PRINCIPLES OF

ROBOT LOCOMOTION

ROBOT LOCOMOTION

As you graduate to building larger mobile robots, you should consider the physical

properties of your creations, including their size, weight, and mode of transport. A

robot that is too heavy for its frame, or a locomotion mechanism that doesn’t provide sufficient stability, will greatly hinder the usefulness of your mechanical invention.

In this chapter you’ll find a collection of assorted tips, suggestions, and caveats for

designing the locomotion systems for your robots. Because the locomotion system is intimately related to the frame of the robot, we’ll cover frames a little bit as well, including their weight and weight distribution. Of course, there’s more to the art and science of robot locomotion than we can possibly cover here, but what follows will serve as a good introduction.

Most hobbyist robots weigh under 20 lbs, and a high percentage of those weigh under 10

lbs. Weight is one of the most important factors affecting the mobility of a robot. A heavy

robot requires larger motors and higher capacity batteries—both of which add even more

pounds to the machine. At some point, the robot becomes too heavy to even move.

On the other hand, robots designed for heavy-duty work often need some girth and

weight. Your own design may call for a robot that needs to weigh a particular amount in order for it to do the work you have envisioned. The parts of a robot that contribute the

most to its weight are the following, in (typical) descending order:

- Batteries

- Drive motors

- Frame

A 12-V battery pack can weigh 1 lb; larger-capacity, sealed lead-acid batteries can weigh

5 to 8 lbs. Heavier-duty motors will be needed to move that battery ballast. But bigger and

stronger motors weigh more because they must be made of metal and use heavier-duty

bushings. And they cost more. Suddenly, your “little robot” is not so little anymore; it has

become overweight and expensive.

If you find that your robot is becoming too heavy, consider putting it on a diet, starting with

the batteries. Nickel-cadmium and nickel metal hydride batteries weigh less, volt for volt,

than their lead-acid counterparts. While nickel-cadmium and nickel metal hydride batteries

may not deliver the amp-hour capacity that a large, sealed lead-acid battery will, your robot

will weigh less and therefore may not require the same stringent battery ratings as you had

originally thought.

When looking at reducing the weight of your robot or modifying it in any way, remember

to try to come up with changes that result in additional benefits. For example, if you

were to change your batteries to a lighter set, you will discover that you do not need as powerful

a motor. Less powerful motors weigh less than the originally specified motors, further

decreasing the weight of the motor. This decrease in the weight of the motor could result in

the need for smaller and lighter batteries, which allows you to look at using even smaller and

lighter batteries, smaller motors, smaller structure, etcetera. This process can repeat multiple

times and it isn’t unusual to see a situation where a 10 percent decrease in battery

weight results in a 50 percent reduction in overall robot weight. The repeating positive

response to a single change is known as a supereffect, and you should remember that the

reverse is also true: a 10 percent increase in weight in a robot’s components could result in

a 50 percent increase in weight in the final robot.

If your robot must use a lead-acid battery, consider carefully whether you truly need the

capacity of the battery or batteries you have chosen. You may be able to install a smaller

battery with a lower amp-hour rating. The battery will weigh less, but, understandably, it will

need to be recharged more often. An in-use time of 60 to 120 minutes is reasonable (that

is, the robot’s batteries must be recharged after an hour or two of continual use).

If you require longer operational times but still need to keep the weight down, consider

a replaceable battery system. Mount the battery where it can be easily removed. When the

charge on the battery goes down, take it out and replace it with a fully charged one. Place

the previously used battery in the charger. The good news is that smaller, lower capacity batteries

tend to be significantly less expensive than their larger cousins, so you can probably

buy two or three smaller batteries for the price of a single big one.

Drive motors are most often selected because of their availability and cost, not because

of their weight or construction. In fact, many robots are designed around the specifications

of the selected drive motors. The motors are selected (often they’re purchased surplus), and

from these the frame of the robot is designed and appropriate batteries are added. Still, it’s

important to give more thought to the selection of the motors for the robot that you have

in mind. Avoid motors that are obviously overpowered in relation to the robot in which they

are being used. Motors that are grossly oversized will add unnecessary weight, and they will

require larger (and therefore heavier and more expensive) batteries to operate.

The frame of the robot can add a surprising amount of weight. An 18-in2, 2-ft high robot

constructed from extruded aluminum and plastic panels might weigh in excess of 20 or 30

lbs, without motors and batteries. The same robot in wood (of sufficient strength and quality)

could weigh even more.

