19

Getting the Wort Out (Lautering)

Okay, let’s see where we are: we have mashed the grist to create the wort; we have discussed how we will measure the gravity of the wort and calculate our extract efficiency; and now it is time to extract the wort by lautering and sparging the wort to the boil kettle.

The Lautering Process

The word “lauter” comes to us from the German word, läuter, which means to clean, clarify, or purify. It also has the secondary meaning to make something more virtuous. Therefore, lautering is the improvement of our wort as we separate it from the mash. A lauter tun consists of a large vessel with a false bottom, or manifold, which allows the wort to drain out while retaining the grain. Lautering usually consists of three steps: recirculation, first runnings, and sparging for the second runnings.

Recirculation

After the mash, the grain bed needs to be readied for draining and sparging. If you were to simply throw the valve of the lauter tun wide open, the grain bed would get sucked down onto the false bottom, no wort would flow, and you would have a stuck sparge. Therefore, at the beginning of the lauter, the wort flow is started slowly so the grain bed settles gently and uniformly and doesn’t stick or clog. The first few quarts or liters of wort are collected in a pitcher or small bucket and poured back into the lauter tun on top of the grain bed. The first few quarts are always cloudy with excess proteins and grain debris, and recirculation helps filters out these materials from your boil kettle. Recirculation is also known as the vorlauf, or more properly, vorläufig, which means preliminary. In other words, it is the preliminary lautering step.

The wort should clear fairly quickly. After the wort starts running clear (it will still be dark and a little bit cloudy, but chunk free), you are ready to collect the wort in the kettle and sparge the grain bed. Recirculation can be done anytime the grain bed is disturbed and bits of grain and husk appear in the runoff, though if your grain bed has good depth disturbing it is unlikely. Recirculation is not entirely necessary, but most brewers do it. It is not used in the brew-in-a-bag process. See the section below on sparging methods for more information.

First Runnings

The first runnings is the highest gravity and richest tasting wort that will come from the mash. The gravity and volume of the first runnings are entirely dependent on the water-to-grist ratio, as was discussed in chapter 18. A high water-to grist ratio will produce a lower gravity first runnings but larger volume, and a lower water-to-grist ratio will produce the opposite. Typically, in commercial brewing practice, the entire first runnings, or first wort, are drained to the kettle after the recirculation step, and then the grain bed is sparged with a rotating shower arm to rinse the grainbed for the second runnings. This method would generally result in grainbed compaction and poor extraction in a homebrewing setup. However, modern commercial lauter tuns are often a separate vessel from the mash tun, and are fitted with revolving rakes and sparge arms that can stir the grain bed just above the false bottom to prevent any channeling and keep the extraction more uniform. Homebrewing lauter tuns don’t have rakes and sparge arms; draining the first wort completely requires the grain bed to be stirred and recirculated before it can be drained of the second runnings.

Sparging for the Second Runnings

Sparging is the rinsing of the grain bed to extract as much of the sugars from the grain as possible without extracting astringent tannins from the grain husks. Sparging means “to sprinkle” and you may have seen sparge arms, or sprinklers, in the lauter tuns of commercial breweries. In commercial breweries, the lauter tun is quite large, and it is fitted with revolving rakes and sparge arms to ensure that every cubic inch of the grain bed is rinsed of all the extract. We don’t need to be that economical on the homebrewing scale, in fact, the smaller scale makes it easier to rinse the grain bed of the wort, but without the rakes we need to take more care to maintain fluidity and uniform flow through the grain bed.

The temperature and pH of the sparge water is important. Hotter water is more effective at extracting residual starch and converting it to sugar via residual alpha-amylase, but it increases the risk of tannin extraction. This risk can be offset by maintaining the runnings at a pH of less than 5.6. (Chapter 21 has a more detailed discussion of water chemistry and pH.) Generally, the sparge water should be no more than 175°F (79°C), as husk tannins become more soluble above this temperature, especially when the wort pH gets to 6.0 or above. This will lead to astringency in the beer. Higher temperatures will also denature any remaining alpha-amylase, increasing the risk of residual starch in the wort.

Methods of Sparging

There are several sparging methods practiced by homebrewers, and each has its pros and cons.

