30

CHAPTER

Dehumidifiers

Dehumidifiers are household appliances that remove moisture (humidity) from an area. Humidity is defined as the amount of water vapor in the air and is measured in terms of relative humidity (RH %). The higher the RH percentage, the more water vapor in the air. The optimum relative humidity level in an area is generally considered to be between 30 percent and 50 percent. Humidity levels exceeding 50 percent with temperatures over 70 degrees Fahrenheit can be uncomfortable, unhealthy, and in most cases cause personal property damage. Anything above this range may promote bacteria growth or mold. In colder climates, during the heating season, humidity levels should be maintained between 30 percent and 40 percent to prevent moisture from collecting or condensing on the windows and doors. Dehumidifiers (Figure 30-1) were designed to remove unwanted moisture from the air in a given area.

FIGURE 30-1 A typical portable dehumidifier.

Sizing a Dehumidifier

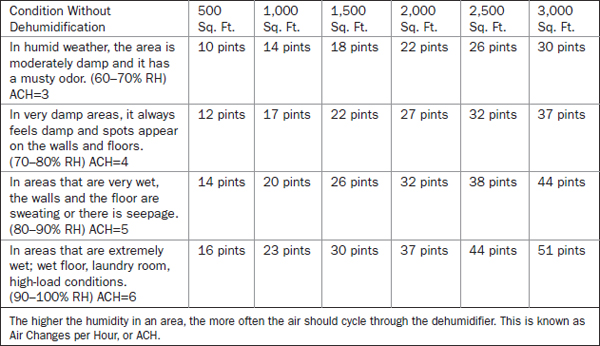

Dehumidifiers, when properly set, can maintain the desired humidity level in that area. The capacity is usually measured in pints per 24 hours and is determined by two factors: the square footage of the space that needs to be dehumidified and the conditions that exist in the space before dehumidification. Table 30-1 depicts a dehumidifier sizing chart.

TABLE 30-1 Dehumidifier Sizing Guidelines

Another measure that can determine the size of dehumidifier the consumer needs is the amount of air the appliance can move over a certain period of time. Dehumidifiers measure this in cubic feet per minute (CFM). The CFM is an important measure for dehumidification because the unit can only extract moisture from the air that passes through the dehumidifier. All of the air in a room must flow through the dehumidifier in order to remove moisture. To calculate the CFM you need from the dehumidifier, multiply the cubic feet of the area by the recommended air changes per hour (ACH) in Table 30-1, and then divide that number by 60 minutes. The resulting number is the CFM the dehumidifier should have.

Principals of Operation

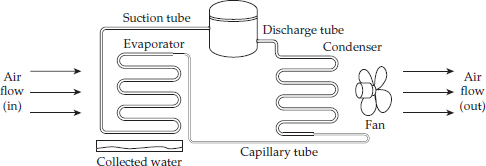

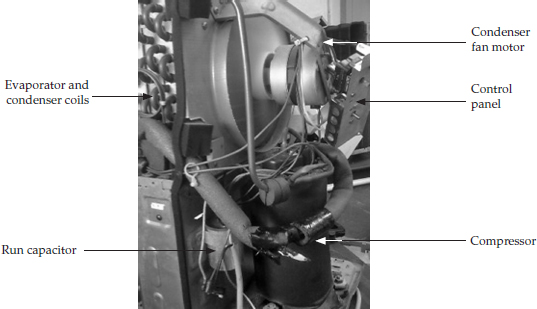

A refrigeration system (Figure 30-2) is used to collect the moisture from the air. The dehumidifier may have either a reciprocating (split phase) or a rotary (permanent split capacitor) compressor that circulates the refrigerant in the dehumidifier. The evaporator operating temperatures are around 33 to 37 degrees Fahrenheit. When moisture-ladened air passes over the evaporator, the moisture will collect on the evaporator coil and condense into a liquid. The cool air is then drawn through the condenser coil and warms the air before it is recirculated back into the room area. The water collected on the evaporator coil will run off the coil into a bucket. Many dehumidifier models include a built-in in humidistat, a device that allows the consumer to set the humidity level desired for that room. Once the room reaches the desired humidity level, the dehumidifier will cycle on and off automatically to maintain that RH level.

