PUMPING WATER FOR AN IRRIGAtion system can be complex and costly, but it doesn’t have to be. With the proper understanding of how pumps work and an efficient design for your irrigation piping, the cost and complexity of pumping water can be kept at a minimum.

It’s important to understand how the various types of water pumps work, and what the differences are between effluent pumps, single-pipe jet pumps, dual-pipe jet and submersible deep-well pumps. It is even possible to use the pump that serves the water distribution system of your home as an irrigation pump.

Any one of the pumps mentioned above might best suit your needs. If you had to guess right now, what type of pump would you think is best for irrigation purposes? In general, a deep-well submersible pump is the best, but there are circumstances when it is not the best choice for lawn and garden irrigation. This is good news, because deep-well pumps and their installation requirements are expensive. It is very likely that you can use your existing water pump or an inexpensive effluent pump to water your lawn and garden.

If you use a municipal water system, you may decide that a pump is not needed for your irrigation purposes. The water provided by your community can be piped directly to your irrigation points, but there is a catch: You may find that the water bill from your town or city is too high to justify watering your lawn or garden as often as you would like. If this is the case, you might want to consider using an alternative water source and pump just for your irrigation needs; so even if you get your water from a municipal source, read on.

Being a master plumber in a rural location, I work with all types of water pumps on a regular basis. My many years of hands-on experience with pumps has proven very helpful for designing irrigation systems and putting them into operation. Reading this chapter will not make you a master plumber, but it will give you more knowledge about pumps than many plumbers possess. While I won’t go into great detail on troubleshooting and repairing pumps, I will provide an in-depth look at the common types of pumps available and how you can make a wise choice in the type that will serve your needs best.

Picking the right pump for irrigation purposes takes some thought. There are several questions you must ask yourself before you run out and buy one. For instance, what type of water source will you be using? Chapter 3 discusses the options for freshwater sources, and Chapter 4 examines the possibilities for using recycled water. The source of your irrigation water will have much to do with the type of pump you buy.

If you’re already using a pump for your home water supply, you may be able to tap into it for irrigation purposes. However, before trying to save a few dollars by using your household pump, there are other considerations involved. For example, straining your well and pump to irrigate your lawn or garden could result in a burned-out pump or a depleted water supply in your well. This is serious and costly business that should not be taken lightly. However, it does not require highly technical knowledge to make a good choice.

You can learn enough about pumps from this chapter to make a sound buying decision. It is not important to understand all the technical aspects of pumps, such as centrifugal action and air-volume control. All you have to decide is what type of pump will do the best job, at the least cost, and with adequate dependability. This is not a monumental feat; I will make it simple, and, perhaps, even fun. Just think of the satisfaction you will have when your neighbors inquire about your new irrigation system and you can spout off facts and figures about pumping water that will amaze them. Following is a step-by-step look at the types of pumps to consider.

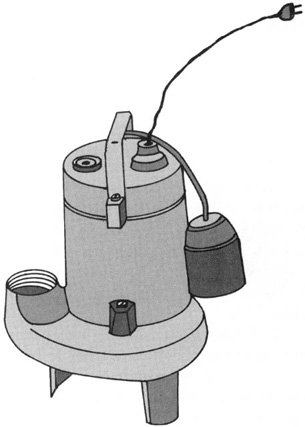

These are the least expensive pumps — selling for under $100 — and are very dependable. General-purpose pumps, they are sometimes called sump pumps or utility pumps. Don’t let the fact that they are often called sump pumps confuse you.

When most people think of a sump pump, they envision a pedestal pump that sits in the corner of a basement and removes unwanted groundwater. Pedestal sump pumps can be used for light irrigation, but typically they create problems and don’t have a long life expectancy when used routinely for pumping the necessary volume of water to irrigate even small lawns and gardens.

Pedestal pumps attract some buyers because they are inexpensive (usually under $60), but beware: You get what you pay for. Pedestal sump pumps are okay for occasionally pumping a sump in a wet basement, but they are not suitable as an irrigation pump.

Submersible effluent pumps, on the other hand, can handle the demands of average home irrigation needs and more. These pumps are more expensive, but not much more, and they are far superior in dependability and longevity.

The convenience of submersible effluent pumps is that typically they are equipped with a standard, plug-in cord so you don’t need to hard wire an electrical system. The downside is that for irrigation purposes, using the pump requires plugging it in and then unplugging it when the watering is complete. This is a bit of a hassle, but relatively simple.

