Powering the Greenhouse

Many of the heating/cooling systems we’ve discussed involve electrical components to move and transfer sustainably generated heat. An inline fan in a GAHT system, a water pump in a solar hot water system, exhaust fans, or simply an overhead light...these are small electric loads, but they do require electricity. Getting that electricity to the greenhouse — conventionally or renewably — is the focus of this chapter.

The first question to ask is: does the greenhouse need power? It is possible to grow year-round in many climates without electrical components, creating a passive solar greenhouse. If electricity is needed, most growers connect the greenhouse to the grid. There’s also the option of adding solar photovoltaic (PV) panels to the greenhouse to produce electricity renewably. Adding solar panels allows a greenhouse to produce as much or more energy than it consumes, becoming a net-zero-energy, or beyond-net-zero-energy structure. Similar to homes, the options of integrating solar panels on a greenhouse include connecting to the grid, adding battery backup or creating a completely off-grid system.

Creating a completely passive greenhouse is an attractive option for many residential growers, and understandably so. It saves the initial cost of bringing electricity to the structure. Moreover, it avoids on going electricity costs, though these are usually minimal for residential greenhouses. Finally, passive greenhouses are quieter, more relaxing spaces because they don’t involve running electric fans.

Common Electrical Systems in a Greenhouse

• Exhaust fan

• Circulation fan

• GAHT fans

• Overhead lighting

• Water pumps for irrigation

To clarify terms, we use passive solar greenhouse to describe a greenhouse that has no electrical components. Passive solar greenhouses are inherently off-grid. It’s also possible to have an off-grid greenhouse that uses electricity but is powered by a stand-alone solar PV system with battery backup. Both are independent of the grid, but they are very different greenhouses.

The primary drawback with a passive structure is that it offers less control over the growing environment. If there is a record-breaking cold spell or hot streak (not unusual occurrences these days), adding a backup heater or fan is not an easy option. For that reason, passive solar greenhouses are at risk of greater temperature fluctuations. They typically freeze at some point in climates with long freezing periods. Good air circulation can be difficult to achieve in the winter because there are no circulation fans. That makes them more prone to issues related to excessive humidity in the winter (when vents need to be closed to keep out cold air).

Given these pros and cons, passive solar greenhouses are a good fit for growers who don’t need a tightly controlled environment. They are often used as three-season greenhouses, shutting down over the most extreme months when temperature control is more difficult. They are not a good fit for commercial greenhouses that have money and profit on the line and depend on the greenhouse maintaining more controlled conditions.

• Ventilation: Passive ventilation is critical since this is the greenhouse’s source of cooling and indoor air circulation. Don’t skimp on vent area. Some vents won’t be needed during the winter; these can be insulated and sealed. Full venting is necessary to control overheating and provide good air circulation in the spring, summer and fall.

Solar-powered fans can provide supplemental venting. These use electricity, but a small built-in PV panel powers them so they don’t require wiring or electrical hookup. We have found these to be good options to easily add mechanical ventilation to an otherwise completely passive greenhouse.

• Heating: Consider passive thermal mass materials, like water and/or phase change material (see Chapter 12). These help store heat during the day and deliver it at night. A rocket mass heater or wood stove (see Chapter 15) can be used for backup heating.

• Cooling: In addition to venting, shade cloth helps prevent overheating in the summer.

• Lighting: Though not absolutely necessary, an overhead light is a nice addition to the greenhouse in case you want to check on things at night. In passive greenhouses, standard bulbs can be replaced with battery-operated LED lights.

Most residential growers wire the greenhouse directly to the home or a nearby structure if they want power. The greenhouse then runs off standard power from the grid. The size and complexity of wiring a greenhouse varies greatly by the energy demand. If the greenhouse occasionally requires a backup heater, but does not need power full time, a simple extension cord from the home can suffice. On the other end of the spectrum, commercial greenhouses with large electric loads need to contact the local utility to evaluate the best way to connect to the grid.

If you don’t have experience doing electrical wiring, we recommend hiring an electrician to complete this process. If you plan on wiring the greenhouse yourself, we still recommend having your work checked by an electrician to verify your own and the greenhouse’s safety. Below, we provide an overview of wiring a greenhouse to the home.