FIGURE 30-2 Dehumidifier Sizing Guidelines

Safety First

Any person who cannot use basic tools or follow written instructions should not attempt to install, maintain, or repair any dehumidifiers. Any improper installation, preventive maintenance, or repairs could create a risk of personal injury or property damage. If you do not fully understand the installation, preventive maintenance, or repair procedures in this chapter, or if you doubt your ability to complete the task on your dehumidifier, please call your service manager.

This chapter covers the electrical components and how to diagnose the sealed system. The actual repair or replacement of any sealed-system component is not included in this chapter. It is recommended that you acquire refrigerant certification (or call an authorized service company) to repair or replace any sealed-system component, as the refrigerant in the sealed system must be recovered properly.

Before continuing, take a moment to refresh your memory on the safety procedures in Chapter 2.

Dehumidifiers in General

Much of the troubleshooting information in this chapter covers dehumidifiers in general, rather than specific models, in order to present a broad overview of service techniques. The illustrations that are used in this chapter are for demonstration purposes only to clarify the description of how to service these appliances. They in no way reflect a particular brand’s reliability.

Location and Installation of a Dehumidifier

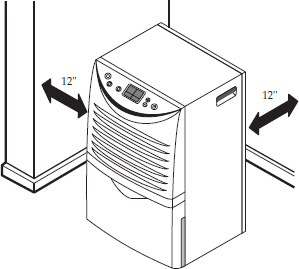

When installing the dehumidifier in the home, you must allow 12 inches of space on all sides of the dehumidifier so that air can circulate properly (see Figure 30-3). The dehumidifier can be installed on the floor, table, or shelf. When installing the dehumidifier on a table or shelf, make sure the table or shelf can support the weight of the dehumidifier, including the weight of the bucket full of water. Next, plug the dehumidifier into a 120 volt properly grounded receptacle, properly polarized. Safety note: Do not use an extension cord with the dehumidifier.

FIGURE 30-3 Place the dehumidifier within 12 inches of any walls or other blockages that might prevent proper air circulation.

Dehumidifier Maintenance

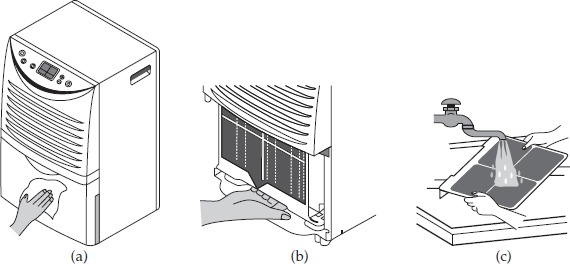

The dehumidifier’s coils should be chemically cleaned at least annually to remove the dirt and slime buildup within the unit. Clean the outer case and cabinet (Figure 30-4a) with a soft cloth and a mild detergent. Next, vacuum the grille, or use a brush on the grill. Do not use abrasives or bleach on the dehumidifier. About once a month, remove the water bucket and clean it to avoid growth of mold, mildew, and bacteria. Don’t forget to wash the air filter and shake off the excess water and let it air dry, and then reinstall it (Figures 30-4b and c) at least once a month also.

FIGURE 30-4 Performing maintenance on the dehumidifier. Clean the outside of the unit (a), front grille (b), and filter (c).

Step-by-Step Troubleshooting by Symptom Diagnosis

When servicing a dehumidifier, don’t overlook the simple things that might be causing the problem. Step-by-step troubleshooting by symptom diagnosis is based on diagnosing malfunctions, with possible causes arranged into categories relating to the operation of the dehumidifier. This section is intended only to serve as a checklist to aid you in diagnosing a problem. Look at the symptom that best describes the problem you are experiencing with the dehumidifier, and then correct the problem.

Dehumidifier Will Not Run (No Fan, No Compressor)

• Check control settings.

• Check voltage to the unit.

• Check bucket; it may be full of water.

• Check wiring.

• Run diagnostics; you may have bad humidistat.

• Check the humidity level in the room and compare that reading against the control setting.

Condenser Fan Motor Runs (Compressor Not Running)

• Check the de-icer thermostat on mechanical models.

