Chapter 18

Scaling Operations throughout the Product Life Cycle

In This Chapter

Implementing strategies for new products and those in the growth stage

Implementing strategies for new products and those in the growth stage

Meeting the challenges of maturing and dying products

Meeting the challenges of maturing and dying products

Preventing the decline of a product

Preventing the decline of a product

Heeding special considerations for new businesses

Heeding special considerations for new businesses

Products and services, like living organisms, have a natural life cycle. Products are conceived and nurtured, they mature, and eventually, they decline and fade away. Each phase of the cycle requires a different operating strategy.

In this chapter we take you on a journey through a product’s life and describe how each life stage influences operating requirements. We start by introducing the common life stages that products typically evolve through and describe how best to manage each stage. We look at ways to prolong product life, and we also describe the special operating considerations of new companies.

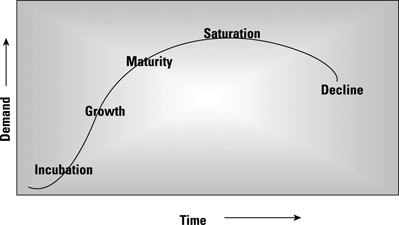

Managing Operations Age-Appropriately

A product goes through four distinct stages as it evolves. These stages (illustrated in Figure 18-1) are quite similar to those of the human life cycle. For instance, at birth, a new product is much like a baby; it needs constant care and nurturing. For a product, this stage of existence is called incubation. After the product starts to get some traction in the marketplace, it enters a growth phase, where it can experience a tremendous sales explosion. Eventually, the product may experience a slower growth rate as it matures, saturates the market, and then enters a state of decline as newer products enter the market and take away market share.

Illustration by Wiley, Composition Services Graphics

Figure 18-1: Product life cycle curve.

Different products move through this cycle at varying speeds. Some products, such as fashion apparel, move through the life cycle so quickly that you may miss them entirely if you blink. Other commodities, such as refrigerators and tax return preparation, may spend many years on the journey.

Table 18-1 highlights the operations strategy differences that exist in each stage of life for a product.

Swooning Over the Baby

New products are like babies — they need constant attention and they change rapidly. New products are said to be in the incubation phase and are typically prototypes; their design can change quickly in response to market reception. You must be flexible and responsive when managing a product in this phase.

The characteristics and operation strategies for a product in the incubation phase include low and unpredictable demand requiring minimal inventory and flexible capacity. These products tend to command a higher price because competition is scarce and the products are often considered novel.

Dealing with low demand

The market for products in the incubation stage is generally nonexistent or very small, and the demand for such products is highly unpredictable. Typically, these products are revolutionary and totally new to the market, which makes demand forecasting more difficult than it is for more established products. When attempting to forecast demand, you must rely on data that’s often unreliable and on feedback from marketing efforts. (See Chapter 6 for more forecasting details.)

Because the market in the incubation phase is small or nonexistent, significant investment in marketing is required. You should focus this marketing effort on better defining the customer and on creating awareness of the product. You can often create demand by using lead customers to promote the product. Using this strategy, you can distribute the product at little or no cost to “beta” customers who can create a buzz surrounding the product and provide sources for product reviews. Apple has used this strategy to promote new products such as the iPod. No matter what strategy you use, it often takes significant time and energy to gain traction in the market.

Keeping capacity flexible

Because demand for new products is small and unpredictable, you must minimize your production costs. The incubation phase is characterized by high development and marketing expenses, which can drain cash flow, making it important to minimize fixed investments in production to preserve cash.

In the incubation phase, you should focus on producing products using a variable cost model. This may involve forgoing automation and using more manual labor until sales increase and you reach economies of scale. This is especially critical for a start-up company. Though an established company may be able to convert some of its existing capacity from an older product to the new one, a new company doesn’t have this luxury. (See the section Managing Start-up Operations later in the chapter for info on the special needs of new companies.)

