Luckily for us, there is a seemingly endless variety of yarns on today’s market. However, with this diversity comes the matter of choice. Which yarn is best for which types of projects? Understanding the characteristics of various yarns will help you determine the answer.

Q: What is yarn made of?

A: Animal, plant, and synthetic fibers are all used to make yarn. Animal fibers include silk produced by silkworms, wool from sheep, alpaca from alpacas, qiviut from the musk ox, angora from rabbits, and mohair from angora goats (go figure!). Plant fibers include cotton from cotton bolls, linen from the flax plant, and ramie from an Asian shrub. There are also yarns made from soy, bamboo, pine, corn, and other plants. Acrylic, nylon, polyester, and other synthetic fibers are man-made, in some cases from recycled materials. Lyocell (Tencel) and rayon are man-made fibers produced from cellulose, which is a natural material. “Metallic” yarns are usually a synthetic, metallic-looking fiber spun with another fiber.

Q: What are some of the common terms used to describe fiber characteristics?

A: All of the following terms will help you understand and describe the fibers you work with:

See also: What is drape?

Q: Why does fiber content matter?

A: A yarn’s characteristics, such as its resiliency, hand, loft, absorbency, and dyeability, are largely determined by the fibers that make up that yarn. Being familiar with the features of different fibers helps you make appropriate selections when you choose yarn for a project. You might decide, for instance, that while a luxurious alpaca throw is an excellent choice for your mother, a washable acrylic-blend yarn is a more suitable choice for your four-year-old son’s afghan. Knowing the fiber content of a yarn is also important when it comes time to launder your finished project.

Q: What are fiber blends?

A: Often fibers are blended to take advantage of the best properties of each one. For example, acrylic might be blended with wool to make the yarn machine washable while maintaining the breathability of the wool fiber. A 50 percent alpaca/50 percent wool blend maintains the luxurious feel of the alpaca but is more affordable and more resilient than a 100 percent alpaca yarn.

The fiber with the higher percentage of content in the yarn dominates the yarn’s characteristics. An 80 percent cotton/ 20 percent wool blend looks like a cotton yarn, but it is lighter weight than a similar, all-cotton yarn would be.

Q: How is yarn made?

A: The initial processing depends on the fiber. Wool, mohair, and alpaca are shorn from the animals, resulting in a fleece made up of staples (short strands similar to locks of hair). Angora rabbits are combed or clipped to remove their hair. Cotton bolls that look somewhat like the cotton balls in your bathroom cabinet are harvested from cotton plants and processed through a gin to remove the seeds. Silk comes off the cocoon of a silkworm in a continuous filament; these filaments may be cut into manageable lengths before they are processed. To make rayon, cellulose from wood or cotton is processed into a solution called viscose and then extruded through tiny nozzles to form the rayon fiber. Tencel is a cellulose product made from tree pulp, processed in an environmentally friendly manner. Other man-made fibers are produced in a single, long filament but are often cut into staple-like lengths before spinning to more closely resemble the properties of natural fibers.

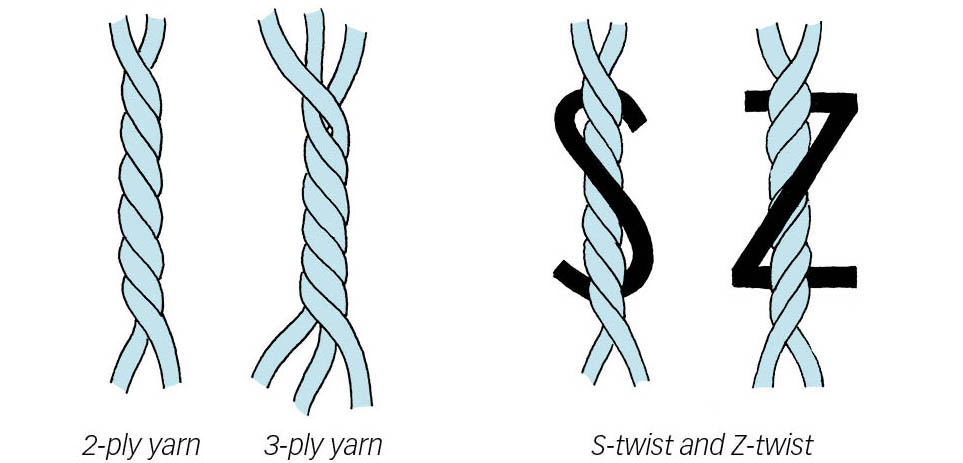

Before the fibers are spun into yarn, they are combed or carded in order to align the fibers. At this point, they may be blended with other fibers. The fibers are then spun together into an S twist or a Z twist, depending on which way they are turned. The twisted strand, or ply, is spun with one or more other plies in the opposite direction to make a multi-plied yarn. Plying fibers adds strength and balance to the yarn. Sometimes the plying step is omitted, however, resulting in a yarn made of one twisted strand, known as singles. Most commercial yarns are spun by machine, but you may also be able to find some lovely handspun yarns. Dyeing may take place before the yarn is processed (referred to as dyed in the fleece), as carded/combed fibers, or as finished yarn.