• Check thermistor on electronic models.

• On electronic models, run diagnostics; replace electronic control board.

• Check compressor overload and relay.

• Check compressor windings.

Condenser Fan Motor Does Not Run (Compressor Is Running)

• Check voltage going to condenser fan motor.

• Test the condenser fan motor windings.

• Check condenser fan blade.

Condenser Fan Motor and Compressor Running (Evaporator Coil Frozen Up)

• Check the room temperature (nonde-icer models); the room temperature must be higher than 65 degrees Fahrenheit. Frost should disappear within 60 minutes. If not, check the sealed system.

Condenser Fan Motor and Compressor Running (No Dehumidification)

• Dehumidifier may have a sealed-system problem.

• Test the humidity in the room; might have low humidity in area.

• Check the air filter.

• Check the evaporator coil. Is it clean?

Dehumidifier Is Running (Insufficient Dehumidification)

• Check and make sure that the grilles are not obstructed.

• Check air filter.

• Check the evaporator coil. Is it clean?

• Run diagnostics on the sealed system; it might have a low refrigerant charge.

• Check the room size. The dehumidifier might be too small for the square footage.

• Check and make sure that the doors and windows are closed.

• Check the room temperature.

Dehumidifier Runs Continuously

• Check the control settings.

• Check the room humidity level; may have to adjust humidity setting.

Repair Procedures

Each repair procedure is a complete inspection and repair process for a single dehumidifier component. It contains the information you need to test and replace components.

Electronic Components

The electronic components consist of the following: electronic control board and touchpad.

The typical complaints associated with the electronic components are:

• Unable to program the touchpad panel functions.

• The display board will not display anything.

• Unusual display readouts.

• Unable to control the relative humidity.

• The compressor will not run.

• The condenser fan motor will not run.

To prevent electrostatic discharge (ESD) from damaging expensive electronic components, follow the steps in Chapter 11.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the dehumidifier controls. Turn off the electricity to the dehumidifier, and wait for two minutes before turning it back on. If a fault code appears, look up the code. If the dehumidifier will not power up, locate the technical data sheet behind the control panel for diagnostics information. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier. The service manual will assist you in properly placing the dehumidifier in the service test mode for testing the dehumidifier functions.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is there electricity to the dehumidifier? The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.) Is the electrical receptacle polarized and properly grounded?

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity. This can be done by pulling the plug out of the wall receptacle. Or disconnect the electricity at the fuse panel or circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

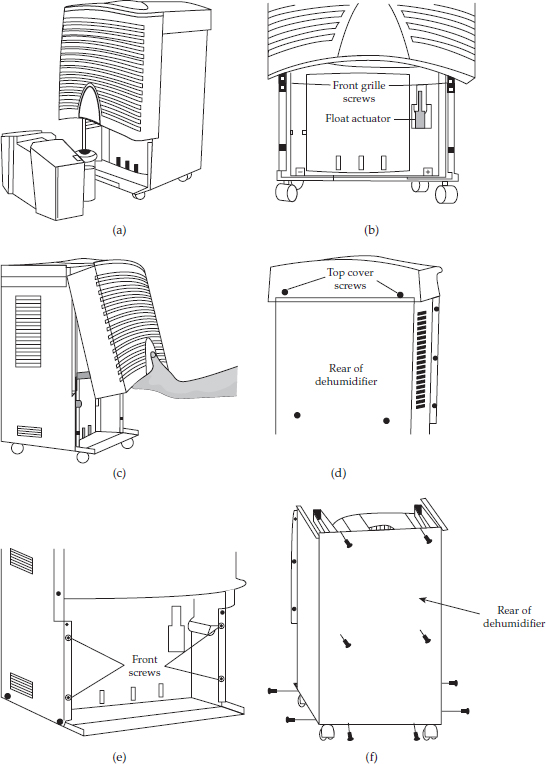

4. Gain access to the electronic components. You can gain access to the electronic components by removing the front grille and the screws on the control panel (Figures 30-5a, b, c, and d). Next, tilt the control panel away from the dehumidifier, making sure not to pull any of the wires off the controls.