The process is like wiring any detached structure or addition, which you or an electrician can complete. First, determine all the appliances you will be running and the wattage of each. Additional circuits are added to the home’s main breaker panel based on the total power draw (wattage) of all components running in the greenhouse. If you divide the total wattage by the voltage (usually 120) you get the amperage needed (from the equation watts = amps × volts). From there, an electrician can determine how many circuits are needed and the amperage of each. We usually install one 20-amp circuit for residential greenhouses. If you will be using grow lights or other energy-intensive equipment, the greenhouse will need several circuits (another reason to evaluate energy-efficient lights like LEDs).

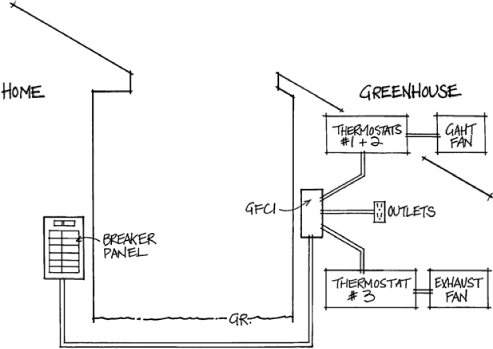

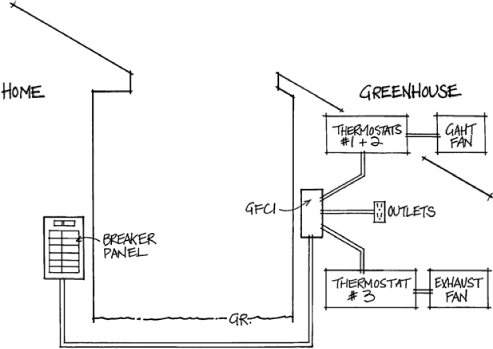

Typically, electric cable housed in conduit is buried underground and run from the home’s breaker panel to the greenhouse, as shown in Fig. 16.1. If wiring the greenhouse yourself, consult the many resources available for creating a wiring diagram and doing the calculations. Roger Marshall spends a chapter in How to Build Your Own Greenhouse on this topic.

FIGURE 16.1. Wiring a Greenhouse to the Home.

• Given the high-humidity of a greenhouse, we recommend adding a ground-fault circuit interrupter (GFCI) where the cable (coming from the breaker panel) enters the greenhouse, as shown in Fig. 16.1. A GFCI will shut off power if there is a ground fault or contact with moisture. That way, if any water comes into contact with a socket, the power shuts off rather than shocking you.

• All outlets should have weatherproof covers, as shown in Fig. 16.2. This prevents water (either from condensation or watering the garden) getting into the outlet and creating a short circuit.

• Consider what equipment you will be using and factor that into the placement of outlets. We usually put outlets on the side walls of the greenhouse near the doors and corners. That leaves the longer north and south wall open for growing.

A common misconception is that “solar greenhouse” refers to “a greenhouse with solar panels.” Indeed, solar photovoltaic (PV) panels are what people most associate with the word “solar.” But there’s a reason these two don’t always match up. While solar panels can be a source of renewable electricity for the greenhouse, they are not a good source of direct heating.

Converting electricity into hot air (called resistive heating) is extremely energy intensive compared to the methods described in Chapters 12–15. Instead of using the sun’s energy directly, resistive heaters powered with solar panels require inefficient conversions: First, solar panels convert sunlight into electricity, then, a heater converts the electricity to hot air. A much wiser use of the sun’s energy is to use the hot air already present in the greenhouse during the day and store it via thermal mass or another method. Solar panels are very useful for powering components that facilitate thermal storage, like fans or pumps.

There are several ways to integrate solar panels into the greenhouse. To find the right one for you, first clarify your objectives. Are you concerned about the reliability of power at your location? Is there no access to the grid? Or, do you simply want to offset carbon emissions from the greenhouse’s electricity usage?

There is no wrong reason to invest in solar panels; but it is important to be clear about your goals, so you can find the best way to meet them. For example, some residential clients tell us they want to add solar panels to their backyard greenhouse so that “it’s sustainable.” We ask them if they already have solar PV on their house. “No, we haven’t thought of that,” they say. This is perplexing. If your goal is to reduce carbon emissions, why not start with the home, where solar panels can have a much greater impact?

PV systems have significant economies of scale because certain components are needed regardless of size. Adding a larger system on your home allows you to get the greatest return on your investment and offset the most carbon emissions. Even though homeowners say they “want a sustainable, solar-powered greenhouse,” what they really want is to live more sustainably. Clarifying that fact allows them to site a PV system where it can do the most good.