An effluent pump is designed to pump water that does not contain large solids. In other words, effluent pumps should not be used to pump household sewage, but they can be used to pump any type of water. The most common use of effluent pumps is for pumping gray water (waste water that doesn’t contain sewage) from plumbing fixtures, such as washing machines, sinks, and bathing units, to gravity-drop drainpipes.

Effluent pumps also are used to control water in wet basements, and to pump water out of pools, ponds, and similar vessels. For irrigation purposes, effluent pumps are very effective in pumping water from cisterns, sumps, and other types of shallow water sources.

Many effluent pumps have 2-inch discharge outlets. A 2-inch pipe can deliver a lot of water to an irrigation system. Other models have 1½-inch outlets or l¼-inch outlets. Any of these sizes is more than adequate for irrigation purposes.

There are several basic terms to be aware of to make a smart buying decision: voltage, horsepower, cable length, and floats.

A submersible effluent (sump) pump is an affordable and convenient way to meet average home irrigation needs. It doesn’t require any special wiring and is very effective for pumping from a variety of shallow water sources.

Voltage is pretty simple to figure out on your irrigation pump. Some pumps require 230 volts, but they are larger than what most homeowners will want for irrigating their properties. A pump with a voltage rating of 115 volts should be adequate, and it is more compatible with average household electrical circuits. Make sure the voltage of any pump you choose is compatible with your household wiring. This is not usually a problem with an effluent pump, but it’s important to double-check.

The horsepower of an effluent pump is important; it affects the height and volume of water that is pumped in a given time. For example, a pump with a ¼-horsepower motor will pump water about 20 feet above the pump location, at a rate of about 38 gallons per minute (gpm). In contrast, the same type of pump with a ⅓-horsepower motor will pump water about 28 feet above the pump, at a rate of about 50 gallons per minute. A ½-horsepower pump produces about 60 gallons of water a minute at a height of about 35 feet.

Horsepower plays a vital role in the performance of a pump. Fortunately, simple irrigation systems do not require extensive water pressure or gallons per minute, which means that you can have a satisfactory system with minimal cost.

When you evaluate your pump needs for irrigation purposes, the most important factor to consider is how high the water must be pumped, determined by how deep your well is, and the ground elevation of the area you’re watering. Once you know this, you are ready to assess the performance curves of various pumps to see if they meet your needs. Any reputable pump dealer will be happy to provide you with performance curve charts on available pumps. The chart will show the number of gallons per minute and the height water can be lifted by a specific pump model.

The length of the electrical cable on an effluent pump limits the depth of water in which it will work. Most of these pumps have either a 10-or15-foot cable length, which has a direct bearing on how deep the pump can be submersed in water. If you plan to install the pump at greater depths you should consider a jet pump.

Floats on effluent pumps work quite simply. When the float has risen to a certain point, the pump comes on; when the float drops back down to a certain point, the pump cuts off. This system works well for most uses of effluent pumps, but is not the most effective for pumping irrigation water, since you don’t want continuous pump operation.

There are three basic types of floats used on effluent pumps. One type is an integral part of the pump housing and normally gives the best service. It also minimizes damage to the float and prevents foreign objects from jamming the float.

Internal floats are the most dependable type of float to use with an effluent pump. With any type of float in operation, you normally have to deal with the inconvenience of plugging and unplugging the pump, but the low cost of the pump offsets this inconvenience somewhat.

The second best type of float is one that moves up and down on a guide attached to the exterior of the pump casing. These floats can become stuck, but generally they are very dependable.

The third type of float is placed on extension arms or connected to the discharge pipe. These tend to get stuck on the sides of sumps. While arm-floats and wire-floats work well most of the time, they are likely to cause more trouble than other types of floats.

In the simplest terms, an effluent pump is an excellent choice (efficient and affordable) when you have a shallow water source (no deeper than 8 to 12 feet) and are not intimidated by having to spend time plugging and unplugging the pump.

A single-pipe jet pump, also called a shallow-well jet pump, normally is used to pump water into a home from a shallow well with a depth of less than 25 feet.

Jet pumps are not submersible; normally they are installed in basements, pump houses, or similar locations, and can be mounted on a pressure tank. These pumps are capable of producing a dependable flow of water at heights of less than 25 feet.

Single-pipe jet pumps are pretty much automatic and require little effort on the user’s part. Once properly installed, a jet pump takes over, which is a big time advantage over an effluent pump.