FIGURE 30-5 This figure depicts how to gain access to the components. Remove the bucket and screws as shown.

WARNING Do not touch the wiring or capacitor until it is discharged. A capacitor will hold a charge indefinitely, even when it is not currently in use. A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor.

5. Test the electronic components. If you are able to run the dehumidifier test mode, check the different functions of the dehumidifier. Use the technical data sheet for the model you are servicing to locate the test points on the wiring schematic. Check all wiring connections and wiring. Using the technical data sheet, test the electronic control and display board, input voltages, and output voltages.

6. Remove the defective component. To remove the defective component, remove the screws that secure the printed circuit board to the dehumidifier console frame. Disconnect the connectors from the electronic control board and display.

7. Install the new component. To install a new component, just reverse the disassembly procedure and reassemble. Reinstall all panels and the front grille and bucket. Then, restore the electricity to the dehumidifier. Test the dehumidifier operation. To prevent ESD from damaging expensive electronic components, simply follow the steps in Chapter 11.

Capacitor

A capacitor is a device that stores electricity to provide an electrical boost for motor starting. Most high-torque motors need a capacitor connected in series with the start winding circuit to produce the desired rotation under a heavy starting load. The capacitor can also be used for motor efficiency.

The typical complaints associated with failure of the capacitor are:

• Fuse is blown or the circuit breaker trips.

• Fan motor will not run.

• Fan motor has a burning smell.

• Motor or compressor tries to start and then shuts off on overload.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the dehumidifier. Listen carefully, and you will hear if there are any unusual noises or if the circuit breaker trips. If you smell something burning, immediately turn off the dehumidifier and pull out the plug. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is the dehumidifier installed properly? Does it have the correct voltage? The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity. This can be done by pulling the plug from the electrical outlet. Be sure that you only remove the dehumidifier plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

4. Gain access to the capacitor. Some models have the capacitor mounted on the fan motor; on other models, it is mounted behind the electrical controls. Remove the front grille and filter. Some units have either a one-piece or a two-piece grille with locking tabs and/or screws (see Figures 30-5 and 30-6). On other models, you should be able to gain access by removing the screws that secure the control panel to the dehumidifier frame.

FIGURE 30-6 A typical dehumidifier without its panels attached.

WARNING Do not touch the wiring or capacitor until it is discharged. A capacitor will hold a charge indefinitely, even when it is not currently in use. A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done.

5.

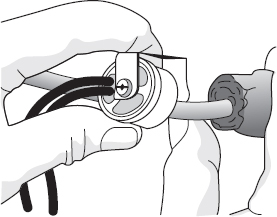

Test the capacitor. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor. Set the ohmmeter on the highest scale and then place one probe on one terminal and the other probe on the other terminal (

Figure 29-15). Observe the meter action. While the capacitor is charging, the ohmmeter will read nearly zero ohms for a short period of time. Then the ohmmeter reading will slowly return toward infinity. If the ohmmeter reading deflects to zero and does not return to infinity, the capacitor is shorted and should be replaced. If the ohmmeter reading remains at infinity and does not dip toward zero, the capacitor is open and should be replaced.

To test for a grounded capacitor, leave one meter probe on the capacitor terminal, and attach the other probe to the outer casing of the capacitor or dehumidifier chassis ground. There should be no reading if the capacitor is not grounded. Next, remove the probe from the capacitor terminal, and place the probe on the other terminal. Again, there should be no reading indicated if the capacitor is not grounded.

When using a capacitor analyzer to test capacitors, it will show whether the capacitor is “open” or “shorted.” It will tell whether the capacitor is within its microfarads rating and it will show whether the capacitor is operating at the proper power-factor percentage. The instrument will automatically discharge the capacitor when the test switch is released.

6. Remove the capacitor. Remove the capacitor from its mounting bracket.

7. Install a new capacitor. To install the new capacitor, just reverse the disassembly procedure and reassemble.

NOTE A capacitor is rated by its working voltage (WV or WVac) and by its storage capacity in microfarads (µF). Always replace a capacitor with one that has the same voltage rating and the same (or up to 10 percent greater) microfarad rating.