Consider ways to lighten your heavy robots, but without sacrificing strength. This can be

done by selecting a different construction material and/or by using different construction

techniques. For example, instead of building the base of your robot using solid  -in (or

thicker) aluminum sheet, consider an aluminum frame with crossbar members for added stability.

If you need a surface on which to mount components (the batteries and motors will

be mounted to the aluminum frame pieces), add a

-in (or

thicker) aluminum sheet, consider an aluminum frame with crossbar members for added stability.

If you need a surface on which to mount components (the batteries and motors will

be mounted to the aluminum frame pieces), add a  -in acrylic plastic sheet as a "skin" over

the frame. The plastic is strong enough to mount circuit boards, sensors, and other lightweight

components on it.

-in acrylic plastic sheet as a "skin" over

the frame. The plastic is strong enough to mount circuit boards, sensors, and other lightweight

components on it.

-in (or

thicker) aluminum sheet, consider an aluminum frame with crossbar members for added stability.

If you need a surface on which to mount components (the batteries and motors will

be mounted to the aluminum frame pieces), add a

-in (or

thicker) aluminum sheet, consider an aluminum frame with crossbar members for added stability.

If you need a surface on which to mount components (the batteries and motors will

be mounted to the aluminum frame pieces), add a  -in acrylic plastic sheet as a "skin" over

the frame. The plastic is strong enough to mount circuit boards, sensors, and other lightweight

components on it.

-in acrylic plastic sheet as a "skin" over

the frame. The plastic is strong enough to mount circuit boards, sensors, and other lightweight

components on it.Aluminum and acrylic plastic aren’t your only choices for frame materials. Other metals

are available as well, but they have a higher weight-to-size ratio. Both steel and brass weigh

several times more per square inch than aluminum. Brass sheets, rods, and tubes (both

round and square) are commonly available at hobby stores. Unless your robot requires the

added strength that brass provides, you may wish to avoid it because of its heavier weight.

Ordinary acrylic plastic is rather dense and therefore fairly heavy, considering its size.

Lighter-weight plastics are available but not always easy to find. For example, ABS and

PVC plastic—popular for plumbing pipes—can be purchased from larger plastics distributors

in rod, tube, and sheet form. There are many special-purpose plastics available that

boast both structural strength and light weight. Look for Sintra plastic, for example, which

has an expanded core and smooth sides and is therefore lighter than most other plastics.

Check the availability of glues and cements before you purchase or order any material. (See Chapter 10 for more on these and other plastics.)

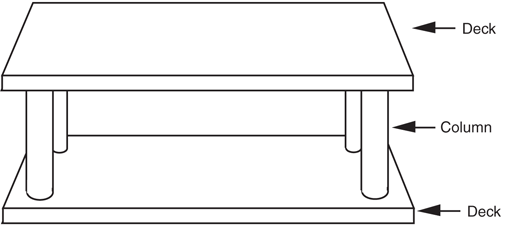

For robots that have additional “decks,” like the robot shown in Fig. 18-1, select construction materials that will provide rigidity but the lowest possible weight. One technique, shown in the figure, is to use  -in thin-wall (Schedule 125) PVC pipe for uprights and attach the "decks" using

-in thin-wall (Schedule 125) PVC pipe for uprights and attach the "decks" using  or

or  all-thread rod. The PVC pipe encloses the all-thread; both act as a

strong support column. You need three such columns for a circular robot, and four columns

for a square robot. For small robots, consider electronic circuit board standoffs, which are

six-sided rods with the ends drilled and tapped for 4-40 screws.

all-thread rod. The PVC pipe encloses the all-thread; both act as a

strong support column. You need three such columns for a circular robot, and four columns

for a square robot. For small robots, consider electronic circuit board standoffs, which are

six-sided rods with the ends drilled and tapped for 4-40 screws.

-in thin-wall (Schedule 125) PVC pipe for uprights and attach the "decks" using

-in thin-wall (Schedule 125) PVC pipe for uprights and attach the "decks" using  or

or  all-thread rod. The PVC pipe encloses the all-thread; both act as a

strong support column. You need three such columns for a circular robot, and four columns

for a square robot. For small robots, consider electronic circuit board standoffs, which are

six-sided rods with the ends drilled and tapped for 4-40 screws.

all-thread rod. The PVC pipe encloses the all-thread; both act as a

strong support column. You need three such columns for a circular robot, and four columns

for a square robot. For small robots, consider electronic circuit board standoffs, which are

six-sided rods with the ends drilled and tapped for 4-40 screws.