Q: What are the characteristics of wool that make it so very popular?

A: Wool is warm, insulating, resilient, breathable, water-repellent, dirt-resistant, naturally flame-retardant, and it takes dye well. Different breeds of sheep yield wool with different characteristics. It is weaker wet than dry, but it can absorb up to 30 percent of its weight in moisture without feeling wet. It may felt if subjected to heat, moisture, and friction. Some manufacturers make wool machine-washable by treating it to the “superwash” process.

See also: Felting

Q: What are the best-known characteristics of cotton?

A: Cotton is inelastic, heavy, absorbent, and non-insulating and takes dye well. It has a tendency to stretch, although it may also shrink when washed. It is usually machine-washable and is stronger wet than dry.

Q: What’s special about alpaca?

A: Alpaca fiber is soft, strong, breathable, and water-repellent. It is more insulating than wool fiber, so it is warmer than wool of the same weight. It comes in many natural colors, as well as dyed colors.

Q: What makes mohair so appealing?

A: Mohair is durable, resilient, strong, and soil-resistant. It accepts dye well and is very warm for its weight. The staples are long and lustrous.

Q: What makes synthetics so useful?

A: The range of synthetic fibers is so vast that it is necessary to generalize. Manufacturers continually attempt to make synthetic yarns that mimic the best properties of the natural fibers. Synthetics are usually durable, water-resistant, strong, non-breathable, non-wicking, and non-insulating. Many synthetics are machine-washable. Most are very sensitive to heat and melt or burn at fairly low temperatures.

Q: What is the difference between yarn and thread?

A: Crocheters use both terms, sometimes interchangeably. Thread is generally thinner, and usually made from cotton, silk, or linen. It is often used for bedspreads, doilies, and lace. Yarn is everything else! In this book, I use the word “yarn” for both, unless otherwise stated.

Q: What do I need to know about yarn size?

A: For years, publishers and yarn manufacturers have attempted to come up with meaningful classifications for the size of yarns, and knitters and crocheters have attempted to pigeonhole yarns into these classifications. Most recently, weight has been the determining factor, but we must be careful with the term because it is used in this case to mean thickness, or the yarn’s diameter. (Yarn diameter is also called grist.) In reality, how much a yarn actually weighs is less meaningful than its diameter and loft. The diameter of the yarn is one of the most important words we can use in effectively describing yarns, yet we still call it weight. Some yarns, such as brushed mohair, have a relatively small diameter compared to their loft (the amount of air between the fibers, or the amount of space the yarn occupies). In other words, the fuzzy bits of the mohair make it a heavier “weight” yarn than it would be without fuzziness.

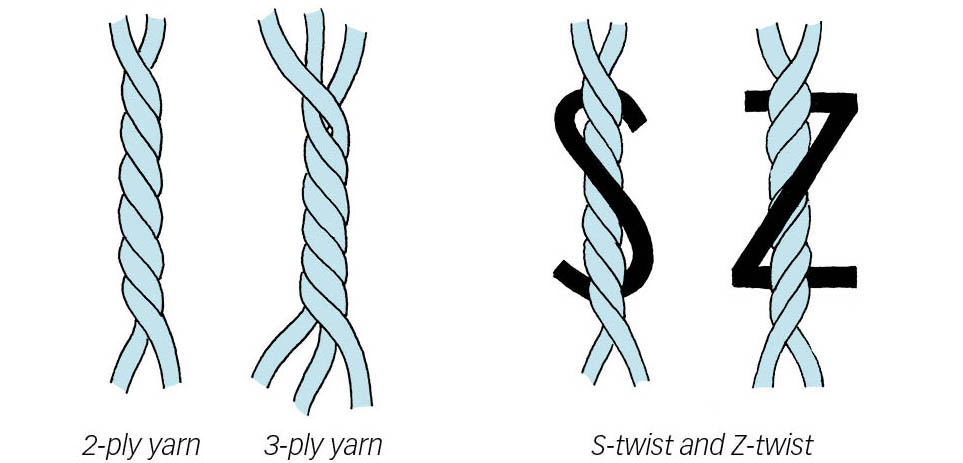

The Yarn Weights with Recommended Hook Sizes and Gauges table gives the generally accepted yarn types in the United States. In the United Kingdom, New Zealand, Australia, and other countries, the same names may refer to different-size yarns, or you may run into different terms altogether.

