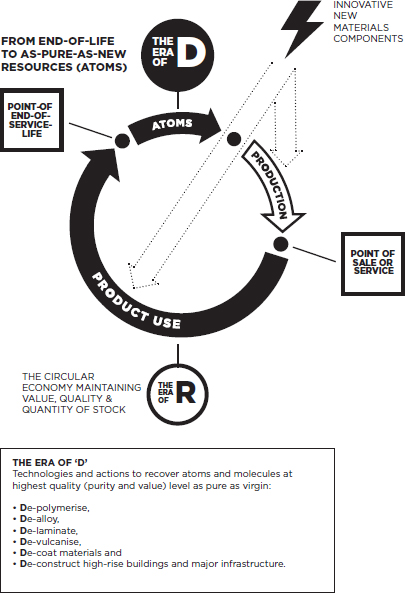

The era of ‘D’ manages stocks of atoms and molecules – chemical elements – with the objective of maintaining the highest value and purity of these stocks. This implies a cultural change in waste management, from volume reduction to value capture, and a non-destructive collection of used goods and unmixed collection of used materials, which increases the profitability of the resource-cum-waste manager. Science is needed to develop innovative separating technologies.

5.1 Managing stocks of atoms and molecules

The centre of the circular economy is YOU, the owner-manager of used objects:

- If you dismantle used objects and re-market the components, which are only used but not broken, then you participate in the circular economy. The same is true if you sell the broken components to somebody else to recover the atoms and molecules.

- If you employ people who cannot work in the normal labour market to dismantle the used objects, you are part of the circular society.

Circularity in nature works well for natural materials, at nature’s own pace. Where manufactured materials are dispersed in use (rubber wear from tyres, micro-plastics in sun creams) or deliberately disposed into the environment after use (drink containers), most manufactured objects and materials will cause a long-time environmental hazard, such as plastics in the oceans. Natural circularity can only de-bond natural materials, such as wood and wool, under favourable conditions and over time. It took a hundred years for nature to digest most of the materials which made up the Titanic, but the iron hull has survived to this day.

Market failures and a ‘linear’ approach to product design explain much of today’s loss of value (of manufactured materials). The reasons for value losses are found throughout the value chain of multiple product categories, as well as the way in which current legislation is designed. Manufacturing companies have few incentives to design products so that materials can be recycled, notwithstanding policies such as ‘extended producer responsibility’. Products therefore impose a negative externality on secondary materials production. Negative external effects also arise in the production of primary materials, but are rarely fully reflected in raw materials prices. Regulations and targets can also steer in the wrong direction, causing materials to be used as low-value aggregates.

(Material Economics 2018)

The era of ‘D’ of the industrial circular economy manages stocks of atoms and molecules with the objective of maintaining the quality (purity) and value of these stocks (Figure 5.1). But today, high-volume low-value recycling technologies are often seen as the solution of last resort in an ‘out of sight out of mind’ approach. This approach leads to the disposal of end-of-service-life objects – ‘waste’ – in order to minimise costs or due to a lack of appropriate recycling technologies. Maintaining the economic and resource value of the materials is not yet perceived as a priority. Yet extracting resources through mining costs money and creates environmental damages; waste prevention thus saves money and protects the environment. But policymakers and economic researchers focused on efficient production and economic growth disregard these opportunities because prevention activities slow GDP growth.

5.2 The need to identify decision takers to maintain highest value in the era of ‘D’

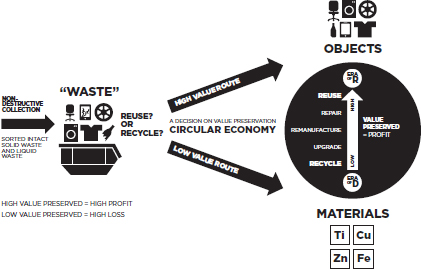

At the ‘end point of service-life’, the decision for the highest value option depends on a mix of waste legislation and functioning markets between the owners of the used goods (waste/resource managers) and economic actors of the era of ‘R’ and the era of ‘D’.