Continuous Sparging

Continuous sparging, also known as fly sparging, usually results in the best yield. In continuous sparging, the wort is recirculated and drained until just under an inch (2.5 cm) of wort remains above the grain bed. The sparge water is then slowly added at the same rate as the wort is drained, such that you achieve a steady flow into and out of the grain bed. The idea is that the grain bed is never actually drained; instead, the wort is gradually exchanged with sparge water. The soluble extract yield is highly dependent on the uniformity of fluid flow through the grain bed to ensure that every grist particle is fully rinsed. Sparge time varies (30–150 min.) depending on the amount of grain and grist particle size.

The sparge is stopped when the gravity from the runnings is ≤1.008, or when enough volume of wort has been collected, whichever comes first. Continuous sparging demands more attention by the homebrewer, but can produce a higher yield per unit weight of malt. Sprinkling is not required; the only requirement is to maintain at least an inch of water above the grain bed so that it stays fluid.

The sparge water can be poured in with a pitcher, or fed in through a hose. If you are going to use a pitcher, then lay a small plate or plastic lid on top of the grain bed and pour onto that to avoid disturbing the bed too much. If you are going to use a hose, make sure it is long enough to lay on top of the grain bed along the perimeter. What you don’t want to do is have the hose pointing down at the grain bed so that it drills a hole in it. You would end up collecting sparge water instead of wort. You always want to maintain about an inch of sparge water above the grain to ensure that the grain bed doesn’t compact when using continuous sparging.

The continuous sparging method is actually the easiest to use if you have a three-tier mashing system, where a hot liquor (water) tank is set up above the mash-lauter tun with a valve and hose to slowly feed sparge water into the tun as the wort is drained to the boil kettle. Using valves makes it relatively easy to adjust flow rates so that you are adding sparge water at the same rate as you are draining wort to the kettle.

Batch Sparging

Batch sparging, another common homebrewing practice, is where a large volume of sparge water is added to the mash all at once instead of gradually. It is most often used with large ice chests or picnic coolers. In practice, the mash is completely drained of the first runnings, and then a second batch of water is mixed in and mashed for a short period of time (e.g., 15 min.). The grain bed is allowed to settle, recirculated for clarity, and the second runnings wort is then drained off.

Batch sparging is most efficient when both runnings are the same volume, in other words, each runnings is half of the intended boil volume. The volume of the first runnings consists of the mash water minus the amount of water retained by the wet grain. If the first runnings volume is less than half of the target boil volume, then more water should be added to the mash to make up the difference before draining. The wet grain retention factor (r) is about 0.5 qt./lb. or 1 L/kg.

For example, if you were mashing 12 lb. of grain, you would expect 6 qt. (1.5 gal.) of the first runnings to be retained by the wet grain. Assuming that you are mashing with a water-to-grist ratio (Rv) of 1.5 qt./lb., that would equal 18 qt., or 4.5 gal., of potential first runnings, minus the 1.5 gal. retained, for 3 gal. net first runnings into the boil kettle. If you were planning on collecting and boiling 7 gal. of wort total, you would add an additional half gallon of water to the mash before draining the first runnings, and then sparge with 3.5 gal. of hot water to get the second half of the boil volume as the second runnings.

Batch sparging differs from the English parti-gyle method (see next) in that the separate runnings are combined to produce a single beer. Batch sparging was originally developed from parti-gyle to make large quantities of porter, and was known as “entire.” It is slightly less efficient than continuous sparging (typically 75% versus 80% efficiency), but it is convenient if you don’t have a large hot liquor tank or gravity flow setup for continuous sparging. Much of the difference in efficiency between batch and continuous sparging comes down to not fully draining the mash of the first runnings before adding the next batch of sparge water for the second runnings.

Parti-Gyle

The parti-gyle method was common in brewing in England before the nineteenth century, and it allows the brewer to make two or more beers from the same mash by blending the different strength worts. A large mash is produced and the first wort is drained completely before more water is added to the grist for a second mash and drained again. The first runnings typically had a gravity of about 1.080 and were used for making an “aging” beer. The second runnings were lighter in gravity and could be used for making a “running” or table beer, and the mash was often “capped” with some additional grain strewn onto the grain bed to produce a low-gravity “small beer.” The worts could be hopped and boiled separately and blended into different products before fermentation, or they could be blended before the boil. Parti-gyle gives the brewer several options for producing a range of products from a single large mash, but you need multiple boil kettles and fermentors to fully utilize it.

