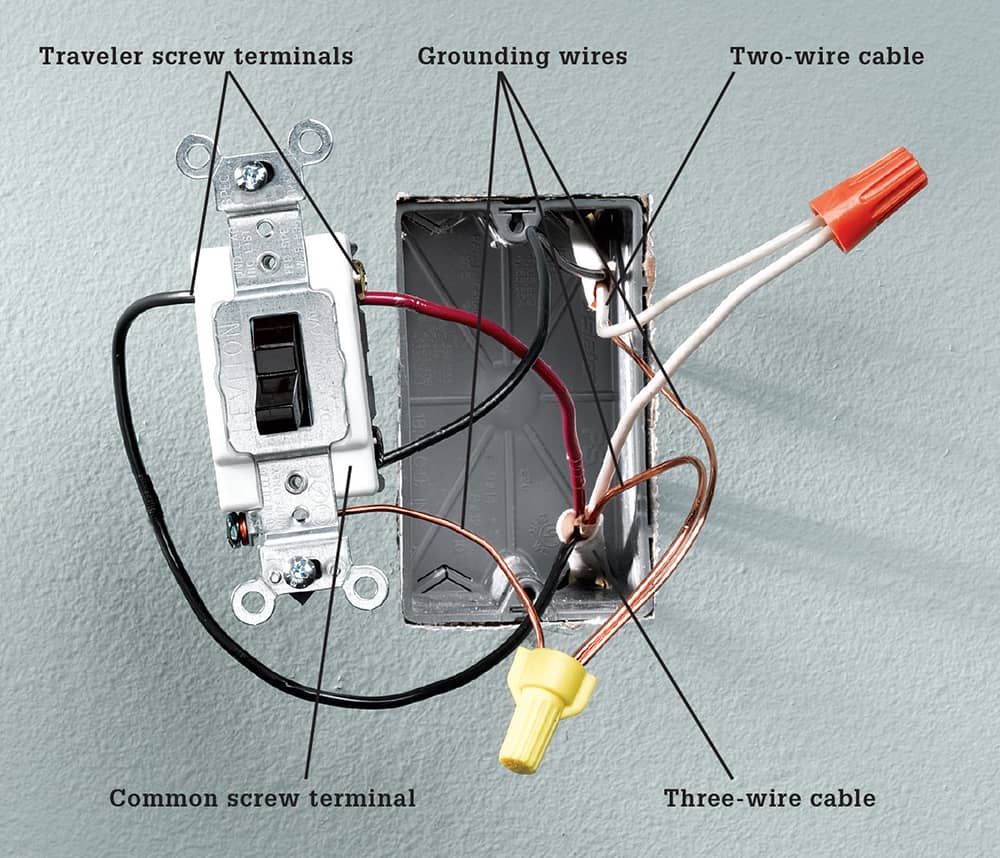

Typical Three-Way Switch Installation

Two cables enter the box: one cable has two wires, plus a bare copper grounding wire; the other cable has three wires, plus a ground. The black wire from the two-wire cable is connected to the dark common screw terminal. The red and black wires from the three-wire cable are connected to the traveler screw terminals. The white neutral wires are joined together with a wire connector, and the grounding wires are pigtailed to the grounded metal box.

How to Fix or Replace a Three-way Wall Switch

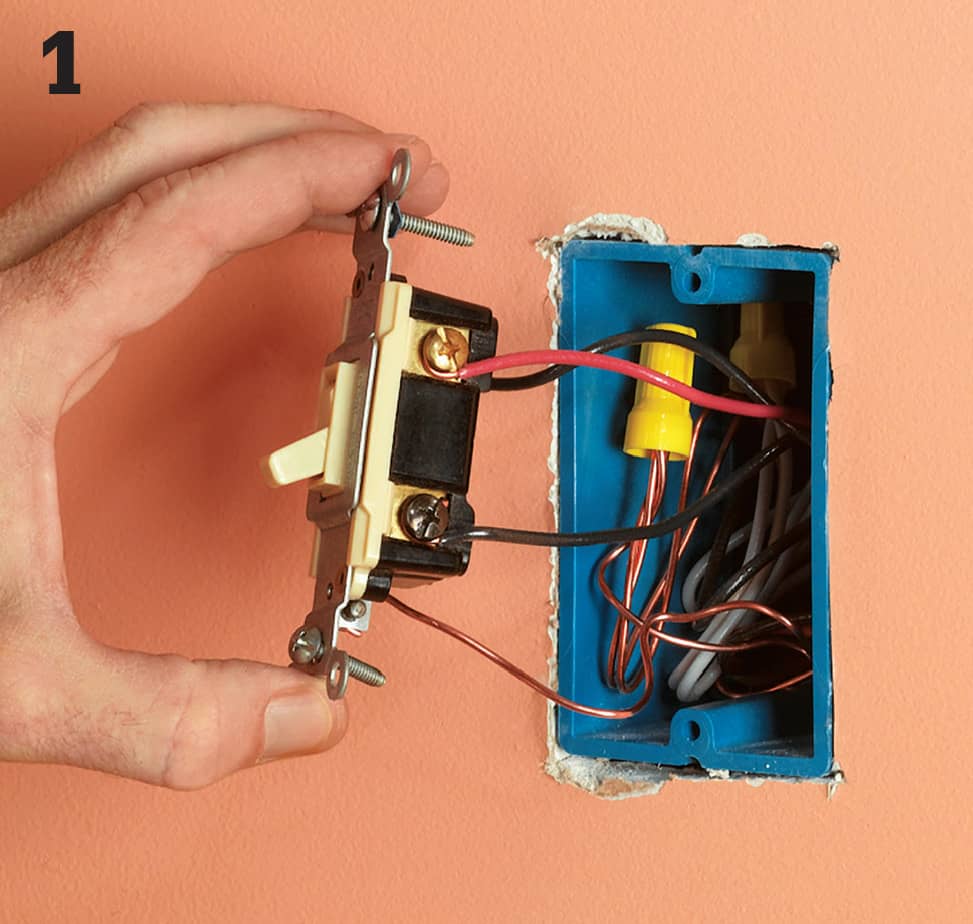

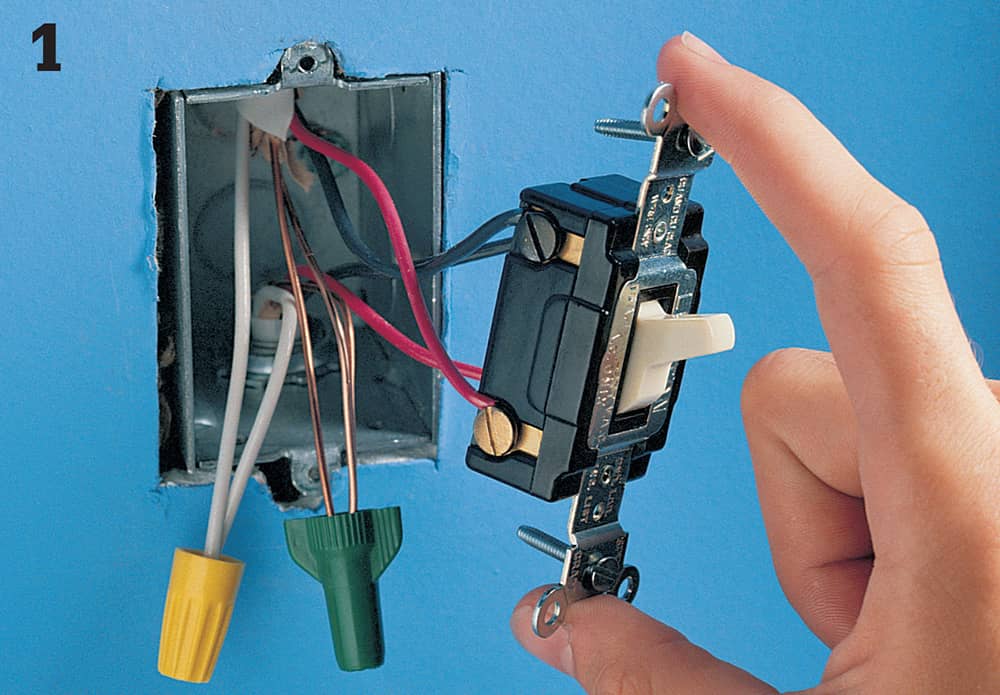

Turn off the power to the switch at the panel, and then remove the switch cover plate and mounting screws. Holding the mounting strap carefully, pull the switch from the box. Be careful not to touch the bare wires or screw terminals until they have been tested for power. NOTE: If you are installing a new switch circuit, you must provide a neutral conductor at the switch.

Test for power by touching one probe of the circuit tester to the grounded metal box or to the bare copper grounding wire and touching the other probe to each screw terminal. Tester should not glow. If it does, there is still power entering the box. Return to the panel, and turn off the correct circuit.

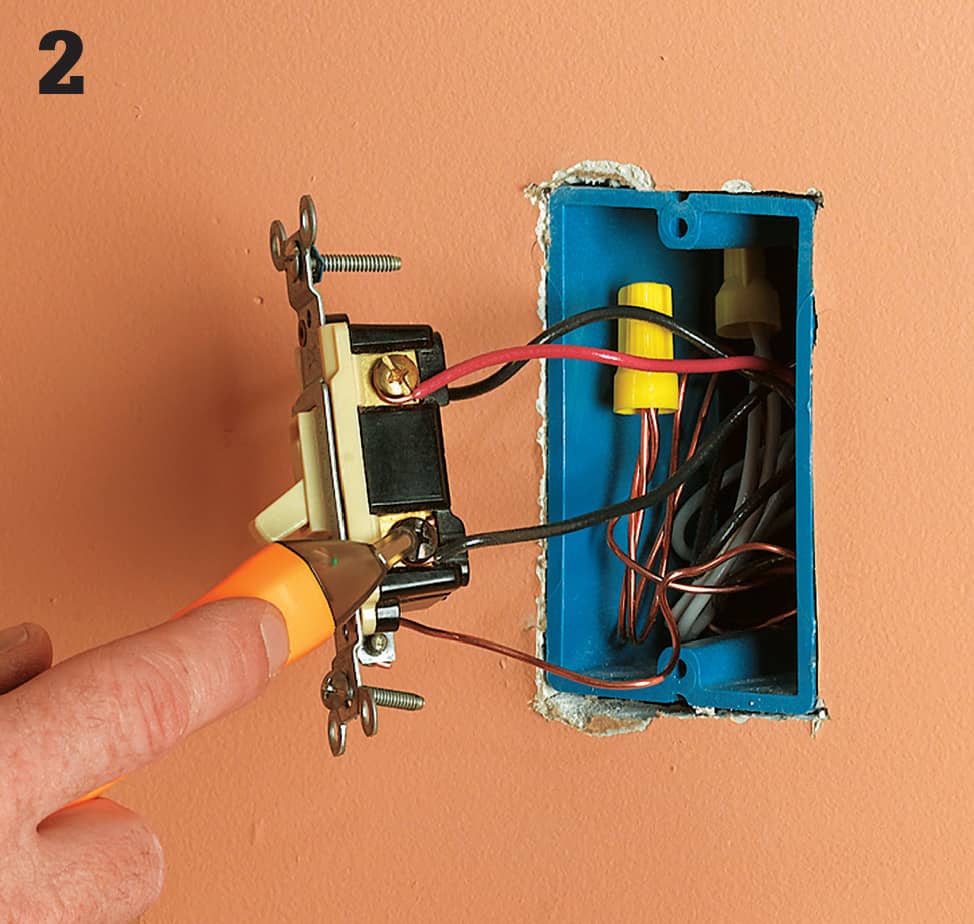

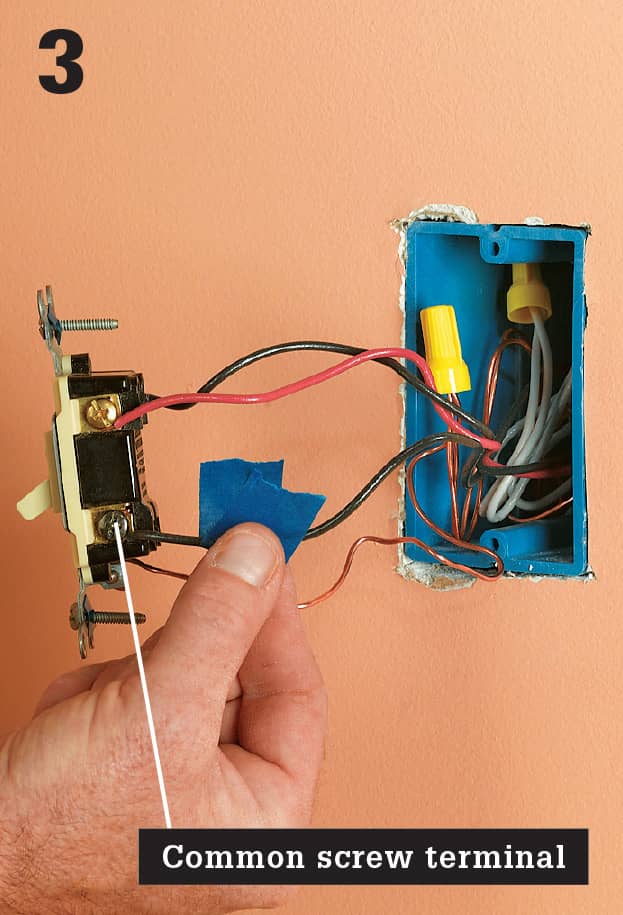

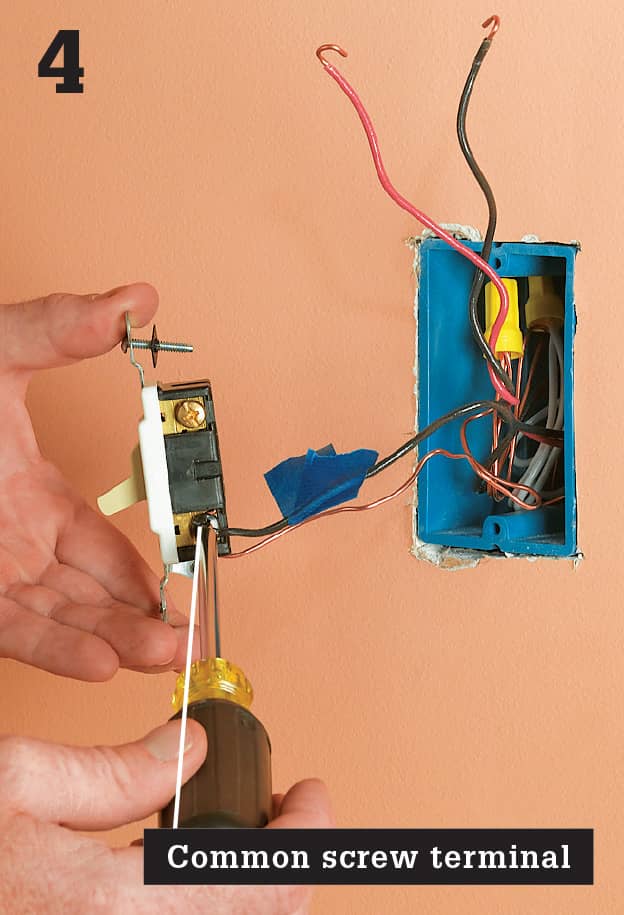

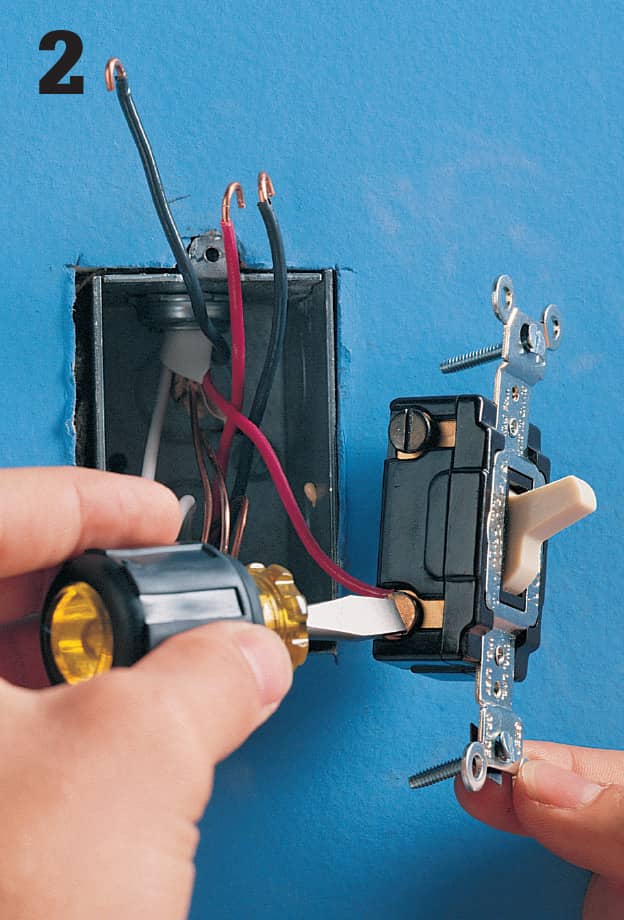

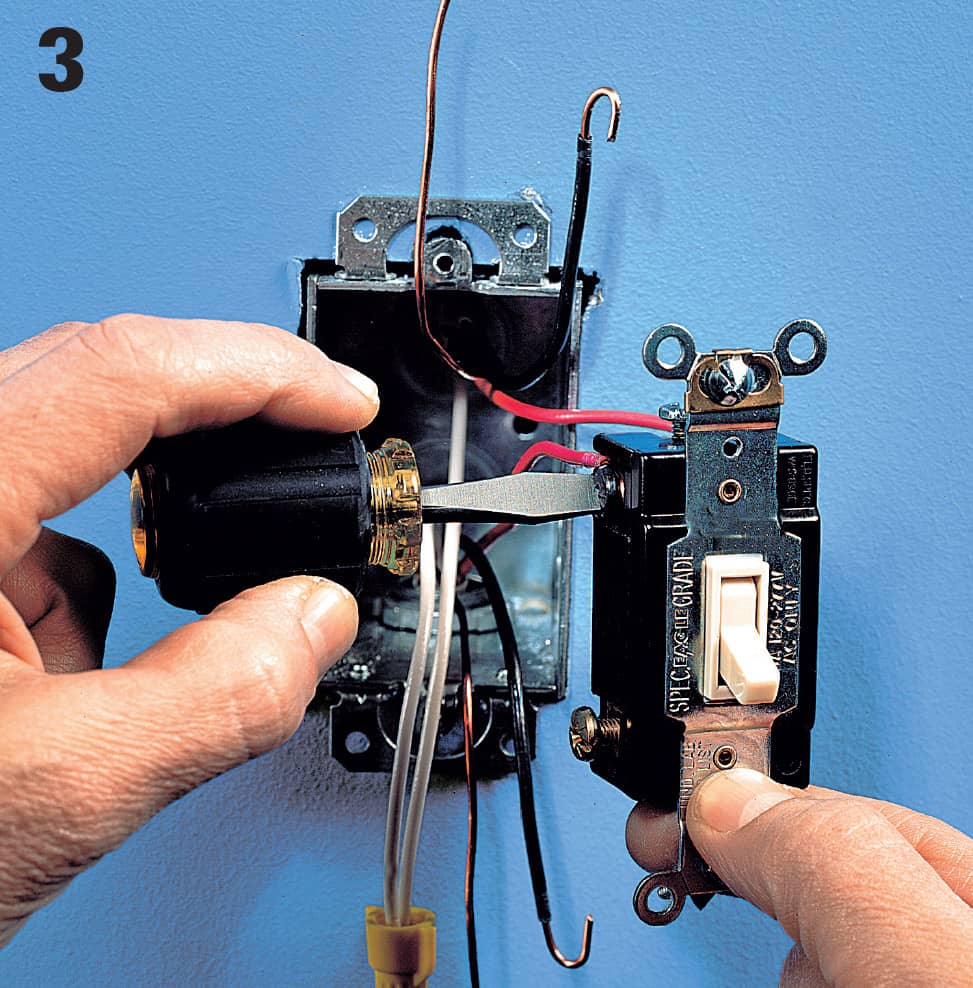

Locate the dark common screw terminal, and use masking tape to label the “common” wire attached to it. Disconnect wires and remove switch. Test the switch for continuity. If it tests faulty, buy a replacement. Inspect wires for nicks and scratches. If necessary, clip damaged wires and strip them.

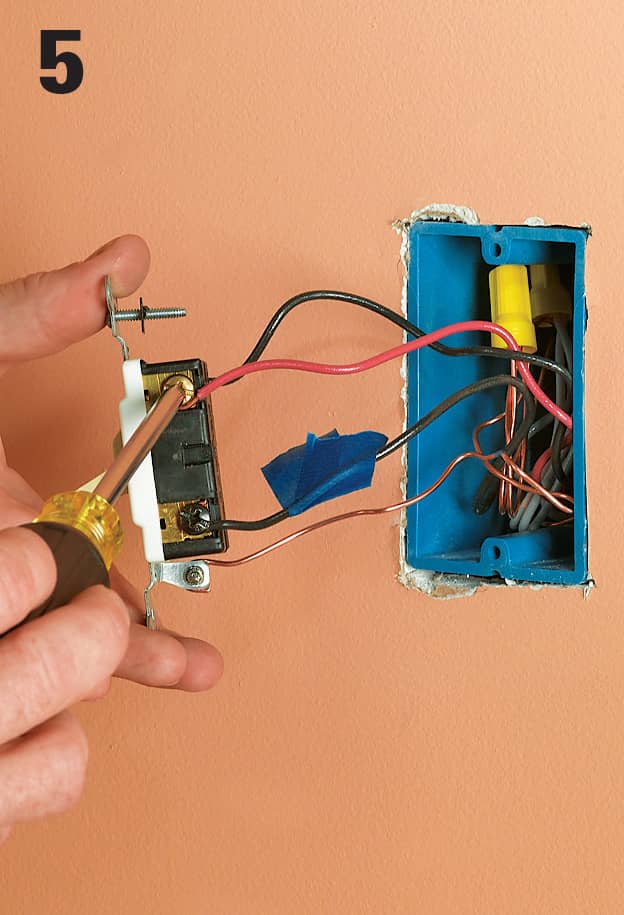

Connect the common wire to the dark common screw terminal on the switch. On most three-way switches, the common screw terminal is black. Or it may be labeled with the word COMMON stamped on the back of the switch. Reconnect the grounding screw, and connect it to the circuit grounding wires with a pigtail.