For individuals, the reuse or remarket option (era of ‘R’) involves substantial personal efforts under time, space, economic and sometimes legal pressure; the collect-and-dispose option, by contrast, can be easily delegated to municipalities in most urban areas.

Municipalities will use legal and cost criteria to make a choice between reuse, recycle and elimination options, such as landfill or incineration.

For ‘waste’ managers, the pursuit of maximum profit may be secondary to the need to minimise costs, or hindered by legal requirements, such as an obligation to destroy objects and recycle materials, even if they could achieve higher economic profits and lower environmental damage by remarketing used objects or components to the highest bidder (OEMs or era of ‘R’ actors). For example, in some regions, the use of disposable plastics instead of the sterilisation of durable objects may be imposed on hospitals by law in order to reduce the risk of pandemics.

The markets between used resource managers – owners of the used goods – and potential buyers of the era of ‘R’ will first need to be created; with few exceptions, they do not exist today: Vetrum, a Swiss company recovering glass bottles from bottle banks for sorting, quality inspection, sterilisation and reuse1 and www.go4circle.be, 2 helping a wide body of companies to adopt circular economic principles, are the exception despite their high profitability, even in societies of abundance.

Three conditions have to be fulfilled for any activities of the era of ‘D’ to be effective (Figure 5.2):

- a safe transition from product use to the end point of service-life;

- a sorting into clean material fractions; and

- a continued ownership and liability for objects and embodied materials.

Figure 5.2 End-of-service-life business opportunities for value preservation: reuse or recycle?

5.3 The characteristics of the era of ‘D’

If and when manufactured objects or their components cannot be reused, the best option is to recover atoms and molecules at their highest utility and value (purity) for reuse (Figure 5.1). This demands technologies and processes to sort mixed (household) waste according to materials into clean fractions, and dismantle used objects into separate material fractions (for example different aluminium alloys) to enable the recovery of pure atoms and molecules (Müller 2018).

The era of ‘D’ is sustainable because:

- In economic terms, recovered molecules are in price competition with virgin resources. As commodity markets have a high price volatility, ‘D’ materials with high collection costs are at a disadvantage. If manufacturers retain ownership of the material, this disadvantage shrinks because recovered molecules have lower transaction and compliance costs compared to virgin resources. Compliance costs arise in establishing certificates to prove the absence of child labour, conflict minerals and environmental impairment in virgin resources procured. In addition, recovered molecules pay no carbon taxes or import duties.

But in many cases, the technologies to recover molecules at a purity-as-new first have to be developed. These technologies will often differ from those used in the refining of virgin resources. ‘Closing the high purity loop’ will need considerable upfront investments in R&D (see Chapter 9). - In environmental terms, recovering spent molecules – in comparison with producing virgin resources – prevents considerable volumes of mining waste and reduces the water and energy consumption of, and the negative impacts on the environment associated with, the mining and refining of virgin resources3 (Schmidt-Bleek 1994).

Existing ‘D’ technologies are based on high volume global processes. If in the future the different alloys of a given metal are recovered separately, the volumes per fraction shrink and the transport distances between the locations of scrap collection and recovery process increase (Müller 2018).

A higher recovery quality will increase the economic value of the recovered molecules, but lead to a higher environmental impairment in the recovery process, if today’s process technologies are used. A standardisation of metal alloys to reduce material diversity in production and the development of small volume ‘mini-mills’ would reduce transport distances and lower costs. - In social terms, the main opportunities for skilled workers in the era of ‘D’ will be commercial – developing new markets between the owners of used goods (used resource managers), the buyers of the era of ‘R’ and the buyers of the era of ‘D’ – and in Research & Development to identify and develop innovative small volume process technologies to recover pure molecules. These research activities can be carried out on a global level wherever qualified labour and investment is available.

The labour input in the era of ‘D’ heavily depends on the value preservation choice of used objects, shown in Figure 5.2. The highest value preservation option necessitates labour-intensive non-destructive collection, dismantling and sorting processes, which have higher costs than collection by compactor trucks and demand higher efforts to remarket components and sorted scrap.