Figure 18-1 “Decked” robots provide extra space for batteries and electronics, but they can also add considerably to the weight. Use lightweight construction materials to avoid unduly increasing the weight of the robot.

Unless your robot is heavy, be sure to use the thinner-walled Schedule 125 PVC pipe.

Schedule 80 pipe, commonly used for irrigation systems, has a heavier wall and may not be

needed. Note that PVC pipe is always the same diameter outside, no matter how thick its

plastic walls. The thicker the wall, the smaller the inside diameter of the pipe. You can readily

cut PVC pipe to length using a PVC pipe cutter or a hacksaw, and you can paint it if you

don’t like the white color. Use Testor model paints for best results, and be sure to spray

lightly. For a bright white look, you can remove the blue marking ink on the outside of the

PVC pipe with acetone, which is available in the paint department of your local home

improvement store.

A critical issue in robot frame design is excessive weight that causes the frame to sag in the

middle. In a typical robot, a special problem arises when the frame sags: the wheels on

either side pivot on the frame and are no longer perpendicular to the ground. Instead, they

bow out at the bottom and in at the top (this is called negative camber). Depending on

which robot tires you use, traction errors can occur because the contact area of the wheel

is no longer consistent. As even more weight is added, the robot may have a tendency to

veer off to one side or the other.

There are three general fixes for this problem: reduce the weight, strengthen the frame,

or add cross-braces to prevent the wheels from cambering. Strengthening the frame usually

involves adding even more weight. So if you can, strive for the first solution instead—reduce

the weight.

If you can’t reduce weight, look for ways to add support beams or braces to prevent sagging.

An extra cross-brace along the wheelbase (perhaps stretched between the two motors)

may be all that’s required to prevent the problem. The cross-brace can be made of lightweight

aluminum tubing or even from a wooden dowel. The tubing or dowel does not need

to support any weight; it simply needs to act as a brace to prevent compression when the

frame sags and the wheels camber.

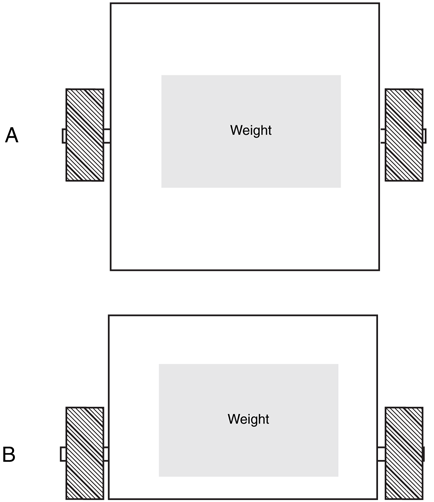

Yet another method is to apply extreme camber to the wheels, as shown in Fig. 18-2.

This minimizes the negative effects of any sagging, and if the tires have a high frictional surface

traction is not diminished. However, don’t do this with smooth, hard plastic wheels as

they don’t provide sufficient traction. You can camber the wheels outward or inward.

Inward (negative) camber was used in the old Topo and Bob robots made by Nolan Bushnell’s

failed Androbot company of the mid-1980s. The heavy-duty robot in Fig. 18-2 uses

outward (positive) camber. The robot can easily support over 20 lbs in addition to its own

weight, which is about 10 lbs, with battery, which is slung under the frame using industrial-strength

hook-and-loop (Velcro or similar) fasteners.

Figure 18-2 This “Tee-Bot” (so named because it employs the T-braces used for home construction)

uses extreme camber to avoid the frame sagging that results from too much weight.

Your robot’s horizontal center of balance (think of it as a balance scale) indicates how well

the weight of the robot is distributed on its base. If all the weight of a robot is to one side,

for example, then the base will have a lopsided horizontal center of balance. The result is

an unstable robot: the robot may not travel in a straight line and it might even tip over.

Ideally, the horizontal center of balance of a robot should be the center of its base (see

Fig. 18-3a). Some variation of this theme is allowable, depending on the construction of the

robot. For a robot with a single balancing caster, as shown in Fig. 18-3b, it is usually acceptable

to place more weight over the drive wheels and less on the caster. This increases traction,

and as long as the horizontal center of balance isn’t extreme there is no risk that the

robot will tip over.