Single-pipe jet pumps retail for between $300 and $400. Additionally, in order for jet pumps to work efficiently and survive for an extended period, a pressure tank and related fittings are required. These cost about $200. The total cost will thus be between $500 and $600.

A jet pump can be used without a reserve pressure tank, but the pump will run longer than necessary, resulting in an early burn-out of the pump. For all practical purposes, you must plan on a complete installation package when installing a jet pump.

There are two primary reasons for buying a jet pump instead of an effluent pump. If the depth of a water source is more than 14 feet, an effluent pump is not feasible. When the height of the pump lift (or the depth of the well) ranges from 15 to 25 feet, a single-pipe jet pump is the most logical choice.

The convenience of a jet pump is another advantage over an effluent pump. A jet pump is hard-wired and automatic, so there is no cord to plug and unplug. There are other advantages.

Effluent pumps produce water at a fairly constant, nonadjustable pressure. Jet pumps, on the other hand, allow regulation of the pressure point. In the case of sprinkler systems, and similar irrigation systems, this feature is very desirable.

Should you choose to pull your irrigation water from a pond, stream, or well with a depth of up to 25 feet, a single-pipe jet pump is a wise decision. Let’s look for a moment at the technical stats on single-pipe jet pumps.

A jet pump with a ⅓-horsepower motor will lift water 25 feet at a rate of 345 gallons per hour (gph) at 30 pounds of pressure. When the pressure is increased to 40 pounds per square inch (psi), the volume drops to 120 gph. If the pressure is reduced to 20 psi, the output is 345 gph, the same as at 30 psi. If the water is only being lifted 15 feet, the output at 20 psi or 30 psi is 600 gph. At 40 psi the volume will be 360 gph.

Increasing the horsepower rating of the pump to ½ horsepower makes a big difference at 40 psi. For example, at 20 psi or 30 psi the output is 395 gph. At 40 psi, the volume of water produced reaches 280 gph, which is more than double the output of a pump with a ⅓-horsepower motor. The greater the horsepower rating, the more volume of water pumped at equal depths and pressures.

Dual-pipe jet pumps are designed for use with wells deeper than 25 feet. These deep-well pumps require two pipes; one to push water and the other to suck it up to the pump.

Dual-pipe jet pumps cost about the same as single-pipe jet pumps. The additional pipe and material required to install a deep-well jet pump adds to the cost, however.

Dual-pipe jet pumps are not as efficient as deep-well submersible pumps (see following section). While jet pumps are less expensive than submersible pumps, the value may not be as good in the long run. Dual-pipe jet pumps are capable of pumping from depths of 120 feet, which is much deeper than their shallow-well cousins can go, but not nearly as deep as deep-well submersible pumps can reach.

Dual-pipe jet pumps in the same basic price range as shallow-well pumps will lift water about 70 feet. At this depth, a 1/3-horsepower pump will produce 200 gph. A ½-horsepower pump will produce 300 gph.

If the water level to be pumped is deeper than what a standard dual-pipe jet pump can handle, you can opt for a multistage pump. These pumps are still jet pumps, but they can pull water up from depths of 160 feet. Multistage pumps cost considerably more than standard jet pumps (between $700 and $925).

When a well is deep enough to require more than a single-pipe pump, submersible pumps are usually the best choice.

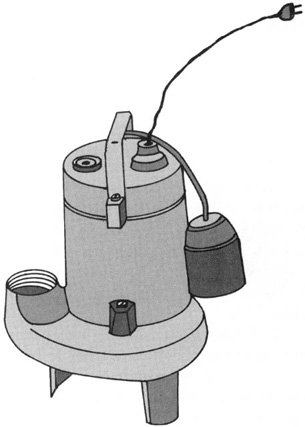

Submersible deep-well pumps are the best option for pumping water that is deep in the earth. They are normally used for wells 40 to 500 feet deep. Unlike jet pumps, submersible pumps are suspended below the water surface inside the well.

The price of an average submersible pump ranges from about $500 to $700. This is, of course, more than the cost of a jet pump, but submersible pumps give better performance and less trouble.

When you get into submersible pumps, you can have more water than you know what to do with if your water source replenishes itself quickly. For example, you can pull 120 gallons of water per minute (gpm) from a depth of 300 feet with a submersible pump. If you want more performance, you can get it with a larger motor or a high-flow pump.

