10.6. Thwaites’ Method

To solve (10.43) at least two additional equations are needed. Using the correlation parameter:

(10.44)

(10.44)

introduced by Holstein and Bohlen (1940), Thwaites (1949) developed an approximate solution to (10.43) that involves two empirical dimensionless functions l(λ) and H(λ):

(10.45, 10.46)

(10.45, 10.46)

that are listed in Table 10.2. This tabulation is identical to Thwaites' original for λ ≥ –0.060 but includes the improvements recommended by Curle and Skan a few years later (see Curle, 1962) for λ < –0.060. The function l(λ) is sometimes known as the shear correlation while H(λ) is commonly called the shape factor.

(10.47)

(10.47)

The definitions of l and H allow the second version to be simplified:

The momentum thickness θ can be eliminated from this equation using (10.44), to find:

(10.48)

(10.48)

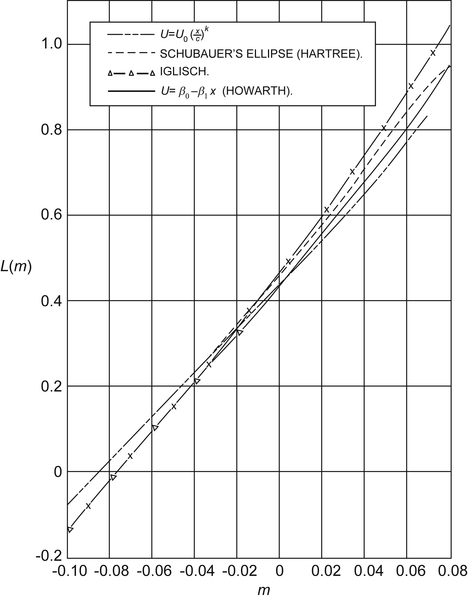

Fortunately, L(λ) ≈ 0.45 – 6.0λ = 0.45 + 6.0m, is approximately linear as shown in Figure 10.9 which is taken from Thwaites’ (1949) original paper where m = –λ. With this linear fit, (10.48) can be integrated:

(10.49)

(10.49)

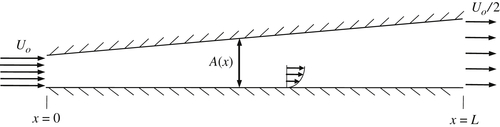

The second version of (10.49) is a first-order linear inhomogeneous differential equation for θ2/ν, and its integrating factor is U e 6  . The resulting solution for θ2 involves a simple integral of the fifth power of the free-stream velocity at the edge of the boundary layer:

. The resulting solution for θ2 involves a simple integral of the fifth power of the free-stream velocity at the edge of the boundary layer:

. The resulting solution for θ2 involves a simple integral of the fifth power of the free-stream velocity at the edge of the boundary layer:

. The resulting solution for θ2 involves a simple integral of the fifth power of the free-stream velocity at the edge of the boundary layer: (10.50)

(10.50)

where x′ is an integration variable, and θ = θ0 and Ue = U0 at x = 0. If x = 0 is a stagnation point (Ue = 0), then it is safe to set θ0 = 0 since the exterior flow must accelerate away from a stagnation point and accelerating external flow leads to boundary-layer initial-condition memory loss. Once the integration specified by (10.50) is complete, the surface shear stress and displacement thickness can be recovered by computing λ and then using (10.45), (10.46), and Table 10.2.

Overall, the accuracy of Thwaites’ method is ±3% or so for favorable pressure gradients, and ±10% for adverse pressure gradients but perhaps slightly worse near boundary-layer separation. The great strength of Thwaites’ method is that it involves only one parameter (λ) and requires only a single integration. This simplicity makes it ideal for preliminary engineering calculations that are likely to be followed by more formal computations or experiments.

Figure 10.9 Plot of L(m) from (10.48) vs. m = –λ from Thwaites' 1949 paper. Here a suitable empirical fit to the four sources of laminar boundary-layer data is provided by L(m) = 0.45 + 6.0m = 0.45 – 6.0λ. Reprinted with the permission of The Royal Aeronautical Society.

Table 10.2

Universal Functions for Thwaites’ Method

| λ | l(λ) | H(λ) |

| 0.25 | 0.500 | 2.00 |

| 0.20 | 0.463 | 2.07 |

| 0.14 | 0.404 | 2.18 |

| 0.12 | 0.382 | 2.23 |

| 0.10 | 0.359 | 2.28 |

| 0.08 | 0.333 | 2.34 |

| 0.064 | 0.313 | 2.39 |

| 0.048 | 0.291 | 2.44 |

| 0.032 | 0.268 | 2.49 |

| 0.016 | 0.244 | 2.55 |

| 0.0 | 0.220 | 2.61 |

| –0.008 | 0.208 | 2.64 |

| –0.016 | 0.195 | 2.67 |

| –0.024 | 0.182 | 2.71 |

| –0.032 | 0.168 | 2.75 |

| –0.040 | 0.153 | 2.81 |

| –0.048 | 0.138 | 2.87 |

| –0.052 | 0.130 | 2.90 |

| –0.056 | 0.122 | 2.94 |

| –0.060 | 0.113 | 2.99 |

| –0.064 | 0.104 | 3.04 |

| –0.068 | 0.095 | 3.09 |

| –0.072 | 0.085 | 3.15 |

| –0.076 | 0.072 | 3.22 |

| –0.080 | 0.056 | 3.30 |

| –0.084 | 0.038 | 3.39 |

| –0.086 | 0.027 | 3.44 |

| –0.088 | 0.015 | 3.49 |

| –0.090 | 0.0 | 3.55 |

Before proceeding to example calculations, an important limitation of boundary-layer calculations that start from a steady presumed surface pressure distribution (such as Thwaites’ method) must be stated. Such techniques can only predict the existence of boundary-layer separation; they do not reliably predict the location of boundary-layer separation. As will be further discussed in the next section, once a boundary layer separates from the surface on which it has formed, the fluid mechanics of the situation are entirely changed. First of all, the boundary-layer approximation is invalid downstream of the separation point because the layer is no longer thin and contiguous to the surface; thus, the scaling (10.6) is no longer valid. Second, separation commonly leads to unsteadiness because separated boundary layers are unstable and may produce fluctuations even if all boundary conditions are steady. And third, a separated boundary layer commonly has an enormous flow-displacement effect that drastically changes the outer flow so that it no longer imposes the presumed attached boundary-layer surface pressure distribution. Thus, any boundary-layer calculation that starts from a presumed surface pressure distribution should be abandoned once that calculation predicts the occurrence of boundary-layer separation.

The following two examples illustrate the use of Thwaites’ method with and without a prediction of the occurrence of boundary-layer separation.