Q: I’ve heard yarn described by its “wpi.” What’s that?

A: Spinners and weavers use the abbreviation “wpi” for “wraps per inch,” which is a way of determining yarn size (weight). The more wraps per inch a yarn has, the smaller diameter it is. The wraps-per-inch measurement helps take into account the loft of a yarn as well as its diameter, although it is a somewhat subjective measurement and various resources disagree on which wpi measurements fit into which weight categories. Wraps per inch should always be used in conjunction with other information in determining yarn characteristics.

Q: How do I measure wraps per inch?

A: Make two marks exactly 1 inch apart on a pencil, dowel, or specially made wpi tool. Wrap the yarn evenly around the pencil or dowel between the marks or inside the notches of the wpi tool, taking care to wrap the strands parallel and adjacent to one another, not too tightly, not too loosely. The number of wraps you can count in that 1-inch space is the wpi. For more accuracy, wrap over 2 inches and divide the resulting count by two. You can also use a ruler, although it is harder to wrap evenly around a ruler.

Q: How is thread size described?

A: Thread is generally described in numbers ranging from a superfine, truly threadlike size 100 to a more yarnlike size 3. The higher the number, the smaller the diameter of the thread. Thread may also be categorized by the number of plies. Some threads are more tightly spun than others. Many cotton yarns are mercerized or subjected to a chemical treatment that adds strength and luster.

Q: How is yarn packaged?

A: Yarn is sold in put-ups of skeins, balls, or loose hanks (also called skeins). A hank (or skein) of yarn is loosely wound, usually from a reel or swift, then tied in several places. You must wind it into a ball before working with it. Balls and commercially wound skeins are neat packages that you can use immediately. The weight of the put-up varies but is commonly 1.75 oz (50 g) or 3.5 oz (100 g). You may find synthetic yarns put up in larger quantities.

Q: What information can I find on the yarn band?

A: Whether packaged in skeins, balls, or hanks, most yarn or thread is labeled with information on the fiber content; suggested gauge; weight and/or yardage of the skein, ball, or hank; laundering instructions; dye lot; color number; and possibly a color name. Many American yarn bands include the Craft Yarn Council yarn weight designation. Suggested crochet hook and knitting needle sizes and gauge are also often included.

See also: How do I clean my finished piece? for information on laundering instructions; Yarn Weights with Recommended Hook Sizes and Gauges for more yarn weight information.

Q: What do all those icons on the yarn band mean?

A: These are international symbols that provide the information described in the previous answer, even if you can’t read the language on the band. The icons are especially helpful if you purchased an imported yarn. Information on the suggested gauge and hook/needle sizes may also be shown in graphic form.

typical yarn label information

See also: Yarn Care Symbols

Q: What is a dye lot?

A: Yarns are dyed together in large batches or dye lots of the same color. Each dye lot is numbered, so you can tell if two skeins of yarn were dyed at the same time in the same batch. There can be subtle or not-so-subtle differences between dye lots.

Q: Does dye lot really matter?

A: Many times it matters a great deal. Even if the dye lot differences are not apparent in the packaged ball or skein, they often show up in the finished project. Whether it matters in your project depends on how close together you use same-color yarns of different dye lots. If they are adjacent, you probably shouldn’t mix them, as even subtle dye lot differences show. However, if the yarns are separated by another color, it is probably safe to mix dye lots in the same item.

When purchasing yarn for a project, your best bet is to be sure that all of the same-color yarn comes from the same dye lot.

Q: How do I know if the yarn colors I’ve chosen will look good together?

A: In the store, hold them together and squint. Try to do this in daylight, not under fluorescent lighting. At home, wrap each of the colors around a white index card side by side, in the same proportions that you will use them in the finished project. Look at the card critically. Are the colors pleasing together or is one of them jarring? Can you put them next to each other in any order? Is there one that shouldn’t be adjacent to another? If you are satisfied with the results on the index card, try all the colors together in a swatch.

You may also want to learn more about color theory. Entire books have been written on the subject, and it can be a lifelong study. The short answer is, if you like the colors together, that's what really matters.

See also: Pages 155–69 for swatching.

Q: I found the perfect color, but my yarn store doesn’t have enough skeins from the same dye lot to complete my project. Do I ever dare use different dye lots in the same project?

A: Try some of these ideas for minimizing problems when using different dye lots:

Q: Why are some yarns labeled “No Dye Lot”?