In addition, flexibility is key to driving down production costs, particularly if the design is still evolving. Outsourcing and using flexible labor to perform more than one task helps keep overhead and employment levels low. For a detailed discussion of capacity, turn to Chapter 7.

Minimizing inventory

Inventory decisions are especially difficult for new products with very low sales. You can use capacity levels and inventory to help maneuver the low and variable demand you face in the incubation phase. You need to keep capacity costs low, not maintain excess capacity, and minimize inventory to avoid being stuck with product that you may not be able to sell. So what should you do?

If possible, you want to produce only when you receive an order (called make to order). This policy, however, requires that you have very low production and delivery lead times because potential customers typically won’t wait for a product, especially a new and unproven one. Few companies, particularly those who sell directly to consumers, have the privilege that Apple has earned to be able to sell everything it makes on pre-order before the product’s release.

Instead, for most consumer products, you often must build inventory in advance so that you can instantaneously make it available to a potential customer. To be successful you must rely on your forecasting methods (see Chapter 6) and your marketing efforts to make sure you place the inventory where your customers are most likely to be.

Starting off with high pricing

During the incubation phase, you can often charge higher prices. With the proper marketing buzz surrounding a product, lead customers are often willing to pay a higher price to get the product first. You saw this phenomenon in consumer products when high-definition TVs first came out; they commanded a high price because of their novelty and their limited availability. Now this is being repeated for 3D TVs.

Many companies rely on higher pricing during the incubation phase to offset the initial development and marketing costs. Because of the upfront costs of introducing a new product, many products experience significant losses in this early stage. A high initial price allows firms to generate more cash to invest in marketing and in producing the product, and this can get the product to profitability quicker.

Although the high-price scenario seems to be the most common, you may sometimes benefit from starting a product at a relatively low price, which could more rapidly increase sales, allowing quicker market penetration and thus visibility to potential customers. After demand has increased, you may be able to raise the price point. However, this strategy can be dangerous because you may lose potential customers because of the price increase.

Designing a supply chain for a new product

Designing a supply chain for a new product can be challenging. Because of the low demand and required production volumes, getting favorable contract terms with a supplier can be difficult. Though pricing is always a priority, flexibility should be at the top of the list in the incubation phase.

Building a supply chain that can produce low volumes with small lead times is critical for new products. One incentive you can offer suppliers to get them to agree to producing smaller quantities while keeping costs low is to offer long-term contracts for the current product and engage the same suppliers on subsequent products. If you’ve successfully worked with a supplier before and have experienced mutual success with a past product, the supplier may be more willing to take a chance on any new product offerings. As lean manufacturers have learned, nothing is more advantageous than a lasting relationship with suppliers.

Defining a market with no competitors

New and innovative products face little or no competition when they’re introduced. This lack of competition allows the first-to-market product to define the market and establish a customer base before competitors can enter, giving such products a commanding market share lead and advantage. Having no competition also allows you to charge the characteristically high price, as discussed earlier.

How long you’re able to maintain your sole hold on the market depends on many industry and technological factors. Factors such as the ease (or lack thereof) of replicating the product and entering the market determine how fast competitors will enter.

Even if you are introducing a product with a competitor in the incubation stage, you are still in a position typically to charge a high price. You also have some leverage over defining the market as market tastes are not fully set yet, although less than if you were the first to come out with the product.

Avoiding failure in incubation

Another reason why products fail in incubation is because continuing to market and produce them becomes too expensive. New products are characterized by upfront losses. If these losses are too big or the time to profit is too long, you may have to pull the plug on the product before it can enter the growth phase. In extremely competitive industries, similar new products can hit the market at roughly the same time, requiring even more investment in marketing to gain sales. This competition also quickly drives down price, removing the expected higher revenue. The extent to which you are affected depends on how fast you can introduce or improve your products features versus how fast potential competitors can produce copycat products.