Connect the remaining two circuit wires to the screw terminals. These wires are interchangeable and can be connected to either screw terminal. Carefully tuck the wires into the box. Remount the switch, and attach the cover plate. Turn on the power at the panel.

Four-Way Wall Switches

Four-way switches have four screw terminals and do not have ON-OFF markings. Four-way switches are always installed between a pair of three-way switches. This switch combination makes it possible to control a set of lights from three or more locations. Four-way switches are common in homes where large rooms contain multiple living areas, such as a kitchen opening into a dining room. Switch problems in a four-way installation can be caused by loose connections or worn parts in a four-way switch or in one of the three-way switches (previous page).

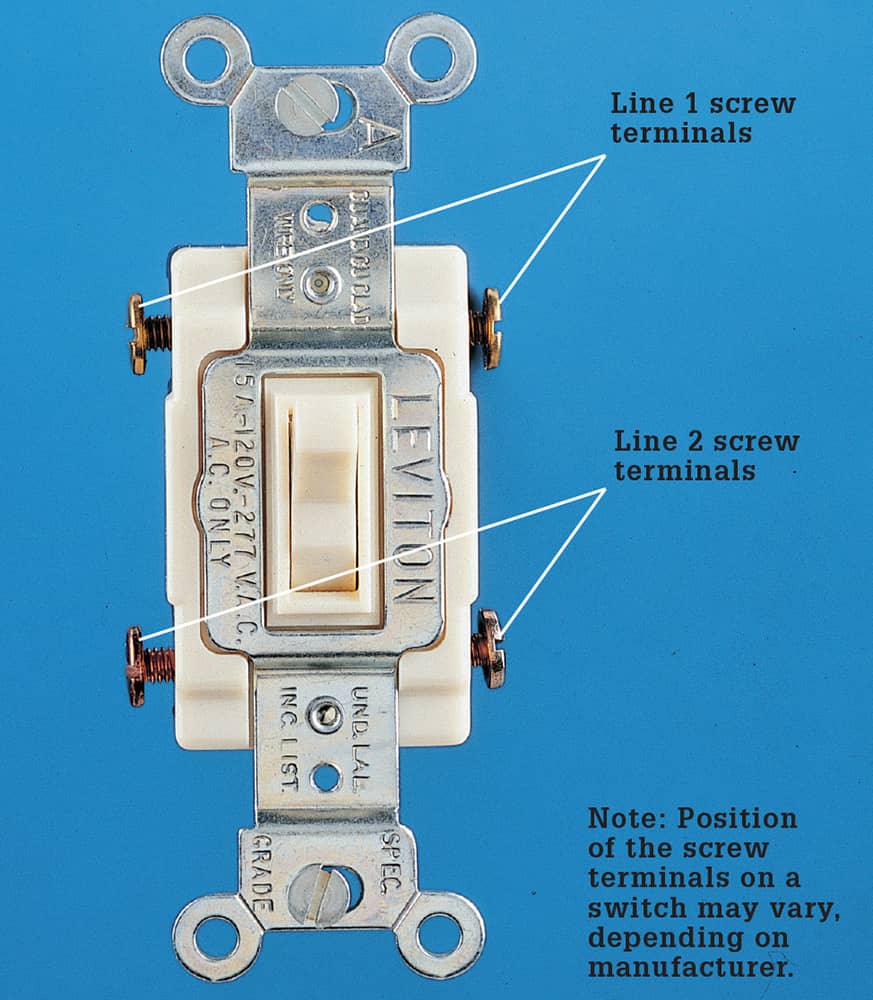

In a typical installation, there will be a pair of three-wire cables that enter the box for the four-way switch. With most switches, the white and red wires from one cable should be attached to the bottom or top pair of screw terminals, and the white and red wires from the other cable should be attached to the remaining pair of screw terminals. However, not all switches are configured the same way, and wiring configurations in the box may vary, so always study the wiring diagram that comes with the switch.

Typical Four-Way Switch Installation

Four wires are connected to a four-way switch. The red and white wires from one cable are attached to the top pair of screw terminals, while the red and white wires from the other cable are attached to the bottom screw terminals. In new switch wiring, the white wire should not supply current to the switched device, and a separate neutral wire should be available in the switch box.

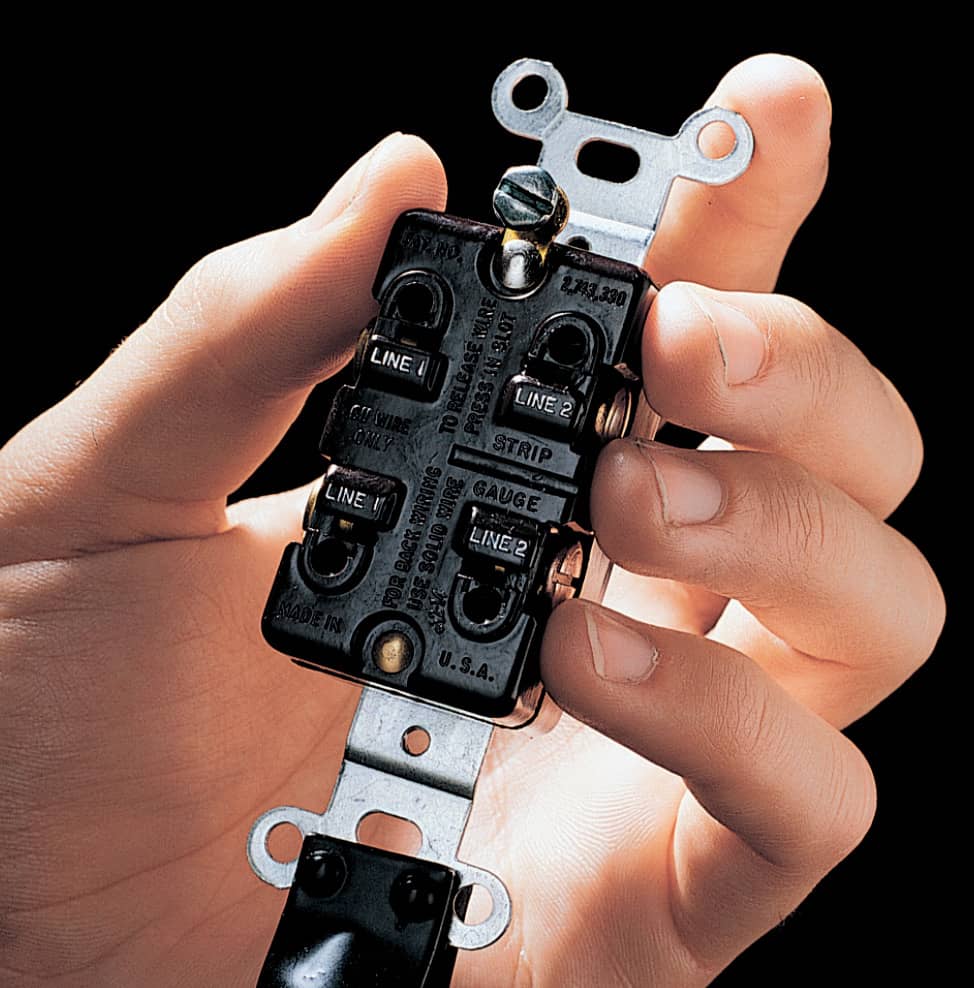

Switch variation: Some four-way switches have a wiring guide stamped on the back to help simplify installation. For the switch shown above, one pair of color-matched circuit wires will be connected to the screw terminals marked LINE 1, while the other pair of wires will be attached to the screw terminals marked LINE 2.

How to Fix or Replace a Four-way Wall Switch

Turn off the power to the switch at the panel, and then remove the switch cover plate and mounting screws. Holding the mounting strap carefully, pull the switch from the box. Be careful not to touch any bare wires or screw terminals until they have been tested for power. Test for power by touching one probe of the neon circuit tester to the grounded metal box or bare copper grounding wire and touching the other probe to each of the screw terminals. The tester should not glow. If it does, there is still power entering the box. Return to the panel, and turn off the correct circuit.

Disconnect the wires and inspect them for nicks and scratches. If necessary, clip damaged wires and strip them. Test the switch for continuity (pages 430 to 431). Buy a replacement if the switch tests faulty.

Connect two wires from one incoming cable to the top set of screw terminals.

Attach remaining wires to the other set of screw terminals. Pigtail the grounding wires to the grounding screw. Carefully tuck the wires inside the switch box, and then remount the switch and cover plate. Turn on power at the panel.

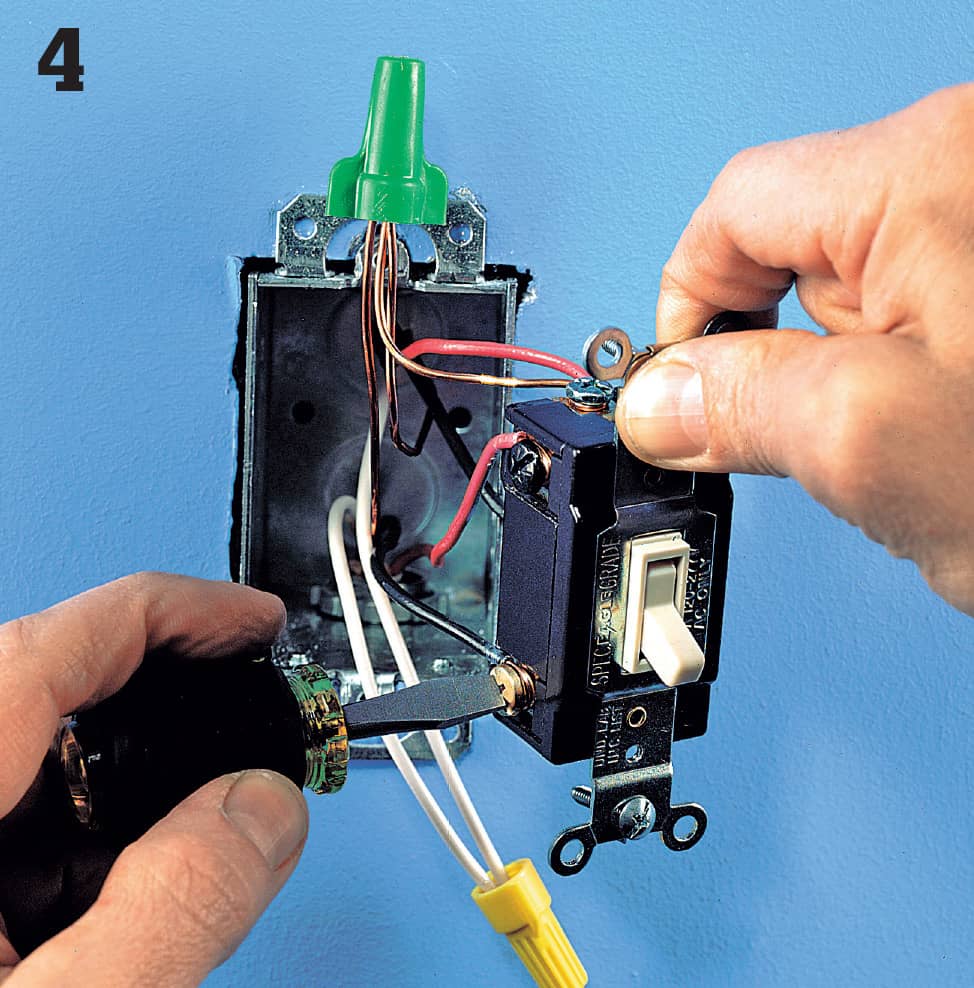

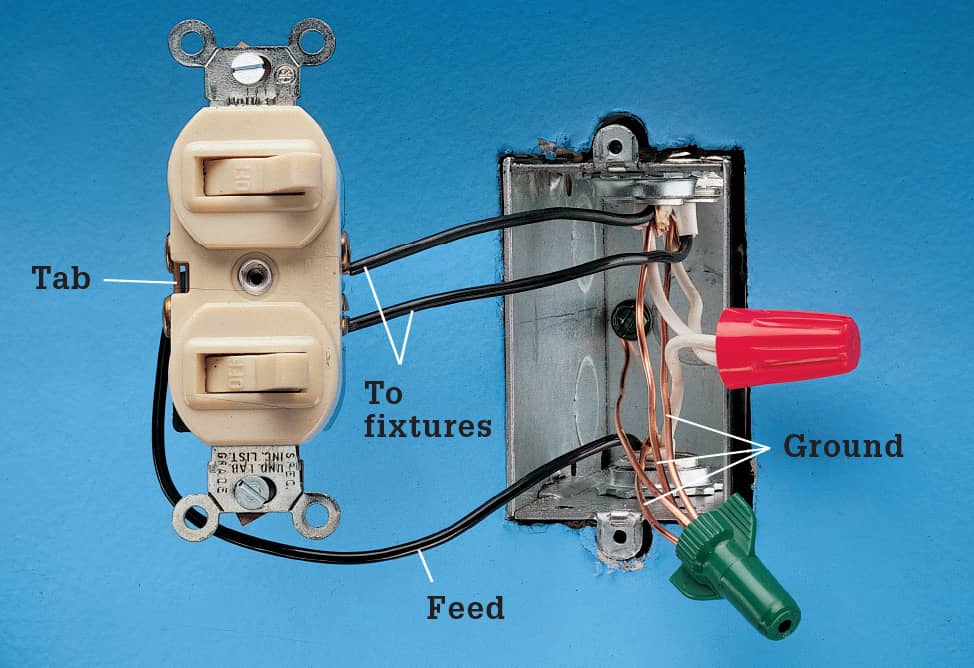

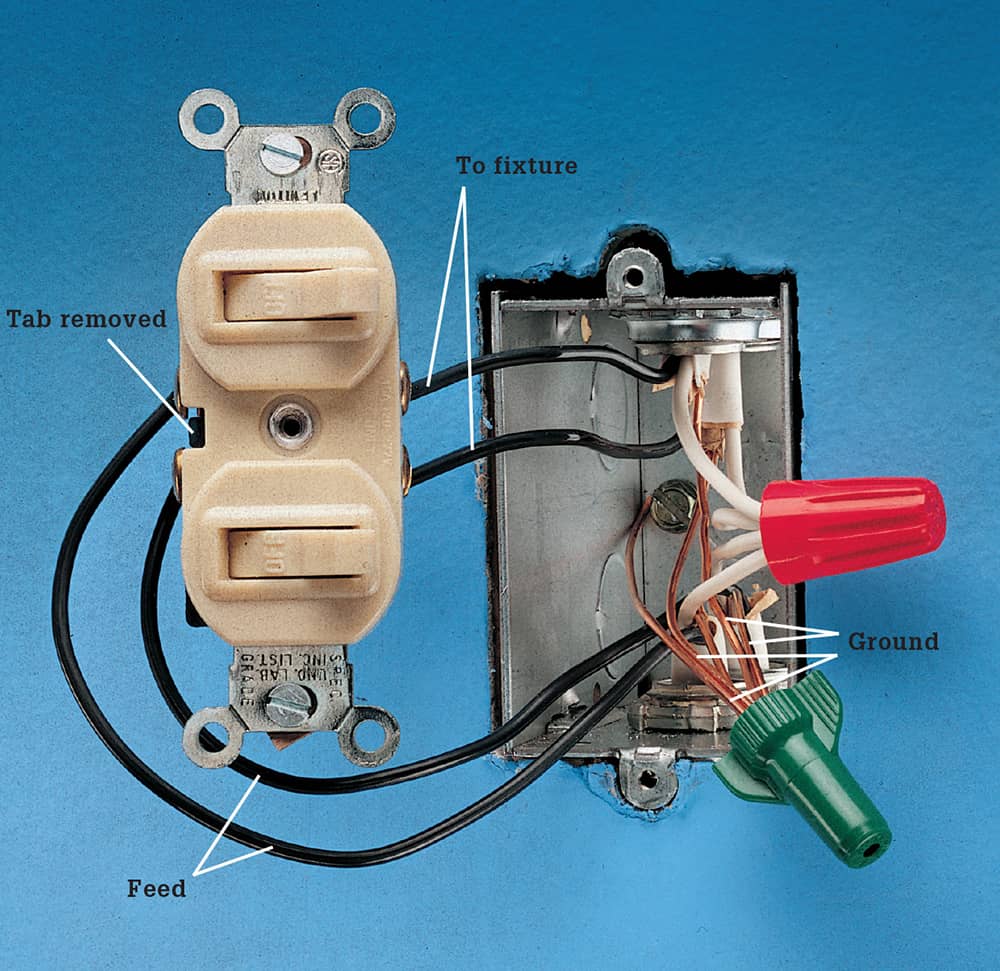

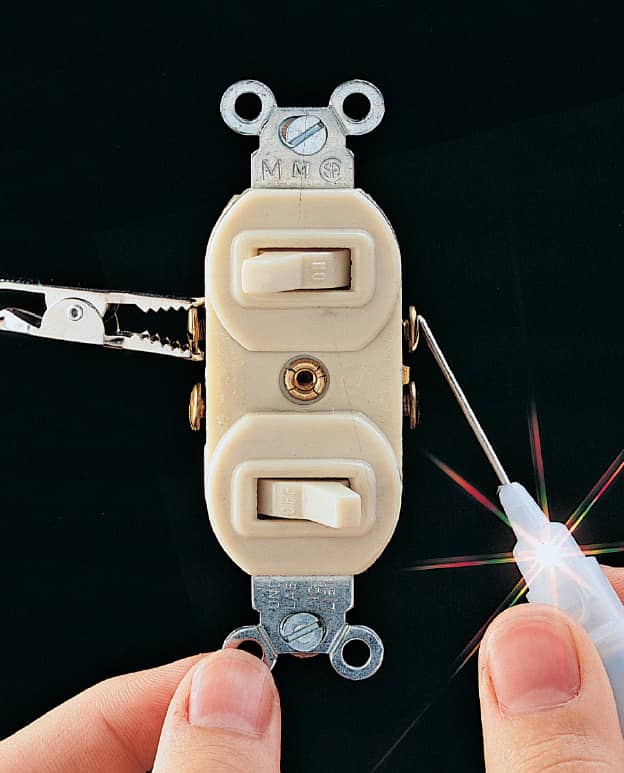

Double Switches

A double switch has two switch levers in a single housing. It is used to control two light fixtures or appliances from the same switch box.

In most installations, both halves of the switch are powered by the same circuit. In these single-circuit installations, three wires are connected to the double switch. One wire, called the feed wire (which is hot), supplies power to both halves of the switch. The other wires, called the switch leg, carry power out to the individual light fixtures or appliances.

Single-circuit wiring: Three black wires are attached to the switch. The black feed wire bringing power into the box is connected to the side of the switch that has a connecting tab. The wires carrying power out to the light fixtures or appliances are connected to the side of the switch that does not have a connecting tab. The white neutral wires are connected together with a wire connector.

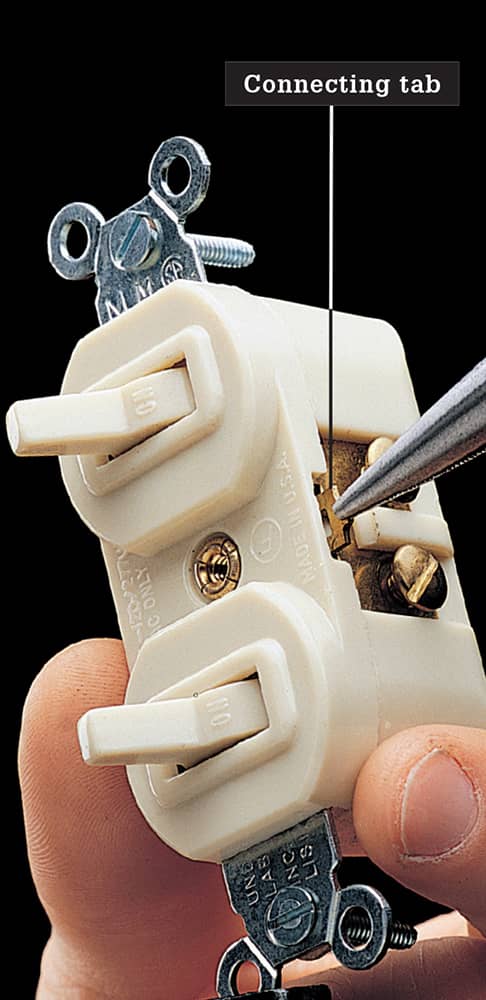

In rare installations, each half of the switch is powered by a separate circuit. In these separate-circuit installations, four wires are connected to the switch, and the metal connecting tab joining two of the screw terminals is removed (see photo below).

Separate-circuit wiring: Four black wires are attached to the switch. Feed wires from the power source are attached to the side of the switch that has a connecting tab, and the connecting tab is removed (photo, below). Wires carrying power from the switch to light fixtures or appliances are connected to the side of the switch that does not have a connecting tab. White neutral wires are connected together with a wire connector.

Remove the connecting tab on a double switch when wired in a separate-circuit installation. The tab can be removed with needlenose pliers or a screwdriver.

Pilot-Light Switches

A pilot-light switch has a built-in bulb that glows when power flows through the switch to a light fixture or appliance. Pilot-light switches often are installed for convenience if a light fixture or appliance cannot be seen from the switch location. Basement lights, garage lights, and attic exhaust fans frequently are controlled by pilot-light switches.

A pilot-light switch requires a neutral wire connection. A switch box that contains a single two-wire cable has only hot wires and cannot be fitted with a pilot-light switch.