Fan Motor

Dehumidifiers use a single fan motor with a single shaft for the fan blade or blower wheel.

The typical complaints associated with failure of the fan motor are:

• No air is blowing out of the discharge grille.

• When the motor runs, there are loud noises.

• The fuse or circuit breaker trips when the air conditioner is started.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by operating the dehumidifier. Listen carefully, and you will hear if there are any unusual noises or if the circuit breaker trips. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is the dehumidifier installed properly? Does it have the correct voltage? The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity. This can be done by pulling the plug out of the wall receptacle. Be sure that you only remove the dehumidifier plug. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

4. Gain access to the fan motor. Before you begin to remove the fan motor, test the motor windings. Remove the outer wrapper and the front grille and filter (Figures 30-5 and 30-6).

WARNING Do not touch the wiring or capacitor until it is discharged. A capacitor will hold a charge indefinitely, even when it is not currently in use. A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor.

5.

Disconnect the motor wire leads. Disconnect the motor wire leads from the control panel, and label them. Check the motor windings for continuity (

Figure 30-6). Using the wiring diagram, check for resistance on the condenser fan motor windings. To check for a grounded winding in the motor, take the ohmmeter probes and check from each motor wire lead to the motor housing. The ohmmeter will indicate continuity if the windings are grounded.

Finally, spin the motor shaft—it should turn freely. If the shaft is hard to turn, replace the fan motor. Now move the motor shaft in an up-and-down motion perpendicular to the motor body. The shaft should have virtually no movement. If there is a lot of play in the end bell bearings, replace the fan motor.1

6.

Remove the fan motor. To remove the fan motor (

Figure 30-6), remove the screws that hold the fan motor bracket in place. Then, remove the fan blade or blower wheel.

Depending on which model you are servicing, the removal of the fan motor will vary from manufacturer to manufacturer. However, the basic steps are the same for every dehumidifier.

NOTE Replace the fan motor with a duplicate of the original for easier installation.

NOTE With the fan motor removed from the unit, it is the perfect time to chemically clean the remainder of the dehumidifier. Everything will be exposed, and it will be easier to clean the unit.

7. Reinstall the fan motor. To reinstall the fan motor, just reverse the instructions in step 6, and reassemble. When you reinstall the condenser fan blade, make sure to place it back on the motor shaft in the same position. Before reinstalling the outer cabinet on the dehumidifier, test the dehumidifier first. Make sure the fan blade or the blower wheel is not hitting against anything.

Compressor and Overload Protector

The compressor (reciprocating or rotary type) is the heart of the vapor compression system. It is used to circulate the refrigerant throughout the sealed system. The overload is attached to the compressor housing. The overload protects the compressor. Some models are equipped with a relay to assist the compressor in starting.

The typical complaints associated with failure of the compressor are:

• The dehumidifier does not run at all.

• The compressor makes a humming or buzzing noise and stops.

• The circuit breaker trips when the dehumidifier starts up.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by asking the customer to describe what the dehumidifier is doing. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is the dehumidifier installed properly? Does it have the correct voltage? Check for a voltage drop during dehumidifier startup. The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Before you begin to service any high-voltage components within the dehumidifier, you must discharge the high-voltage capacitors first.

WARNING A capacitor will hold a charge indefinitely, even when it is not currently in use.

A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

4. Gain access to the compressor. To access the compressor, remove the outer cabinet (Figures 30-5 and 30-6). This will expose the compressor, fan motor, and electrical controls (Figure 30-6). Next, remove the compressor terminal cover (Figure 29-20) by removing the retaining nut or clip that secures the cover. Remove the terminal cover and washer.

5. Test the overload protector. To test the overload protector, remove the wires from the overload and compressor terminals. Next, place the probes of the ohmmeter on the overload terminals (see Figure 29-20). Set the meter scale on R x 1. The reading will show continuity. If not, replace the overload protector.