Unless you are going to drill a special well just for your irrigation needs, you probably will not need a deep-well pump. Even if you are planning a separate well for irrigation purposes, it is unlikely the well will have to be deeper than what a shallow-well pump will handle.

Having a deep well drilled and installing a submersible pump is expensive. The well will probably cost between $1,000 and $1,800. When you add the cost of a pump, pressure tank, and related installation equipment, your total cost could easily hit $2,500 or more. This kind of expense is justified only to serious irrigation enthusiasts.

An alternative to installing independent pumping systems for irrigation work is to use your existing well and water pump and keep your costs to a minimum. Combining pump duties for household and irrigation use is often possible for average home lawn and garden needs. There are, however, a few factors to weigh before making the decision to force your existing well and water pump into double duty.

You can determine your well’s water reserve, or how much water is available in your well at any given time, by performing a simple test.

Take a piece of jute cord, or some similar string, and tie a small weight to the end — an old bolt or even a kitchen fork will do. The length of the cord depends on the depth of your well; it should be a little longer than what you believe the depth of the well to be.

Remove the cover from your well and lower the weighted end of the string into it until the weight hits bottom and the string begins to develop slack. Retrieve the string.

As you pull the string out of the well you will notice a point where the string is wet. Mark the wet spot with a marker or a knot. Pull the remainder of the cord out of the well and lay it on the ground. Measure the length of the cord from the weight to the mark where you first found water. This simple procedure will tell you the depth of your water reserve.

To determine how much water is available in your well at a given time (the reserve), tie a small weight to the end of a piece of cord and drop it to the bottom of the well. Once you’ve pulled it up, measure the length of string that is wet.

Once you know this, measure the diameter of the well. Drilled wells have diameters of about four inches and dug wells will be about three feet wide. From these two measurements, a pump dealer can calculate the number of gallons of water available in the well. For example, a shallow well with a diameter of 3 feet and a water reserve of 7 feet contains approximately 371 gallons of water.

If you have a dug well, the recovery rate probably will not be known. Drilled wells, however, are measured for recovery rates at the time of drilling. If you have the paperwork from your well installation, it may indicate the recovery rate.

If you can’t find any documentation on the recovery rate of your well, you can figure out some average numbers. Most residential wells have recovery rates of at least 3 to 5 gpm. Some wells don’t produce as much water, and others have recovery rates much higher. Planning on a rate of 3 to 5 gpm is probably safe. If you want to know precisely, call a professional plumber or a well expert to measure the recovery rate for you.

A pump’s flow rate is rated in gallons per minute (gpm). If you are going to be tapping into an existing well and pump system, this information is not too critical. However, if you are planning to install a second pump in your existing well to water your grounds, you need to make sure the pump you install doesn’t produce at a gpm rate higher than the well’s recovery rate.

If you have a well with a recovery rate of 3 gpm and you install a pump with a flow rate of 5 gpm, you will have a problem. The pump will be capable of pumping water faster than the well can produce it, which will result in a well that is pumped dry.

Knowing your well’s reserve and its recovery rate, and your pump’s flow rate, will give you a good starting point to determine if your well is capable of providing adequate water for irrigation and domestic use. It is wise, however, to consult with a local professional, once you have these basic facts, to make certain the well can pull double duty.

Once you are satisfied that your well is strong enough to provide the volume of water needed, you must decide how to combine your irrigation system with your domestic water system. There are two basic options. In some cases, you can install a separate pump system for the irrigation work and use the existing well. A less expensive and easier alternative is to tap into the existing well piping or water distribution pipes for your irrigation supply. When the quantity and frequency of irrigation water demand is moderate, as it is with most home gardens and lawns, tapping into the existing plumbing system makes a lot of sense and saves a lot of money.

Installing a second pump for an existing well is not a huge job. Most handy homeowners can accomplish the task in one weekend. The cost for this type of work, however, can be substantial, and there are times when it doesn’t make sense.

If you have a deep well equipped with a submersible pump, it is not feasible to install a second pump for the well. The diameter of a drilled well is too small to accommodate two pumps safely.

Normally a shallow well has a large diameter and can accept the suction pipes from several pumps. In some cases it makes sense to install a separate pump system for irrigation when a shallow well is the water source, but the process is still more expensive than tapping into the existing pump system. Unless there is some functional reason why the existing pump cannot be tapped into, such as location and proximity to the site to be irrigated, tapping is the most economical solution.

Chapter 9 provides detailed technical information for making connections, adding second pumps, and a variety of other aspects of installations.