Other growers have valid reasons for adding PV panels to the greenhouse. The top of a large south-facing greenhouse roof can be a good site for a PV system (as long as it does not detract from the glazing area too much). Some locations have frequent power outages; others don’t have power access. Finally, some growers are morally driven to be independent from the electric grid. Each of these situations lends itself to a particular PV strategy.

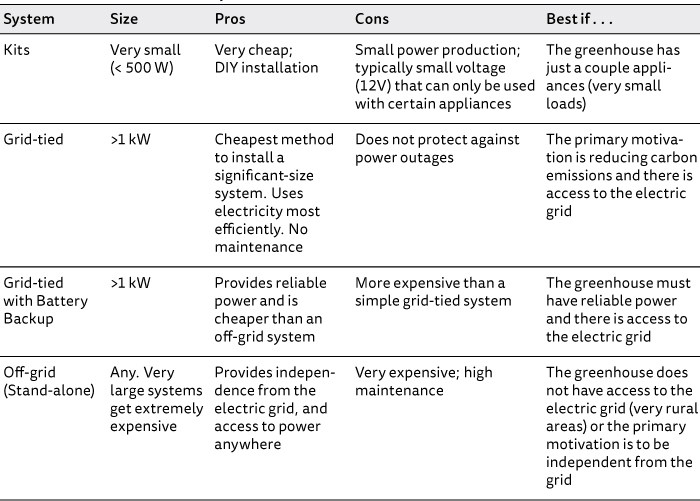

The options for integrating solar panels are the same as for homes: You can add a grid-tied system (with or without battery backup), or you can go off-grid with a stand-alone system that includes a large battery bank. If the greenhouse has a very small electrical load, you may also have the option of purchasing a small kit system and running the greenhouse entirely in DC. Each strategy has pros and cons, summarized in Fig. 16.3.

FIGURE 16.3: Solar Photovoltaic Systems—Overview

Across all of them, PV panels can be housed on the greenhouse roof or ground-mounted next to it. In small greenhouses, roof placements can cover a significant amount of glazing, shading the greenhouse. If possible, use existing south-facing roof space on adjacent structures (like a house). It is likely that there is more space, which can be better utilized.

You may have seen a portable solar panel kits at a hardware store or from online retailers. These are becoming increasingly popular for charging small appliances like phones, often used at camping sites and other remote applications. However, many are large enough that they can power a greenhouse with a small electric demand.

Kit systems are similar to stand-alone/off-grid systems, except the power capacity of these systems is typically 500 W (watts) or less. In comparison, a mid-size residential PV system would be in the range of 5,000 W (5 kilowatts [kW]), ten times the size. Thus, they are good if the electric demand is less than 2 kWh per day, which is about the energy expenditure of a single circulation fan. (For more on how to determine energy usage, see “Sizing a Greenhouse PV System” below.) Most kit systems come with the restriction that they provide power in low voltages, like 12 V. Thus, all appliances in the greenhouse must be 12 V, which limits your options for equipment (since most things run in 120 V).

If applicable, kit systems are low cost, typically less than $1,000. They are commonly self-installed, which takes out much of the cost of solar. Kits include an inverter (to convert DC power to AC for appliances). They can also be hooked up to a small 12-volt battery.

Solar panels produce direct current (DC) electricity. Batteries, likewise, store and discharge DC. However, most appliances run on alternating current (AC). Converting DC to AC requires an inverter, which happens to be one of the most expensive parts of a PV system.

Inventive DIYers can save money by avoiding an inverter and running the greenhouse in DC. Power can be stored in low-cost batteries like 12 V car batteries to reduce costs even further. There are also efficiency gains (between 10%–30% depending on end-use equipment) when you do not have to convert DC to AC. The practicality of this all depends on the electrical loads and whether it’s possible to find the electrical components you need (fans, pumps, etc.) in direct current.

Though options are more limited for DC appliances, they do exist, thanks largely to the RV and boat industries. Snap-Fan is a company that makes DC exhaust fans specifically for off-grid greenhouses. The solar attic fans mentioned in Chapter 7 also apply, since they are designed to run directly off the panel. If you have few appliances and are installing your own system, you can evaluate whether to run the whole greenhouse in DC.