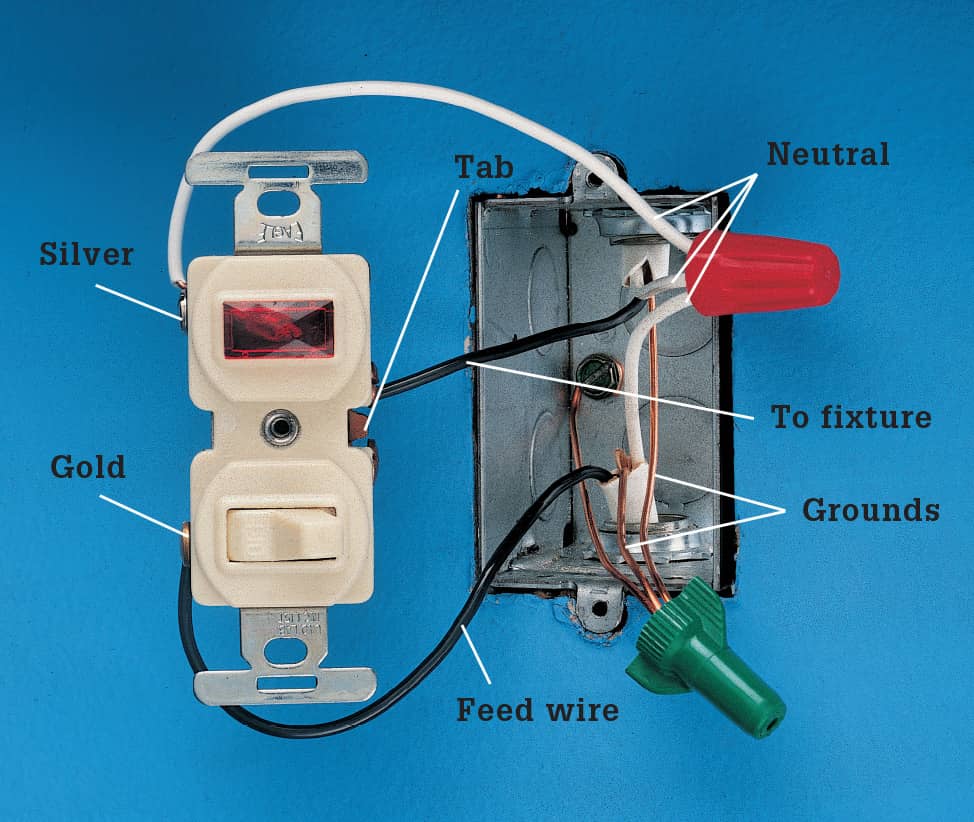

Pilot-light switch wiring: Three wires are connected to the switch. One black wire is the feed wire that brings power into the box. It is connected to the brass (gold) screw terminal on the side of the switch that does not have a connecting tab. The white neutral wires are pigtailed to the silver screw terminal. The black wire carrying power out to a light fixture or appliance is connected to the screw terminal on the side of the switch that has a connecting tab.

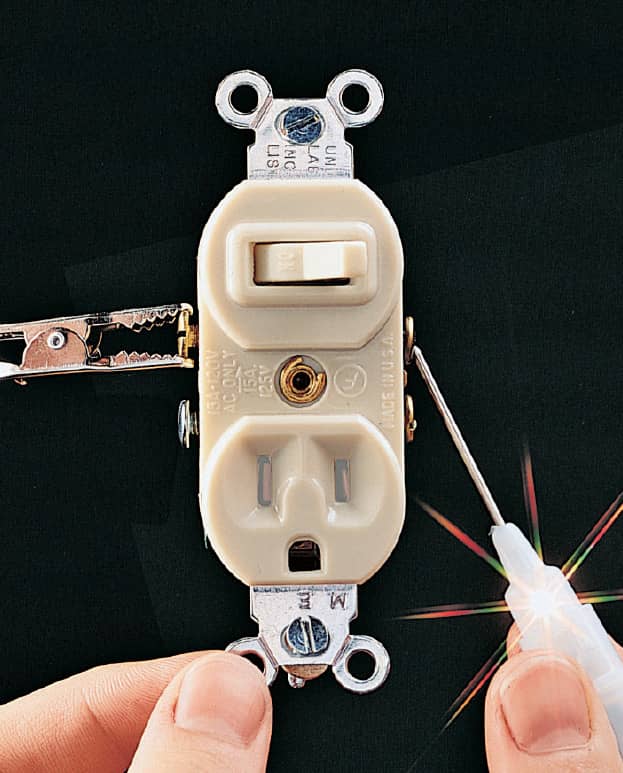

Switch/Receptacles

A switch/receptacle combines a grounded receptacle with a single-pole wall switch. In a room that does not have enough wall receptacles, electrical service can be improved by replacing a single-pole switch with a switch/receptacle.

A switch/receptacle requires a neutral wire connection. A switch box that contains a single two-wire cable has only hot wires and cannot be fitted with a switch/receptacle.

A switch/receptacle can be installed in one of two ways. In the most common installations, the receptacle is hot even when the switch is off (photo, right).

In rare installations, a switch/receptacle is wired so the receptacle is hot only when the switch is on. In this installation, the hot wires are reversed, so that the feed wire is attached to the brass screw terminal on the side of the switch that does not have a connecting tab.

Switch/receptacle wiring: Three wires are connected to the switch/receptacle. One of the hot wires is the feed wire that brings power into the box. It is connected to the side of the switch that has a connecting tab. The other hot wire carries power out to the light fixture or appliance. It is connected to the brass screw terminal on the side that does not have a connecting tab. The white neutral wire is pigtailed to the silver screw terminal. The grounding wires must be pigtailed to the green grounding screw on the switch/receptacle and to the grounded metal box.

Specialty Switches

Specialty Switches

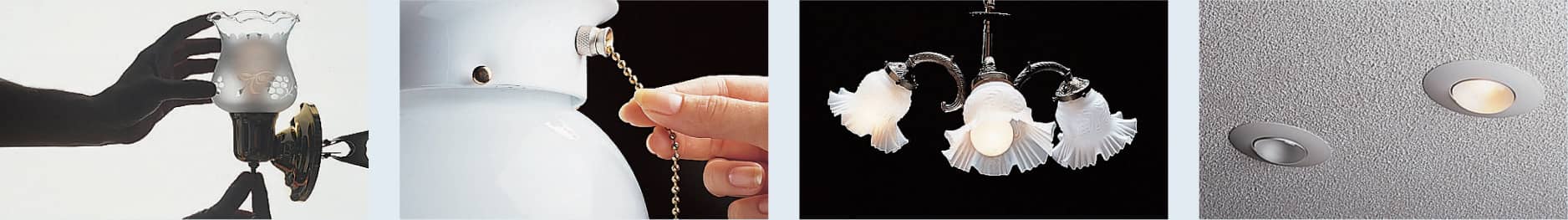

Your house may have several types of specialty switches. Dimmer switches (pages 428 to 429) are used frequently to control light intensity in dining and recreation areas. Timer switches and time-delay switches (below) are used to control light fixtures and exhaust fans automatically. Electronic switches provide added convenience and home security, and they are easy to install. Electronic switches are durable, and they rarely need replacement.

Most specialty switches have preattached wire leads instead of screw terminals and are connected to circuit wires with wire connectors. Some motor-driven timer switches require a neutral wire connection and cannot be installed in switch boxes that have only one cable with two hot wires. It is precisely due to the rise in popularity of “smart” switches that the NEC Code was changed in 2014 to require an available neutral wire in newly installed switch boxes.

If a specialty switch is not operating correctly, you may be able to test it with a continuity tester. Timer switches and time-delay switches can be tested for continuity, but dimmer switches cannot be tested. With electronic switches, the manual switch can be tested for continuity, but the automatic features cannot be tested.

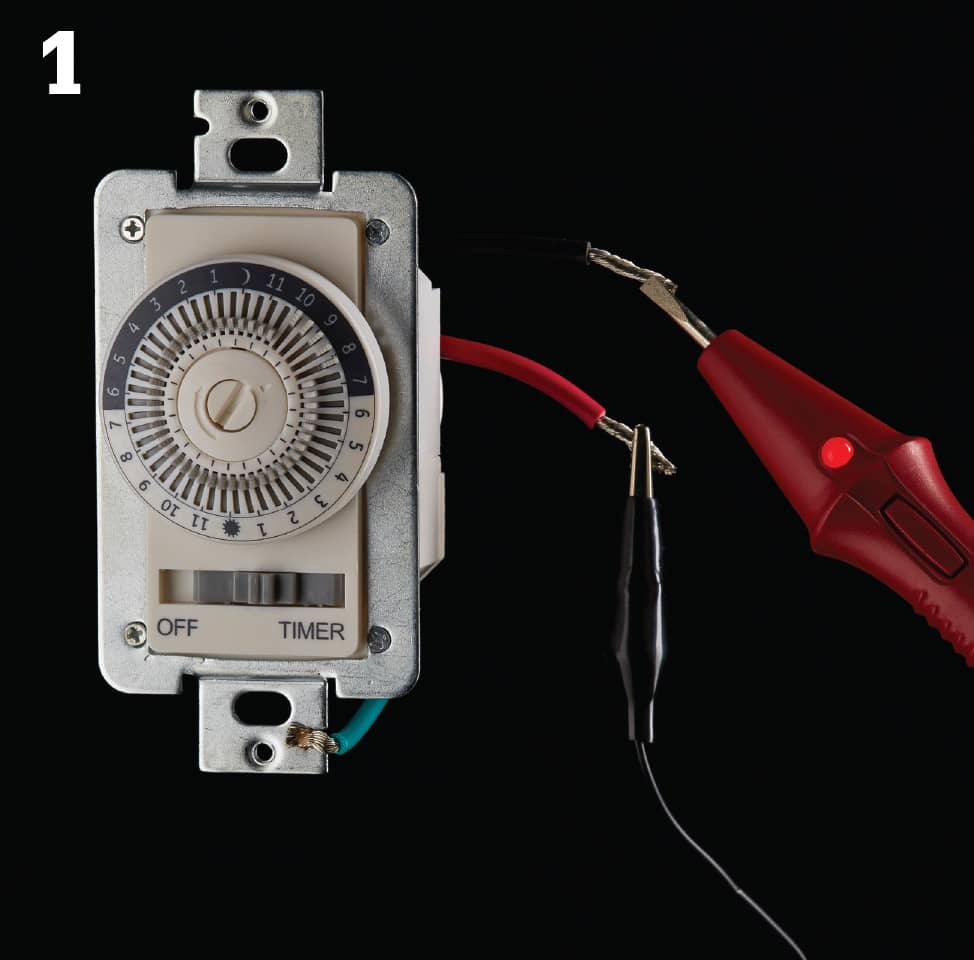

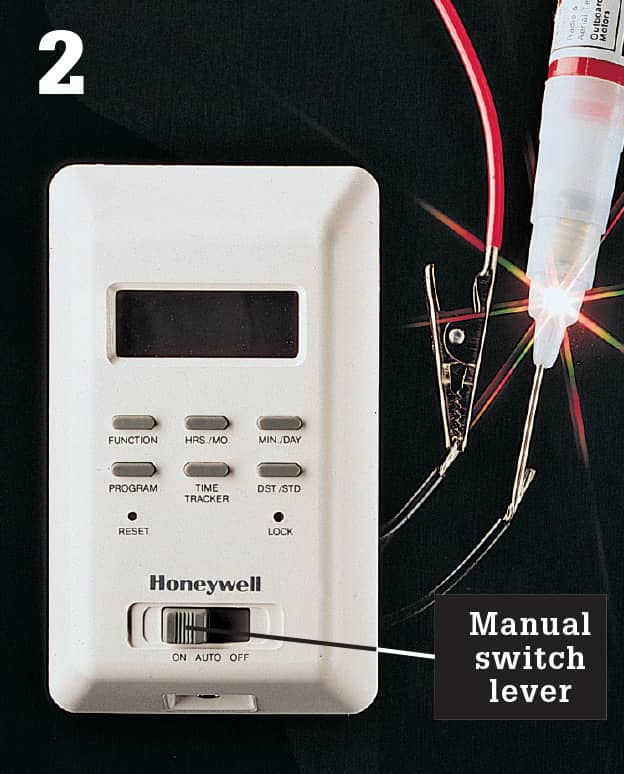

Timer Switches

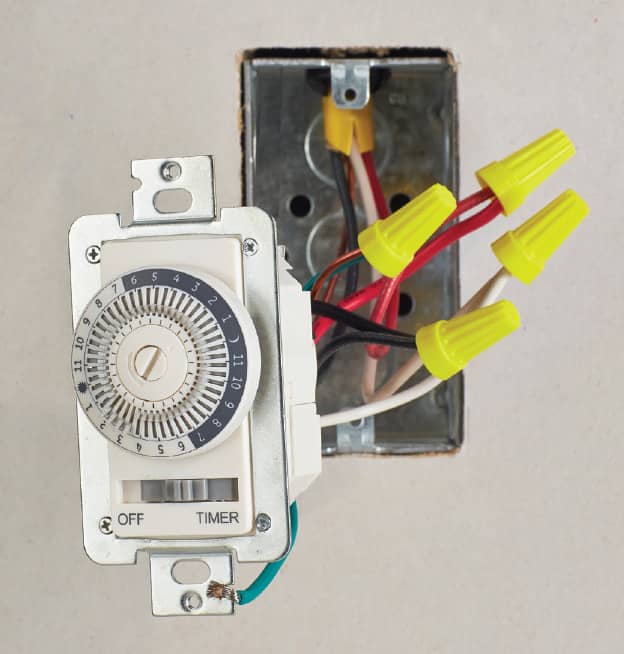

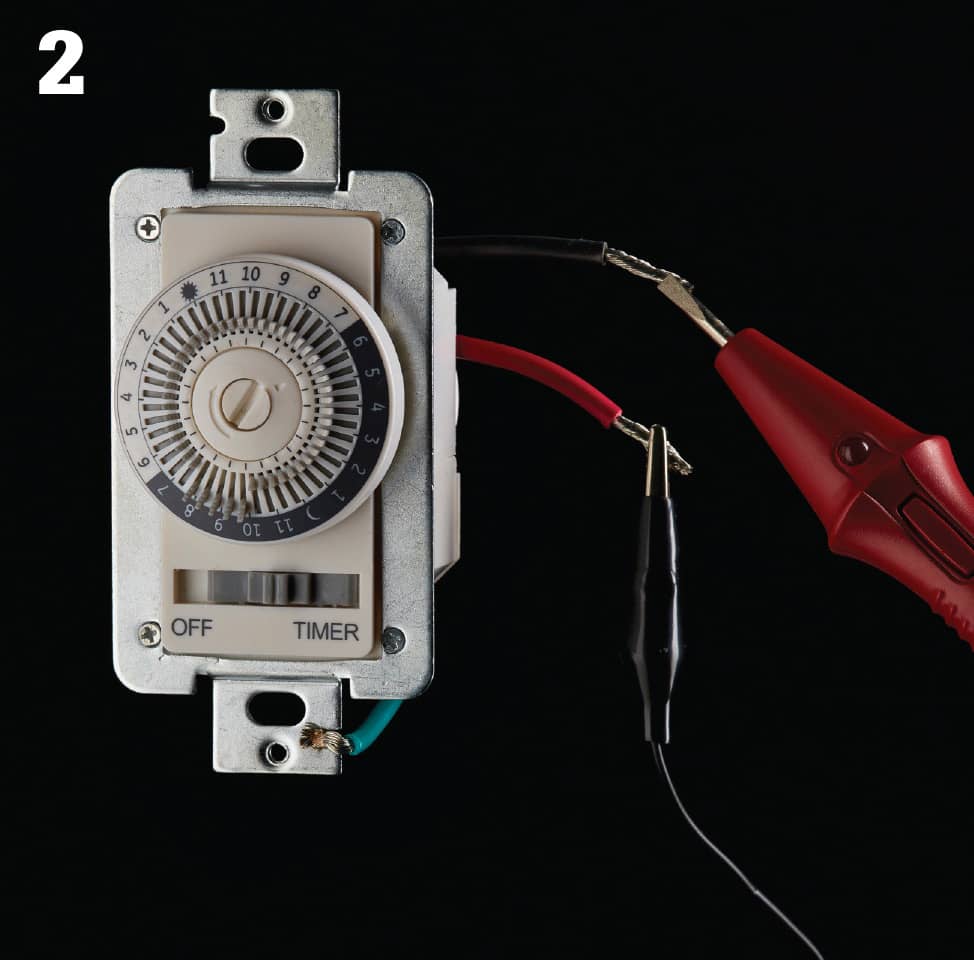

Countdown timer switches can be set to turn lights or fans on and off automatically once each day. They are commonly used to control outdoor light fixtures.

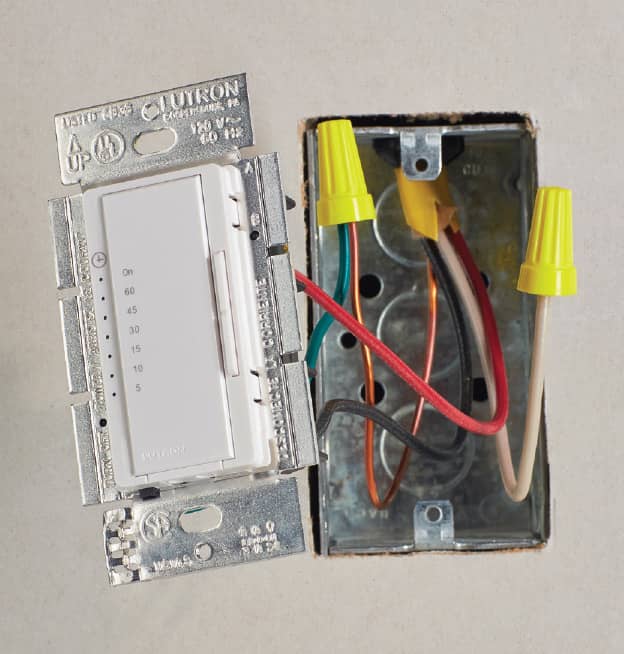

Timer switches have three preattached wire leads. The black wire lead is connected to the hot feed wire that brings power into the box, and the red lead is connected to the wire carrying power out to the light fixture. The remaining wire lead is the neutral lead. It must be connected to any neutral circuit wires. A switch box that contains only one cable has no neutral wires, so it cannot be fitted with a timer switch.

After a power failure, the dial on a timer switch must be reset to the proper time.

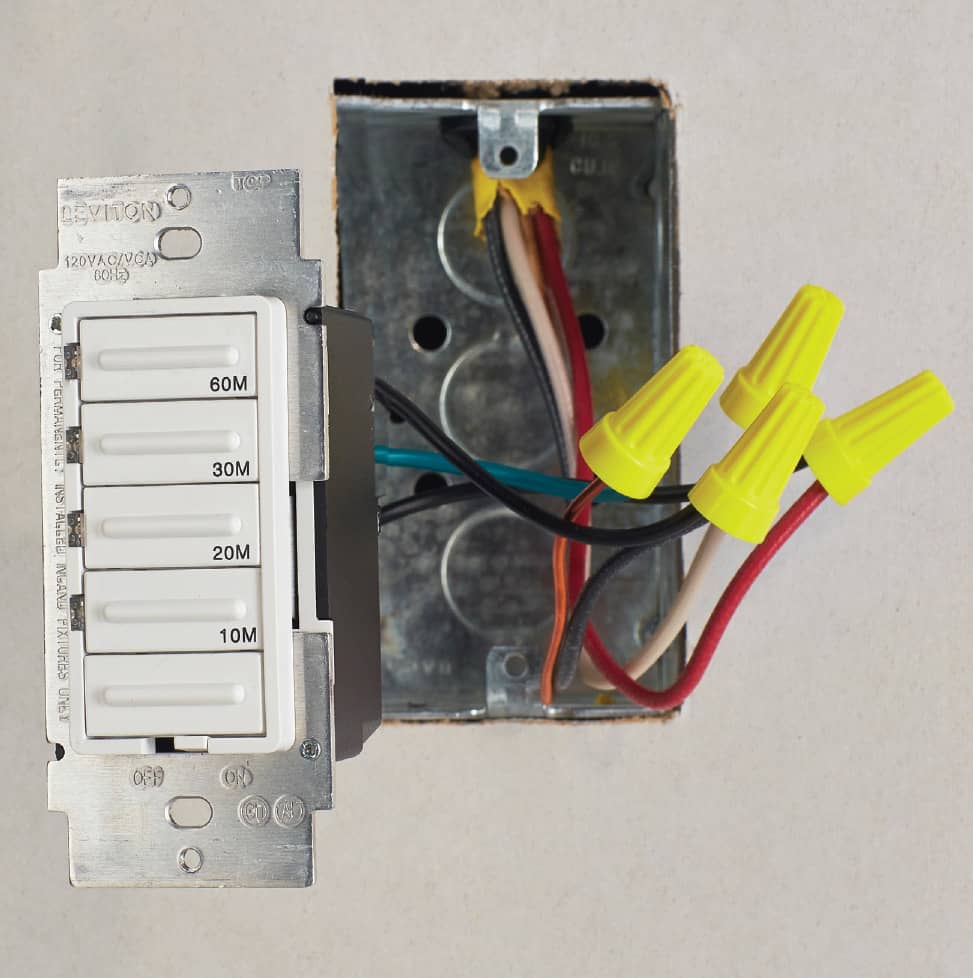

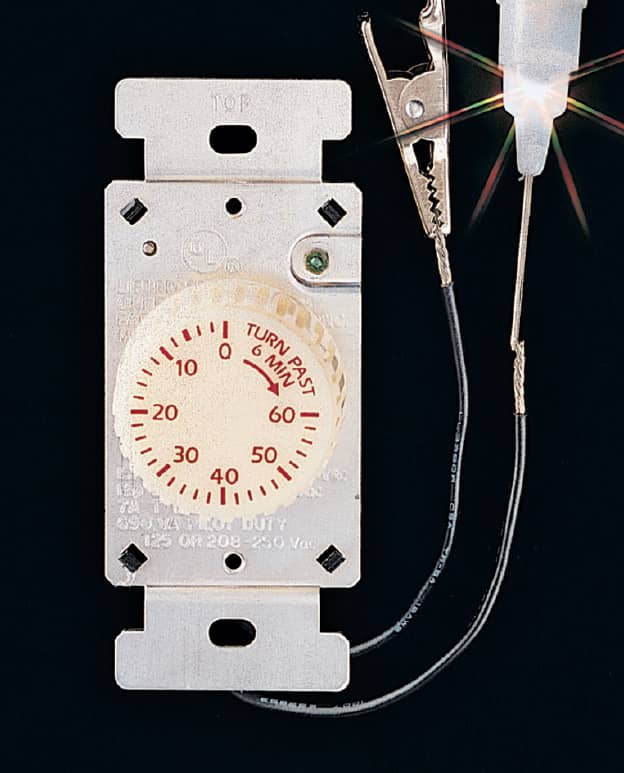

Countdown timer switch. This rocker-type switch gives you the option to easily program the switch to shut off after a specified time: from 5 to 60 minutes. Garage lights or basement lights are good applications: anywhere you want the light to stay on long enough to allow you to exit, but not to stay on indefinitely. These switches often are used to control vent fans.