Tapping into an existing well system is not complicated or expensive. It is a job any mechanically inclined individual can do in less than a day, and the cost for the tap-in will be under $20. This cost doesn’t include the piping and fittings used in the irrigation system, but it covers all the items used in the actual tap-in.

When you compare a tap-in, at a cost of $20, to the installation of a pump system, at rates ranging from just under $500 to over $1,000, it doesn’t take long to see the advantages of tapping into an existing system.

There are many ways to make the connection between an irrigation system and an existing pump system, but the most common is in the pump house, basement, or crawl space, whichever is applicable to the specific job. This makes accessibility reasonably good and keeps strenuous work to a minimum.

Depending on the type of pipe used in the existing system, the tap-in can be completed in less than an hour by someone with a little experience in do-it-yourself projects. A professional can do it in less than 15 minutes.

With all factors considered, tapping into an existing system is the most economical way to get your irrigation water. As long as your existing well and pump are capable of producing the water you want, and any good pump dealer or plumber will be able to advise you on this issue, you can’t beat the low cost and convenience of the tap-in method.

If you are going to drill a new well for irrigating your property, you will need to install a new pump system. This is not as difficult as many people believe.

A single-pipe jet pump works on a suction principal. The pump sucks the water up the pipe and into the home. With a perfect vacuum at sea level, a shallow well pump may be able to lift water to 30 feet. This maximum lift is not recommended and is rarely achieved. If you need to lift water higher than 25 feet, investigate other types of pumps. If you can use a shallow-well jet pump, begin by asking a pump dealer to size your pump.

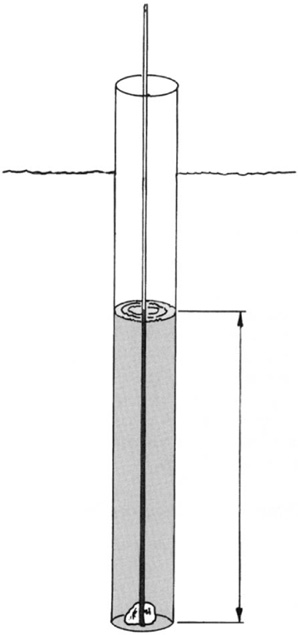

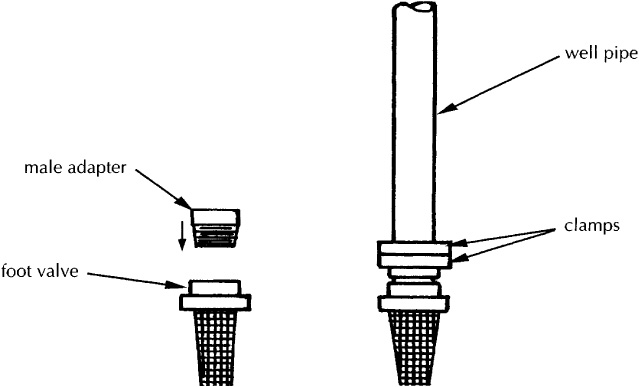

The single pipe from the well to the pump usually has a diameter of 1¼ inches. A standard well pipe material is polyethylene, rated for 160 psi. Begin by making sure the single suction pipe is not kinked or coiled. If the pipe holds an air pocket, priming the pump can be quite difficult. In most cases a foot valve will be installed on the end of the pipe to be submerged in the well.

Installing the pipe in the well. Screw a male insert adapter into the foot valve. Place two stainless steel clamps over the well pipe and slide the insert fitting into the pipe. Tighten the clamps to secure the pipe to the insert fitting. Lower the pipe and foot valve into the well, but don’t let the foot valve sit on the bottom of the well. If the suction pipe is too close to the bottom of the well, it may suck sand, sediment, or gravel into the foot valve, preventing the pipe from pulling water from the well.

When the pipe reaches the upper portion of the well, make a 90-degree turn in the pipe with an insert-type elbow in order to exit the well casing. Always use two clamps to hold the pipe to its fittings. When the pipe leaves the well, it should be buried underground, deep enough so that it will not freeze in the winter. This depth will vary from state to state. Your local plumbing inspector will be able to tell you how deep to bury the water supply pipe.