Figure 18-3 The distribution of weight on a robot affects its stability

and traction. a. Centering the weight down the middle in a robot

with two balancing casters; b. sliding the center of balance toward the

drive wheel in a single-caster ’bot.

Unequal weight distribution is the most troublesome result if the horizontal center of balance favors one wheel or track over the other—the right side versus the left side, for example. This can cause the robot to continually “crab” toward the heavier side. Since the heavier

side has more weight, traction is improved, but motor speed may be impaired because of the extra load.

City skyscrapers must be rooted firmly in the ground or else there is a risk they will topple

over in the slightest wind. The taller an object is, the higher its center of gravity. Of critical

importance to vertical center of gravity is the “footprint” or base area of the object—that is,

the amount of area in contact with the ground. The ratio between the vertical center of

gravity and the area of the base determines how likely it is that the object will fall over. A

robot with a small base but high vertical center of gravity risks toppling over. You can correct

such a design in either of two ways:

- Reduce the height of the robot to better match the area of the base, or

- Increase the area of the base to compensate for the height of the robot.

(There is also a third method called dynamic balance. Here, mechanical weight is

dynamically repositioned to keep the robot on even kilter. These systems are difficult to

engineer and, in any event, are beyond the scope of this book.)

Which method you choose will largely depend on what you plan to use your robot for.

For example, a robot that must interact with people should be at least toddler height. For a

pet-size robot, you’ll probably not want to reduce the height, but rather increase the base

area to prevent the robot from tipping over.

The way your robot gets from point A to point B is called locomotion. Robot locomotion

takes many forms, but wheels and tracks are the most common. Legged robots are also

popular, especially among hobbyists, as designing them represents a challenge both in construction

and weight-balance dynamics.

Wheels, and to a lesser extent tracks, are the most common means chosen to move robots

around. However, some wheels are better for mobile robots than others. Some of the

design considerations you may want to keep in mind include the following:

- The wider the wheels, the more the robot will tend to stay on course. With very narrow wheels, the robot may have a tendency to favor one side or the other and will trace a slow curve instead of a straight line. Conversely, if the wheels are too wide, the friction created by the excess wheel area contacting the ground may hinder the robot’s ability to make smooth turns.

- Two driven wheels positioned on either side of the robot (and balanced by one or two casters on either end) can provide full mobility. This is the most common drive wheel arrangement and is called a differential drive.

- Tracks turn by skidding or slipping, and they are best used on surfaces such as dirt that readily allow low-friction steering.

- Four or more driven wheels, mounted in sets on each side, will function much like tracks. In tight turns, the wheels will experience significant skidding, and they will therefore create friction over any running surface. If you choose this design, position the wheel sets close together.

- You should select wheel and track material to reflect the surface the robot will be used on. Rubber and foam are common choices; both provide adequate grip for most kinds of surfaces. Foam tires are lighter in weight, but they don’t skid well on hard surfaces (such as hardwood or tile floors).

Thanks to the ready availability of smart microcontrollers, along with the low cost of R/C

(radio-controlled) servos, legged automatons are becoming a popular alternative for robot

builders. Robots with legs require more precise construction than the average wheeled

robot. They also tend to be more expensive. Even a basic six-legged walking robot requires

a minimum of two or three servos, with some six- and eight-leg designs requiring 12 or

more motors. At about $12 per servo (more for higher-quality ones), the cost can add up

quickly!

Obviously, the first design decision is the number of legs. Robots with one leg (hoppers)

or two legs are the most difficult to build because of balance issues, and will not be

addressed here. Robots with four and six legs are more common. Six legs offer a static balance

that ensures the robot won’t easily fall over. At any one time, a minimum of three legs

touch the ground, forming a stable tripod.

In a four-legged robot, either the robot must move one leg at a time—keeping the other

three on the ground for stability—or else employ some kind of dynamic balance when only

two of its legs are on the ground at any given time. Dynamic balance is often accomplished

by repositioning the robot’s center of gravity, typically by moving a weight (such as the

robot’s head or tail, if it has one). This momentarily redistributes the center of balance to

prevent the robot from falling over. The algorithms and mechanisms for achieving dynamic

balance are not trivial. Four-legged robots are difficult to steer, unless you add additional

degrees of freedom for each leg or articulate the body of the beast like those weird segmented

city buses you occasionally see.