No-Sparge

The no-sparge method is the least efficient in terms of the amount of malt used, but it’s easy and has the benefit of being immune to tannin extraction that may occur during the sparge. Like batch sparging, no-sparge is a draining rather than a rinsing method, and the beer is produced entirely from first runnings, resulting in a smoother, richer tasting wort at the expense of efficiency. There are a couple of ways of working this method to produce all the wort needed for the boil. First, you can create a mash large enough, with a specific water to grist ratio, to yield the entire volume of wort at the target gravity needed for your boil. These calculations will be discussed later in this chapter. Alternatively, you can produce high-gravity wort at a smaller volume than your target boil volume and gravity, and dilute that wort in the kettle with water to reach your target. Homebrewers will often turn a no-sparge brew into a parti-gyle brew, because they can’t stand to waste the extract potential left over in the mash tun. Decisions, decisions …

Brew-in-a-Bag

The brew-in-a-bag (BIAB) method turns the traditional process on its head by removing the grain from the mash instead of removing the wort from the grain. It is a combination of batch sparge and no-sparge where the entire boil volume plus the retained water volume is used for the mash (i.e., there is a very high water-to-grist ratio). The grist is contained in a mesh bag and at the conclusion of the mash the bag is lifted out of the tun (typically the boil kettle), allowed to drain, and the grain is discarded. The wort is brought to a boil and brewing proceeds as usual. The grain bag is usually not sparged, only allowed to drain. The amount of wort retained by the grain is typically half that of normal lautering due to the weight of the grain in the bag squeezing more wort out; a typical retention rate is 0.25 qt./lb. (0.5 L/kg). The BIAB method can use a much finer crush for better yield, because it doesn’t depend on wort flow through the grain bed for good extraction. However, the very high water-to-grist ratio, near 4.3 qt./lb. (9 L/kg) in low-gravity worts (≤1.040), means that these mashes are more sensitive to water chemistry and pH than other methods. But generally BIAB works well, and it uses less equipment, so there is less to clean up at the end of the day.

One thing to consider for BIAB is that you will probably need a small block and tackle to hoist the wet grain bag out of the kettle and hold it there for several minutes while it drains. (My kid’s arms got tired.)

Rinsing versus Draining

Commercial breweries use continuous sparging with large rotating sparge arms and grain rakes, because that is the most efficient way to rinse the grain in a lauter tun that is twenty feet across. As homebrewers, the difference in scale is in our favor. Large commercial systems need to engineer solutions to problems we just don’t have. We can spend an extra dollar on malt to make up for a lack of efficiency, and pour the sparge water directly onto the grain bed, whereas a large commercial brewery would have to spend an extra five hundred dollars and monitor uniformity of the flow.

Continuous sparging is a rinsing process that depends on uniform flow through the grain bed to achieve the best yield. The first runnings are rich in sugar, making a dense first wort. As the sparge water moves through the grain bed, this first wort is displaced by the less dense sparge water, so the grain does not float as well. This causes the grain bed to compact, which can lead to a stuck sparge. You will also get a stuck sparge if the runoff rate is too fast, because this creates a partial vacuum under the false bottom, or around the manifold, which compacts the grain against it. The maximum recommended runoff rate for continuous sparging is about 1 qt./min. (roughly 1 L/min.). After the heavy first wort has been displaced, the remaining sugars in the grist particles will diffuse into the sparge water. This diffusion process takes time, which is another reason to go slowly, otherwise the sparge water will simply fill the boil kettle without having extracted much of anything.

The grain bed can be a few inches to a couple of feet deep (between 5 and 60 cm), but the optimum depth depends on the overall tun geometry and the total amount of grain being mashed. If the grain bed is very shallow, for example, from lautering too little grain in too large a tun, then the filter bed will be inadequate, the wort won’t clear, and you will get hazy beer. A minimum useful depth is probably about 4 in. (10 cm) but a depth of about 8 in. (20 cm) is preferable. In general, deeper is better, but if the grain bed is too deep then it is more easily compacted, making uniform lautering nearly impossible. Since fluids always follow the path of least resistance, compaction can lead to preferential flow, in which some regions of grain are completely rinsed while others are not rinsed at all (i.e., channeling). Non-uniform flow is a major cause of poor efficiency or low yield.