5.4 The foundation of the era of ‘D’: R&D, technology, knowledge and people

The three key opportunities are to:

- change attitudes from ‘solution of last resort’ in waste management to maintaining the highest value and purity of molecules;

- replace the concept of secondary resources in favour of a collection and recovery system of clean and sorted ‘waste’ fractions;

- create new and further develop current technologies and processes to recover pure molecular resources.

The export of mixed material wastes for recycling abroad, as part of the European waste management strategy of the last decades, is a thing of the past. China – the biggest recycler – in 2017 banned any imports of mixed materials for recycling, be it plastics or metals. Several other countries in Asia have followed China’s policy.

This increases the pressure on governments, industry and academia in Europe to develop methods to recover pure high value atoms and molecules for reuse in manufacturing. Innovative industrial actors should be in the driver’s seat of the era of ‘D’ because of the ‘not invented here’ syndrome. The Science and Technology opportunities to recover atoms and molecules are almost unlimited but only an early cooperation with industry will accelerate their application. Governments might ban the use of materials, which cannot be de-bonded, and promote new ‘D’ solutions and technologies that will emerge from research, such as to:

- de-polymerize plastics, currently done for nylon, fluorinated polymers (PTFE); or re-extrude plastic such as used HDPE;

- de-alloy metals; the presence of Ni, Cr or Cu in steel reduces the quality and economic value of steel; no technologies exist today to de-alloy these metals;

- de-laminate carbon-fibre composites, which are increasingly used in big volumes in the production of aircraft, automobiles and windmill blades; no technologies are used in Europe to de-link the composites and recover the molecules;

- de-vulcanize tyres to recover rubber and steel; several technologies exist but their commercialisation is hindered by subsidies to incinerate used tyres;

- de-coat objects; technologies to strip the paint off the fuselage of aircraft exist using CO2 pellets or water jets in a closed loop instead of chemicals;

- de-construct high-rise buildings: an intelligent deconstruction of existing high-rise buildings allows actors to disassemble technical equipment and interior fittings for remarketing, and to recover part of the energy invested in the original construction; the higher the structure the more energy was needed to hoist materials up. This hoisting energy can be recovered when bringing the components and materials down in a smart deconstruction process, as was demonstrated in the deconstruction of a major hotel in Tokyo;

- de-construct major infrastructure: many infrastructures to produce electricity, such as dams and pressure pipelines, date from the early twentieth century and will be decommissioned in the coming decades. These are massive, sometimes monolithic constructions built to last and many will have to be de-constructed at some point in the future. Off-shore windmills, with 75 per cent of total material input embodied in the underwater foundations, may be next.

However, there are limits to the era of ‘D’. In some cases, such as nuclear power stations, the reuse of materials that have been irradiated may be illegal. In the case of dissipative uses, such as bituminous road surfaces containing broken glass to increase visibility at night and rubber from tyres to reduce tyre noise, it will be impossible to recover glass and rubber particles, but the bituminous mix as such can be re-melted and reused on-site.

5.5 The ownership fork

As many materials at the end of their service life have no or a negative value, the question arises who should do the activities of the era of ‘D’, and who should pay for it?

The recovery of pure atoms or molecules is feasible and established for few materials such as gold, silver and copper; where it is not, beginning-of-pipe preventive solutions, such as component design for multiple reuses, are environmentally more efficient than end-of-pipe resource recovery.

If prevention is impossible, profitable technologies can be developed for instance to recover pure phosphorous from municipal, and gold from industrial, waste water streams. Support for the era of ‘D’ may also come from research into single-atom technologies. The Centre for Single-Atom Electronics and Photonics, operated jointly by ETH Zurich and KIT Karlsruhe, has started looking at electronics and photonics.

Managers of used resources have a broad responsibility to achieve the main objective of the circular industrial economy, which is to maintain the highest value and utility for objects, and a stewardship to manage a material system that retains the highest value and purity of atoms and molecules. In order to achieve the highest return on their investments, they need the liberty to develop the solutions with the highest value preservation (see Figure 5.2). The use value of objects dwarfs their material value – in fact, many used goods have a negative economic value as recycling costs are higher than their scrap value. The non-destructive collection of such used objects as furniture and bottles, and end-of-life materials such as newspapers and plastics, and the sorting into pure material fractions is therefore a precondition to exploit the highest priced options. The higher the value preserved, the higher the waste manager’s profit and incentive to prevent waste.