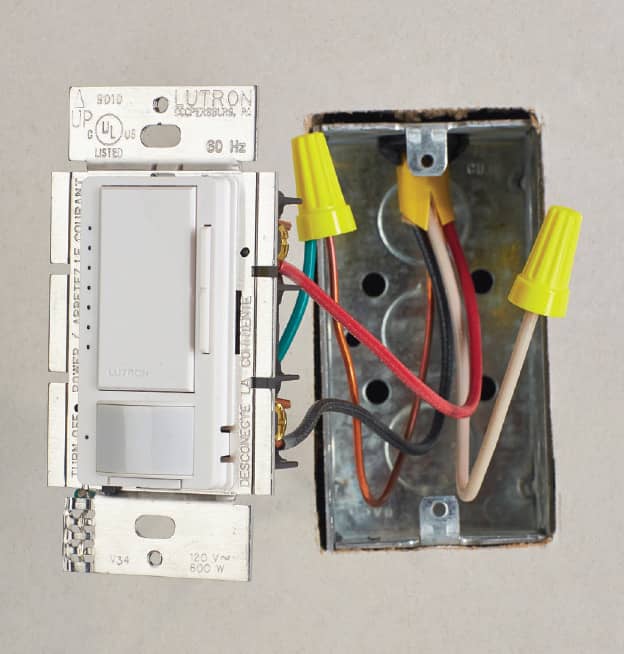

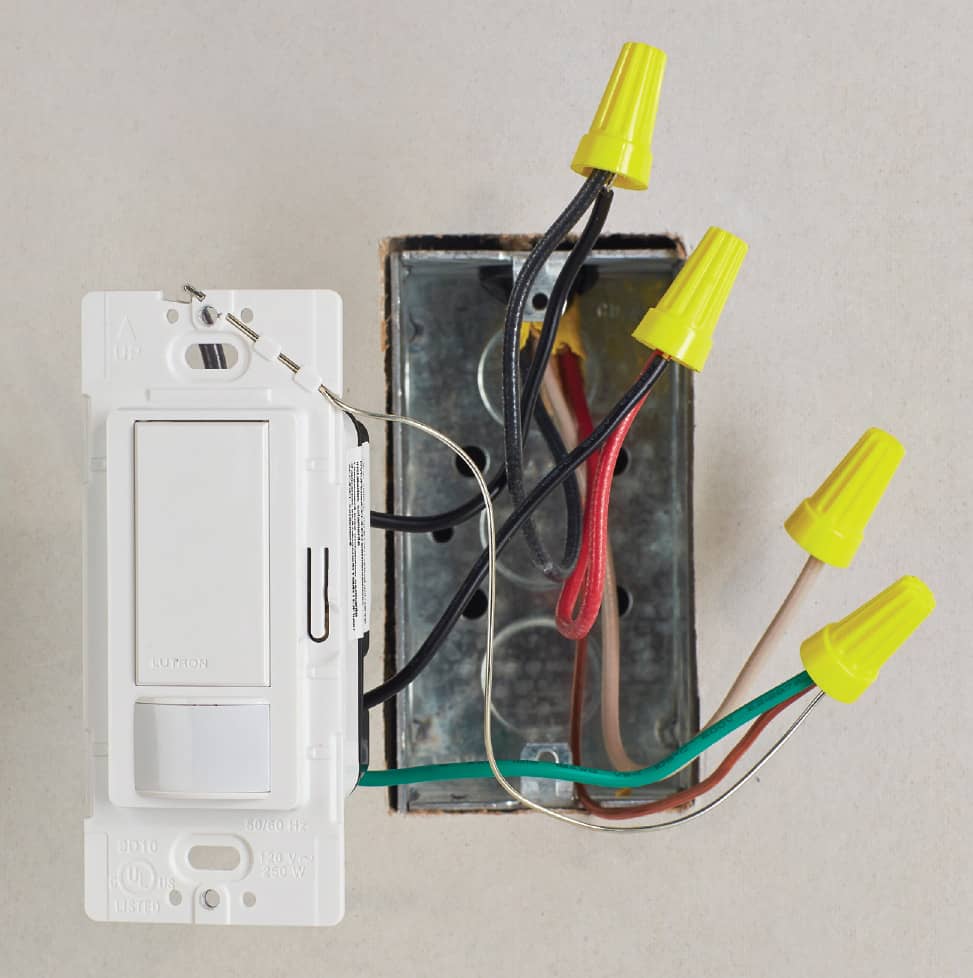

Occupancy sensor. Many smart switches incorporate a motion detector that will switch the lights on if they sense movement in the room and will also shut them off when no movement is detected for a period of time. The model shown above also has a dimmer function for further energy savings.

Programmable timer switch. A dial-type timer allows you to program the switch to turn on for specific time periods at designated times of day within a 24-hour cycle. Security lights, space heaters, towel warmers, and radiant floors are typical applications.

Preset timer switch. This lets you turn on lights, heat lamps, and other loads for a designated amount of time (10 to 60 minutes) with one easy push of a button. The green LED at the bottom of this unit provides a readout of how much time is left before the switch shuts off. The model shown is not compatible with fluorescent ballasts.

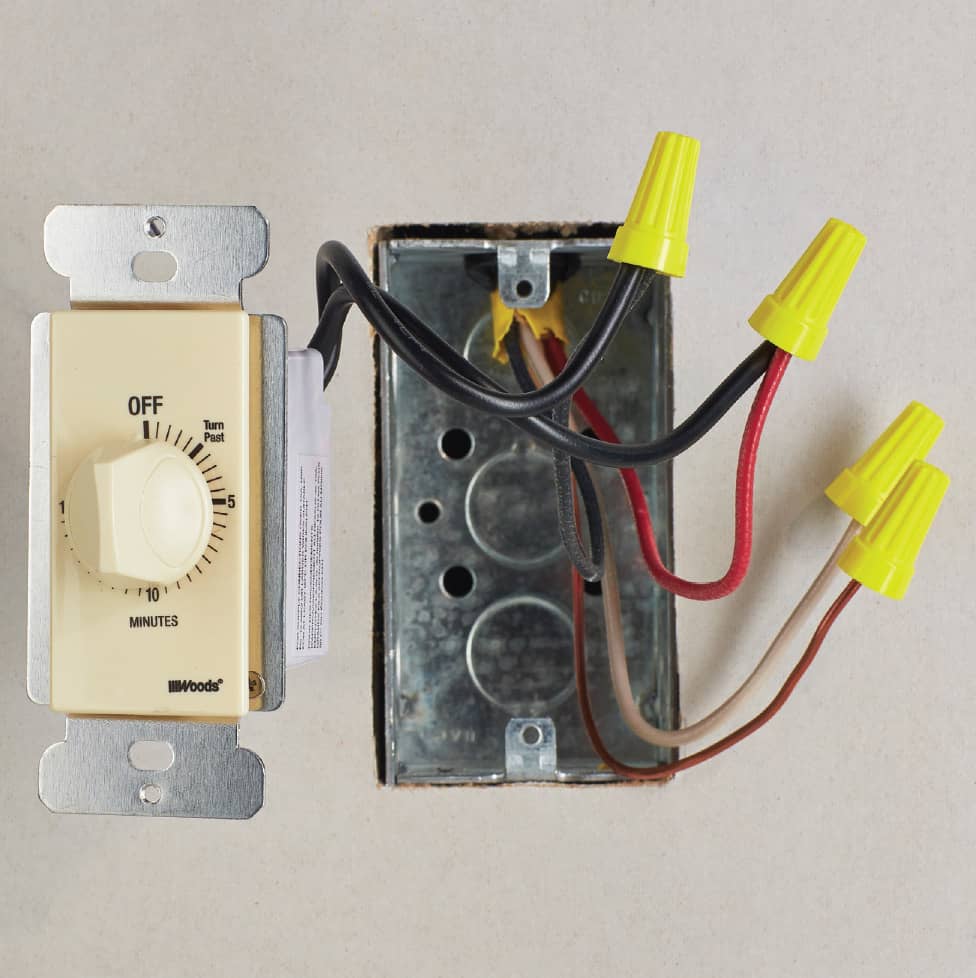

Spring-wound timer switch. A relatively simple device, this timer switch functions exactly like a kitchen timer, employing a hand-turned dial to and spring mechanism to shut the switch off in increments up to 15 minutes.

Daylight sensor switch. This switch automatically turns on when light levels drop below a proscribed level. It can also be programmed as an occupancy sensor to shut off when the room is vacant and turn on when the room is entered.

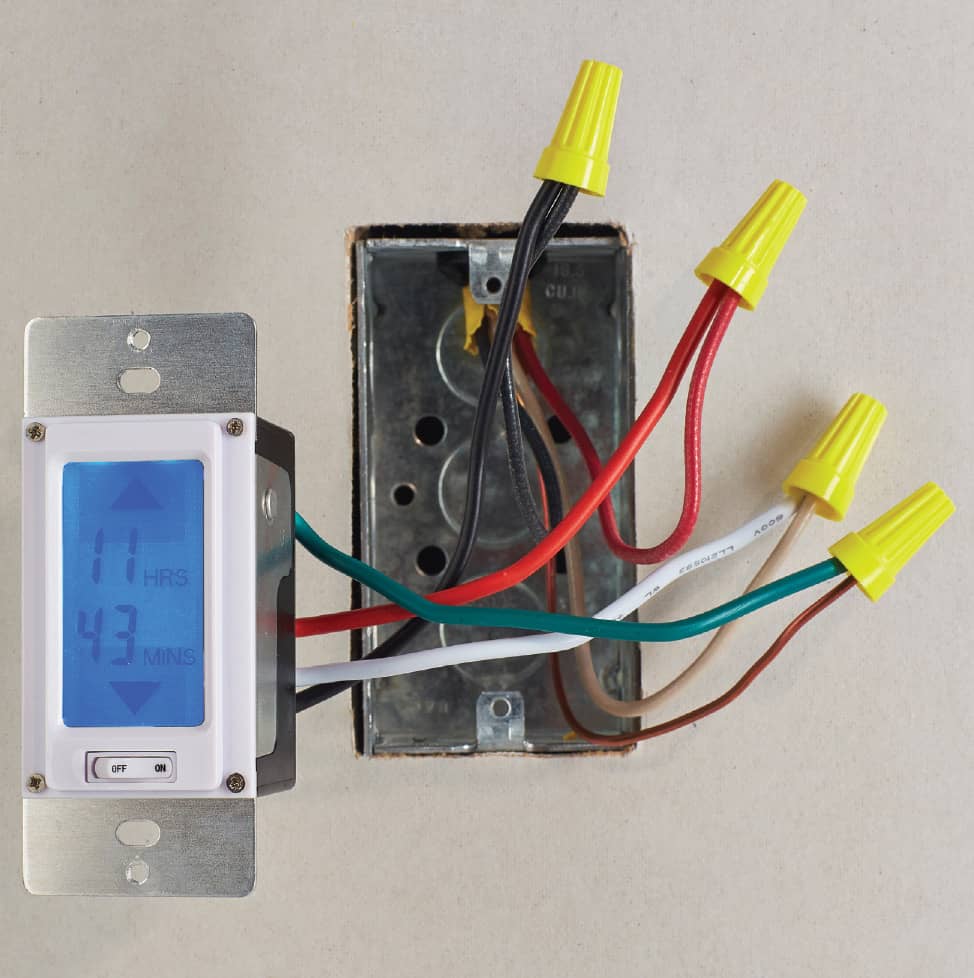

Backlit countdown timer. This digital switch lets you program lights or other devices to stay on for up to 24 hours and then shut off automatically. The backlit, LED readout gives a countdown, in minutes, of the amount of time left in the “on” cycle. Up and down buttons let you raise or lower the remaining time easily, and a manual override button will shut off the switch until it is turned back on.

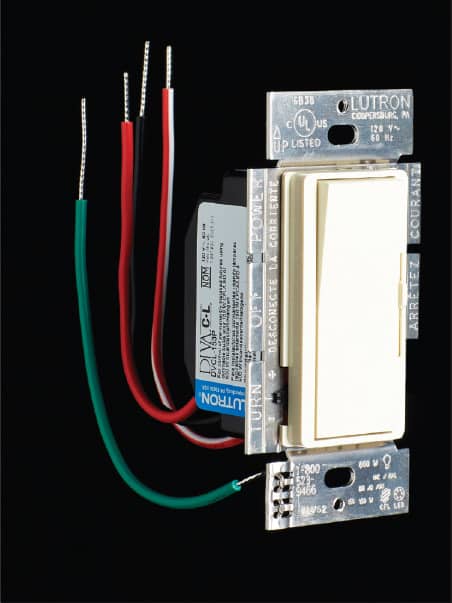

Dimmer Switches

A dimmer switch makes it possible to vary the brightness of a light fixture. Dimmers are often installed in dining rooms, recreation areas, or bedrooms.

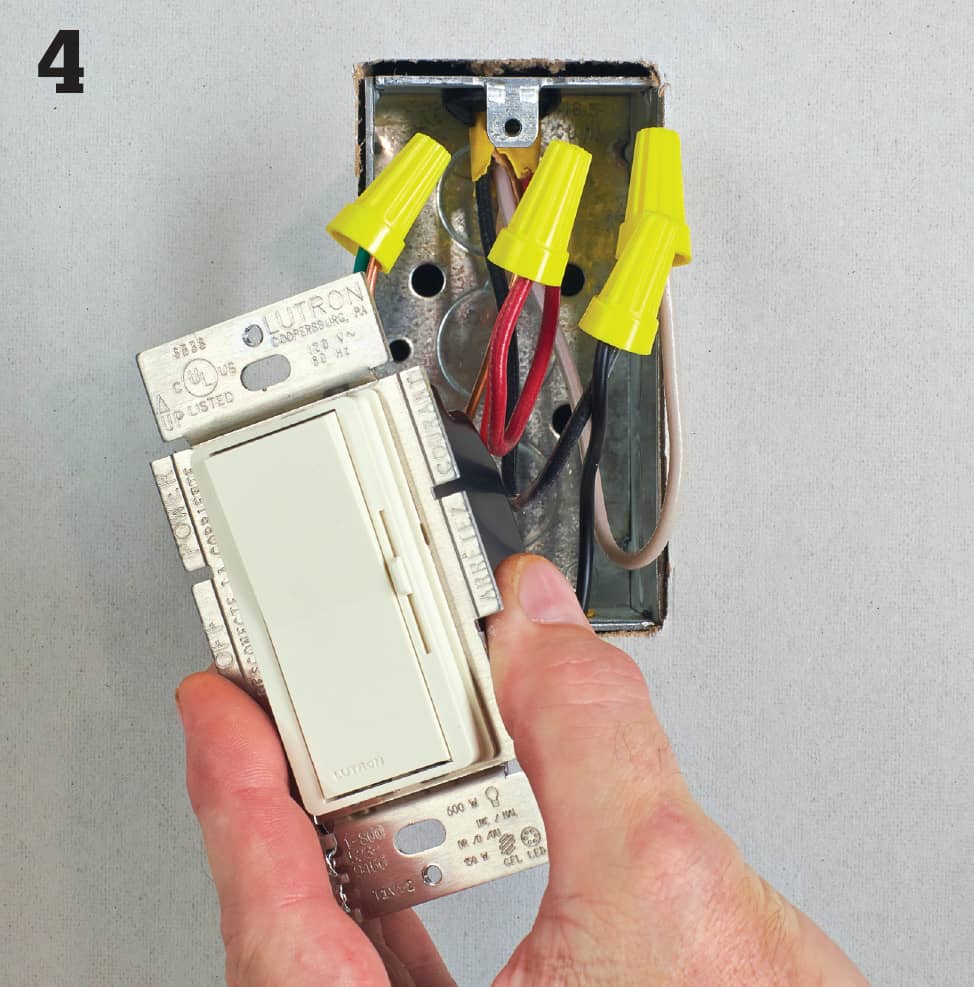

Any standard single-pole switch can be replaced with a dimmer, as long as the switch box is of adequate size. Dimmer switches have larger bodies than standard switches. They also generate a small amount of heat that must dissipate. For these reasons, dimmers should not be installed in undersized electrical boxes or in boxes that are crowded with circuit wires. Always follow the manufacturer’s specifications for installation.

In lighting configurations that use three-way switches (pages 420 to 421), buy a packaged pair of three-way dimmers designed to work together.

Dimmer switches are available in several styles (see photo, right). All types have wire leads instead of screw terminals, and they are connected to circuit wires using wire connectors. Some types have a green grounding lead that should be connected to the grounded metal box or to the bare copper grounding wires. Until very recently, dimmers were designed to work only with incandescent lamps. They may not work well, or may not work at all, with CFL and LED lamps. When replacing incandescent lamps with CFL and LED lamps, make sure the new lamps are designed to work with older dimmers. When replacing dimmers, make sure the new dimmers are designed to work with CFL and LED lamps.

Switch Action Options

How to Install a Dimmer Switch

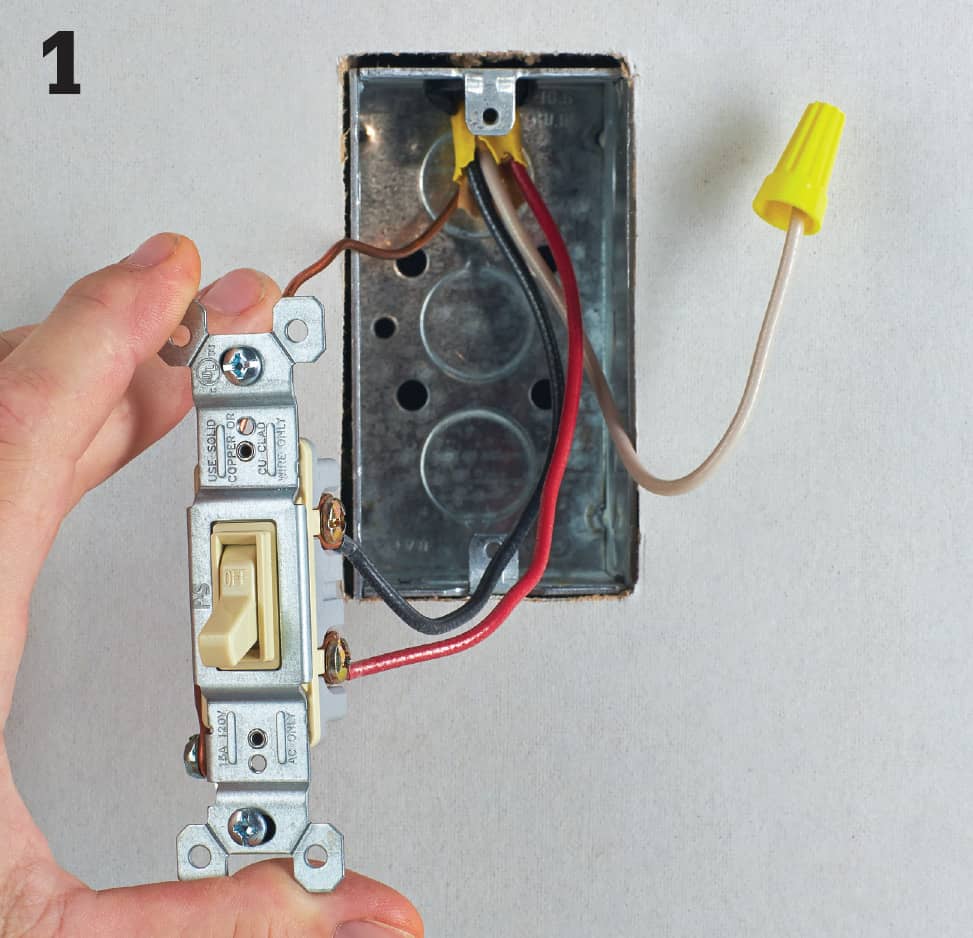

Turn off power to the switch at the panel, and then remove the cover plate and mounting screws. Holding the mounting straps carefully, pull the switch from the box. Be careful not to touch bare wires or screw terminals until they have been tested for power. In new switch wiring, the white wire should not supply current to the switched device, and a separate neutral wire should be available in the switch box.

Disconnect the circuit wires and remove the switch. Straighten the circuit wires, and clip the ends, leaving about 1/2" of the bare wire end exposed.

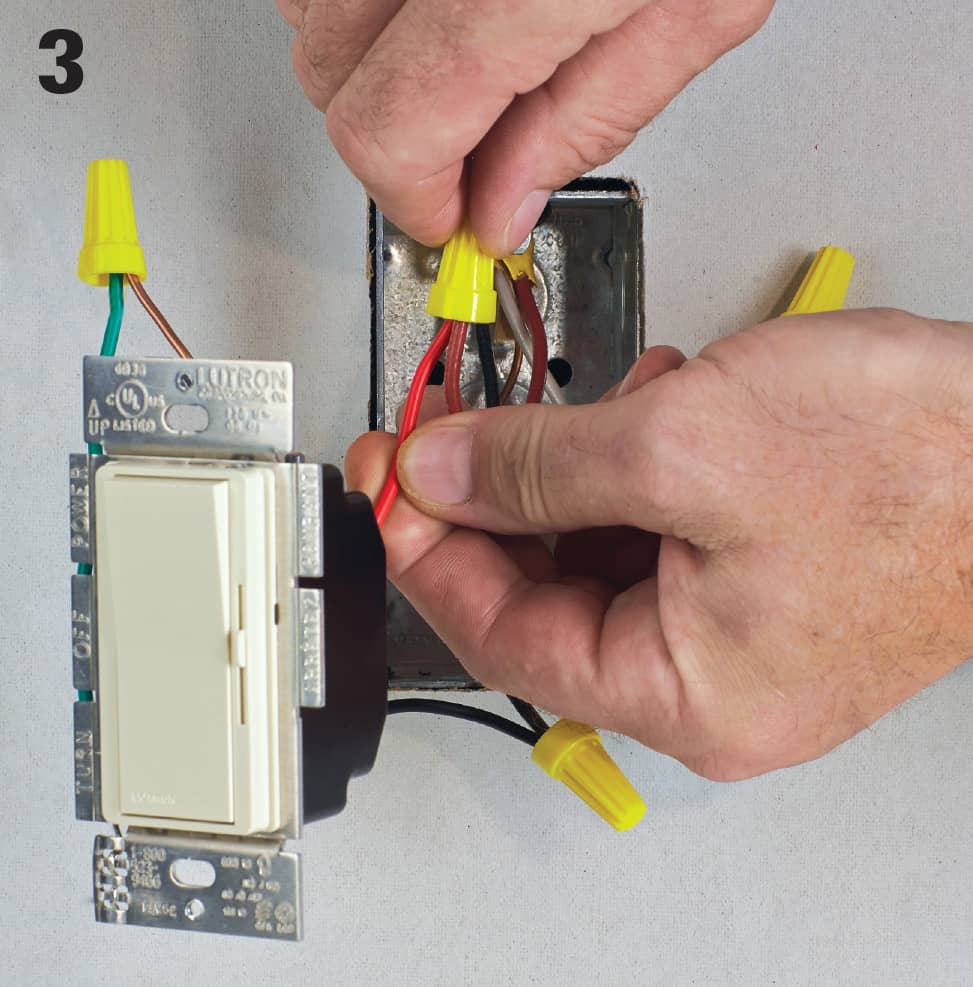

Connect the wire leads on the dimmer switch to the circuit wires using wire connectors. The switch leads are interchangeable and can be attached to either of the two circuit wires.