A: These are synthetic (man-made) yarns. The chemical process allows producers to get exactly the same color results every time they produce a fiber in a particular color.

Q: Can I use a different yarn than the pattern calls for?

A: Yes, but you’ll need to use a yarn similar to the one the pattern calls for to get similar results. Because of their unique properties, novelty yarns may be tricky to substitute in a pattern, but ordinary yarns can often be substituted quite successfully.

See also: Novelty yarn

Q: How do I find a substitute yarn?

A: Try these suggestions for evaluating a substitute.

Compare data about the yarns. Start by noting what you know about the original yarn. What weight is it? What gauge does the pattern call for? What is the suggested hook size? Then, look at the yarn you’d like to substitute and make sure it is the same weight as the original yarn. (Remember, this refers not to how much the packaged yarn weighs but rather the weight classification.) The yarn band gives you the suggested gauge and hook size for the new yarn; you should be able to crochet the new yarn to the same gauge as stated in your pattern.

Consider other characteristics of the original yarn. What is the fiber content? Is it a plain yarn? Fuzzy? Smooth? Bumpy? Stiff? Tightly or loosely spun? A loosely spun yarn or a single-ply yarn will look different from a yarn with a tighter twist or multiple plies, even if they are the same weight. You should be able to determine these characteristics from the description in the pattern or from some online research.

Consider the characteristics of the item you are going to make. Is there lots of textured patterning that would not show up well with a variegated or slubby yarn? Is it a lacy item that works best with a natural fiber that can be properly blocked?

Buy a single ball of the new yarn, if possible, and swatch with it to ensure you are happy with the results. You may not mind if the substitute yarn is not exactly the same as the original, but it’s best to make informed choices. If you are unsure, check with a knowledgeable sales clerk where you buy your yarn.

Q: My pattern calls for 3-ply wool. Will any 3-ply wool be sufficient?

A: Not necessarily. In the past, yarns were often categorized according to the number of plies. This worked because there were a limited number of commercially available yarns, and everyone understood a 3-ply yarn to be of a certain diameter. These days, it is not sufficient to describe yarns by ply alone, as some multi-ply yarns are very fine and some singles are ultra bulky. You’ll need to determine the weight classification of the original yarn and choose an appropriate substitute.

See also: Yarn Weights with Recommended Hook Sizes and Gauges for yarn weight classifications.

Q: Can I buy yarn by weight?

A: If you’re referring to its weight classification, then the answer is, “Probably.” If you mean you want to figure the amount of yarn you need to buy based on how much each skein weighs, then the answer is, “Bad idea.” Buying by skein weight is another holdover from the past, when most yarns were wool and of a fairly uniform size. Length (yardage) is what matters, not how much the yarn weighs. Cotton yarn weighs more per yard than wool; some wools weigh more per yard than others. If yardage is not listed on the ball band, see if you can determine it from the Internet or other sources so that you buy sufficient yardage for your project.

Q: Can I use two lighter weight yarns together to make a heavier yarn?

A: Yes, but you’ll have to work a gauge swatch to see if you can get the correct gauge. To get off on the right foot, try using this rule of thumb: Add the suggested gauge of each of the two yarns and divide by 3 for the suggested gauge of the two yarns held together.

For example: Using two strands of sport-weight yarn with a suggested gauge of 4 sc = 1", double the gauge of the yarn and divide by 3:

(4 × 2) ÷ 3 = 2.67 sc = 1"

If the gauge you are expecting to use is in the ballpark of 2.5 sc = 1", then you might be able to use those two strands of sport-weight yarn together. Don’t forget that you’ll need a larger hook than you would for a single strand of sport-weight yarn. You’ll probably start with the hook size listed in the pattern instructions. Swatch with your proposed yarn and hook to see how close you are. If you are using a yarn doubled, remember that you’ll also have to double the amount of yardage called for in the pattern!

See also: Pages 155–69 for swatching.

Q: If I’m substituting yarn, how much do I buy?

A: Figure out how much yardage you need by multiplying the number of skeins the pattern calls for by the number of yards or meters per skein of the original yarn. You should be able to find this information in the pattern instructions. Once you know the total length you need for your project, divide that number by the number of yards or meters per skein in the yarn you want to use. You’ll probably get a fraction. Be sure to round up since you cannot buy a fraction of a ball of yarn.

For example: My pattern calls for 8 skeins of Pretty Yarn (100% acrylic, 200 yds/100 g). I want to use Beautiful Yarn (100% wool, 240 yds/4 oz) instead. Here’s the math:

8 skeins × 200 yards = 1600 yards

1600 yards ÷ 240 yards = 6.67, or 7 balls

You may want to buy one additional ball for safety’s sake. Remember, you’ll be using up yarn making a good-size swatch.