Batch sparging, no-sparge, and BIAB get around these problems by draining instead of rinsing. By draining, you are simply extracting what is already there, rather than trying to extract more. It’s like picking all the low-hanging fruit—you get a rich wort with little effort. The problem is that quite a bit of wort can be left behind. Batch sparging solves this problem by mixing another batch of water into the mash tun to obtain a second runnings. The second wort in batch sparging typically has a gravity ≥1.016, so tannin extraction due to rising mash pH, as can happen in continuous sparging, is usually prevented (see chapter 21 for more discussion of this issue). The BIAB method handles it a little differently by essentially pre-sparging, initially using more water so that the wort retained by the grain bed is at a much lower gravity than that retained from the first runnings of batch sparging.

Efficiencies of Sparging Methods

The extract yields given for the various malts in chapter 18, “Extraction and Yield,” are based on the traditional mash, lauter, and continuous sparging techniques that are used in breweries all over the world. Continuous sparging takes a little longer, but is the most efficient of the methods. Batch sparging, no-sparge, and BIAB can take less time and use less equipment, but lose a little bit in efficiency, requiring a bit more grain to produce the same volume and gravity of wort. For homebrewers, where grain is relatively inexpensive and time and equipment are more so, these less efficient but quicker options are attractive. Let’s compare these methods by using the following example.

Table 19.1 is a comparison of grain weights and efficiencies for a simple 1.050 OG brown ale recipe brewed using different sparge methods. We will assume that we are collecting 7 gal. (27 L) of wort at 1.043 from the mash, to boil down to 6 gal. (23 L) at 1.050 to go into the fermentor, to finally yield at least 5 gal. (19 L) into our keg or bottles. We will assume 80% brewing efficiency for the standard continuous sparge method, which is about 30 PPG (250 PKL). The same comparisons are made in table 19.2, this time using metric units. The two sets of examples in tables 19.1 and 19.2 are not exact conversions of each other due to the small difference between brewing based on quarts per pound versus liters per kilogram.

Table 19.1—Grain Weights and Brewing Efficiencies Compared between Sparge Methods

| Grain bill | Continuous sparging | Batch sparging | No-sparge | BIAB |

|---|---|---|---|---|

|

Pale ale malt (lb.) |

8.65 |

9.45 |

9.8 |

8.88 |

|

Biscuit malt (lb.) |

0.5 |

0.55 |

0.56 |

0.51 |

|

Crystal 60 malt (lb.) |

0.5 |

0.55 |

0.56 |

0.51 |

|

Chocolate malt (lb.) |

0.5 |

0.55 |

0.56 |

0.51 |

|

Total weight (lb.) |

10.15 |

11.1 |

11.5 |

10.4 |

|

Water-to-grist ratio (Rv) |

1.8 |

1.8 |

2.9 |

2.9 |

|

Brewing efficiency |

80.0% |

73.2% |

70.7% |

78.0% |

|

Total mash volume (gal.) |

5.5 |

5.9 |

9.5 |

8.6 |

BIAB, brew-in-a-bag.

Note: Grain bill in each case is for the same 1.050 OG brown ale recipe, assuming 7 gallons of wort collected and boiled to 6 gallons, based on a 5 gal. batch size.

Each sparge method produces the same 7 gal. of 1.043 wort, but using differing quantities of grain. Similarly, the size of the mash differs: 5.9 gal. for batch sparging and 9.5 gal. for no-sparge, versus 5.5 gal. for continuous sparging. The values for BIAB don’t follow the same trend as batch sparging and no-sparge, because the retention factor for BIAB is about half that for the other processes due to the suspended weight of the grain squeezing more wort out. This means BIAB can deliver 7 gal. of 1.043 wort with less grain and higher efficiency.

Table 19.2—Grain Weights and Brewing Efficiencies Compared between Sparge Methods, Metric Units

| Grain bill | Continuous sparging | Batch sparging | No-sparge | BIAB |

|---|---|---|---|---|

|

Pale ale malt (kg) |

4.0 |

4.33 |

4.46 |

4.1 |

|

Biscuit malt (g) |

225 |

244 |

251 |

229 |

|

Crystal 60 malt (g) |

225 |

244 |

251 |

229 |

|

Chocolate malt (g) |

225 |

244 |

251 |

229 |

|

Total weight (kg) |

4.7 |

5.1 |

5.2 |

4.8 |

|

Water-to-grist ratio (Rv) |

3.7 |

3.7 |

6.2 |

6.2 |

|

Brewing efficiency |

80.0% |

73.9% |

71.7% |

78.6% |

|

Total mash volume (L) |

21.0 |

22.6 |

36.4 |

33.2 |

BIAB, brew-in-a-bag.