The movement of the legs with respect to the robot’s body is often neglected in the

design of legged robots. The typical six-legged (hexapod) robot uses six identical legs. Yet

the crawling insect a hexapod robot attempts to mimic is designed with legs of different

lengths and proportions—the legs are made to do different things. The back legs of an

insect, for example, are often longer and are positioned near the back for pushing (this is

particularly true of insects that burrow through dirt). The front legs may be similarly constructed for digging, carrying food, fighting, and walking. You may wish to replicate this

design, or something similar, for your own robots. Watch some documentaries on insects

and study how they walk and how their legs are articulated. Remember that the cockroach

has been around for over a million years and represents a very advanced form of biological

engineering!

Next to the batteries, the drive motors are probably the heaviest component in your robot.

You’ll want to carefully consider where the drive motor(s) are located and how the weight is

distributed throughout the base.

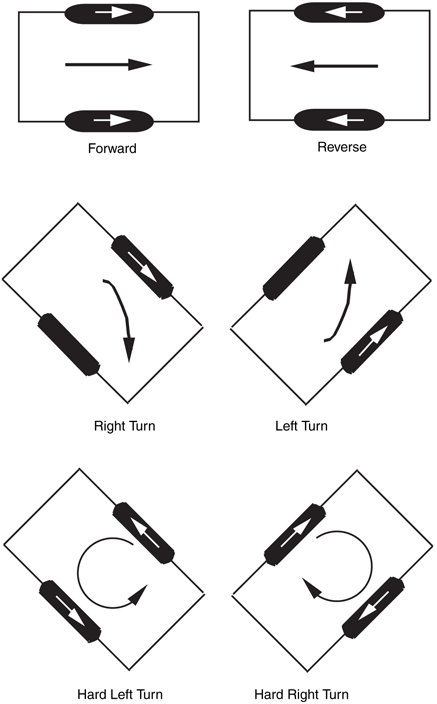

One of the most popular mobile robot designs uses two identical motors to spin two

wheels on opposite sides of the base (the differentially driven robot). These wheels provide

forward and backward locomotion, as shown in Fig. 18-4, as well as left and right steering.

If you stop the left motor, the robot turns to the left. By reversing the motors relative to one

another, the robot turns by spinning on its wheel axis (turns in place). You use this forward-reverse

movement to make hard or sharp right and left turns.

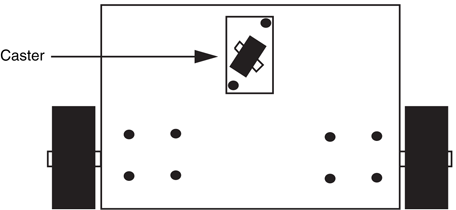

Figure 18-4 Two motors mounted on either side of the robot can

power two wheels. Casters provide balance. The robot steers by changing

the speed and direction of each motor.

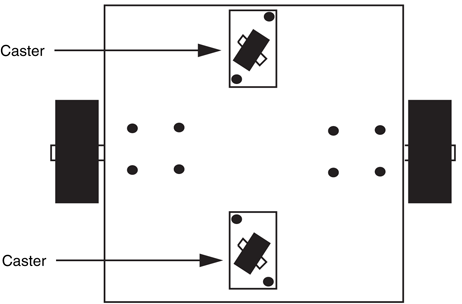

You can place the wheels—and hence the motors—just about anywhere along the length

of the platform. If they are placed in the middle, as shown in Fig. 18-5, you should add

two casters to either end of the platform to provide stability. Since the motors are in the

center of the platform, the weight is more evenly distributed across it. You can place the

battery or batteries above the centerline of the wheel axis, which will maintain the even

distribution.

Figure 18-5 A robot with a centerline motor mount uses two casters

(very occasionally one) for balance. When using one caster, you may need

to shift the balance of weight toward the caster end to avoid having the

robot tip over.

A benefit of centerline mounting is that the robot has no “front” or “back,” at least as far

as the drive system is concerned. Therefore, you can create a kind of multidirectional robot

that can move forward and backward with the same ease. Of course, this approach also

complicates the sensor arrangement of your robot. Instead of having bump switches only in

the front of your robot, you’ll need to add additional ones in the back in case the robot is

reversing direction when it strikes an object.