Burying the pipe. Dig a trench that is approximately 1 foot wide and below the frost-line. Place the pipe in the trench, being careful not to lay it on sharp rocks or other objects that might wear a hole in it. Backfill the trench with clean fill dirt. If you dump rocks and cluttered fill on the pipe, it can be crimped or cut. To bring the pipe into your home, run it through a sleeve where it comes through or under the foundation. The sleeve should be two pipe sizes larger than the water supply pipe.

Installation of a jet pump begins with the foot valve. Screw a male adapter into the valve, and then secure the well pipe to the foot valve with two stainless steel clamps.

Connecting to the pump. Once inside the pump house, or wherever your pump will be located, the water supply pipe should run directly to the pump. The foot valve acts as a strainer and as a check valve. When you have a foot valve in the well, there is no need for a check valve at the pump.

Attach your incoming pipe to the pump at the inlet opening with a male adapter. At the outlet opening, install a short nipple and a tee fitting. At the top of the tee, install reducing bushings and a pressure gauge.

From the center outlet of the tee, your pipe will run to another tee fitting. Install a gate valve in this section of pipe, near the pump. At the next tee, pipe the center outlet to a pressure tank. From the end outlet of the tee, your pipe will run to yet another tee fitting. At this tee, the center outlet will become the main pipe for your irrigation system. On the end outlet of the tee, install a pressure-relief valve. All of these tee fittings should be in close proximity to the pressure tank.

Wiring. Your pump will be equipped with a control box that requires electrical wiring. This job should be done only by a licensed electrician.

Priming. The pump has a removable plug in its top to allow for priming. Remove the plug and pour water into the priming hole. Continue this process until water is standing in the pump and visible at the hole. Apply pipe dope to the plug and screw it back into the pump. When you turn the pump on, you should have water pressure. If you don’t, continue the priming process until the pump is pumping water. This can be a time-consuming process; don’t give up.

Pressure Setting. Once the pump is pumping water, the pressure tank will fill. When the tank is filled, your pressure gauge should read between 40 and 60 psi. The pump’s controls will be preset at cut-in and cut-out intervals. These settings regulate when the pump cuts on and off. Typically, a pump will cut on when the tank pressure drops below 20 pounds. The pump will cut off when the tank pressure reaches 40 pounds.

If you prefer higher water pressure, the pressure switch can be altered. You might have the controls set to cut on at 40 pounds and off at 60 pounds. These settings are adjusted inside the pressure switch, around electrical wires. There is possible danger of electrocution when making these adjustments. Unless you are experienced with such work, leave the adjustments to a licensed plumber or electrician.

The adjustments are made by turning a nut that sits on top of a spring in the control box. If you attempt this, and I don’t recommend that you do, cut off the power to the pressure switch before opening it. You will see a coiled spring, compressed with a retaining nut. By moving this nut up and down the threaded shaft, you can alter your cut-in and cut-out intervals.

CAUTION: The voltage from the wires in the pressure switch can deliver a fatal shock. Do not attempt this job unless you are experienced in such work.

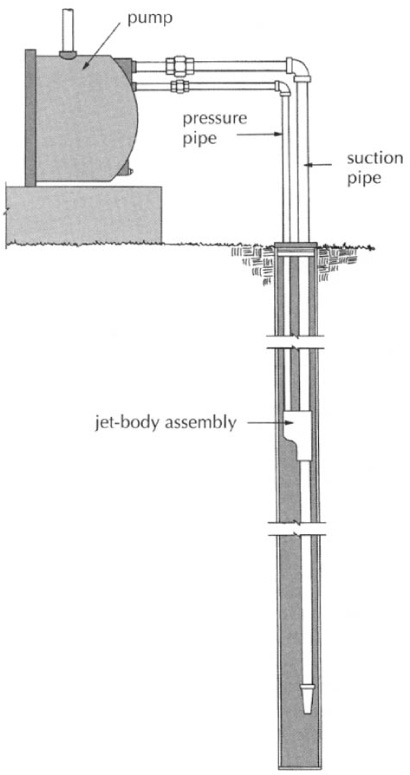

Dual-pipe jet pumps, also known as deep-well jet pumps, are needed when your water level is more than 25 feet below the pump. A dual-pipe pump or a submersible pump are your options for this deep a well. Submersible pumps normally are used in deep wells. However, dual-pipe jet pumps also will get the job done.

Dual-pipe jet pumps look similar to single-pipe pumps, are installed above ground, and are piped in a manner similar to them as well. The noticeable difference is the number of pipes going into the well.

The operating principals of the two types of pumps differ. Single-pipe (shallow-well) jet pumps suck water up from the well. Dual-pipe (deep-well) jet pumps push water down one pipe and suck water up the other.