Note: Grain bill in each case is for the same 1.050 OG brown ale recipe, assuming 27 L collected and boiled to 23 L, based on a 19 L batch size.

Continuous Sparging Efficiency

For continuous sparging, brewing efficiency typically varies little, usually being between 75% and 80%. The brewing efficiency is most dependent on the lautering equipment and uniformity, topics discussed in detail in appendices E and F.

When using continuous sparging, calculating the grist weight and volumes is as discussed in chapter 18, being simply the OG and recipe volume (or boil gravity and boil volume) divided by either 30 PPG or 250 PKL (depending on units), assuming 80% brewing efficiency in this case. If the brewing efficiency is taken to be 75%, then the values are about 28 PPG and 234 PKL.

The water-to-grist ratio (R) can vary at the discretion of the brewer, although ratios in the 2.5–4.0 range are most common.

Batch Sparging Efficiency

The key to understanding the various efficiencies of all these methods is to understand figure 18.4, which shows the gravity of the first wort as a function of R and typical yield. We will refer to the gravity of the first runnings as SG1. If you refer back to the sidebar on the weight per weight water-to-grist ratio in chapter 17, you will remember that R (the weight to weight water-to-grist ratio) is related to Rv (the volume to weight water-to-grist ratio) by the density of the water, represented by ρ (rho). As explained in chapter 17, the value of ρ at mash temperatures is taken to be 2.055 lb./qt. (0.985 kg/L). Knowing Rv and R allows us to calculate the gravity of the wort in the mash according to the equation for initial wort gravity as a function of R, given in chapter 18:

where,

R = Rv × ρ

Note: SG1 is calculated as specific gravity, for example, 1.077, but only the degrees of gravity portion (i.e., gravity points) will be used in subsequent calculations, which in this example is 77.

Batch sparging is most efficient when the volume of the first (SG1) and second runnings (SG2) are identical, meaning they are each equal to half of the target boil volume. The ratio, Rv, is calculated from half of the boil volume and the grist weight according to the equation:

Rv = [Vb + (G × r)] / 2G

where,

Vb is the boil volume,

G is the grist weight,

r is the wet grain wort retention factor, taken to be about 0.5 qt./lb., or 1 L/kg.

The above equation reduces to:

Rv = (Vb / 2G) + r

The grist weight (G) is equal to the total degrees of gravity (i.e., OG × post-boil volume, or BG × boil volume) divided by your expected yield in PPG or PKL based on the extract efficiency.

or,

where,

Max. yield = maximum malt yield in PPG or PKL based on %FGDB.

In the solutions worked out for the sparge efficiencies in tables 19.3-19.8, located at the end of this chapter, the maximum yield is taken as 80% FGDB soluble extract by weight, which is about 37 PPG, or 307 PKL (see table 18.5). The maximum yield is multiplied by the brewing efficiency, which can range anywhere from 50% to 85% depending on Rv. The batch sparging efficiency must be solved by iteration, as I will explain below.

The second runnings is the wort that is retained in the wet grain and then diluted by the volume of sparge water (remember this is equal to Vb/2). The gravity of the second runnings, which we will refer to as SG2, is related to the gravity of the first runnings by the ratio of the two ratios: r and Rv.

Remember: SG1 must be input as degrees of gravity (gravity points) instead of specific gravity (i.e., 56 instead of 1.056).

The combined gravity of the collected wort, as gravity points, in the boil kettle is:

boil gravity = (SG1 + SG2) / 2

The total mash volume (Vm) is given by:

In quarts: Vm = G(R + 0.38)

In liters: Vm = G(R + 0.8)

The problem with these equations is that solving for the grist weight and Rv is indeterminate; there are many combinations of gravity, volume, and grist weight that work together, but there is only one solution that gives us our target runnings volume and combined boil gravity. This solution must be solved iteratively with the aid of a spreadsheet or by using higher math. I chose a spreadsheet. The result is table 19.3 and table 19.4, and also the tables further on that deal with alternative sparge methods (see relevant sections below). The nice thing about these tables is that the numbers are robust; they depend on malt modification, not degree of crush, and if your volume and weight measurements are accurate, you will hit your numbers every time.

Note: The numbers for the same OG between tables 19.3 and 19.4 are slightly different, because 6 and 7 gal. are not exact equivalents of 23 and 27 L.