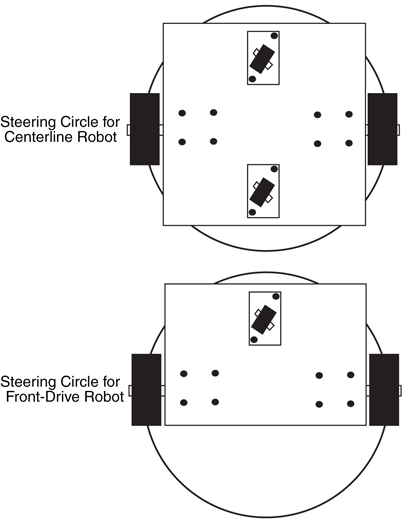

You can also position the wheels on one end of the platform. In this case, you add one

caster on the other end to provide stability and a pivot for turning, as shown in Fig. 18-6.

Obviously, the weight is now concentrated more on the motor side of the platform. You

should place more weight over the drive wheels, but avoid putting all the weight there since

maneuverability and stability may be diminished.

Figure 18-6 A robot with a front-drive motor mount uses a single

opposing caster for balance. Steering is accomplished using the same technique

as a centerline motor mount.

One advantage of front-drive mounting is that it simplifies the construction of the robot.

Its steering circle, the diameter of the circle in which the robot can be steered, is still the same diameter as the centerline drive robot. However, it extends beyond the front/back

dimension of the robot (see Fig. 18-7). This may or may not be a problem, depending on

the overall size of your robot and how you plan to use it. Any given front-drive robot may

be smaller than its centerline drive cousin. Because of the difference in their physical size,

the diameter of the steering circle for both may be about the same.

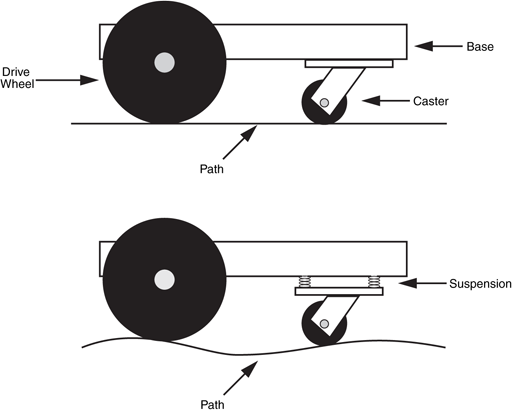

As mentioned earlier, most robots employing the two-motor drive system use at least one

unpowered caster, which provides support and balance. Two casters are common in robots

that use centerline drive-wheel mounting. Each caster is positioned at opposite ends of the

robot. When selecting casters it is important to consider the following factors:

- The size of the caster wheel should be in proportion to the drive wheels (see Fig. 18-8).

- When the robot is on the ground, the drive motors must firmly touch terra firma. If the caster wheels are too large, the drive motors may not make adequate contact, and poor traction will result. You might also consider using a suspension system of your own design on the casters to compensate for uneven terrain.

- The casters should spin and swivel freely. A caster that doesn’t spin freely will impede the robot’s movement.

- In most cases, since the caster is provided only for support and not traction you should construct the caster from a hard material to reduce friction. A caster made of soft rubber will introduce more friction, and it may affect a robot’s movements.

- Consider using ball casters (also called ball transfers), which are primarily designed to

be used in materials processing (conveyor chutes and the like). Ball casters (see Fig. 18-9)

are made of a single ball—either metal or rubber—held captive in a housing, and they

function as omnidirectional casters for your robot. The size of the ball varies from about

to over 3 in in diameter. Look for ball casters at mechanical surplus stores and also

at industrial supply outlets, such as Grainger and McMaster–;Carr.

to over 3 in in diameter. Look for ball casters at mechanical surplus stores and also

at industrial supply outlets, such as Grainger and McMaster–;Carr.

Figure 18-8 The height of the caster with respect to the drive wheels will greatly

influence the robot’s traction and maneuverability. A spring-loaded caster (a kind of

suspension) can improve functionality of the robot on semirough terrain.

Figure 18-9 Ball casters (or ball transfers) are omnidirectional. For medium- to

large-sized robots consider using them instead of wheeled casters.

A variety of methods are available to steer your robot. The following sections describe several of the more common approaches.

For wheeled and tracked robots, differential steering is the most common method for getting

the machine to go in a different direction. The technique is exactly the same as steering

a military tank: one side of wheels or treads stops or reverses direction while the other

side keeps going. The result is that the robot turns in the direction of the stopped or

reversed wheel or tread. Because of friction effects, differential steering is most practical

with two-wheel-drive systems. Additional sets of wheels, as well as rubber treads, can

increase friction during steering.