To avoid this painful and extremely expensive death, you can benefit from an agile product development process. Focusing efforts on product development facilitates a faster time to market with a superior product. Though product development is outside the scope of this book, see Chapter 12 to discover the house of quality, which successful firms often use in their product development process. Also see Part I for information on how to design efficient processes, because you can apply many of these techniques to the product development process.

Surviving the Awkward Stage of Quick Growth

You may think that after you make it through infancy, you have a clear path to success. This is anything but true; many products that make it out of the incubator fail in the growth phase. Just like the teenage years, the growth phase is almost always turbulent. The product faces both internal and external obstacles. Demand, market forces, and the competition are rapidly evolving.

The characteristics and operation strategies for a product in the growth phase include rapidly increasing and unpredictable demand, gradual increases in competition and decreases in product price, expanding your supply chain, and investing in developing standard processes to improve scalability and begin to reduce defects.

Adjusting to growing demand

Demand rapidly changes in the growth phase, making traditional forecasting methods especially unreliable (check out Chapter 6 for the lowdown on forecasting). You must observe the trend and adjust your inventory and capacity to meet this changing demand.

Another factor influencing demand is that the customer profile may be changing as the product penetrates the market. For example, in the incubation phase of a high-tech product, the primary customer is usually technically sophisticated, but later buyers may be less so. This change in customer may require product changes to make the product desirable to a larger market. In addition, you may introduce new features, increasing the product variety to appeal to a greater customer base. These changes may make inventory and capacity decisions more difficult.

Increasing capacity

When demand is unpredictable, producing enough product to meet it is difficult. Because bringing new capacity on-line by adding facilities, purchasing equipment, or hiring and training workers often requires time, you may find your capacity levels lagging behind demand.

During this growth phase, many companies transition to fixed capacity and make investments in automation and equipment. These assets allow you to increase production in an efficient manner at a lower cost structure, taking advantage of economies of scale.

Product proliferation often occurs during the growth phase. This increase in product variety requires that you maintain focus on keeping your capacity flexible to accommodate producing smaller volumes of more variations. You can benefit by designing products to be as similar as possible while at the same time maintaining product differentiation. This enables you to use the same manufacturing facilities to produce all varieties as much as possible.

Maintaining enough inventory

In the growth phase, inventory takes on a significant role in improving market position. Competition is usually fierce, and if you don’t have your product on the shelf when the customer wants it, the customer will probably buy a competitor’s product. Not only will you lose that sale, but it may cost you future sales and customer goodwill. (Turn to Chapter 8 for all you need to know about inventory.)

Most companies adapt some form of make-to-stock process (see Chapter 5 for details), producing to a forecast in anticipation of future demand. However, you can counterbalance the amount of inventory that you need to hold with effective capacity management and lead time reduction.

Slowly decreasing your pricing

Falling prices is a normal condition for most products in the growth phase due to the increase of competition in the marketplace. Many firms try to get around this decrease in price by introducing incremental changes to the product. When the new feature is released, the product is usually sold at a premium over the price of the older product. The new and improved product can either replace the existing one or be sold in tandem, offering multiple models with varying prices.

You can often turn a very nice profit at the lower price if you pay attention to reducing your costs and taking advantage of growing market opportunities.

Growing your supply chain

Just as the product is going through a growth spurt, so must the supply chain. As cutting costs to maintain profits becomes necessary, you should start looking at ways to make your supply chain more efficient. Though you don’t want to alienate the suppliers that helped you through the incubation phase (you never know when you may need them again for your next new product), they need to grow with you and provide the levels of efficiency and service that you need in a growing market.

During the growth phase, you may consider offshoring or globalizing your supply chain. This is a complex decision, and you must consider many factors. Check out Chapter 17 for a detailed discussion of outsourcing. One benefit of globalizing your supply chain is that doing so can get you into new markets and expand the demand for your product.