No-Sparge Efficiency

The model for no-sparge is basically the first half of the batch sparging model described above, we just have to scale up the amount of grist and the water-to-grist ratio (Rv) to get all of our boil volume and gravity in the first runnings, SG1. The numbers for no-sparge are given in tables 19.5 and 19.6. The equation for the boil gravity as a function of R is the same as for the first runnings in batch sparging, but note that the equation for Rv in no-sparge is not divided by 2.

boil gravity = 259 / {259 – [75 / (R+1)]}

where,

or,

Note: The numbers for the same OG between tables 19.5 and 19.6 are slightly different, because 6 and 7 gal. are not exact equivalents of 23 and 27 L.

Brew-in-a-Bag Efficiency

The model for BIAB, tables 19.7 and 19.8, is very similar to no-sparge described in the section above, except that the wort retention factor, r, is roughly half that of the other methods because the suspended weight of the grain bag squeezes out more wort from the grist. The value of r is taken to be roughly 0.25 qt./lb. (0.5 L/kg) when using BIAB. This changes the runnings volume and therefore the efficiency and amount of grain needed to hit the boil gravity. The water-to-grist ratio (Rv) is the same as for no-sparge, but remember that the retention factor is different.

Note: The numbers for the same OG between tables 19.7 and 19.8 are slightly different, because 6 and 7 gal. are not exact equivalents of 23 and 27 L.