Be sure you are using consistent units of measure (yards or meters). If one yarn is labeled in meters and one in yards, you’ll need to convert the meters to yards or vice versa before calculating how much yarn you need. It’s not as important as it is in rocket science, but differing units can trip you up.

Q: Do you have any advice on how much yarn I’ll need when I’m designing my own projects?

A: That’s the six-million-dollar question, isn’t it? The amount of yarn you need depends on the size of the yarn, the stitch pattern, your gauge, and the size of the item you are making. Of course, when you follow a published pattern, the instructions are your guide. Many people regularly buy an extra ball of yarn, just to be certain to have enough. You can always use leftover yarn for another project, and many stores accept returns of extra balls for credit. If you don’t have a pattern to go by, find a published pattern for an item similar to your design, using a yarn of similar weight, and estimate your needs. You can also estimate your yarn needs when you make your swatch.

Q: How do I calculate yarn amounts from a swatch?

A: You’ll need to calculate the yarn weight or yardage used in the swatch, then apply that to the finished measurements of your intended project.

Measuring by swatch weight. This is possibly the most accurate method. (For advice if you don’t have access to a scale, see the next question.) Make a swatch at least 6" square, using the same colors and hook you plan to use in the project, and with the intended gauge. Do not trim or weave in your yarn tails. Calculate the area of the swatch by measuring width times length. Don’t round off your measurements, and be sure to include partial inches! Weigh the swatch on a food scale or postage scale and make a note of the number of grams it weighs. (Grams is a more accurate measurement than ounces.)

For example: My swatch weighs 20 g and measures 6 × 6.5 inches = 39 square inches. My yarn comes in 100-gram skeins of 220 yards each.

Now, estimate the total area of your project in square inches. It’s easy if your project is a square or rectangle: just multiply the width times the height. If you’re making a sweater, the calculation is a bit more complicated; see here for that formula.

For example: For an afghan that measures 48" wide and 60" long,

48" × 60" = 2880 square inches

Use these formulas to calculate the number of balls needed:

(Weight of swatch × Total area of project) ÷ Area of swatch = Total weight for project

Total weight for project ÷ Weight of 1 ball = Number of balls needed for project (round up!)

For example: Using the numbers from the examples above,

(20 g × 2880 square inches) ÷ 39 square inches = 1476.9 g

1476.9 g ÷ 100 g = 14.77, rounded to 15 balls

Since this is an estimate, you might want to buy 16 balls just to be safe. And of course, if you are using multiple colors, you may need more than this, depending on how the colors are distributed. Estimate what percentage of each color is used in your swatch, and multiply that percentage by the total amounts, then round way up to allow for estimating errors. Remember, you can't buy a partial ball of yarn.

If you want an estimate of actual yardage, multiply the calculated number of balls times the number of yards per ball.

14.77 × 220 = 3249.4 yds

If you don’t have access to a scale. Before you begin the swatch, pull out a length of yarn (say, 5 or 10 yards or meters), jot down the measurement, and tie a loose overhand knot. If you reach the knot before completing your swatch, untie the knot, reel out more yarn, jot down the new measurement, and tie another loose knot. When the swatch is complete, measure how much yarn is left before you get to the knot. Subtract this amount from the total of the length that you pulled out of the ball. This is the length you used for the swatch, including yarn tails. And yes, you could just rip out the swatch and measure the yarn used, but then you won’t have the swatch to refer to.

See also: Pages 155–69 for swatching.

For example, a 6" × 61⁄2" swatch used 44 yards. How much yarn is needed for a 48" × 60" afghan using yarn that has 220 yards per skein?

Get the total yardage needed for the project using the following formula:

(Yardage in swatch × Total area of project) ÷ Area of swatch = Total yardage for project

(44 yds × 2880 square inches) ÷ 39 square inches = 3250 yds (rounded up)

3250 yds ÷ 220 yds per ball = 14.77 Rounded to 15 balls (or to 16, if you want to be safe)

Q: How do I convert from yards to meters?

A: One meter equals 1.09 yards, so divide the number of yards by 1.09 to get the conversion to meters.

For example: To convert 15 yards to meters:

15 ÷ 1.09 = 13.76 meters

Or just ask the nearest electronic device.

Q: How do I convert from meters to yards?

A: Reverse the process and multiply the number of meters by 1.09. Another way to think of it is that it takes about 10 percent more yards than meters.

For example: To convert 25 meters to yards:

25 × 1.09 = 27.25 yards

See also: Metric Conversion Chart

Q: My pattern calls for a yarn that has been discontinued. Is there any way to find out about the characteristics of discontinued yarns to help me choose an appropriate substitute?