Grid-tied systems currently comprise the majority of PV applications, as they are the simplest and cheapest way to add a decent-size solar PV system. In a grid-tied system, the solar panels feed power to the home. They are also directly connected to the grid so that the grid can absorb or supplement power if the panels produce more or less than the greenhouse needs.

Most utilities offer “net metering,” which gives you credit for any surplus power produced. If panels produce more energy than the greenhouse needs, the surplus is fed back to the grid, causing the electric meter to run backward. When the greenhouse has a higher power demand than the panels can supply, the grid supplements power.

Net metering allows the grid to act like an infinite battery — it absorbs the excess energy when it is plentiful, and fills in when more is needed. Furthermore, as a storage mechanism, the grid is much more efficient than batteries. Storing energy in physical batteries creates conversion losses. The electrical energy produced by the panels must be converted to chemical energy stored in the batteries, and this is not 100% efficient. In other words, you can’t get 100% of the energy produced back when using batteries. With grid-tied systems, the electricity simply slips on and off the grid in the same form. You get credit for all of the electrons produced.

Grid-tied systems are also smaller than off-grid, because the system does not have to produce all the power needed for each day. If there is a cloudy day, and the panels can’t produce enough, the grid supplements. On a sunny day, the solar panels “make up” for those electrons. Grid-tied systems are sized to meet the average annual demand, rather than the daily demand. In contrast, off-grid systems need to be large enough to supply power for the extremes — the rare week of cold and cloudy weather. That makes off-grid systems larger and more expensive.

The downside to grid-tied systems is that they don’t protect against power outages. If there is a power failure, the system can’t operate. If power outages are a concern in your area, and consistent power is essential for your greenhouse, you will need to add batteries for backup power.

Grid-tied with battery backup systems are the middle ground between grid-tied and off-grid systems. These function exactly like a grid-tied system 99% of the time. The 1% difference is in the case of a power outage. If the grid goes down, a small battery bank takes over and powers the greenhouse. Some advanced components make the switch from grid power to battery power automatic and seamless.

Batteries and added controls make battery backup systems significantly more expensive than grid-tied systems. Thus, they only make sense for growers who absolutely need consistent power. They are cheaper, however, than off-grid systems. The battery bank is sized to only power “critical loads” during a power outage. The batteries in a hybrid system are only about one third the size of an off-grid system.

Critical loads are the components considered essential to keep running. In a greenhouse, critical loads may include parts of an aquaponics growing system, like water pumps or aerators, or climate controls, if growing high-value crops like medical marijuana. The majority of greenhouses, however, can survive a power outage without much consequence. For that reason, grid-tied with battery backup systems are rare in greenhouses. Most growers that invest in solar PV either opt for grid-tied or go completely off-grid.

Note: Much of the information in this section was provided in Dan Chiras’s course on off-grid solar (see Further Reading), which we recommend for a more detailed exploration of how to design and install an off-grid system.

We’ve already mentioned small-scale off-grid systems — those that can power a fan or a light but not much else. Full-blown off-grid systems involve much larger PV systems and large battery banks capable of powering the greenhouse every day of the year. For some growers, off-grid systems fulfill a romantic ideal of severing the tie to the utility and living independently. For others, they are a practical necessity if there is no utility connection at the greenhouse site. In either case, it’s important to evaluate the realities and challenges of going off-grid before diving in.

An off-grid solar PV greenhouse is both the power consumer and the power plant. All the electricity the greenhouse needs is produced and stored on-site. But what if there is week without sun? Hopefully, you have a large enough battery bank to tide the greenhouse over. This requirement — large battery storage — puts off-grid systems in class of their own in terms of cost.

Additionally, the PV array in an off-grid system must be sized much larger than a grid-tied version because the panels must power the electric loads and also keep the batteries charged. The size needed depends on the climate — specifically, the average length of a typical overcast period. In sunny Colorado, for example, a battery system is commonly sized to provide power for three consecutive days. In the Midwest, the norm is five days, given the cloudier climate.

As you can tell, the cost and practicality of an off-grid PV system depends on your climate. Cloudy climates require much larger battery banks and PV arrays, which greatly increase the cost. The reasonableness of going off-grid also strongly depends on the power demand of the greenhouse. The size of the electric load determines how big of a “power plant” you need to build. If you are trying to run numerous HID (high intensity discharge) grow lights for 16 hours a day, costs will quickly go through the roof. If you are only trying to power a couple small electronic devices that run infrequently, adding a small battery bank is doable.