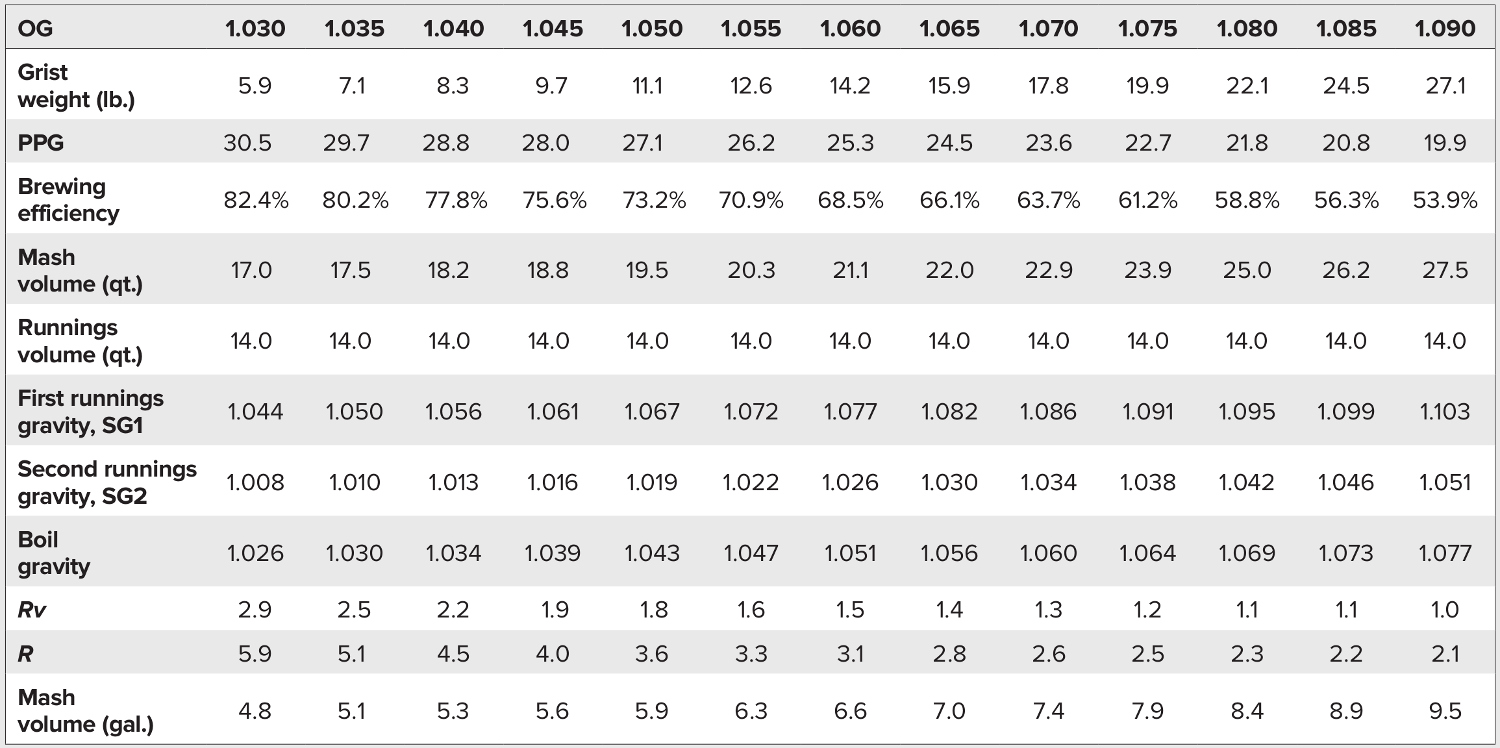

Table 19.3—Batch Sparging Targets Using Pounds, Quarts, and Gallons

OG, original gravity; PPG, (gravity) points per pound per gallon; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 7 gal. to yield 6 gal. to the fermentor at the stated OG. For discussion of calculations used, refer to the section “Batch Sparging Efficiency.”