Distinguishing your product from competitors’ products

During the growth phase, the market size grows, and more and more competitors enter. This increased competition pushes prices down and puts a premium on quality products that are available on the shelf (or online) when the customer wants to purchase them. At the same time that you’re focusing on quality, functionality, and availability, you must also continually look for ways to reduce costs.

Your marketing of the product can change during this phase as it becomes important to distinguish your product from the pack. The growth phase is when you build your brand, which requires establishing a product image and promoting the product to a mass market, usually through extensive advertising. The key is to place your product above the others in the eye of the customer and make it the one everyone must have.

Upping production to meet increased demand

Although a firm failing in the growth phase may seem implausible — after all, who could possibly fail with increasing demand? — companies often face their greatest challenges during this phase. In the incubation phase firms face little if any competition, and the entrance of competitors into the market often catches them off guard and unprepared to actually compete.

Perhaps the greatest cause of death in this phase is an inability to grow with the market. You may not have the capacity or the managing ability to keep up with the increasing demand. This results in lost sales because product isn’t available, disappointing potential customers and sending them into the welcoming arms of entering competitors.

Getting Comfortable with Market Maturity

As a product matures, its sales usually level off as the market becomes saturated. This saturation phase is usually a relatively calm period in which the demand, products, and competition are stable. Despite the stability, this can be a challenging time for a company. Because the total market size is generally already determined, firms start looking for new ways to get a bigger slice of the existing pie by stealing market share from competitors.

The characteristics and operation strategies for a product in the saturation phase include steady customer demand, increasingly competitive pricing, and reducing costs and defects to gain market share.

Staying the course with steady demand

In the saturation phase, demand is fairly constant and predictable, and sales may be just to replace an existing product. The needs of the customer base are well known, and the rate of introduction of improvements decreases.

To increase sales in a market of constant size, you must find ways to increase market share at the expense of your competitors. You can accomplish this by continuing to reduce costs so you can reduce prices, focusing on ways to differentiate the product from the competition, and increasing marketing efforts. For more on ways to prolong entering the saturation phase before eventually entering decline, see the Emerging Anew section later in the chapter.

Exploiting predictable capacity

In the saturation phase, capacity is established, required levels are available, and reducing costs takes center stage. Production volumes peak during the saturation phase (refer to Figure 18-1), and these volumes allow you to take advantage of economies of scale. The predictable sales also allow you to better utilize automation equipment and to schedule production.

Reducing your inventory

The stable demand and efficient production characteristics of the saturation phase enable you to better manage inventory. Variability in demand often requires you to hold larger quantities of inventory to meet surges in customer demand. Because this variability is reduced in the saturation phase, you can reduce inventory levels while maintaining customer service levels. If you’re curious about how variability influences required inventory levels, flip to Chapter 8.

Stable demand also reduces the risks of not being able to sell inventory. This reduced risk associated with inventory may allow you to use inventory to reduce the needed peak capacity, resulting in reduced capacity costs.

Offering competitive pricing

Products often become commodities in the saturation phase, meaning that customers have many substitute choices. At this point, price becomes a competitive advantage. Faced with similar products with equal quality levels, a customer typically purchases the lowest-priced product, leading to decreasing prices.

To gain market share and possibly force competitors out of business, you may have to force pricing wars, offering aggressive pricing at or even below cost to eliminate competition with the hope of increasing prices as you corner the market.

One way to counteract this pricing pressure without putting yourself on the verge of bankruptcy is to continue to market and build a brand where your product is considered superior to the others. Doing so can prevent your product from becoming a commodity and can protect it from the increasing price pressure.

Balancing a mature supply chain

By the time a product reaches the saturation phase, the supply chain should also be relatively mature. Chances are good that you’ve built solid relationships and that the supply chain runs smoothly. At this point, however, you may consider outsourcing some processes or even bringing some of the work back in-house to consolidate operations and maintain economies of scale, especially if demand could soon be in decline.