A three-way dimmer has an additional wire lead. This “common” lead is connected to the common circuit wire. When replacing a standard three-way switch with a dimmer, the common circuit wire is attached to the darkest screw terminal on the old switch. In new switch wiring, the white wire should not supply current to the switched device, and a separate neutral wire should be available in the switch box.

Testing Switches

Testing Switches

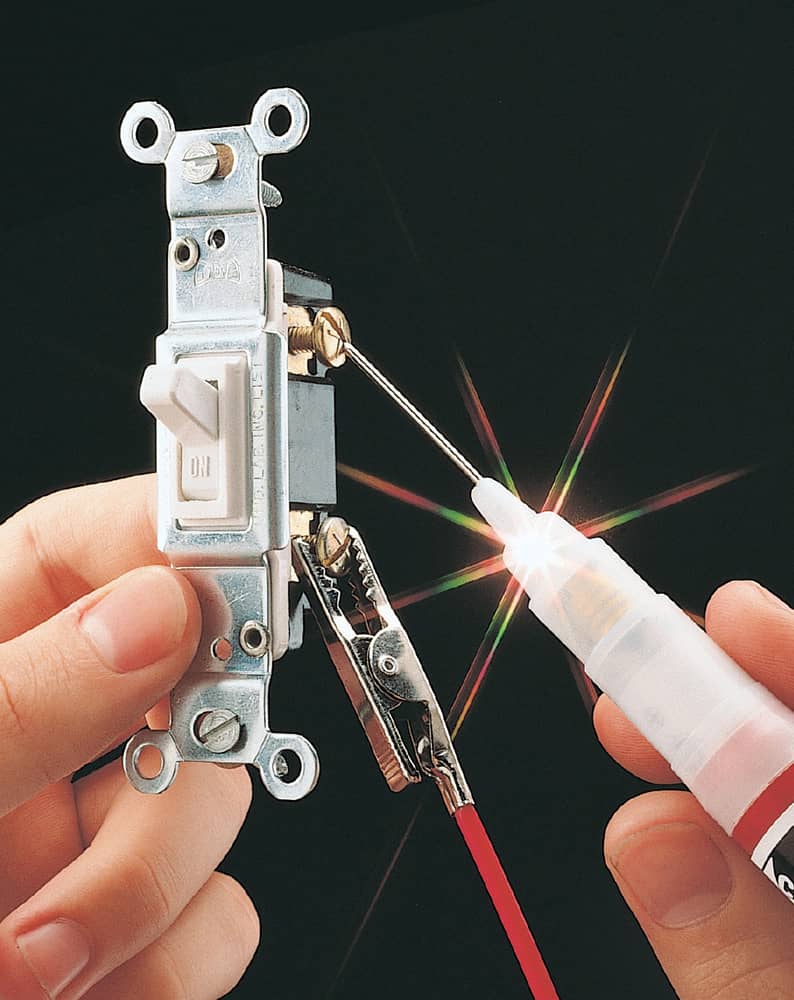

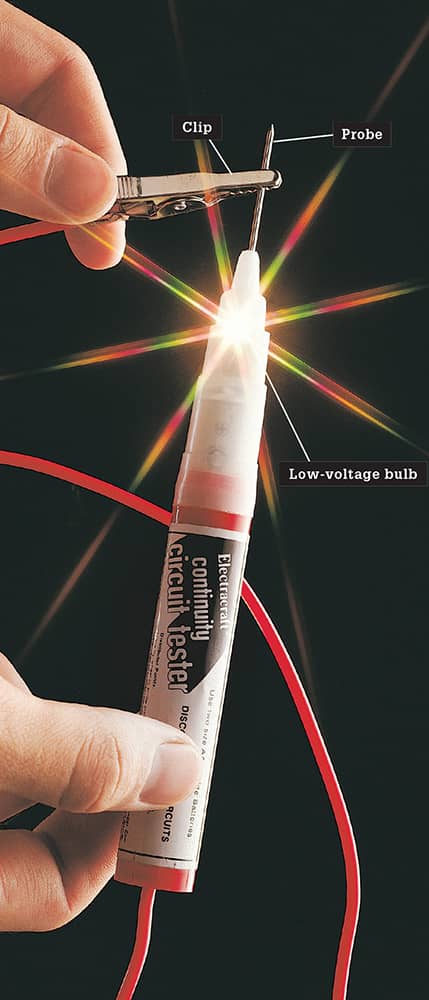

A switch that does not work properly may have worn or broken internal parts. Test switches with a battery-operated continuity tester. The continuity tester detects any break in the metal pathway inside the switch. Replace the switch if the continuity tester shows the switch to be faulty.

Never use a continuity tester on wires that might carry live current. Always shut off the power and disconnect the switch before testing for continuity.

Some specialty switches, such as dimmers, cannot be tested for continuity. Electronic switches can be tested for manual operation using a continuity tester, but the automatic operation of these switches cannot be tested.

How to Test a Single-Pole Wall Switch

Attach the clip of the tester to one of the screw terminals. Touch the tester probe to the other screw terminal. Flip the switch lever from ON to OFF. If the switch is good, the tester glows when the lever is ON but not when it’s OFF.

A continuity tester uses battery-generated current to test the metal pathways running through switches and other electrical fixtures. Always “test” the tester before use. Touch the tester clip to the metal probe. The tester should glow. If not, then the battery or lightbulb is dead and must be replaced.

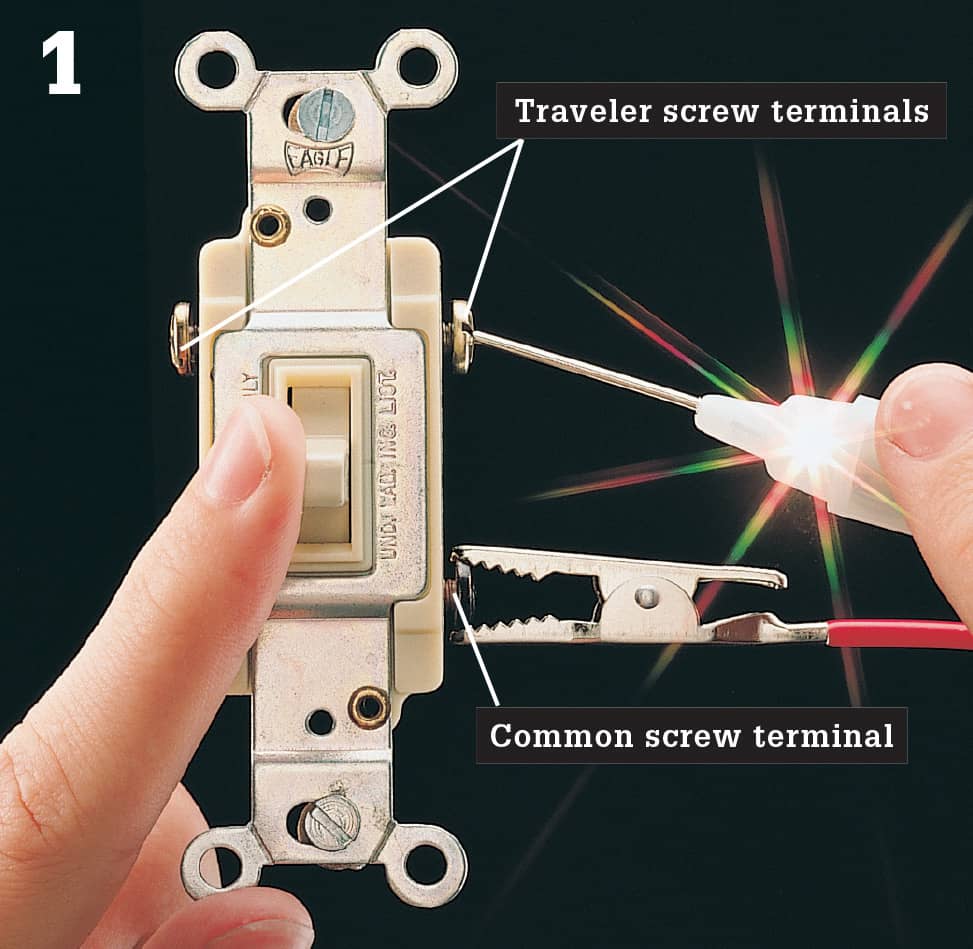

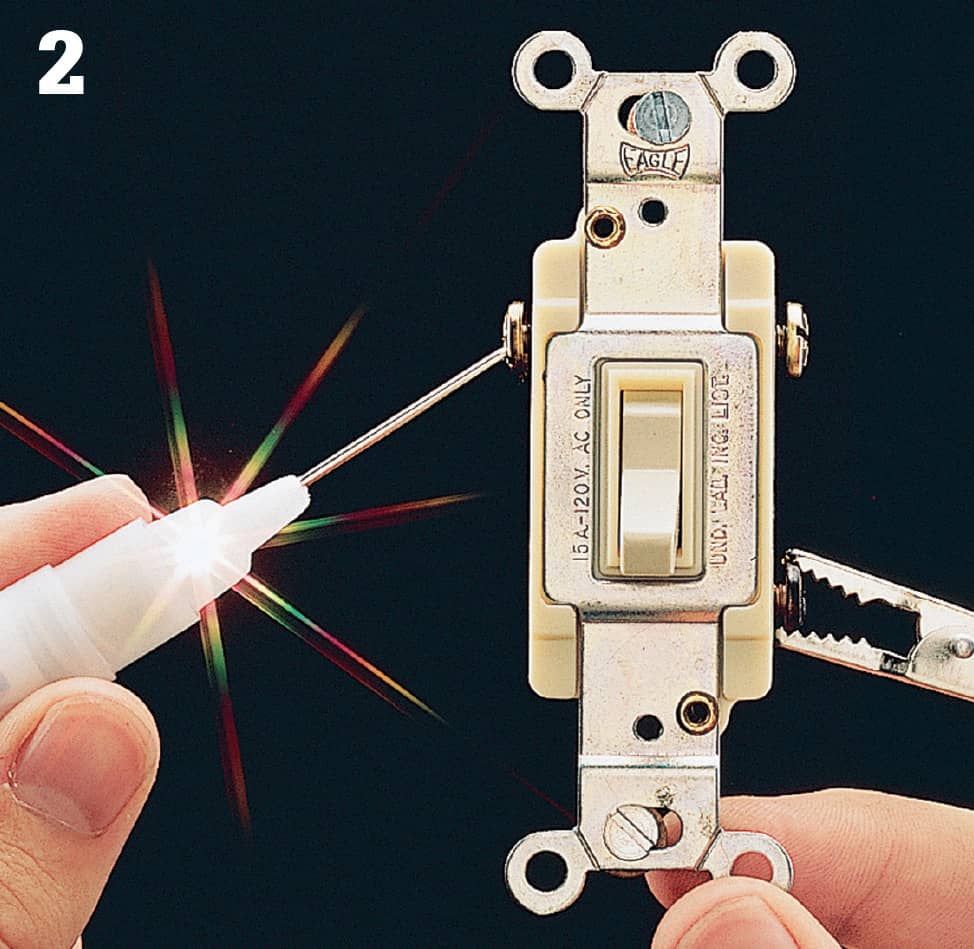

How to Test a Three-way Wall Switch

Attach the tester clip to the dark common screw terminal. Touch the tester probe to one of the traveler screw terminals, and flip the switch lever back and forth. If the switch is good, the tester should glow when the lever is in one position, but not both.

Touch the probe to the other traveler screw terminal, and flip the switch lever back and forth. If the switch is good, the tester will glow only when the switch lever is in the position opposite from the positive test in step 1.

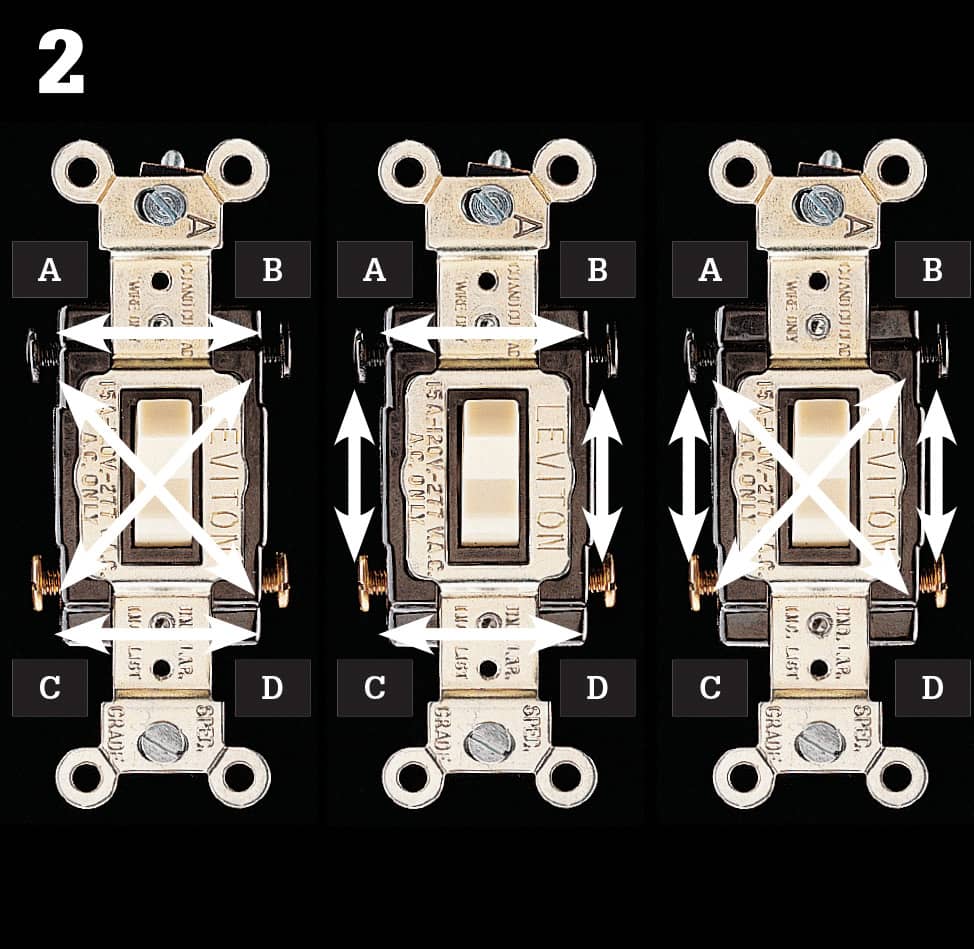

How to Test a Four-way Wall Switch

Test the switch by touching the probe and clip of the continuity tester to each pair of screw terminals (A-B, C-D, A-D, B-C, A-C, B-D). The test should show continuous pathways between the two different pairs of screw terminals. Flip the lever to the opposite position, and repeat the test. It should show continuous pathways between two different pairs of screw terminals.

If the switch is good, the test will show a total of four continuous pathways between screw terminals—two pathways for each lever position. If not, then the switch is faulty and must be replaced. (The arrangement of the pathways may differ, depending on the switch manufacturer. The photo above shows the three possible pathway arrangements.)

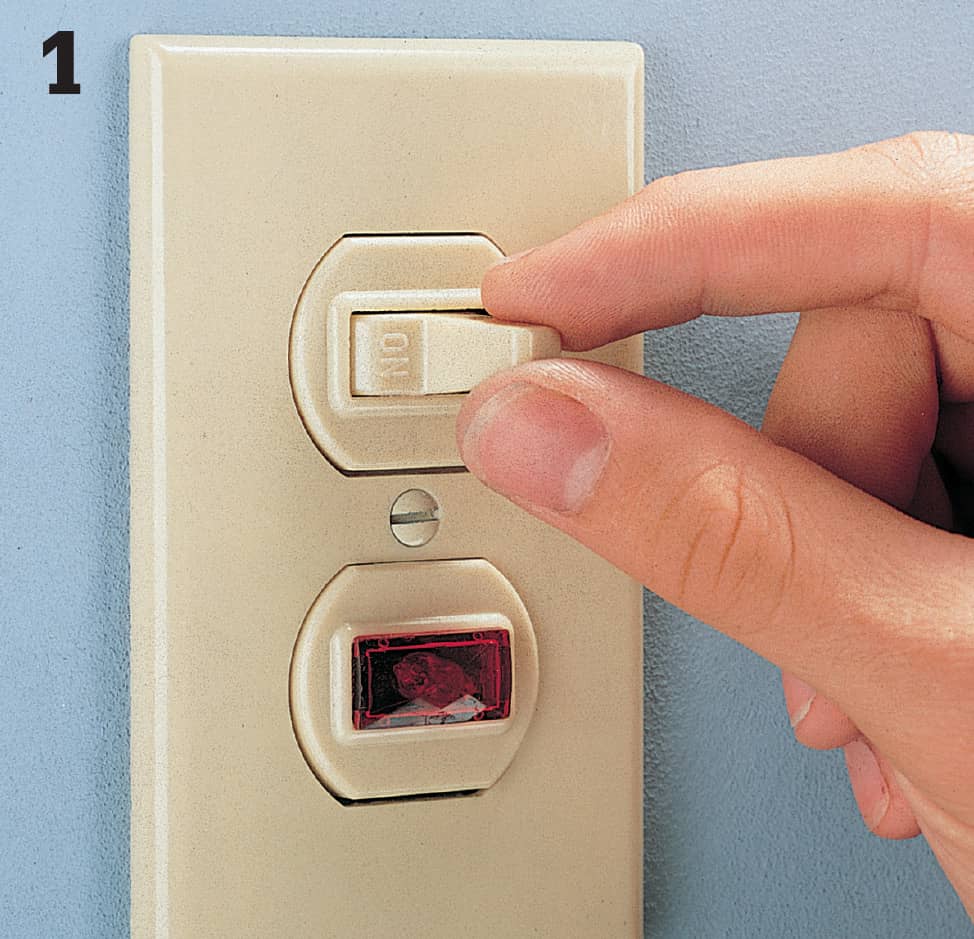

How to Test a Pilot-Light Switch

Test the pilot light by flipping the switch lever to the ON position. Check to see if the light fixture or appliance is working. If the pilot light does not glow even though the switch operates the light fixture or appliance, then the pilot light is defective and the unit must be replaced.

Test the switch by disconnecting the unit. With the switch lever in the ON position, attach the tester clip to the top screw terminal on one side of the switch. Touch the tester probe to the top screw terminal on the opposite side of the switch. If the switch is good, the tester will glow when switch is ON but not when OFF.

How to Test a Timer Switch

Attach the tester clip to the red wire lead on the timer switch, and touch the tester probe to the black hot lead. Rotate the timer dial clockwise until the ON tab passes the arrow marker. The tester should glow. If it does not, the switch is faulty and must be replaced.

Rotate the dial clockwise until the OFF tab passes the arrow marker. The tester should not glow. If it does, the switch is faulty and must be replaced.

How to Test a Switch/Receptacle

Attach the tester clip to one of the top screw terminals. Touch the tester probe to the top screw terminal on the opposite side. Flip the switch lever from ON to OFF position. If the switch is working correctly, the tester will glow when the switch lever is ON but not when it’s OFF.

How to Test a Double Switch

Test each half of the switch by attaching the tester clip to one screw terminal and touching the probe to the opposite side. Flip the switch lever from ON to OFF position. If the switch is good, the tester glows when the switch lever is ON but not when it’s OFF. Repeat the test with the remaining pair of screw terminals. If either half tests faulty, replace the unit.

How to Test a Time-Delay Switch

Attach the tester clip to one of the wire leads, and touch the tester probe to the other lead. Set the timer for a few minutes. If the switch is working correctly, the tester will glow until the time expires.

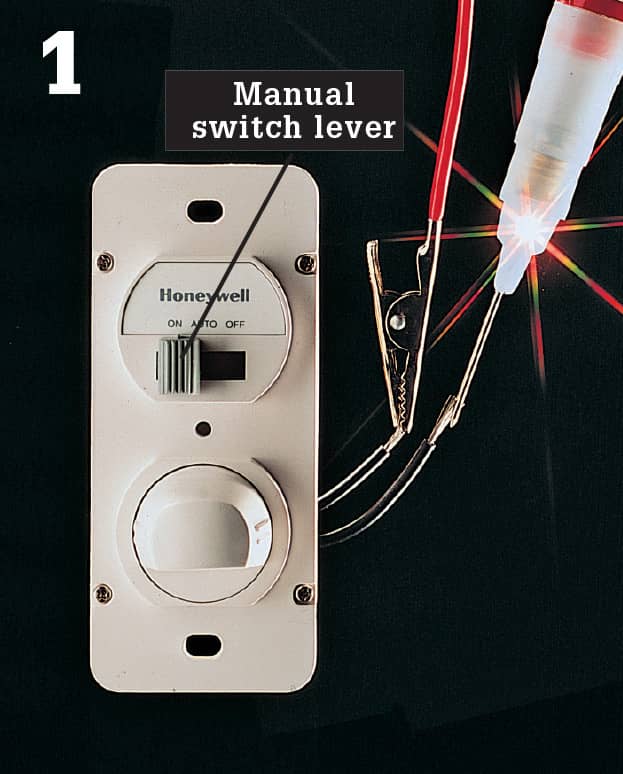

How to Test Manual Operation of Electronic Switches

Automatic switch: Attach the tester clip to a black wire lead, and touch the tester probe to the other black lead. Flip the manual switch lever from ON to OFF position. If the switch is working correctly, the tester will glow when the switch lever is ON but not when it’s OFF.