By creating a more energy-efficient greenhouse, you reduce the total energy demand. In turn, you reduce the size of the PV system you need to install. Buying the most efficient fans, lights, pumps, etc. saves you money in the end because you avoid the cost of installing additional solar panels.

When it comes to efficiency, we recommend doing everything possible to avoid having to run electric heaters. Also called resistive heaters, these are incredibly energy-intensive equipment. A small electric space heater uses 1,500 watts. A standard CFL light bulb, in comparison, is 12–14 watts. Investing more in insulation and passive thermal storage will pay off hugely in the end because you won’t have to power heaters. A rocket mass heater or nonelectric system can provide backup heating during intense cold periods. The same applies for grow lights: upgrading to the highest efficiency LEDs is a no-brainer if going off-grid. In short, you can invest the money in either efficiency or a larger battery system. The better investment is always efficiency.

The two most common battery types for off-grid solar applications are lead-acid and lithium-ion. Lead-acid batteries (specifically, flooded lead-acid, also called wet cell) are the traditional choice for the large battery banks required of off-grid systems. They are the cheapest way to store lots of energy. The downside is that they require significant maintenance. The liquid solution in the battery must be checked monthly.

Lead-acid batteries are intended to deep-cycle, but they should not remain overly discharged for long periods. This reduces their lifespan. If properly cared for, deep-cycle lead-acid batteries can last 10–15 years, but many first-time owners fry the batteries in just 4–5 years because they underestimate the need for maintenance. If you kill the battery bank, you’ll need to make the huge initial investment all over again. Finally, lead-acid batteries should be housed in a protected environment where they will not get wet, damaged, freeze or overheat.

The alternative is lithium-ion batteries, which are making inroads into large-scale power storage. Currently more expensive than lead-acid, their costs are declining rapidly — to the point where they will soon be cost-competitive per watt with lead-acid. Lithium-ion batteries come with many practical advantages. First, they don’t have the maintenance and safety considerations of lead-acid batteries. They also have high power densities — they’re able to store more energy in a smaller volume. The Tesla Powerwall, for instance, made by the electric car company, is a compact lithium-ion battery that can store about 6.4 kWh of electricity. Currently, it costs $3,000 for the battery plus about $2,000 for the inverter. Adding installation, the cost likely comes to over $6,000. That is expensive energy storage compared to lead-acid batteries, but many people are drawn to its sleek, compact form. It can be housed on a wall instead of requiring a separate room and is virtually maintenance-free.

Whatever battery option you go for, it’s important to realize that large-scale battery storage is likely a few thousand dollar investment. That is on top of the cost of the solar panels, inverter, and other necessary components if using standard AC equipment. In total, this puts the cost of typical off-grid system for a residential greenhouse over $10,000. We point that out solely to provide a “reality check” for potential off-grid growers: though it is a very enticing option, building a decent-size off-grid system only makes sense if you are strongly motivated to be independent from the electric grid, or if you do not have access to the grid at your site. (The latter case justifies off-grid PV because hooking up to the electric utility will probably require bringing power lines out to the site — an even larger cost.)

The good news is that costs for solar panels and battery systems are dropping quickly due to mass production. Whatever size or scale of system you are considering, consult a PV installer about your options. The economics of PV vary hugely by area. Only by evaluating the economics of solar panels in your location (given productivity/peak sun-hours, tax incentives and local utility rates) can you understand the cost-benefit of going off-grid.

The size of a solar PV system depends on the power demand of the equipment in the greenhouse, how often the equipment runs, and the energy available from the sun in a particular site (peak sun-hours per day). You have control over the first two variables, but the third depends on your location. Additionally, design factors like the tilt and orientation of the panels, shading and panel efficiency affect the energy output, and thus the size of the system.

FIGURE 16.4. Tesla Powerwall. Credit: Tesla

The Difference between Watts and Kilowatt Hours (kWh)

Watts is a rate of energy usage. Think of it like the speed a car is traveling. Watt-hours is a unit of energy, derived by multiplying the rate (watts) by the time the electrical component is running. Think of it as the total distance a car travels. 1 kilowatt-hour (kWh) = 1,000 watt-hours.