Gaining market share over your competitors

By the saturation phase, the competitors are usually established, and competition is fierce. Gaining market share becomes critical, and because the market as a whole is saturated, the only way to gain market share is to “steal” sales from the competitors. During this phase, some competitors may transition out of the market or, in some cases, may buy operations from or sell operations to, or merge with, a former competitor.

Foreseeing the market’s decline

In the saturation phase, firms usually leave of their own volition as they see the decline of the market and the squeezing of profit margins. This may create a temporary advantage for those products remaining as they capture market share from those products exiting the market.

Preparing for the End

Most products reach a point at which sales start to decrease. This declining phase requires many important end-of-life decisions, such as when to permanently retire the product, how to handle the repair of existing products in the market, and what to do with current capacity.

The characteristics and operation strategies for a product in the decline phase include decreasing demand and prices, an emphasis on reducing costs through efficiency and reduction of inventory, shrinking your supply chain, and beginning to reallocate resources.

Adapting to decreasing demand

Demand for the product decreases during the decline phase. As it decreases, it often becomes less predictable. Just as it’s important to capture the upward trend of the growth phase, it’s equally important to capture the rate of the decline so that you can adjust capacity and inventory levels.

The decline phase may have an upside if you choose to stay in the market while competitors exit, leaving their market share behind. You may be able to increase sales. The pie is shrinking, but you can get a bigger piece, although this increase may be short-lived, depending on the rate of market decline.

Repurposing capacity

An important decision that you must make in this phase is if and when to exit the market. Declining sales may make it unprofitable to continue production. What to do with existing capacity that you no longer need is an important decision. You may look to repurpose the capacity to make other products, sell the resources (some companies may sell the product line entirely to a competitor), or just scrap the resources altogether.

One consideration in this decision is how to handle servicing existing products still in use by customers. This is an important concern, especially in durable consumer goods. You have several choices. You can cease production and stop servicing the product, although doing so may have serious repercussions on customer satisfaction and affect future sales of other products as customers fear not getting full use out of a product. To get around this, you may offer incentives for the customer to upgrade to a next-generation product if one is available.

You can also maintain a small capacity to make replacement parts as needed, carry a stockpile of parts in inventory for future replacement demand, or outsource the product entirely to a supplier that would take responsibility for the outgoing product.

Reducing inventory

As with capacity, you want to make efforts to reduce your inventory costs. However, if you choose to stop production altogether, you may want to build an inventory to serve the remaining market.

Making the most of lower pricing

Product prices tend to also decline in this phase. However, in some cases, prices may actually increase as the product and competing products become hard to find. Often, when a firm announces a product’s exit from the market, consumers purchase the product before it becomes extinct. This buy-it-before-it’s-gone mentality may temporarily raise the product’s price.

Consolidating the supply chain

You’ll probably be looking for ways to reallocate the supply chain to other products you’re making or developing. You may consolidate suppliers to produce the lower volumes and to reduce costs.

Increasing sales as competitors exit

Competitors exit as the market declines. This may be an opportunity to increase sales for a brief period.

Emerging Anew

Some products, such as baking soda or refrigerators, are fortunate enough to never reach the decline phase; they remain in the saturation phase for eternity, usually at a lower sales level than they reached at their peak. This section covers a few strategies you can take to help prevent the decline of a product or to avoid it stalling out in the saturation phase.

Repositioning

One tried-and-true method of breathing new life into a product is to find alternate uses for it. Take baking soda. When sales for the product were in the saturation phase, manufacturer Arm & Hammer came up with a brilliant idea to take advantage of the product’s odor-absorbing properties and started an advertising campaign suggesting that customers place whole boxes of the product in their refrigerator to keep it smelling fresh. Arm & Hammer even put a spot on the box where customers could record the date they placed it in the refrigerator, and the company recommended a regular replacement schedule. To exploit the advantages even further, the firm advised customers to dispose of the contents of the old box down the garbage disposal to keep their drains smelling fresh as well. (Basically saying, buy our product, take it home, and dump it down the drain!) Now you can find baking soda in a wide range of cleaning products.