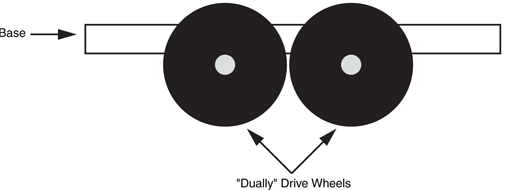

- If you are using multiple wheels (dually), position the wheels close together, as shown in Fig. 18-10. The robot will pivot at a virtual point midway between the two wheels on each side.

- If you are using treads, select a relatively low-friction material such as cloth or hard plastic. Very soft rubber treads will not steer well on smooth surfaces. If this cannot be helped, one approach is to always steer by reversing the tread directions. This will reduce the friction.

Figure 18-10 “Dually” wheels should be placed close to one another. If they

are spaced farther apart the robot cannot steer as easily.

Pivoting the wheels in the front is yet another method for steering a robot (see Fig. 18-11).

Robots with car-type steering are not as maneuverable as differentially steered robots, but

they are better suited for outdoor uses, especially over rough terrain. You can obtain somewhat

better traction and steering accuracy if the wheel on the inside of the turn pivots more

than the wheel on the outside. This technique is called Ackerman steering and is found on

most cars but not on as many robots.

Figure 18-11 Car-type steering offers a workable alternative for an outdoors robot, but it is less useful indoors or in places where there are many obstructions that must be steered around.

One of the biggest drawbacks of the differentially steered robot is that the robot will veer off

course if one motor is even a wee bit slow. You can compensate for this by monitoring the

speed of both motors and ensuring that they operate at the same r/min. This typically

requires a control computer, as well as added electronics and mechanical parts for sensing

the speed of the wheels.

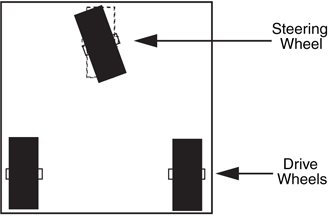

Car-type steering, described in the last section, is one method for avoiding the problem

of “crabbing” as a result of differences in motor speed simply because the robot is driven by

just one motor. But car-type steering makes for fairly cumbersome indoor mobile robots. A

better approach is to use a single drive motor powering two rear wheels and a single steering

wheel in the front. This arrangement is just like a child’s tricycle, as shown in Fig. 18-12.

The robot can be steered in a circle just slightly larger than the width of the machine. Be

careful about the wheelbase of the robot (distance from the back wheels to the front steering

wheel). A short base will cause instability in turns, and the robot will tip over opposite the

direction of the turn.

Figure 18-12 In tricycle steering, one drive motor powers the robot and a single wheel in front steers the robot. Try and to avoid short wheelbases as this can result in a robot that tips easily when the robot turns.

Tricycle-steered robots must have a very accurate steering motor in the front. The

motor must be able to position the front wheel with subdegree accuracy. Otherwise,

there is no guarantee the robot will be able to travel a straight line. Most often, the steering wheel is controlled by a servo motor. Servo motors use a closed-loop feedback system that provides a high degree of positional accuracy (depending on the quality of the

motor, of course). Read more about servo motors in Chapter 22, “Working with Servo

Motors.”

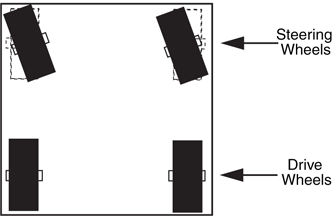

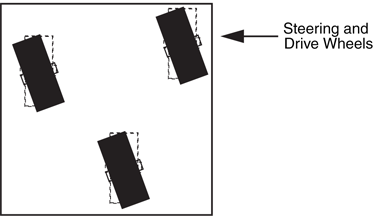

To have the highest tech of all robots, you may want omnidirectional drive. It uses steerable

drive wheels, usually at least three, as shown in Fig. 18-13. The wheels are operated by two

motors: one for locomotion and one for steering. In the usual arrangement, the drive/steering

wheels are ganged together using gears, rollers, chains, or pulleys. Omnidirectional

robots exhibit excellent maneuverability and steering accuracy, but they are technically

more difficult to construct.

The speed of the drive motors is one of two elements that determines the travel speed of

your robot. The other is the diameter of the wheels. For most applications, the speed of the

drive motors should be under 130 r/min (under load). With wheels of average size, the

resultant travel speed will be approximately 4 ft/s. That’s actually pretty fast. A better travel

speed is 1 to 2 f/s (approximately 65 r/min), which requires smaller diameter wheels, a

slower motor, or both.