6. Test the compressor. The compressor terminals are marked C, S, and R: C indicates the common winding terminal, S indicates the start winding terminal, and R indicates the run winding terminal. Refer to the wiring diagram for the model that you are servicing. Set the meter scale on R x 1, touch the probes together, and adjust the needle setting to indicate a zero reading. Next, place the probes of the ohmmeter on the terminals marked S and R (see Figure 25-37a). The meter reading will show continuity. Now place the meter probes on the terminals marked C and S. The meter reading will show continuity. Finally, place the meter probes on the terminals marked C and R. The meter reading will show continuity. The total number of ohms measured between S and R is equal to the sum of C to S plus C to R. The compressor should be tested for proper resistance, as indicated on the wiring diagram.

To test the compressor for ground, place one probe on a compressor terminal, and attach the other probe to the compressor housing or to any good ground (see Figure 25-37b). Set the meter scale to R x 1000. The meter reading will show no continuity. Repeat this for the remaining two terminals. The meter reading will show no continuity. If you get a continuity reading from any of these terminals to ground, the compressor is grounded. Replace it.

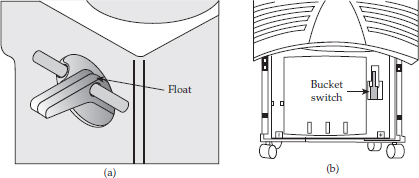

Bucket Switch

The bucket switch is a single-pole, double-throw (SPDT) device that shuts off the dehumidifier when the bucket is full of water. The switch is mounted to the frame directly behind the bucket (Figure 30-7). The switch is activated by the float assembly.

FIGURE 30-7 Do not run the dehumidifier without the bucket. (a) The float assembly. (b) The float switch in the rear of the dehumidifier.

The typical complaints associated with failure of the bucket switch are:

• The dehumidifier does not run at all.

• Water spills out of the dehumidifier.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by asking the customer to describe what the dehumidifier is doing. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is the dehumidifier installed properly? Does it have the correct voltage? Check for a voltage drop during dehumidifier startup. The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Before you begin to service any high-voltage components within the dehumidifier, you must discharge the high-voltage capacitors first.

WARNING A capacitor will hold a charge indefinitely, even when it is not currently in use.

A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

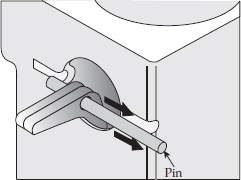

4. Gain access and removal of the bucket switch and float. Pull the bucket toward you, releasing the actuator from the float assembly (Figures 30-5a and b). Remove the outer wrapper to gain access to the bucket switch (Figure 30-6). To remove the float assembly, pull the pin (Figure 30-8), and remove the float assembly. To remove the bucket switch assembly (Figure 30-9a), squeeze the tabs to remove the bucket switch.

FIGURE 30-8 Pull the pin to release the float assembly.

FIGURE 30-9 (a) Squeeze the tabs to release the bucket switch. (b) SPST bucket switch. Use the ohmmeter to test the switch contacts.

5. Test the bucket switch. Use the ohmmeter to test the resistance between the three terminals on the switch. Figure 30-9b shows testing between common and normally open terminals. In the switch rest position, there will be maximum resistance. From common to the normally closed terminal, there should be zero resistance. When the bucket switch lever is depressed, common to the normally open terminals, there should be zero resistance. From the common to the normally closed terminals, you should have a reading of maximum resistance.

6. Install the new component. To install a new component, just reverse the disassembly procedure and reassemble. Reinstall all panels and the front grille and bucket. Then, restore the electricity to the dehumidifier. Test the dehumidifier operation. To prevent ESD from damaging expensive electronic components, simply follow the steps in Chapter 11.

Defrost Thermostat

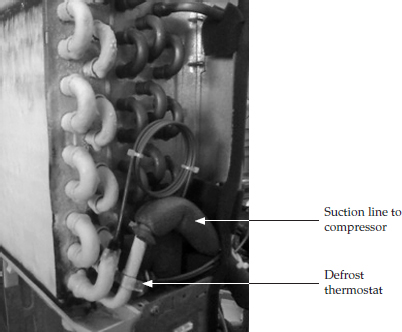

The defrost thermostat is mounted on the suction line (Figure 30-10).

FIGURE 30-10 Defrost thermostat attached to the suction line. When the evaporator goes below 37 degrees Fahrenheit, the defrost thermostat opens, shutting off the compressor. The condenser fan motor will continue to run. When the suction line temperature rises to 59 degrees Fahrenheit, the defrost thermostat closes and the compressor starts up.