The only major installation differences between a single-pipe jet pump and a dual-pipe jet pump are the number of pipes used in the installation, and the use of a pressure control valve. Dual-pipe jet pumps use a foot valve and have a jet-body assembly that is submerged in the well and attached to both pipes and the foot valve. The pressure pipe connects to the jet body first, and the foot valve hangs below this pipe. There is a molded fitting on the jet body for connecting the suction line. The jet body allows both pipes to connect in a natural and efficient manner.

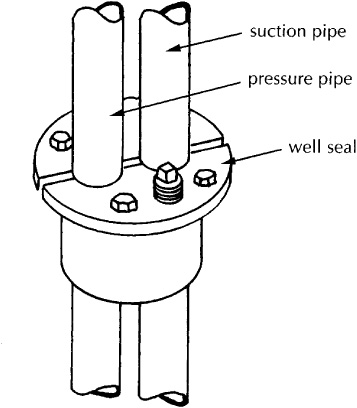

Dual-pipe jet pumps push pressure down the pressure pipe with water pushed through the jet-body assembly, and makes it possible for the suction pipe to pull water up from the deep well. From the suction pipe, water is brought into the pump and distributed to the potable water system. When you look at the head of a dual-pipe jet pump, you will see two openings: The larger one is for the suction pipe, the smaller opening for the pressure pipe. The suction pipe usually has a diameter of 1¼ inches. The pressure pipe typically has a diameter of 1 inch.

Detail of dual-pipe installation at ground level.

A dual-pipe jet pump works by pressure applied down through the pressure pipe, which results in water being pulled up through the jet-body assembly and then to the suction pipe. Once in the pump, the water is distributed to the potable water system.

The piping from the pump to the pressure tank needs a pressure-control valve to ensure a minimum operating pressure for the jet-body assembly. Single-pipe pumps do not require a pressure-control valve. Once the pressure control valve is installed, the remainder of the piping is done in the same manner as used for a single-pipe pump.

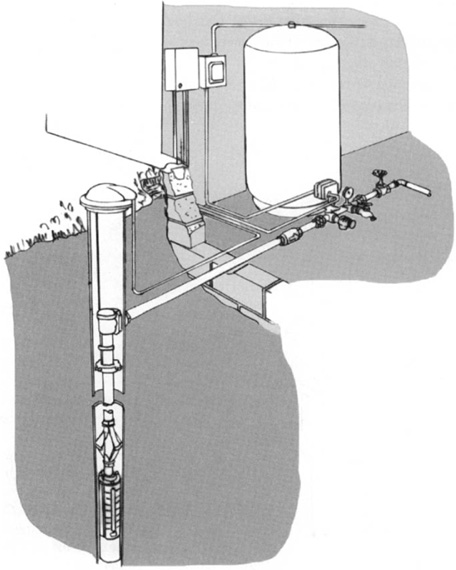

Submersible pumps are very different from jet pumps. Jet pumps are installed outside of the well. Submersible pumps are installed in the well, submerged in the water. Jet pumps use suction pipes. Submersible pumps have only one pipe and they push the water up the pipe, from the well. Jet pumps use a foot valve, submersible pumps don’t. Submersible pumps are much more efficient than jet pumps; they also are easier to install. Under the same conditions, a ½-horsepower submersible pump can produce nearly 300 gallons more water per minute than a ½-horsepower jet pump. With so many advantages, it is almost foolish to use a jet pump, when you could use a submersible pump.

A submersible pump is installed inside the well, submerged in water. The water is then pushed up from within the well. This pump is more efficient than a jet pump.

Installing a submersible pump requires techniques different from those required for a jet pump. Since submersible pumps are installed in the well, electrical wires must be run down the well to the pump. Before installing your submersible pump, consult a licensed electrician about the wiring needs of your pump.

Installing the pitless adapter. You will need a hole in the well casing to install a pitless adapter to provide a watertight seal for your well pipe to feed your water service. When you purchase your pitless adapter, it should be packaged with instructions on the size hole you will need in the well casing.

You can cut a hole in the well casing with a cutting torch or a hole saw. The pitless adapter attaches to the well casing and seals the hole. On the inside of the well casing, you will have a tee fitting on the pitless adapter, which is where your well pipe is attached. This tee fitting is designed to allow you to make all of your pump and pipe connections above ground. After all the connections are made, lower the pump and pipe into the well, and the tee fitting slides into a groove on the pitless adapter.