Programmable switch: Attach the tester clip to a wire lead, and touch the tester probe to the other lead. Flip the manual switch lever from ON to OFF position. If the switch is working correctly, the tester will glow when the switch lever is ON but not when it’s OFF.

Motion-sensor switch: Attach the tester clip to a wire lead, and touch the tester probe to the other lead. Flip the manual switch lever from ON to OFF position. If the switch is working correctly, the tester will glow when the switch lever is ON but not when it’s OFF.

Receptacles

Receptacles

Several different types of receptacles are found in the typical home. Each has a unique arrangement of slots that accepts only a certain kind of plug, and each is designed for a specific job.

Household receptacles provide two types of voltage: normal and high. Although voltage ratings have changed slightly over the years, normal receptacles should be rated for 110, 115, 120, or 125 volts. For purposes of replacement, these ratings are considered identical. High-voltage receptacles are rated at 220, 240, or 250 volts. These ratings are considered identical.

When replacing a receptacle, check the amperage rating of the circuit at the main service panel, and buy a receptacle with the correct amperage rating.

15 amps, 120 volts. Polarized two-slot receptacles are common in homes built before 1960. Slots are different sizes to accept polarized plugs.

15 amps, 120 volts. Three-slot grounded receptacles have two different-sized slots and a U-shaped hole for grounding which is required in all new wiring installations.

20 amps, 120 volts. This three-slot grounded receptacle features a special T-shaped slot. It is installed for use with large appliances or portable tools that require 20 amps of current.

15 amps, 240 volts. This receptacle is used primarily for window air conditioners. It is available as a single unit or as half of a duplex receptacle, with the other half wired for 120 volts.

30 amps, 120/240 volts. This grounded receptacle is used for clothes dryers. It provides high-voltage current for heating coils and 120-volts to run lights and timers.

50 amps, 120/240 volts. This new, grounded receptacle is used for ranges. The high voltage powers heating coils, and the 120-volts run clocks and lights.

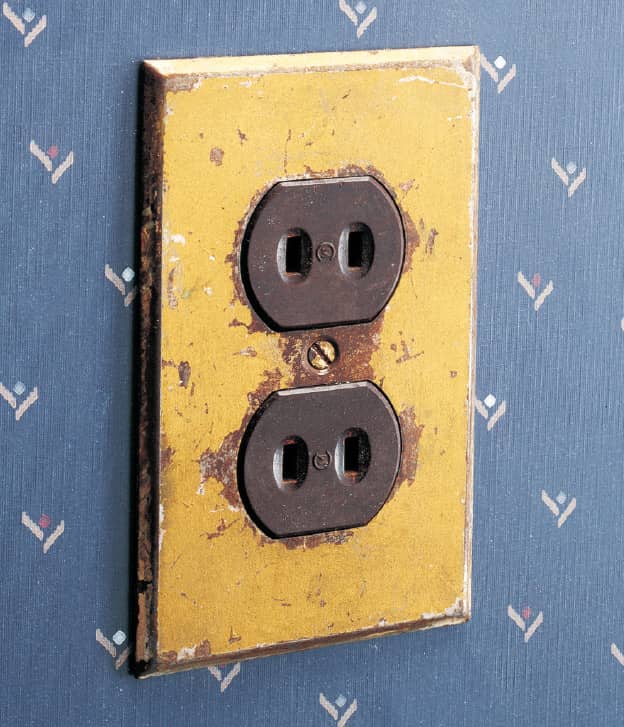

Older Receptacles

Older receptacles may look different from more modern types, but most will stay in good working order. Follow these simple guidelines for evaluating or replacing older receptacles:

• Never replace a receptacle with one of a different voltage or higher amperage rating.

• Do not replace a two-slot receptacle with a three-slot receptacle. Replace the two-slot receptacle with a polarized two-slot receptacle or with a GFCI receptacle.

• If in doubt, contact an electrician.

• Never alter the prongs of a plug to fit an older receptacle. Altering the prongs may remove the grounding or polarizing features of the plug.

The earliest receptacles were modifications of the screw-in light bulb. This receptacle was used in the early 1900s.

Unpolarized receptacles have same-length slots. Modern plugs may not fit these receptacles. Never modify the prongs of a polarized plug to fit the slots of an unpolarized receptacle.

Surface-mounted receptacles were popular in the 1940s and 1950s for their ease of installation. Wiring ran behind hollowed-out base moldings. These receptacles are usually ungrounded.

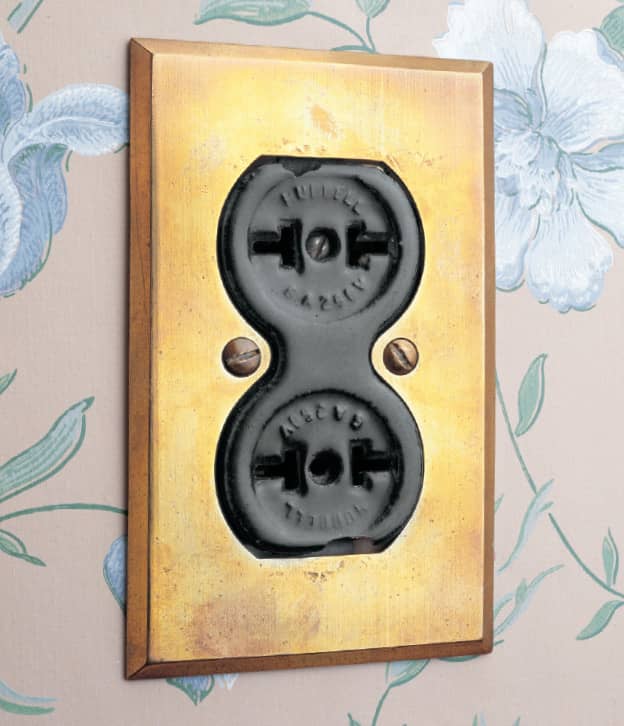

Ceramic duplex receptacles were manufactured in the 1930s. They are polarized but ungrounded, and they are wired for 120 volts.

Twist-lock receptacles are designed to be used with plugs that are inserted and rotated. A small tab on the end of one of the prongs prevents the plug from being pulled from the receptacle.

This ceramic duplex receptacle has a unique hourglass shape. It is rated for 250 volts but only 5 amps and would not be allowed by today’s electrical codes.

High-Voltage Receptacles

High-voltage receptacles provide current to large appliances such as clothes dryers, ranges, and air conditioners. The slot configuration of a high-voltage receptacle (page 434) will not accept a plug rated for 120 volts.

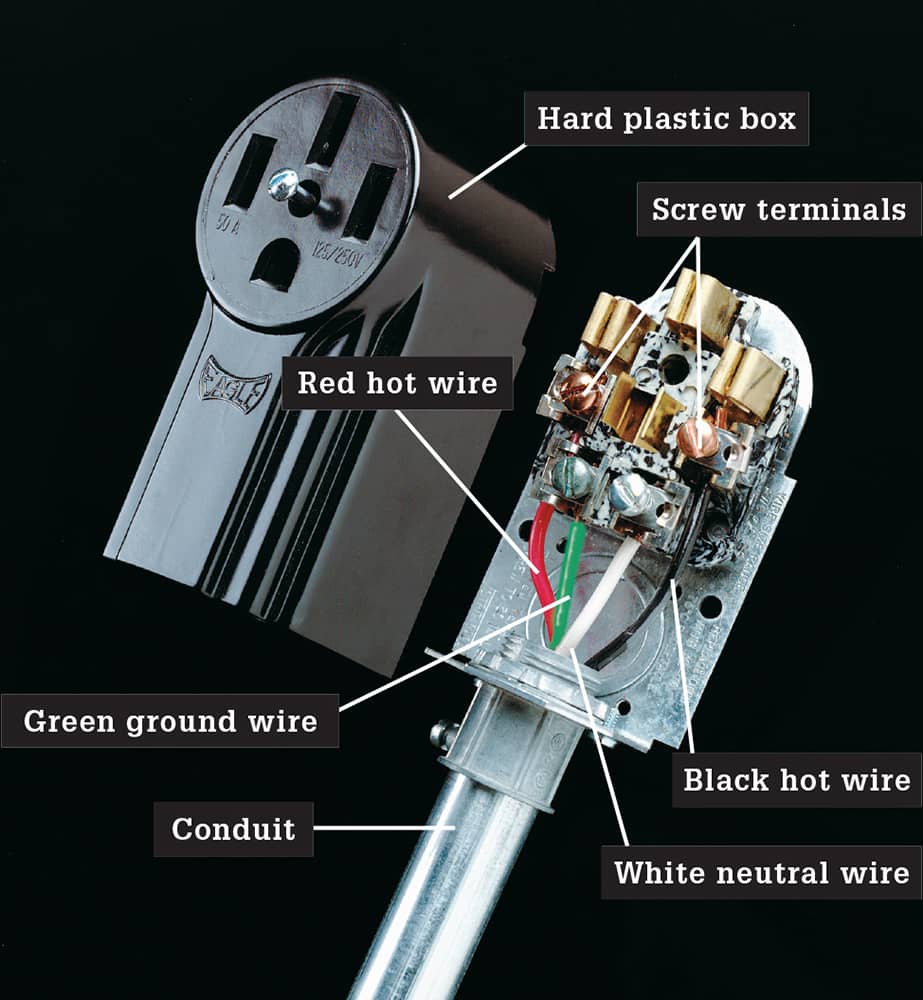

A high-voltage receptacle can be wired in one of two ways. In one type of high-voltage receptacle, voltage is brought to the receptacle with two hot wires, each carrying a maximum of 120 volts. No white neutral wire is necessary, but a grounding wire should be attached to the receptacle and to the metal receptacle box. Conduit may also act as a grounding conductor from the metal receptacle box back to the panel in old circuits without a grounding wire. This method is not allowed today.

A clothes dryer or range also may require 120 volts to run lights, timers, and clocks. If so, a white neutral wire will be attached to the receptacle. The appliance itself will split the incoming electricity into a 120-volt circuit and a 240-volt circuit.

It is important to identify and tag all wires on the existing receptacle so that the new receptacle will be properly wired.

One type of receptacle rated for 240 volts has two incoming hot wires and no neutral wire. A grounding wire is pigtailed to the receptacle and to the metal receptacle box.

A receptacle rated for 120/240 volts has two incoming hot wires, each carrying 120 volts, a white neutral wire, and a copper grounding wire. Connections are made with setscrew terminals at the back of the receptacle.

This surface-mounted receptacle rated for 240 volts has a hard plastic box that can be installed on concrete or block walls. Surface-mounted receptacles are often found in basements and utility rooms.

Childproofing

Childproof your receptacles or adapt them for special uses by adding receptacle accessories. Before installing an accessory, be sure to read the manufacturer’s instructions.

Homeowners with small children should add inexpensive caps or covers to guard against accidental electric shocks.

Plastic caps do not conduct electricity and are virtually impossible for small children to remove. A receptacle cover attaches directly to the receptacle and fits over plugs, preventing the cords from being removed. Tamper-resistant receptacles are now required in all new residential installations.

Standard receptacles present a real shock hazard to small children. Fortunately there are many products that make receptacles safer without making them less convenient.

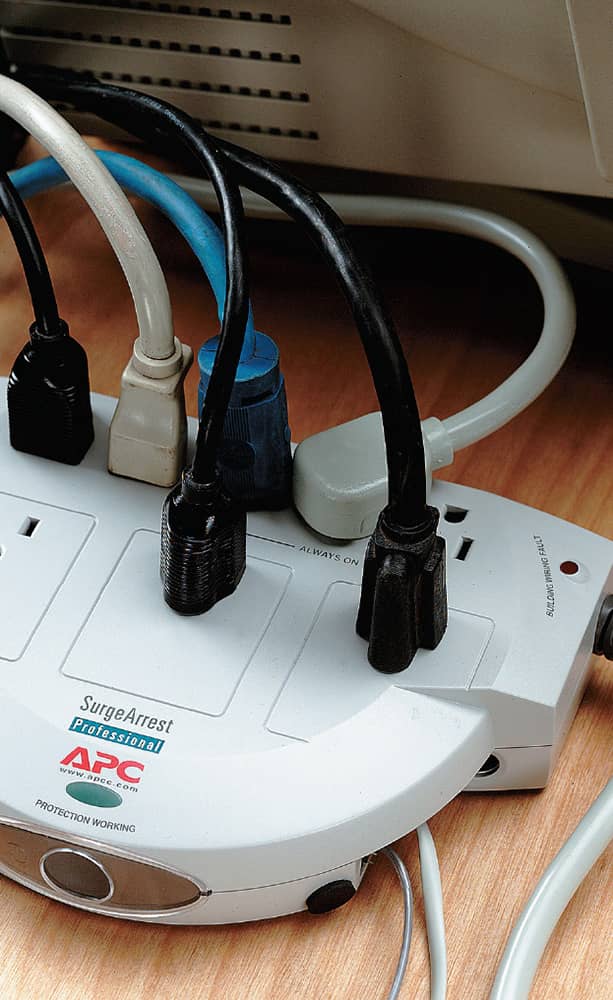

Protect electronic equipment, such as a home computer or stereo, with a surge protector. The surge protector reduces the chance of any damage to sensitive equipment caused by sudden drops or surges in power.

A recessed wall receptacle permits a plug-in clock to be hung flush against a wall surface.

Snap protective caps over sockets to prevent children from having access to the slots.

Duplex Receptacles

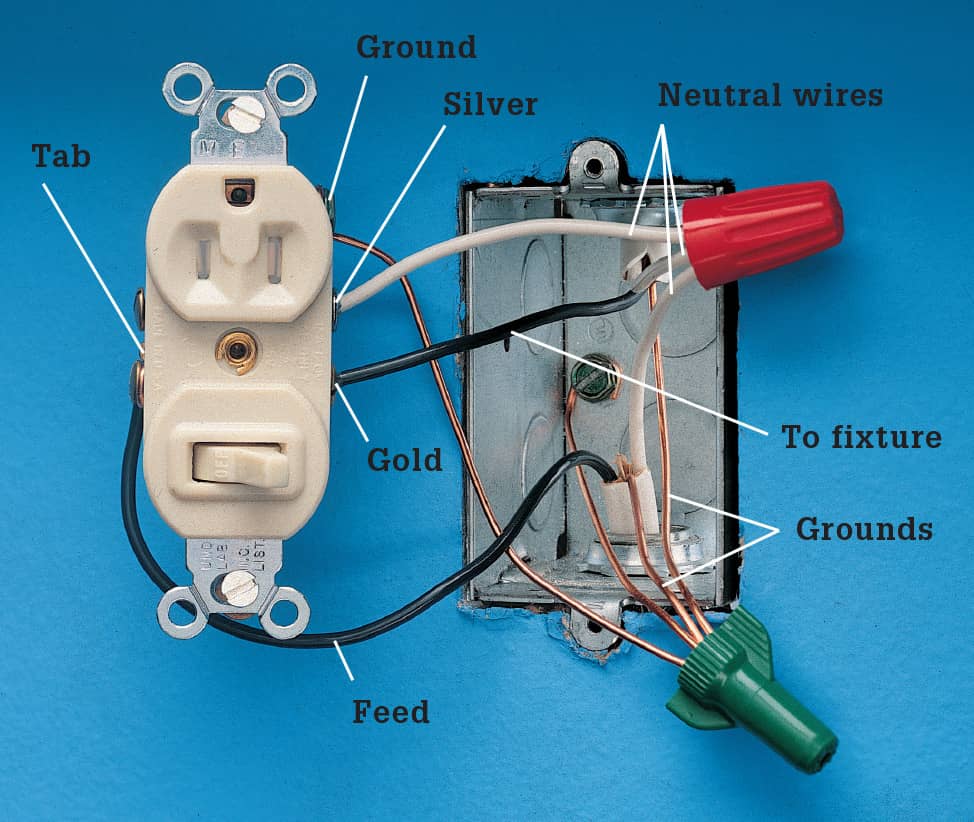

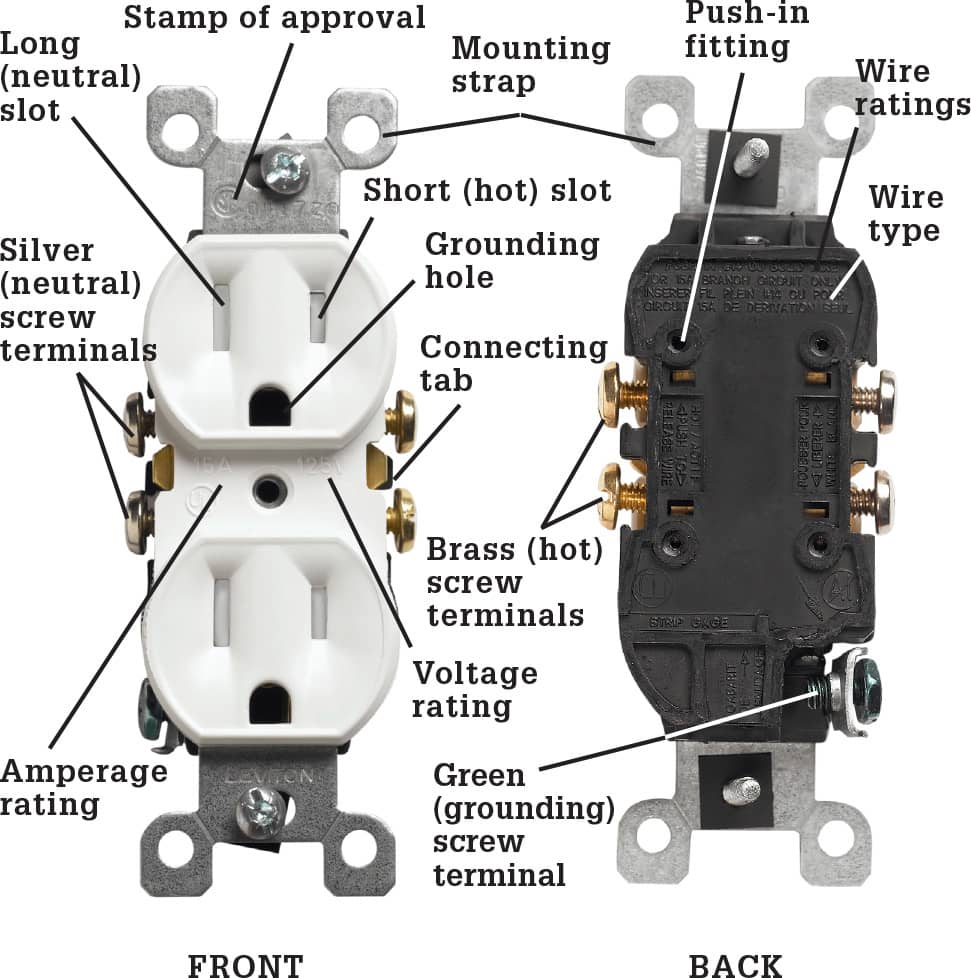

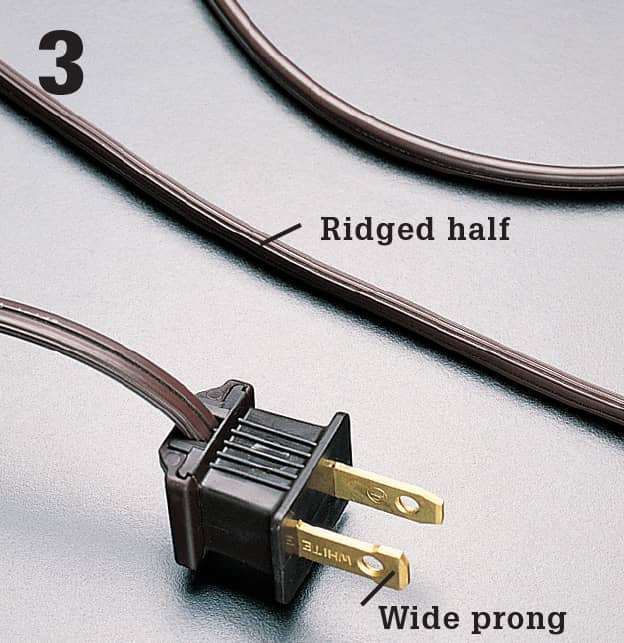

The standard duplex receptacle has two halves for receiving plugs. Each half has a long (neutral) slot, a short (hot) slot, and a U-shaped grounding hole. The slots fit the wide prong, narrow prong, and grounding prong of a three-prong plug. This ensures that the connection between receptacle and plug will be polarized and grounded for safety.

Wires are attached to the receptacle at screw terminals or push-in fittings. A connecting tab between the screw terminals allows a variety of different wiring configurations. Receptacles also include mounting straps for attaching to electrical boxes.

Stamps of approval from testing agencies are found on the front and back of the receptacle. Look for the symbol UL or UND. LAB. INC. LIST to make sure the receptacle meets the strict standards of Underwriters Laboratories.

The receptacle is marked with ratings for maximum volts and amps. The common receptacle is marked 15A, 125V. Receptacles marked CU or COPPER are used with solid copper wire. Those marked CU-CLAD ONLY are used with copper-coated aluminum wire. Only receptacles marked CO/ALR may be used with solid aluminum wiring. Receptacles marked AL/CU no longer may be used with aluminum wire, according to code.