The typical complaints associated with failure of the defrost thermostat (heat pump models only) are:

• Ice buildup on the outdoor coil.

• The air conditioner will not heat.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the control setting. Turn the control to the highest setting for heat, and then turn it back to a normal setting to see if the dehumidifier starts heating. It will be helpful if you can locate the actual service manual for the dehumidifier model you are working on to properly diagnose the dehumidifier.

2. Check for external factors. You must check for external factors not associated with the dehumidifier. Is the dehumidifier installed properly? Explain to the user how to set the controls. The voltage at the wall receptacle must be within ±10 percent of the voltage rating on the model and serial data plate. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the dehumidifier, disconnect the electricity to the unit. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the control panel or remove the outer cabinet, you can position the panel in such a way that the wiring will not make contact with metal. This will allow you to test the components without electrical mishaps.

4. Gain access to the defrost thermostat. To access the defrost thermostat, remove the outer wrapper and the front grille and filter (Figures 30-5 and 30-6). Next, tilt the control panel away from the dehumidifier, making sure not to pull any of the wires off the controls. The manufacturer placed the defrost thermostat control on the suction line (Figure 30-10). The defrost thermostat is a nonadjustable thermostat without a stem or knob attached to it. On other models, the defrost thermostat might be a bimetal thermostat that is clamped to the end of the evaporator coil with two wires coming out of it that lead back to the control panel.

WARNING Do not touch the wiring or capacitor until it is discharged. A capacitor will hold a charge indefinitely, even when it is not currently in use. A charged capacitor is extremely dangerous. Discharge all capacitors immediately any time that work is being conducted in their vicinity. Redischarge after repowering the equipment if further work must be done. Many capacitors are internally fused. If you are not sure, you can use a 20,000 ohm 2-watt resistor to discharge the capacitor. Do not use a screwdriver to short out the capacitor. By doing so, you will blow out the fuse in the capacitor and the capacitor will not work. Safely use an insulated pair of pliers to remove the wires from the capacitor and place the resistor across the capacitor terminals. When checking a dual capacitor with a capacitor analyzer or ohmmeter, you must test both sides of the capacitor.

5. Test the defrost thermostat. To test the defrost thermostat, disconnect the wires from the defrost thermostat terminals on the control panel, label them, and place the ohmmeter probes on the terminals (see Figure 29-6b). Set the range scale on R x 1, and test the thermostat for continuity. If the temperature is above 60 degrees Fahrenheit, the resistance reading will be zero, indicating that the contacts are closed. Now, place the thermostat in a bucket of ice. With the ohmmeter leads still attached, the contacts should open when the temperature drops below 37 degrees Fahrenheit.

6. Remove the thermostat. With the thermostat exposed and the wires already removed, the defrost thermostat must now be removed from the suction line. The thermostat is held in place on the suction line with a spring load clamp (Figure 30-11). Remove the thermostat clamp. If the clamp comes off the suction line, remember where the clamp goes back. The placement of the clamp and thermostat is crucial for the dehumidifier to function properly.

FIGURE 30-11 Remove the insulation from around the defrost thermostat so that the spring clamp is exposed.

7. Install a new thermostat. To install the new defrost thermostat, just reverse the order of disassembly and reassemble. Then test the defrost thermostat by running the dehumidifier. Just remember to reinstall the bimetal clamp in the same location from which it was removed. If you do not, the dehumidifier will not cycle properly.