Another familiar example that probably happened initially by accident is the wide use of duct tape. Initially created to be used on heating ducts, the tape is now the universal “go-to” for holding anything together. If you look around most homes, you’re sure to find a roll or two, and most likely it isn’t used for its intended purpose. In fact, you can probably find duct tape in almost any color. The array of alternate uses for duct tape took a product with a very limited market and made it a household product.

Making improvements

Companies have become wise to the fact that, by introducing even small improvements to their product, they can entice consumers to abandon the old product even though it still provides good service and to purchase a new one. The iPhone is a familiar example.

A classic example of how incremental improvements breathed new life into a product that was in its saturation phase is the refrigerator. Although the refrigerator will probably never enter a total decline, it had certainly reached a saturation point where most sales, especially in the United States, were replacement sales. Manufacturers have found that by continually introducing new features, they can persuade some consumers to replace their refrigerator long before it stops working and actually needs replacement.

The first major feature that sent consumers back to the store was the addition of the automatic ice maker. This was followed by the side-by-side door design that facilitated putting the ice and water dispensers on the outside. The newest design is the French-door model that fixes a major flaw of the side-by-side, which is that you can’t fit a pizza box in without significant rearranging of shelves and contents. Making these incremental improvements is a creative way to get more revenue out of a product because the improvements continuously reset the product’s position on the life cycle curve.

Changing the product portfolio

Rapidly changing technology has sped up the product life cycle and created the need for companies to introduce new products much more quickly. The computer industry has experienced these dynamics. The technology changed so rapidly at one point that a device could become obsolete within months of being purchased.

Illustration by Wiley, Composition Services Graphics

Figure 18-2: Introducing new products into the market.

Managing Start-up Operations

Managing the incubation phase and entering the growth phase is much easier for a company with multiple products in different phases of the curve than for one that has only one product that it’s trying to commercialize. Not only does the multiple-product company already have a reputation, but also, the products in the growth phase can help fund and fuel those products trying to survive incubation. The products in saturation can also provide a base upon which to introduce new products. A new company trying to get its first product into the market doesn’t have these advantages. In this section we present the special challenges facing a new company trying to get footing in the marketplace.

Operating on a shoestring

Though all businesses face financial constraints, the situation is often more critical in a new business attempting to introduce a new product into the market. Unlike established companies, a start-up doesn’t have a recurring source of revenue upon which to support its development efforts. New companies typically operate on money raised directly from investors or on their own personal cash. Because more cash is flowing out than in, the firm must find ways to do more with less.

Above all it’s important for a new company to stay flexible. Because of the inability to afford a large staff, the company’s founders often have to take on multiple roles. They must handle not only the financials but also the design, production, and marketing of their product. This requires workers to be flexible and have a wide breadth of knowledge.

In terms of operations management in a new company, you must produce the product with as minimal an amount of cash outflow as possible. Doing so often involves outsourcing much of the initial production to keep costs variable rather than fixed to preserve cash.

Outsourcing is often a difficult decision for many companies that are worried about protecting their technologies from potential competitors. Proper intellectual property protection through the attainment of patents can protect you from these issues. However, the patent process can be very expensive and can take considerable time, eating up valuable resources.

Whether you produce in-house or outsource, maintaining flexibility in your capacity is important. For details on flexible capacity, see Chapter 7. For information on how to establish a flexible supply chain, visit Chapter 10, and for suggestions on how to protect core competencies and outsource, turn to Chapter 17.

Transitioning to growth

If you’re a start-up, perhaps one of the greatest challenges you face is the transition to the growth phase of your product. This transition requires you to meet several needs:

Documented processes: As the complexity of your organization increases, so does the need for defined and documented processes. These processes are necessary to promote smooth operations and planning. See Part I for more on designing processes to meet your organizational and product needs.