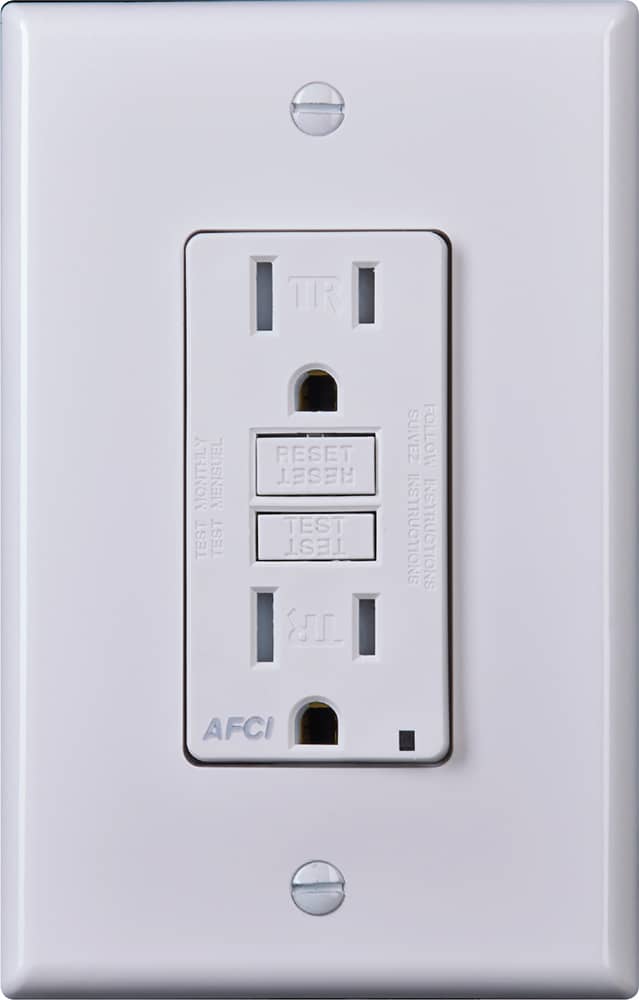

AFCI receptacles have integral protection against arc faults and may be required in some remodeling situations where AFCI protection cannot be provided at the service panel.

The ground-fault circuit-interrupter, or GFCI, receptacle is a modern safety device. When it detects slight changes in current, it instantly shuts off power. The larger picture shows a modern GFCI with an alert bulb that lights when the device is tripped. The older but more familiar style is seen in the inset photo.

Receptacle Wiring Configurations

Receptacle Wiring Configurations

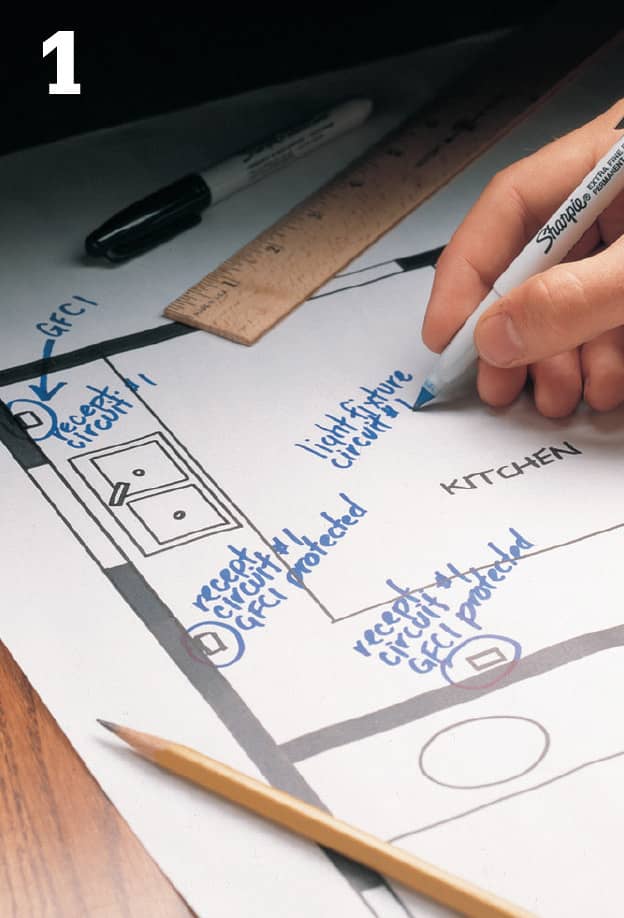

A 120-volt duplex receptacle can be wired to the electrical system in several ways. The most common are shown on these pages.

Wiring configurations may vary slightly from these photographs, depending on the kind of receptacles used, the type of cable, or the technique of the electrician who installed the wiring. To make dependable repairs or replacements, use masking tape and label each wire according to its location on the terminals of the existing receptacle.

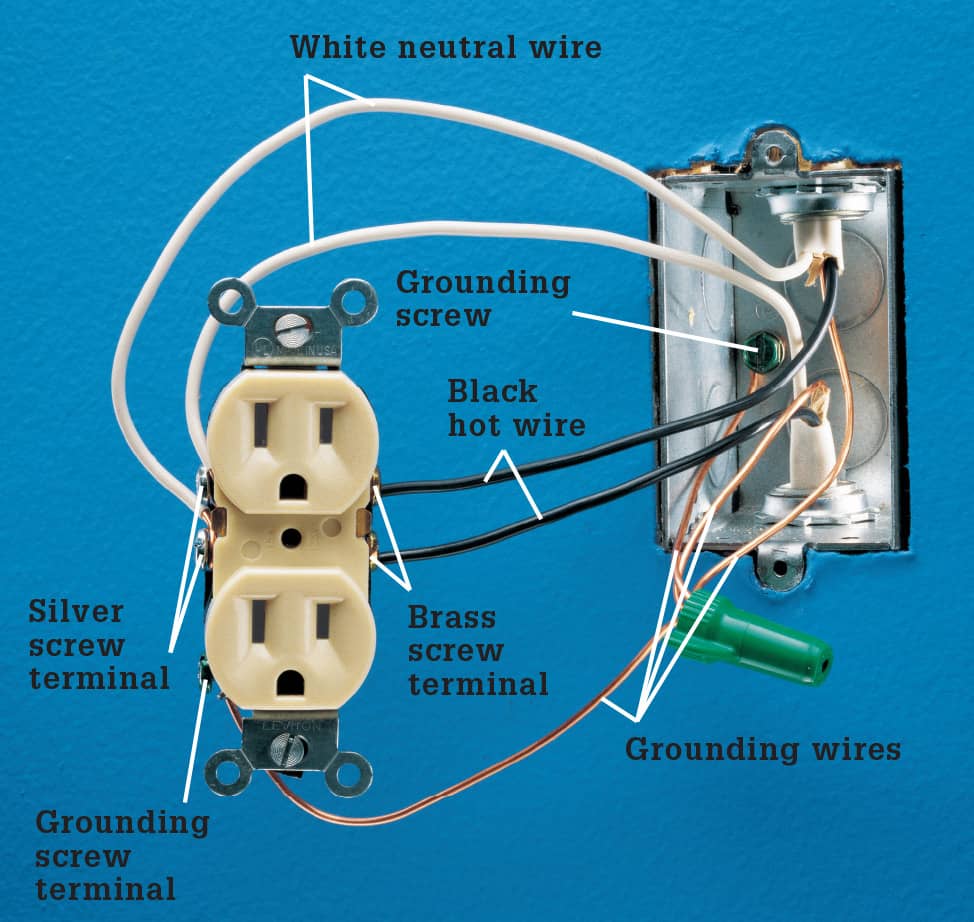

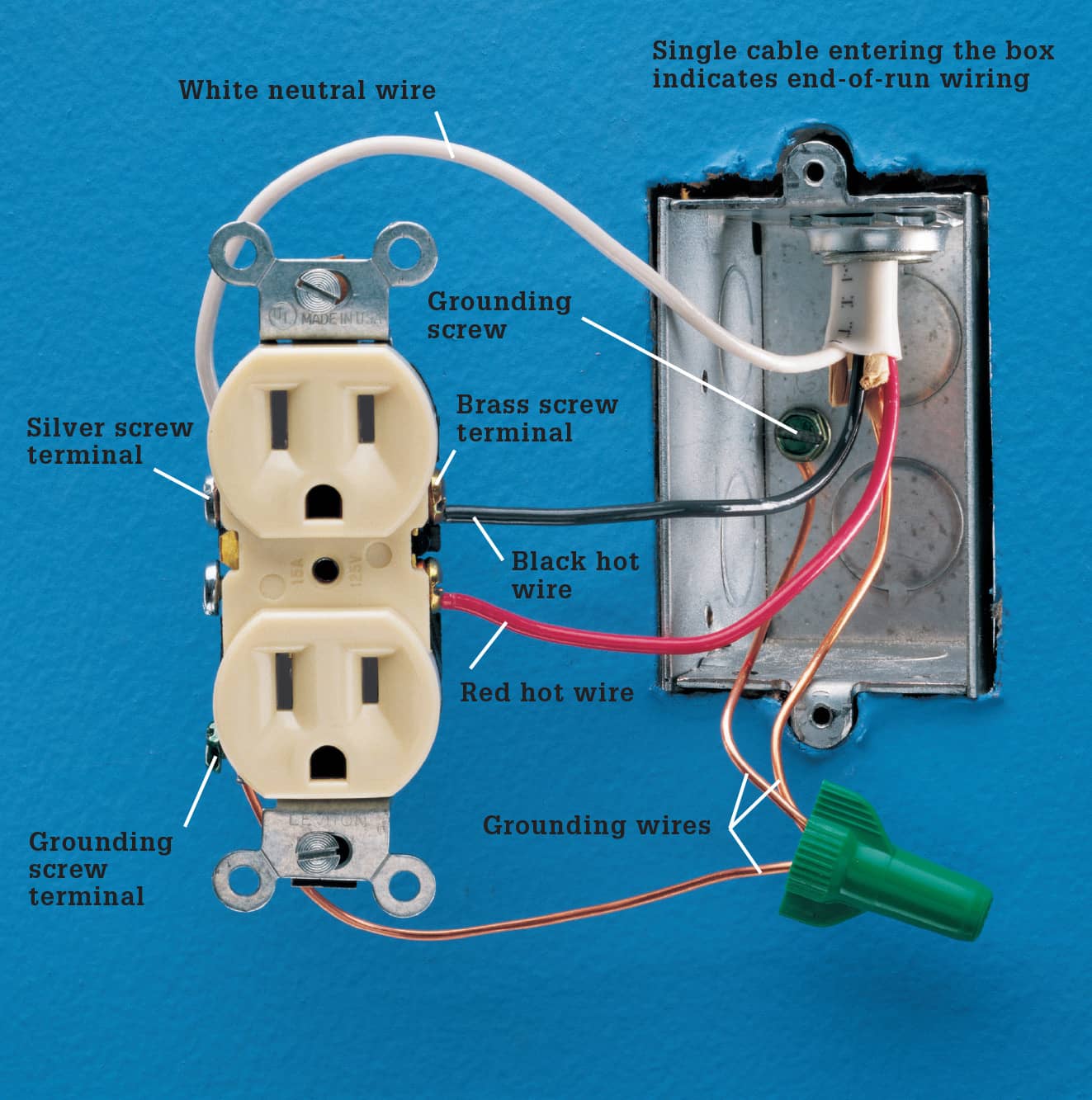

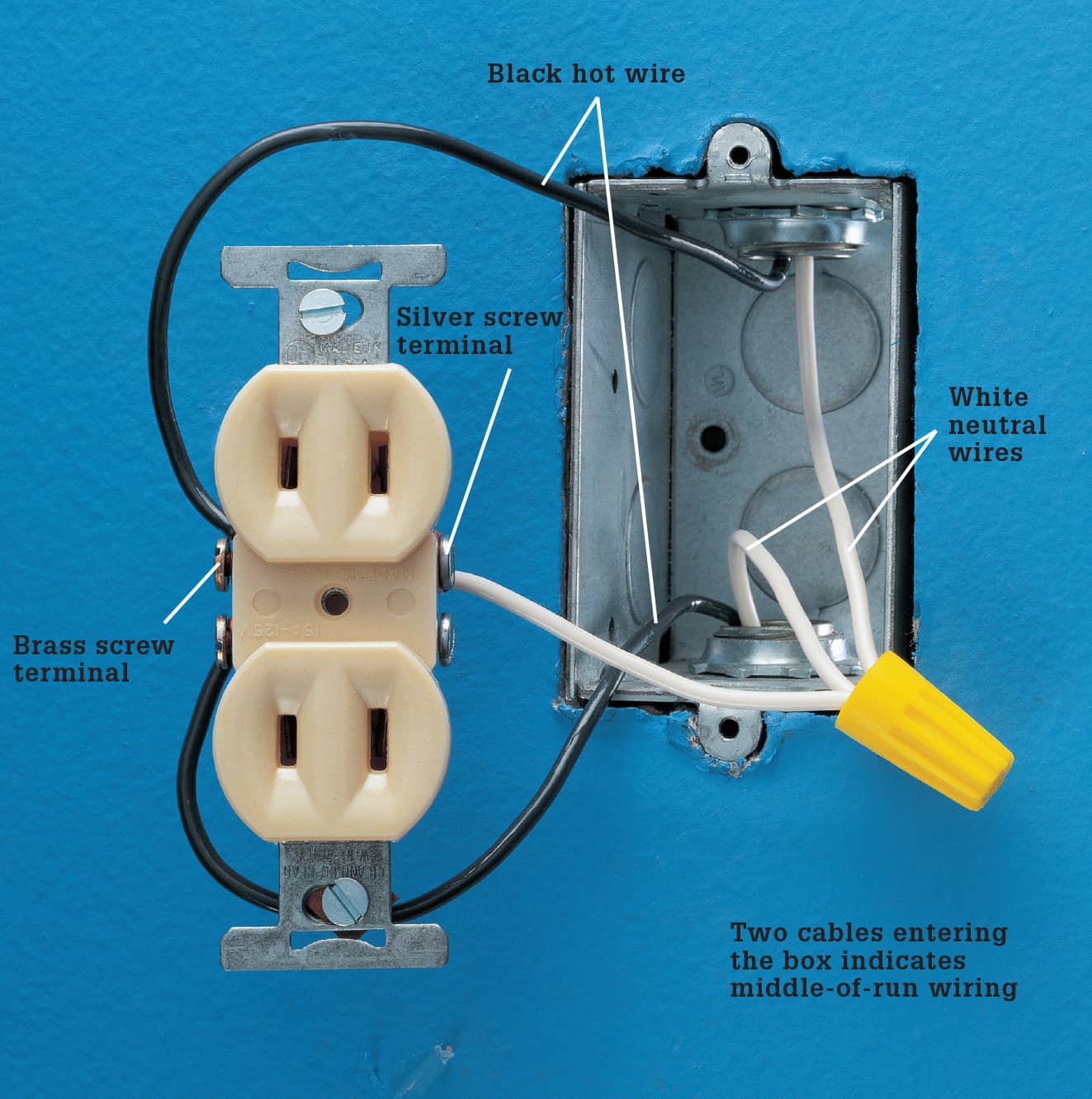

Receptacles are wired as either end-of-run or middle-of-run. These two basic configurations are easily identified by counting the number of cables entering the receptacle box. End-of-run wiring has only one cable, indicating that the circuit ends. Middle-of-run wiring has two cables, indicating that the circuit continues on to other receptacles, switches, or fixtures.

A split-circuit receptacle is shown on the next page. Each half of a split-circuit receptacle is wired to a separate circuit. This allows two appliances of high wattage to be plugged into the same receptacle without blowing a fuse or tripping a breaker. This wiring configuration is similar to a receptacle that is controlled by a wall switch. Code requires a switch-controlled receptacle in most rooms that do not have a built-in light fixture operated by a wall switch.

Split-circuit and switch-controlled receptacles are connected to two hot wires, so use caution during repairs or replacements. Make sure the connecting tab between the hot screw terminals is removed.

Two-slot receptacles are common in older homes. There is no grounding wire attached to the receptacle, but the metal box may be grounded with armored cable or metal conduit. Tamper-resistant receptacles are now required in all new residential installations.

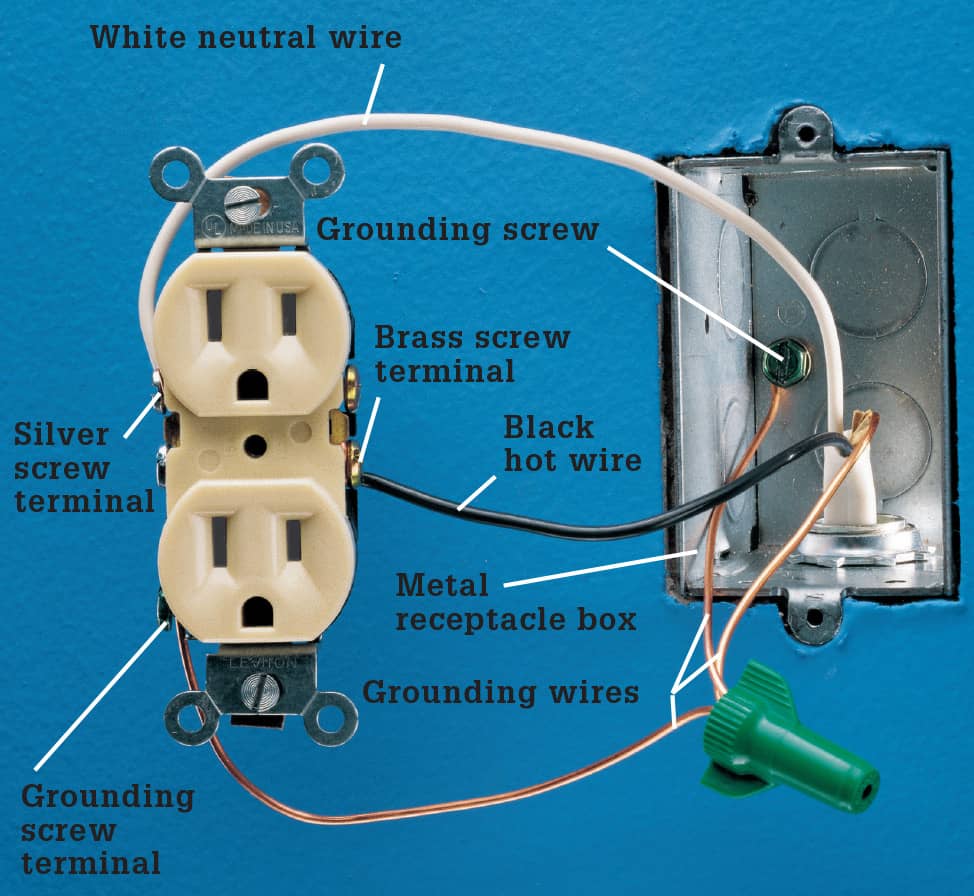

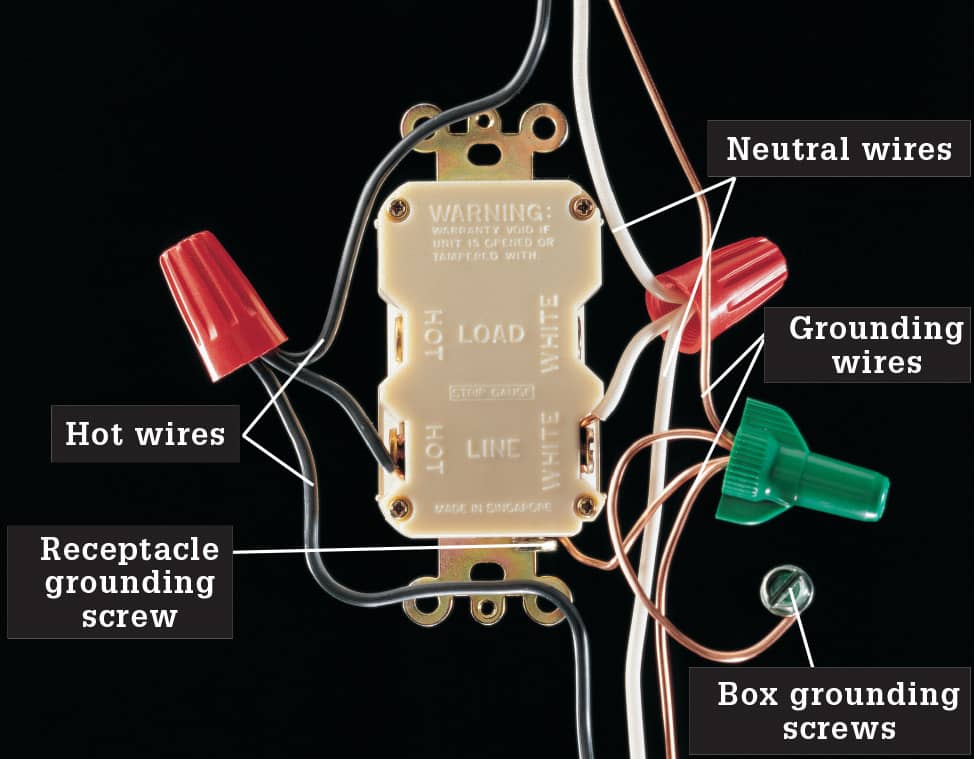

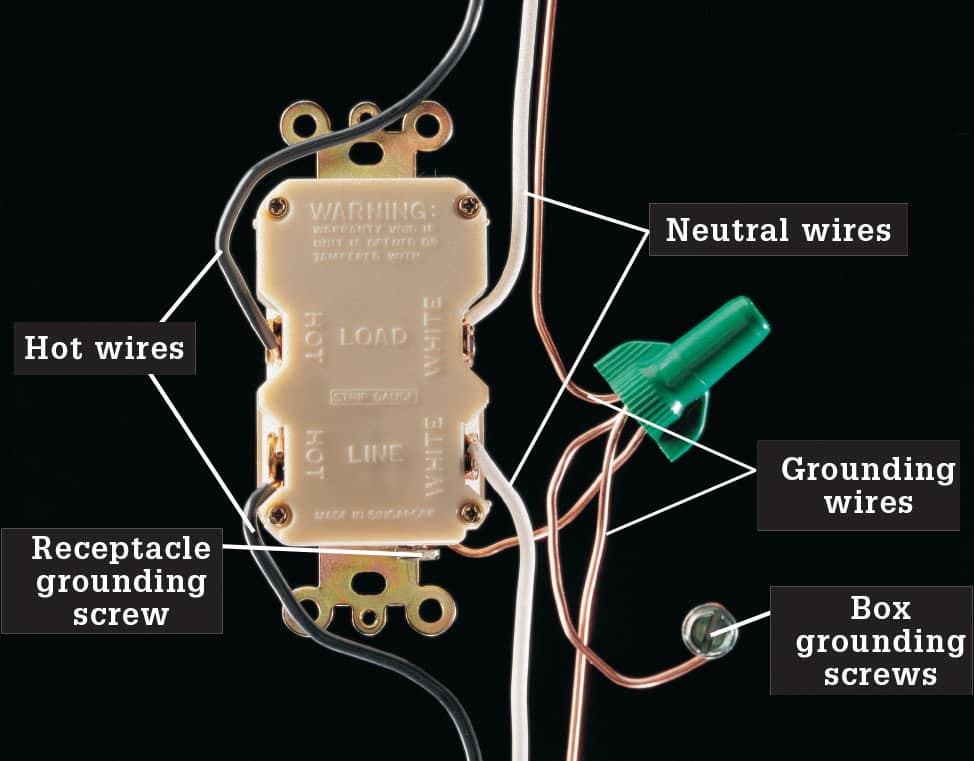

A single cable entering the box indicates end-of-run wiring. The black hot wire is attached to a brass screw terminal, and the white neutral wire is connected to a silver screw terminal. If the box is metal, the grounding wire is pigtailed to the grounding screws of the receptacle and the box. In a plastic box, the grounding wire is attached directly to the grounding screw terminal of the receptacle.