While we can’t flesh out every detail of sizing a PV system (that should be done in conjunction with a professional or more resources), we can give a basic overview of the process in order to help elucidate whether it is in the realm of budgetary possibility. The basic steps are:

1. First you must determine what electrical components will be running in the greenhouse. Find the power usage (given in watts) for each component. Then, estimate the number of hours each component will be running per day. Multiply this by the watts of that component to determine the total energy usage; the result is in kilowatt hours (kWh).

2. Add up the energy demand of each component to determine the total energy demand of the greenhouse on a monthly or annual basis.

3. The next step is more complicated. You must now figure out what size PV system is required to produce that much energy at your location. The easiest way to approach this is to use online tools that evaluate the solar resource at your location. A website like PVWatts (pvwatts.nrel.gov) can estimate the power production of a PV system at your site. Since you don’t know the size of your system yet, PVWatts requires narrowing down the range with estimates. Start with a 1 kW system, and see the annual energy production in kWh. Then adjust to get to your energy demand. In other online calculators, you can input the energy demand and get a system size, but they are not as accurate in terms of climate data. You can also use rule-of-thumb metrics for the average annual energy production of a solar panel in your area. These can be found online or by talking to solar PV installers.

Using this basic process, you can get a ballpark estimate of the required system size. Though the cost of solar PV is consistently declining, it is worth noting that as of this writing the cost per installed watt is $3–$4 in the US for a grid-tied system. Keep in mind that this range does not include batteries or any components needed to create a battery backup or off-grid system.

The examples below walk you through this process using three hypothetical greenhouses and their equipment. The goal is to compare the system sizes and note how they change as electric loads are added. We assume that the solar panels in these examples are located in Denver, Colorado (a relatively sunny location).

In this scenario, the owners rely on passive systems for climate control. They install water barrels and phase change material. They also use battery-operated lights and passive venting to reduce the electric demand to nearly zero. They only want to run a circulation fan, and thus need a very small system.

• Components: 1 circulation fan (40 watts)

• Energy consumption per day: 120 watt-hours (runs for 3 hours per day × 40 watts)

• Average energy consumption per year: 44 kWh (120 watt-hours × 365 days)

• Can be supplied by a 100-watt PV system (commonly, a kit system)

In this scenario, the growers have opted for a 200-watt exhaust fan in addition to a circulation fan. They also use a GAHT system to keep their larger greenhouse at a more stable temperature throughout the year.

• Components: 1 exhaust fan (200 watts), 2 inline GAHT fans (each 120 watts)

• Energy consumption per day: 2.8 kWh

• Assuming exhaust fan runs for 2 hours per day and GAHT fans run for 10 hours per day: (200 watts × 2 hours) + (120 watts × 10 hours × 2 fans)

• Average energy consumption per year: 1,022 kWh

• Can be supplied by a 0.63 kW PV system

In our final example, the growers in the previous example decide to add an aquaponics system. They live in a cold climate and will need to incorporate some water heating for about half the year. They still incorporate the exhaust fans and GAHT system above. The aquaponics system adds a number of components, necessitating a much larger PV system. (For more on aquaponics growing, see Chapter 18.)

• Additional components: 1 air pump (20 W); 1 water pump (40 W); and a water tank heater (400 W)

• Energy consumption per day (aquaponics only): 3.4 kWh (assuming the pumps run 24 hours a day and a water heater runs 5 hours a day on average, throughout the year)

• Energy consumption per day (total, fans included): 6.2 kWh

• Average energy consumption per year: 2,263 kWh

• Can be supplied by a 1.5 kW PV system

• Passive solar greenhouses (no electricity usage) create quiet and cost-effective backyard greenhouses, but offer less control.

• Many residential growers wire the greenhouse to their home breaker panel, a process easily completed by an electrician or someone with electrical experience.

• If considering adding solar panels to the greenhouse, consider the power demand of your greenhouse and your objectives. Both of these influence the best strategy for the system, whether grid-tied, grid-tied with battery backup, or off-grid.

Marshall, Roger. How to Build Your Own Greenhouse. Storey Publishing, 2006. Good information about wiring a greenhouse.

Chiras, Dan. Solar Electricity Basics: A Green Energy Guide. New Society Publishers, 2010. Consult this book if you are interested in installing solar panels.

Chiras, Dan. “Off-Grid Aquaponics.” DVD. Available from The Aquaponic Source (theaquaponicsource.com) and through the Evergreen Institute (evergreeninstitute.org). All about solar panel systems, especially off-grid systems.