Documented processes: As the complexity of your organization increases, so does the need for defined and documented processes. These processes are necessary to promote smooth operations and planning. See Part I for more on designing processes to meet your organizational and product needs.

Organizational structure: While in the incubation phase, you probably didn’t have any policies or procedures in place. You may not have needed them because your staff was small, and everyone was up to speed on what was going on. However, with growth comes the need to add staff, giving rise to the organization chart, complete with a need for a reporting structure.

Organizational structure: While in the incubation phase, you probably didn’t have any policies or procedures in place. You may not have needed them because your staff was small, and everyone was up to speed on what was going on. However, with growth comes the need to add staff, giving rise to the organization chart, complete with a need for a reporting structure.

Systematic planning: In the beginning of your new venture, you may have done things by the seat of your pants. Your staff may have acted on any opportunity that came along as quickly as possible. But as your enterprise matures and grows, planning becomes essential because coordinating the organization becomes more difficult.

Systematic planning: In the beginning of your new venture, you may have done things by the seat of your pants. Your staff may have acted on any opportunity that came along as quickly as possible. But as your enterprise matures and grows, planning becomes essential because coordinating the organization becomes more difficult.

Task specialization: As you grow, the need for specialized individuals increases. Dedicated resources to such tasks as operations, marketing, and sales become increasingly important, and your firm may establish separate departments. This task specialization makes seeing the big picture more difficult and requires more coordination across the organization.

Task specialization: As you grow, the need for specialized individuals increases. Dedicated resources to such tasks as operations, marketing, and sales become increasingly important, and your firm may establish separate departments. This task specialization makes seeing the big picture more difficult and requires more coordination across the organization.

These changes can be difficult for those involved with a start-up. Larger companies often have different groups that take over product management as a product transitions from one phase to another. This is often necessary because the skills required in each phase tend to be different. Because the introduction of a new product is so unpredictable and fast-paced, individuals who thrive in such an environment don’t often perform well in an environment that requires more structure, monitoring, and control.

Finally, as your firm grows, more control of the company must be delegated. This loss of control may be difficult for those involved in starting up a business, but without some delegation, the firm’s growth may be stalled.

You need to make the inventory and capacity decisions in concert because trade-offs exist in both. Developing flexible capacity allows you to be more nimble in production and possibly reduce the need for inventory. Outsourcing capacity may help you control production costs, but doing so may also require you to carry a greater quantity of inventory because of possible minimum production requirements of the supplier. If you do choose to outsource, you must make sure that your supply chain can support your needs, and if your product contains innovative technology or processes, you must make sure you properly protect your intellectual property.

You need to make the inventory and capacity decisions in concert because trade-offs exist in both. Developing flexible capacity allows you to be more nimble in production and possibly reduce the need for inventory. Outsourcing capacity may help you control production costs, but doing so may also require you to carry a greater quantity of inventory because of possible minimum production requirements of the supplier. If you do choose to outsource, you must make sure that your supply chain can support your needs, and if your product contains innovative technology or processes, you must make sure you properly protect your intellectual property. Proper intellectual property protection can often hinder competition and allow you more time to establish your lead in the market.

Proper intellectual property protection can often hinder competition and allow you more time to establish your lead in the market. Almost any misstep in the incubation phase can kill a product. A primary mistake is a product with no sustainable market. Many times a product may catch on with a small niche market but quickly die as other new products capture the eye of the consumer. In most cases, the anticipated market never materializes beyond the initial niche market. This could be because of poor market research or because the product didn’t perform as expected. For more information on how to effectively capture the needs of the customer and translate them into product functionality, flip to

Almost any misstep in the incubation phase can kill a product. A primary mistake is a product with no sustainable market. Many times a product may catch on with a small niche market but quickly die as other new products capture the eye of the consumer. In most cases, the anticipated market never materializes beyond the initial niche market. This could be because of poor market research or because the product didn’t perform as expected. For more information on how to effectively capture the needs of the customer and translate them into product functionality, flip to