Two cables entering the box indicate middle-of-run wiring. Black hot wires are connected to brass screw terminals and white neutral wires to silver screw terminals. The grounding wire is pigtailed to the grounding screws of the receptacle and the box.

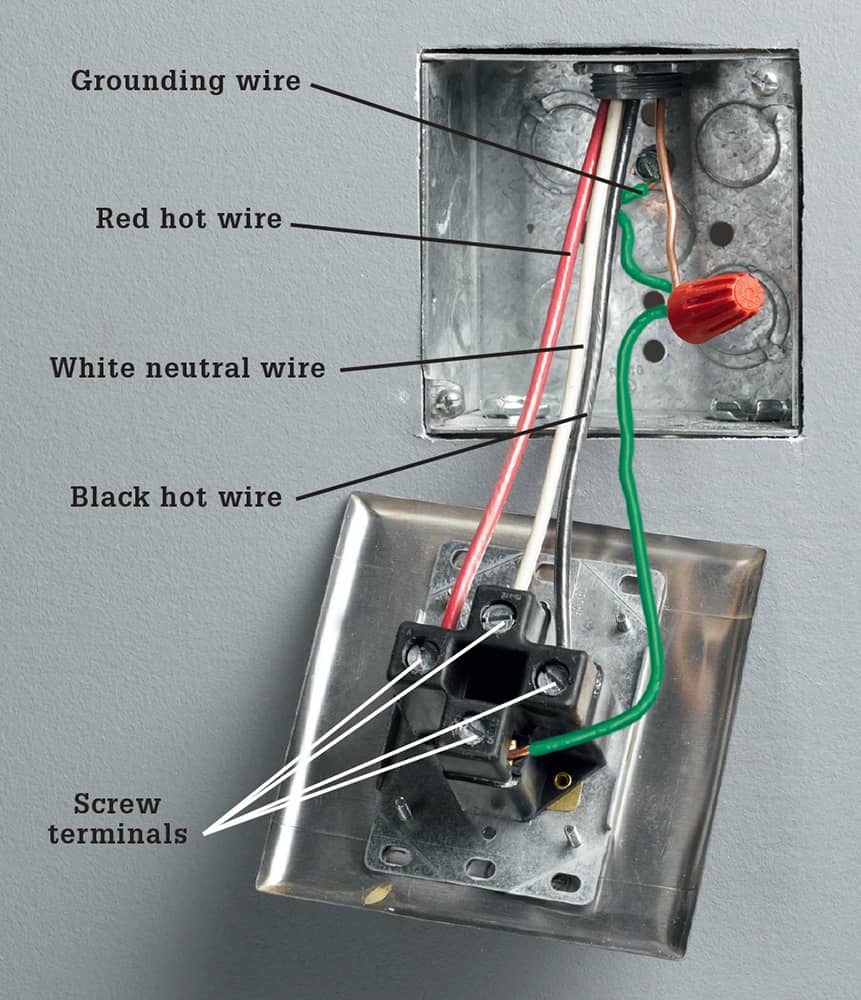

A split-circuit receptacle (technically a multi-wire branch circuit) is attached to a black hot wire, a red hot wire, a white neutral wire, and a bare grounding wire. The wiring is similar to a switch-controlled receptacle. The hot wires are attached to the brass screw terminals, and the connecting tab or fin between the brass terminals is removed. The white wire is attached to a silver screw terminal, and the connecting tab on the neutral side remains intact. The grounding wire is pigtailed to the grounding screw terminal of the receptacle and to the grounding screw attached to the box.

A two-slot receptacle is often found in older homes. The black hot wires are connected to the brass screw terminals, and the white neutral wires are pigtailed to a silver screw terminal. Two-slot receptacles may be replaced with three-slot types, but only if a means of grounding exists at the receptacle box. In some municipalities, you may replace a two-slot receptacle with a GFCI receptacle as long as the receptacle has a sticker that reads “No equipment ground.”

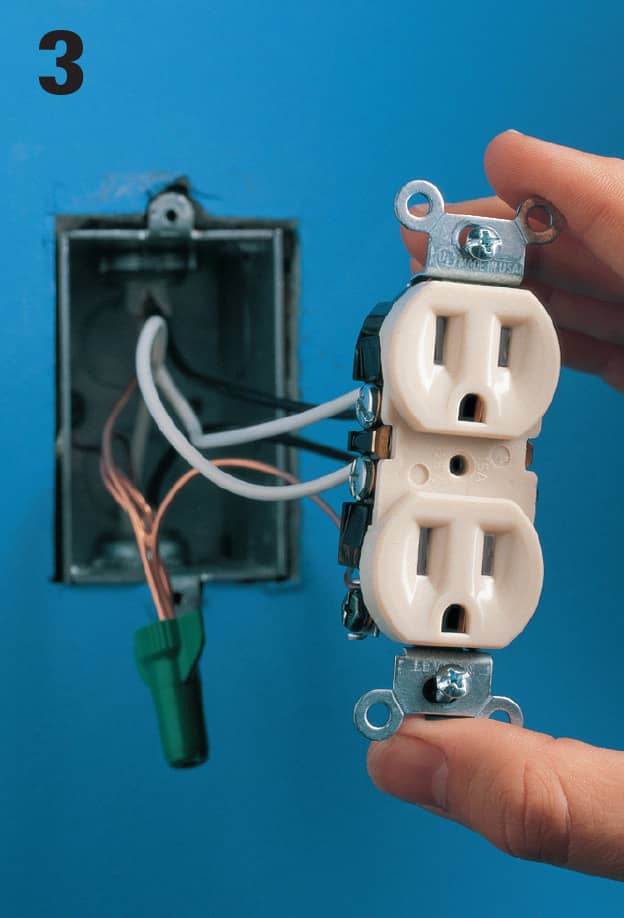

How to Install a New Receptacle

Position the new old work box on the wall and trace around it. Consider the location of hidden utilities within the wall before you cut.

Remove baseboard between the new and existing receptacle. Cut away the drywall about 1" below the baseboard with a jigsaw, wallboard saw, or utility knife.

Drill a 5/8" hole in the center of each stud along the opening between the two receptacles. A drill bit extender or a flexible drill bit will allow you a better angle and make drilling the holes easier.

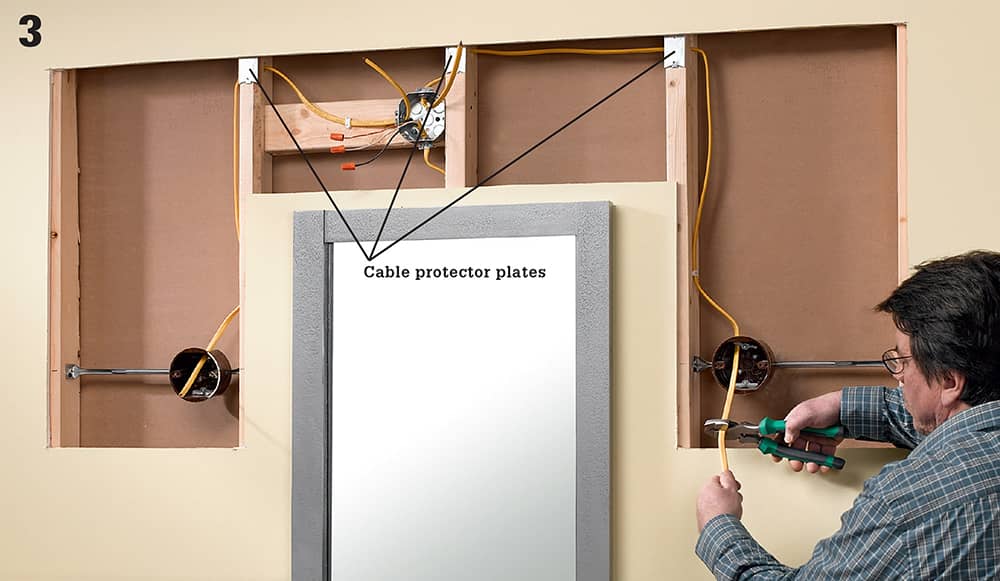

Run the branch cable through the holes from the new location to the existing receptacle. Staple the cable to the stud below the box. Install a metal nail plate on the front edge of each stud that the cable routes through.

Turn off the power at the panel and test for power. Remove the old receptacle and its box, and pull the new branch cable up through the hole. Remove sheathing and insulation from both ends of the new cable.

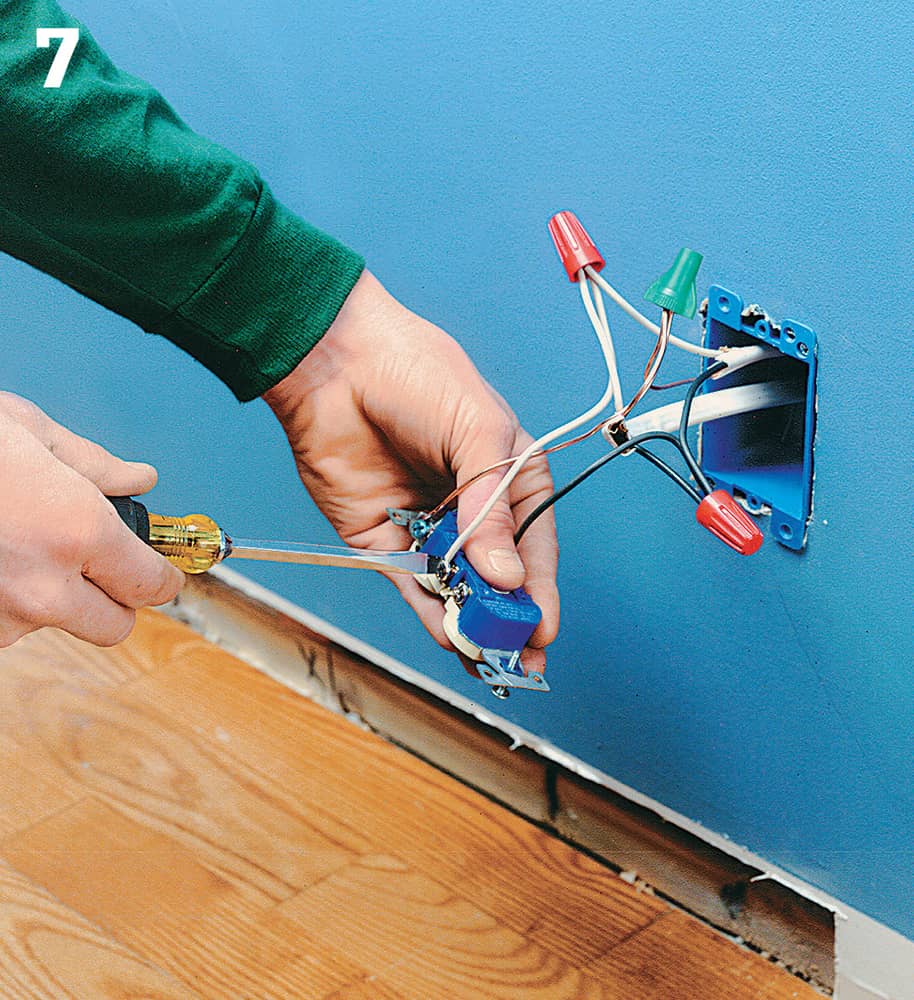

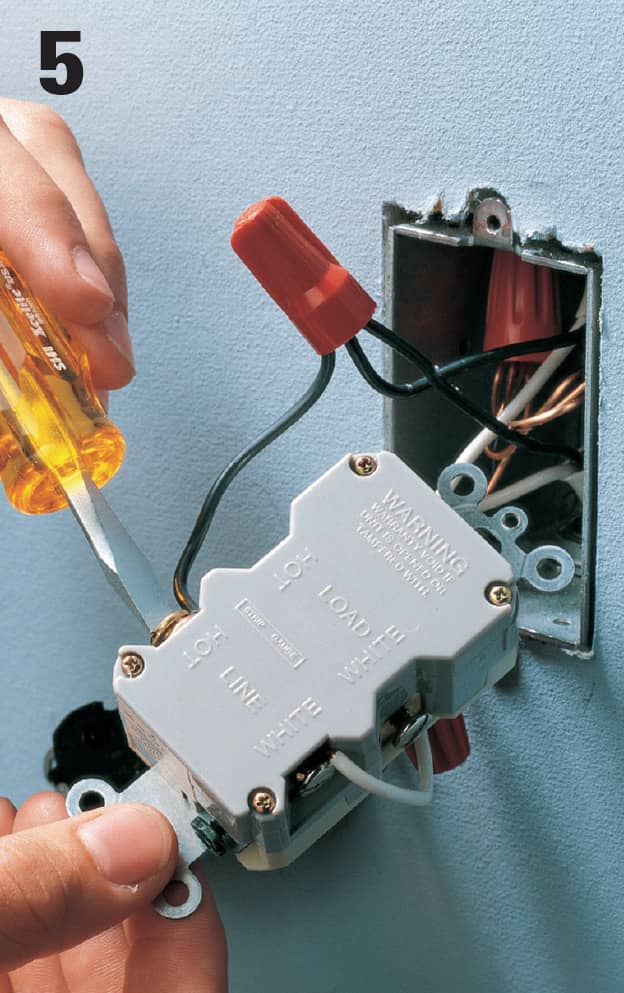

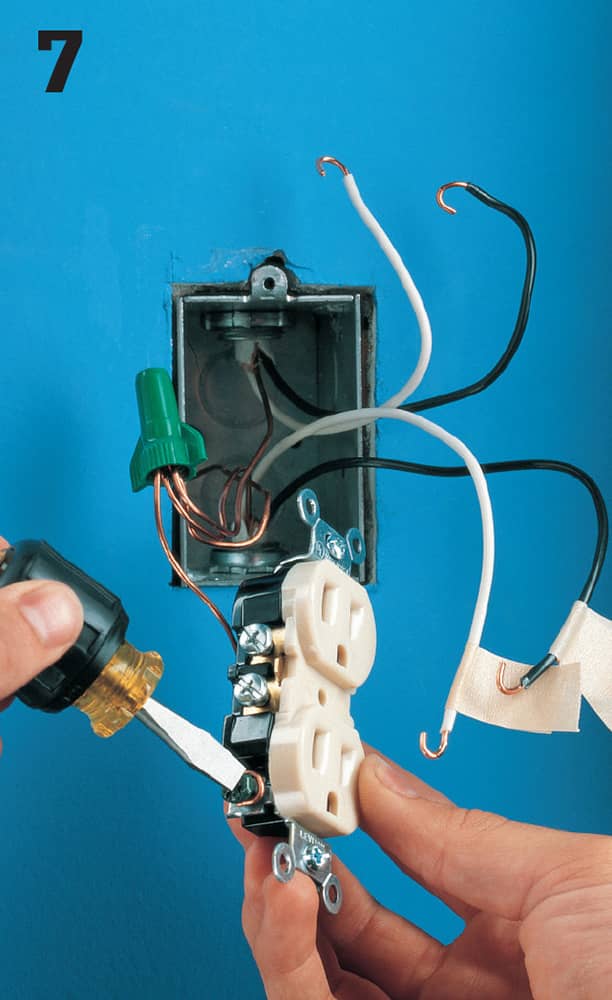

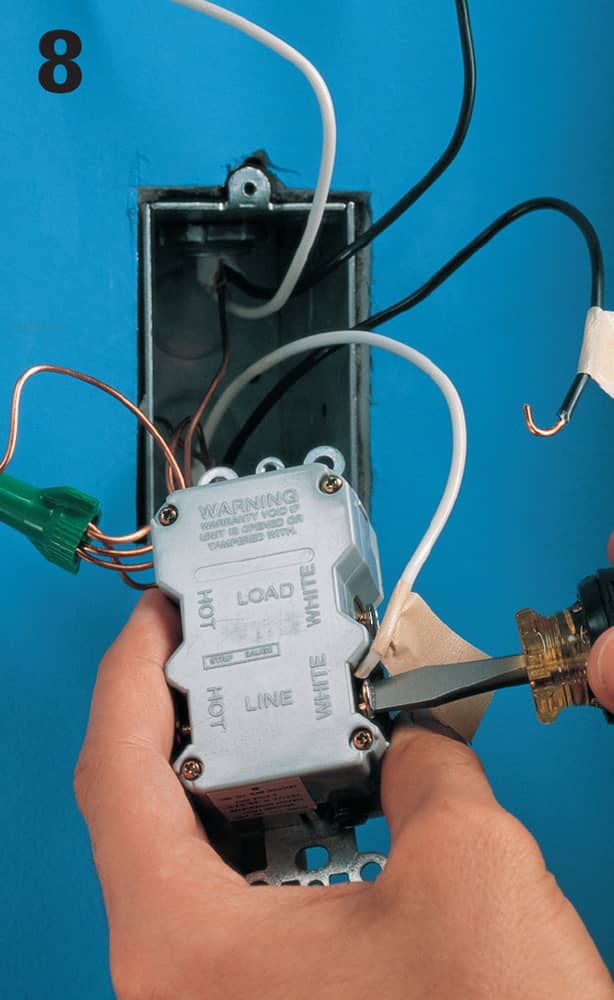

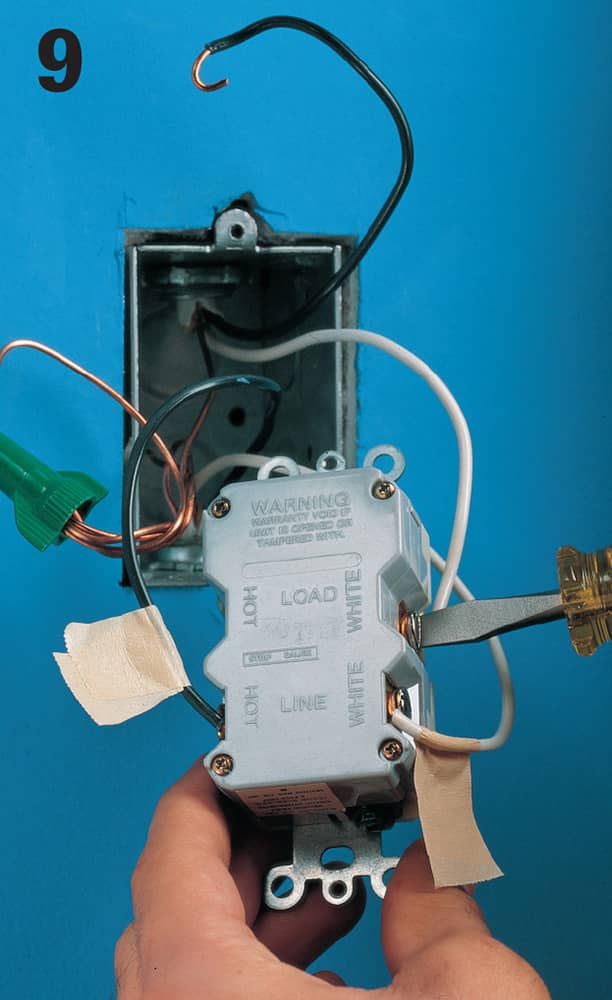

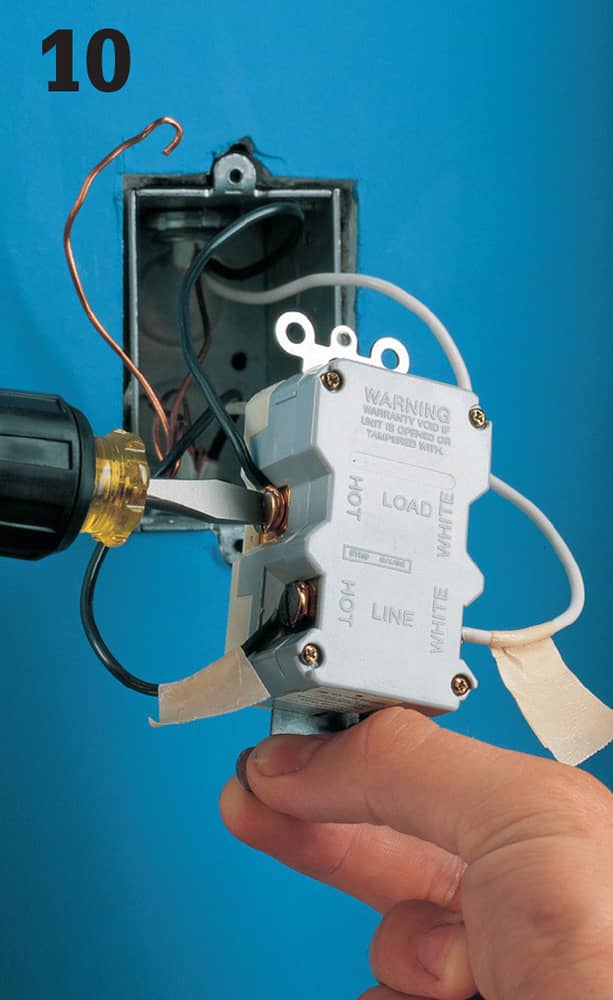

Thread the new and old cables into an old work box large enough to contain the added wires and clamp the cables. Fit the box into the old hole and attach it.