A: There are resources available to help you find out more about yarns, even those that are discontinued. With luck, the pattern will list information such as weight, yardage, and fiber content to help you make substitutions. Local yarn shop owners often have information on discontinued yarns, and very experienced ones may even be able to play “Name That Yarn” with just a glance. You can also search the Internet. Sellers on eBay often offer older yarn, complete with fiber and yardage information. Try Google or other search engines for the yarn name and manufacturer. Try contacting the yarn manufacturer. As of the time of this writing, www.ravelry.com and other sites have information and reviews on yarns, both current and discontinued.

Q: What is the best way to pull yarn from the ball?

A: Usually pulling from the center is best. If you are using a commercially packaged skein or ball, first look to see if the outside strand of the yarn is tucked into the center of the ball. If it is, pull it out but don’t use it. Stick your fingers into the center of the ball and fish around to see if you can find the inner end. You may need to pull out a little wad of yarn and unravel it in order to find the tail. This is the end to use as it will draw from the inside of the skein.

commercially wound ball

Note: If you are working with the yarn doubled, you may use both the end from the center and the one from the outside of the ball.

Q: How do I handle a loose hank or skein of yarn?

A: Don’t try to work directly from the hank or you’ll be sorry! You need to wind it into a ball before you start stitching. You can use a yarn swift, lampshade, chair, or someone willing to hold the yarn for you. Untwist the hank and hang it carefully on your holder. If the yarn is tied in several places, cut the shorter pieces of yarn and throw them away. Sometimes there is a single knot where the beginning and end meet, wrapped in such a way as to keep the yarn from tangling. Be especially watchful in the beginning, because you may have to unwrap the yarn from around the skein for the first few revolutions. Cut the knot, and take a single end in your hand, winding carefully for the first round or two until you are certain that the yarn is unwinding without tangling.

See also: Ball winders and swifts

Q: Can I create my own center-pull ball?