Installing the pipe. To make the pump and pipe connections, you will need to know the depth of the well. The well driller should provide you with the depth and rate of recovery for the well. Once you know the depth, cut a piece of plastic well pipe to the desired length. The pump should hang at least 10 feet above the bottom of the well and at least 10 feet below the lowest expected water level.

Apply pipe dope to a male-insert adapter and screw it into the pump. This fitting is normally made of brass. Slide a torque arrestor over the end of your pipe. Next, slide two stainless steel clamps over the pipe. Place the pipe over the insert adapter and tighten the two clamps. Compress the torque arrestor to a size slightly smaller than the well casing and secure it to the pipe. The torque arrestor absorbs thrust and vibrations from the pump and helps to keep the pump centered in the casing.

Slide torque stops down the pipe from the opposite end of the pump. Space the torque stops at routine intervals along the pipe to prevent the pipe and wires from scraping against the casing during operation. Secure the electrical wiring to the well pipe at regular intervals to eliminate slack in the wires. Apply pipe dope to a brass, male-insert adapter and screw it into the bottom of the tee fitting for the pitless adapter. Slide two stainless steel clamps over the open end of the pipe and push the pipe onto the insert adapter. After tightening the clamps, you are ready to lower the pump into the well.

Installing the pump in the well. Before lowering the pump, it is a good idea to tie a safety rope onto it. After the pump is installed, this rope is tied to the top of the casing to prevent the pump from being lost in the well, in case the pipe becomes disconnected from the pump. Next, screw a piece of pipe or an adapter into the top of the tee fitting for the pitless adapter. Most plumbers use a rigid piece of steel pipe for this purpose.

Once you have a pipe extending up from the top of the tee fitting, lower the whole assembly into the well casing. This job is easier if you have someone to help you. Be careful not to scrape the electrical wires on the well casing as the pump is lowered. If the insulation on the wires is damaged, the pump may not work.

Holding the assembly by the pipe extending from the top of the pitless tee, guide the pitless adapter into the groove of the adapter in the well casing. When the adapter is in the groove, push it down to fit into the mounting bracket. This concludes the well part of the installation.

Connecting the Water Distribution System. Attach your water service pipe to the pitless adapter on the outside of the casing. You can do this with a male-insert adapter. Once inside the pump house, the water pipe should have a union installed in it. The next fitting should be a gate valve, followed by a check valve. From the check valve, your pipe should run to a tank tee.

The tank tee is a device that screws into the pressure tank and allows the installation of all related parts. The switch box, pressure gauge, and boiler drain can all be installed on the tank tee. When the pipe gets to the tank tee, the water is dispersed to the pressure tank, the drain valve, and the water main. When the water main leaves the tank tee, you should install a tee to accommodate a pressure relief valve. After this tee, you can install a gate valve and continue piping to the water distribution system. The only task left is to test your system; you do not have to prime a submersible pump.

I mentioned alternative water sources earlier in this chapter. People who pay for their water by the gallon or who don’t have wells capable of handling the demands for domestic use and irrigation, often seek alternative water sources. We already have looked at most types of water sources in previous chapters, but let’s take a little time to see how to get that water to your lawn or garden.

Unless you have a massive area to irrigate you probably will not want to make the cash investment required to drill a well and install an independent pump system. This makes sense and is certainly understandable. A driven well, a stream, a pond, or even a catch basin can overcome the high cost of drilling a well for modest irrigation needs. The problem is, how do you get the water to where you want it?

With any of the less expensive water sources, a jet pump should be more than capable of getting the job done. Effluent pumps will perform well in many instances, and there will almost never be a need for a deep-well pump. This is all good news economically.

Depending upon your creativity, you may be able to water your garden without the use of a pump. This saves money on the cost of equipment and on the cost of electricity, plus it is more environmentally responsible. We are going to explore this possibility in the next chapter.

It has been my experience that effluent pumps and jet pumps are the only two types of pumps generally needed for residential irrigation. I have told you about deep-well pumps to inform you and to be fair to you, even though I doubt that you will have to install one. It is, however, very likely that you will work with deep-well pumps if you elect to use the tap-in method of connection.

The simplicity and low cost of effluent pumps and single-pipe jet pumps makes setting up a home irrigation system a breeze. Given the proper circumstances, you can avoid high water bills and still enjoy a lush lawn and a green garden.