How do you calculate the travel speed of your robot? Follow these steps:

1. Divide the r/min speed of the motor by 60. The result is the revolutions of the motor

per second (r/s). A 100-r/min motor runs at 1.66 r/s.

2. Multiply the diameter of the drive wheel by pi, or approximately 3.14. This yields the

circumference of the wheel. A 7-in wheel has a circumference of about 21.98 in.

3. Multiply the speed of the motor (in r/s) by the circumference of the wheel. The result is

the number of linear inches covered by the wheel in 1 s.

With a 100-r/min motor and 7-in wheel, the robot will travel at a top speed of 35.168

in/s, or just under 3 ft. That’s about 2 mi/h! You can readily see that you can slow down

a robot by decreasing the size of the wheel. By reducing the wheel to 5 in instead of 8, the

same 100-r/min motor will propel the robot at about 25 in/s. By reducing the motor

speed to, say, 75 r/min, the travel speed falls even more, to 19.625 in/s. Now that’s more

reasonable.

Bear in mind that the actual travel speed once the robot is all put together may be lower

than this. The heavier the robot, the larger the load on the motors, so the slower it will turn.

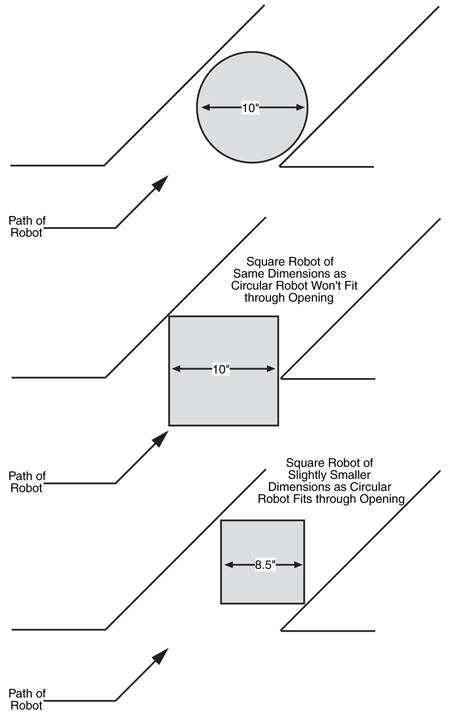

Robots can’t locomote where they can’t fit. Obviously, a robot that’s too large to fit through

doorways and halls will have a hard time of it. In addition, the overall shape of a robot will

also dictate how maneuverable it is, especially indoors. If you want to navigate your robot

in tight areas, you should consider its basic shape: round or square.

- A round robot is generally able to pass through smaller openings, no matter what its orientation when going through the opening (see Fig. 18-14). To make a round robot, you must either buy or make a rounded base or frame. Whether you’re working with metal, steel, or wood, a round base or frame is not as easy to construct as a square one.

- A square robot must orient itself so that it passes through openings straight ahead rather than at an angle. Square-shaped robot bases and frames are easier to construct than round ones.

Figure 18-14 A round robot versus a square robot. All things

being equal, a round robot is better able to navigate through small

openings. However, rounded robots also have less usable surface area,

so a square-shaped robot can be made smaller and still support the

same on-board “real estate.”

While you’re deciding whether to build a round- or square-shaped robot, consider that

a circle of a given diameter has less surface area than a square of the same width. For

example, a 10-in circle has a surface area of about 78 in2. Moreover, because the surface

of the base is circular, less of it will be useful for your robot (unless your printed circuit

boards are also circular). Conversely, a 10-by-10-in square robot has a surface area

of 100 in. Such a robot could be reduced to about 8.5 in2, and it would have about the

same surface area as a 10-in round robot, and its surface area would be generally more

usable.

To learn more about . . . |

Read |

|

Selecting wood, plastic, or metal to construct your robot |

||

Choosing a battery for your robot |

Chapter 17, "Batteries and Robot Power Supplies" |

|

Selecting motors |

Chapter 18, "Choosing the Right Motor" |

|

Building a walking robot |

Chapter 24, "Build a Heavy-Duty Six-Legged Walking Robot" |

|

Constructing a treaded robot |

Chapter 25, "Advanced Locomotion Systems" |

|

Controlling the speed of a two-motor-driven robot |

Chapter 20, "Working with DC Motors" |