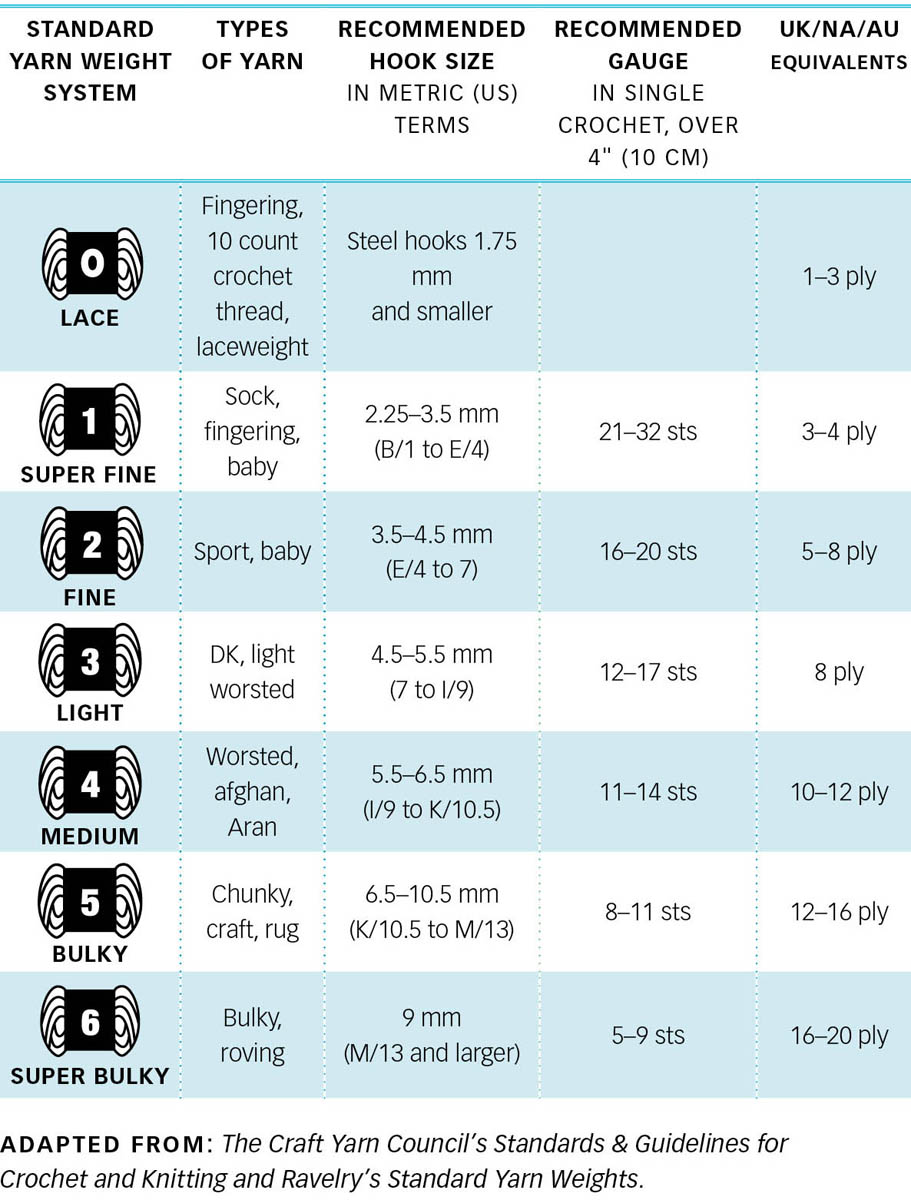

A: Yes. The easiest way is with a ball winder, which winds the skein into a nice center-pull form. If you don’t have a ball winder, however, you can do it manually:

Q: How do I know if my ball is wound too tightly?

A: Your ball should not be hard — it should have a bit of spring to it. Yarn wound too tightly is stretched and tense, which is apt to cause trouble once it’s made into a fabric. The yarn may become permanently stretched, decreasing its elasticity. Even if it isn’t permanently ruined, if you stitch the yarn up in its stretched state and then wash it, it will return to its natural, unstretched state, with possible undesirable consequences to the size of the piece! If you wind a center-pull ball, the ball collapses in on itself as it is used, releasing any extra tension.

Q: How can I keep my yarn from splitting?

A: If your yarn splits, it may be that the yarn is not of high quality or that it is loosely spun. Some hooks with pointy tips may split the yarn. In that case, you may need to stitch extra carefully to avoid splitting the yarn, or use a different hook. A hook with a rough spot also sometimes causes trouble. Try sanding the rough spot with very fine sandpaper. If that doesn’t work, discard the hook.

If your yarn is coming untwisted as you work, examine how you are pulling it from the ball. If you are using a center-pull ball, you may be removing twist because of the direction you are pulling. Try pulling from the opposite side of the ball or using the end from the outside of the ball.

Q: What should I do when I reach a knot in the yarn?

A: Even high-quality yarns may have a knot or a weak spot every now and then. Don’t work over it. Instead, cut the yarn several inches before the knot, leaving a tail to be woven in later. Cut out the bad spot, then begin again, just as you would when adding a new ball.

When you begin a new row, pull out enough yarn to work the entire row, so that you can see any imperfection before you reach it. You can then cut the yarn and rejoin it at the beginning of the row and thus avoid starting a new yarn in the middle of the fabric.

See also: How do I add a new yarn?

A: Just as its name implies, this isn’t your run-of-the-mill yarn. You’ll know it when you see it. The fun of a novelty yarn comes from its unique characteristics; it can be made from almost anything and spun in almost any way. It may have a great deal of texture, or it may be spun with non-fiber additives such as beads or feathers. It may have little bits of stuff hanging from a main core. It may be a thin “crochet along” (or “knit along”) thread meant to be held together with another strand of yarn as you stitch, or it may be as bulky as your thumb.

Novelty yarns are often described by their characteristics: eyelash, slub, metallic, ribbon, or bouclé (meaning curly in French). When substituting one novelty yarn for another, choose a similar yarn type in order to achieve a similar look.

bouclé

slub

eyelash

ribbon

Q: I’ve tried working with novelty yarns but found them frustrating. Do you have any suggestions?

A: Novelty yarns and fuzzy yarns are beautiful, but they can present a challenge for crocheters. Here are some tips that may make it easier if you are using a novelty yarn:

See also: How do I put my hook between stitches?

Q: Do you have tips for working with slippery yarn?

A: Silk, rayon ribbon, and other slick yarns are beautiful to look at, but they also present a challenge. Even if you wind them carefully, the balls have a tendency to melt into a puddle at the first opportunity. Try corralling them into a sandwich bag or wrap them with a Yarn Bra, old pantyhose, or other stretchy material for better control.

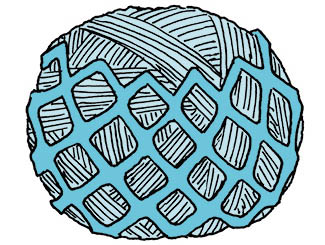

Yarn Bra

See also: Weaving in slippery ends

Q: Is there anything I can do to keep variegated yarns from appearing splotchy?