However, legislation may limit their liberty of action to maximise profits. The European Union’s Directive on Waste of Electrical and Electronic Equipment (WEEE) may be a case in point. Introduced as a measure to extend the responsibility of manufacturers for end-of-service-life waste costs, the contractual obligations between manufacturers and waste managers may block the opportunities of the era of ‘R’ and oblige the latter to act exclusively in the era of ‘D’. Policymakers are hindered by conflicting legislations, such as protecting the environment, Intellectual Property Rights, and the ‘right to destroy’ – which differentiates ownership from stewardship – in short, the lack of a holistic policy approach.

The unmixed collection of end-of-service-life materials creates an attitude of caring in customers and increases the profitability of the resource/waste manager. Treating used goods as broken goods, and used materials as unwanted materials – not as waste – makes a big difference with regard to environmental, social and economic sustainability of businesses. Topics such as product and component standardisation and the knowledge of the identity of all materials contained in objects take on a new strategic importance and can have a decisive influence on the value preserved, and therefore the profitability of the era of ‘D’ activities (see also Figure 5.2).

For manufactured objects and materials outside the circularity of nature, producers should accept liability for their products at the end of their service-life, because they had the choice of the:

- materials used in producing the objects and their components; using a limited number of standardised materials in product design and resource procurement would facilitate activities in the era of ‘D’ (Charter 2019);

- strategy to design goods in a systems approach, using standardised components for ease of disassembly, remanufacture and reuse;

- distribution channels, including the option of reverse logistics for later take-back or buy-back, in commercialising the objects.

5.6 Innovation and opportunities for policymakers in the era of ‘D’

In the area of the built environment, recent policy interests in resource security and resource efficiency has fuelled research into the stock of materials embodied in existing infrastructure and constructions. Urban mining is one of the catch words used in this context (Baker-Brown 2018), but little information exists on the quality of these material deposits and suitability for later high purity recovery.

Buildings as Material Banks (BaMB)4 aims to create ways to increase and sustain the value of building materials via a ‘material passport’, which lists all materials used in a construction by quantity and quality. Madaster Foundation,5 designed as a public online library or archive of materials, components and products for reuse, pursues the idea that every building is a material depot. Registering the material input into new buildings should provide the basis for later urban mining activities (Oberhuber 2016).

In contrast to other manufactured objects, infrastructure and buildings can have service-lives of a hundred years or more. Only the future can tell if the quality of the embodied materials will satisfy the market’s needs of the twenty-second century. Modular building systems using standardised components could probably greatly increase any options for a future reuse of building components or molecule recovery.

What is certain is that a circular industrial economy needs functioning markets to fulfil its objective of retaining the highest value and purity of objects and molecules. In this aspect, the circular economy does not differ from the linear industrial economy; it needs efficient marketplaces to remarket used goods and components as much as to recover pure molecules.

References

Baker-Brown, Duncan (2019) Who is mining the Anthropocene? In Martin Charter (ed.) Designing for the circular economy. Routledge, London.

Charter, Martin (2019) Designing for the circular economy. Routledge, London.

Material Economics (2018) Ett värdebeständigt svenskt materialsystem (Retaining value in the Swedish materials system). Economic value measured in billion Swedish Kroner versus material measured in tonnes. Research study, unpublished.

Müller, Daniel (2018) Conference presentation at SINTEF Circular Economy conference, Trondheim, 31 May. Unpublished.

Oberhuber, Sabine (2016) Material matters. ECON im Ullstein Verlag, Berlin.

Schmidt-Bleek, Friedrich (1994) Wieviel Umwelt braucht der Mensch? MIPS — Das Mass für ökologisches Wirtschaften. Birkhäuser Verlag, Basel.

Stahel, Walter (2010) The performance economy,second edition. Palgrave Macmillan, Houndmills.