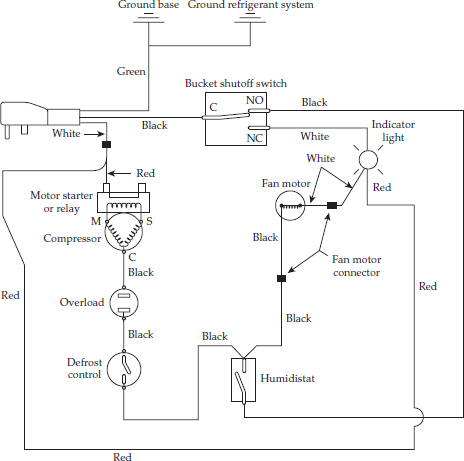

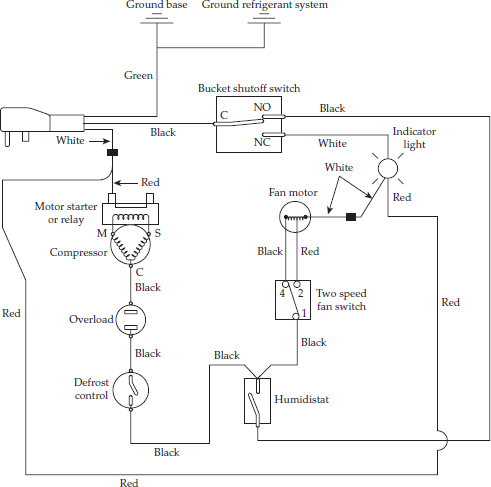

Wiring Diagrams and Schematics

The wiring diagrams and schematics that are used in this chapter might be helpful to diagnose a dehumidifier (see Figures 30-12, 30-13, 30-14, 30-15, and 30-16). These diagrams are not a substitution for the exact wiring schematic that might be on the inside cover of the outer wrapper.

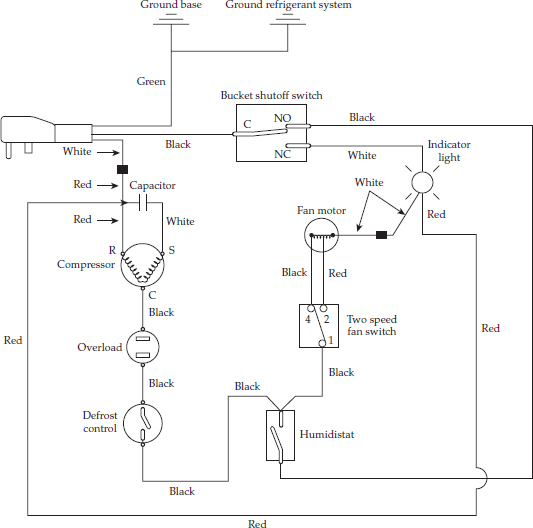

FIGURE 30-12 A typical model with a reciprocating compressor with a single-speed fan motor.

FIGURE 30-13 A typical model with a reciprocating compressor with a double-speed fan motor.

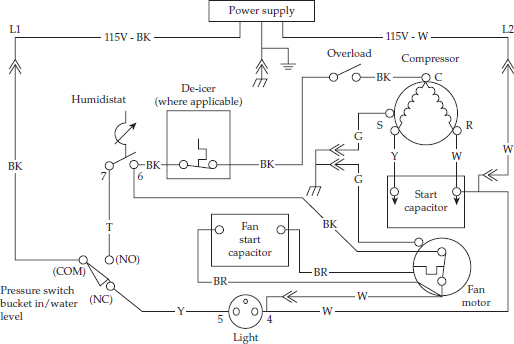

FIGURE 30-14 A typical model with a rotary compressor with a double-speed fan motor.

FIGURE 30-15 A typical wiring schematic for a dehumidifier with mechanical controls.

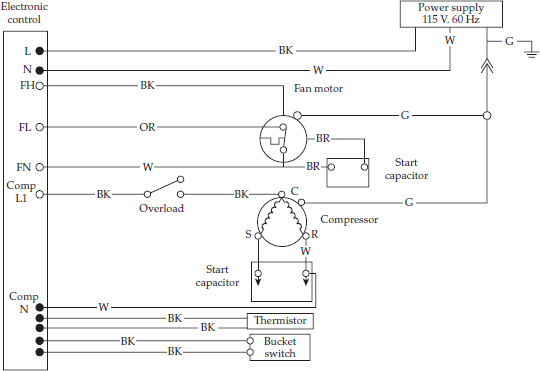

FIGURE 30-16 A typical wiring schematic for a dehumidifier with electronic controls.

Endnote

1. When the bearings wear out in the end bell of the motor, the motor will begin to make a vibrating sound or a growling noise.