A: When you get noticeable odd-shaped areas of a single color in the middle of a piece of crochet, it’s known as pooling. Try alternating two balls of yarn or use the inside and outside ends of a single ball of yarn each row or round to avoid pooling. Or use a stitch pattern that breaks up large expanses of the variegated yarn: spike stitches, contrasting-color stripes, or texture stitches.

As the distance across the piece changes, the frequency with which certain colors show up changes. For instance, on a sweater, the yarn travels a shorter distance when you shape the armholes and neck edge than it does across the full width of the body, so the color repeats create a different pattern on these shorter rows than in the longer rows below. Therefore, you may need to use anti-pooling techniques on some parts of a garment and not on others. (Voice of Experience: You can’t tell from a small swatch if your colors are going to pool.)

Q: Is there any kind of yarn I can’t crochet with?

A: Not that I’ve found, although some yarns may be more challenging than others. Don’t think you have to stick to “yarn,” either! You can crochet with plastic bags cut into strips (plarn), wire, audiotape, paper, rope . . . whatever you can imagine.

A: There are several ways to add a new yarn, depending on the circumstances.

No matter what technique you use to join a new yarn, always leave a tail at least 6" long on both the old and new yarns so that you can weave in the ends later.

See also: Stitch height

adding a new yarn mid-row

Q: What does it mean to “join with sc in first stitch”?

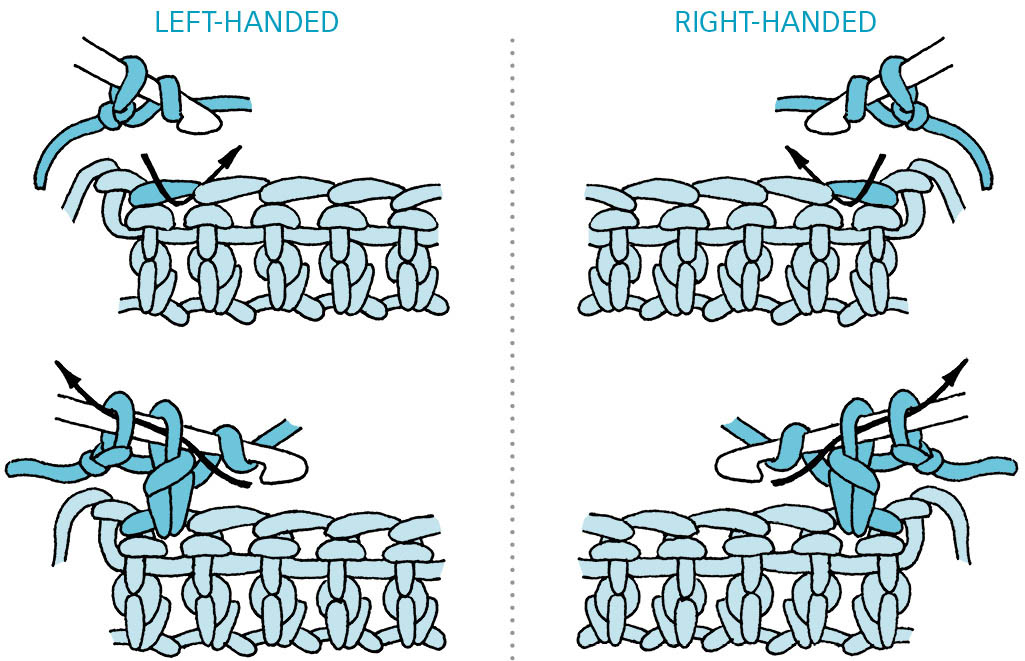

A: The most common meaning of this phrase is to begin a new yarn with a standing single crochet. Standing stitches are used when there is not already an existing stitch on the hook, as when the previous yarn has been fastened off. It is “standing” because the yarn starts at the top of the stitch, rather than at the bottom as with a turning chain.

Any standing stitch can be made by beginning with a slip knot on the hook. Treating the loop on the hook as you would any existing loop, work the desired stitch. For example, for a standing single crochet (or “join with sc”), begin with a slip knot on the hook, insert hook into the designated stitch or space, yarnover and pull up a loop, yarnover and pull through both loops on hook. You have completed a single crochet.

standing single crochet

To “join with dc in first stitch” means to make a standing double crochet in the first stitch: Begin with a slip knot on the hook, holding the slip knot with your index finger to keep it from slipping, yarnover, insert the hook into the first stitch, yarnover and pull up a loop, (yarnover and pull through two loops) two times. (Another meaning of “join with dc in first st” sometimes crops up when working in the round.)

More experienced crocheters work their standing stitches by simply wrapping the yarn over the hook an extra time before starting the stitch without first putting a slip knot on the hook.

See also: Joining with dc in top of turning chain

beginning a row without a chain