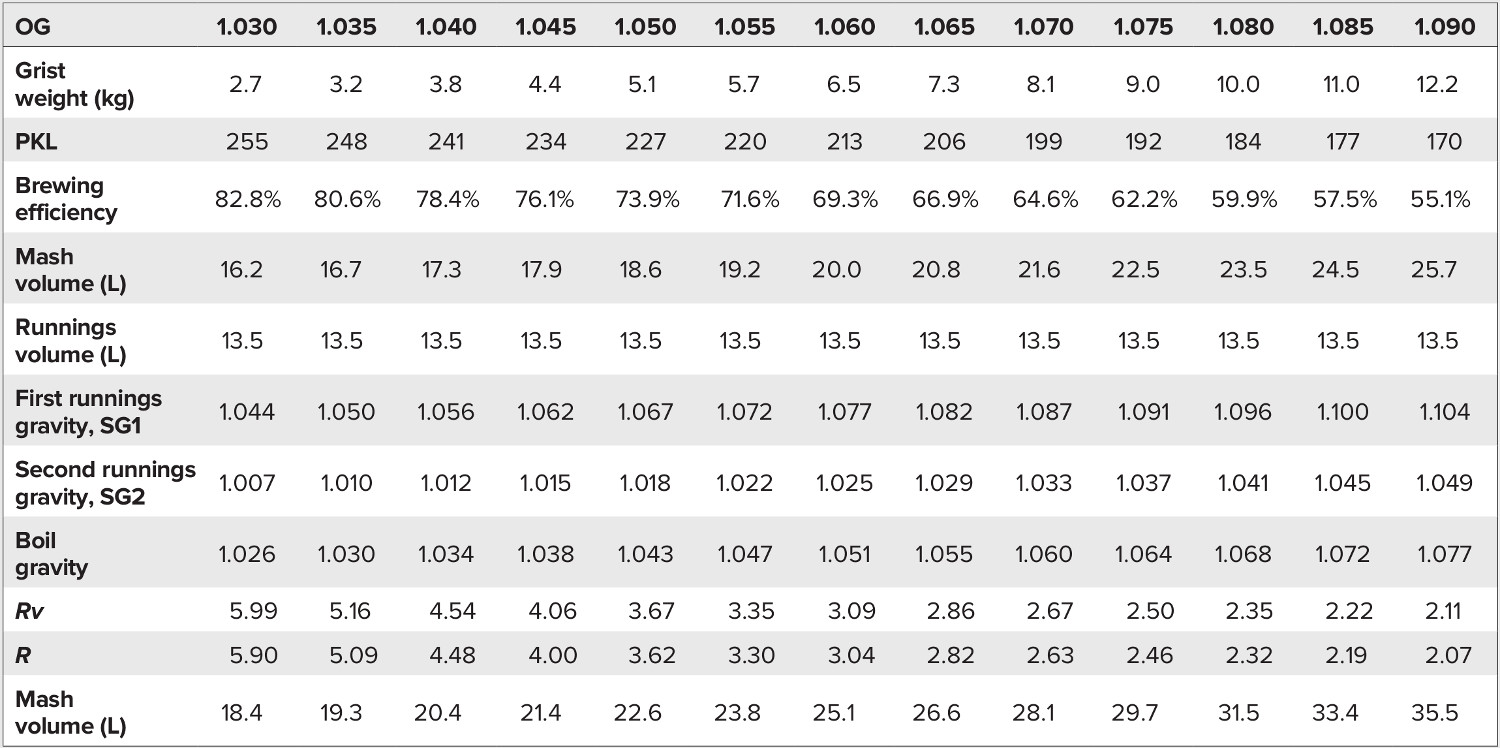

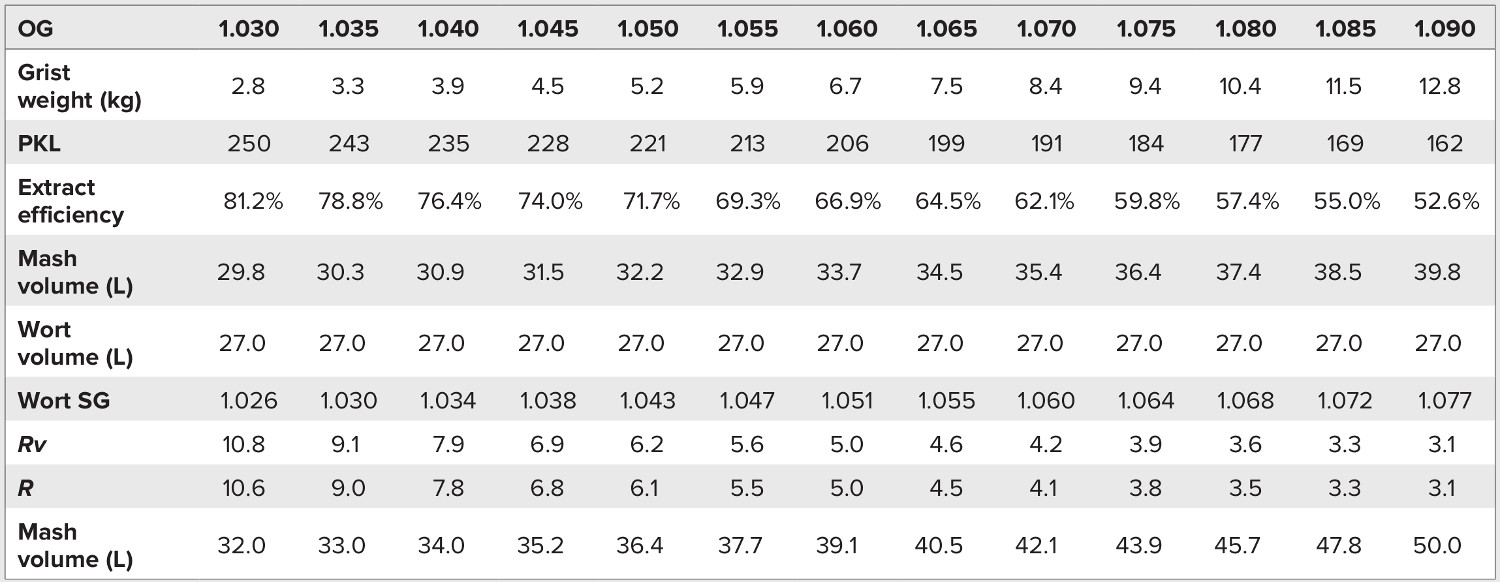

Table 19.4—Batch Sparging Targets Using Kilograms and Liters

OG, original gravity; PKL, (gravity) points per kilogram per liter; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 27 L to yield 23 L to the fermentor at the stated OG. For discussion of calculations used, refer to the section “Batch Sparging Efficiency.”

Table 19.5—No-Sparge Targets Using Pounds, Quarts, and Gallons

OG, original gravity; PPG, (gravity) points per pound per gallon; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 7 gal. to yield 6 gal. to the fermentor at the stated OG. For discussion of calculations used, refer to the section “No-Sparge Efficiency.”

Table 19.6—No-Sparge Targets Using Kilograms and Liters

OG, original gravity; PKL, (gravity) points per kilogram per liter; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 27 L to yield 23 L to the fermentor at the stated OG. For discussion of calculations used, refer to the section “No-Sparge Efficiency.”

Table 19.7—BIAB Targets Using Pounds, Quarts, and Gallons

BIAB, brew-in-a-bag; OG, original gravity; PPG, (gravity) points per pound per gallon; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 7 gal. to yield 6 gal. to the fermentor at the stated OG. For discussion of calculations used, refer to the section “Brew-in-a-Bag Efficiency.”

Table 19.8—BIAB Targets Using Kilograms and Liters

BIAB, brew-in-a-bag; OG, original gravity; PKL, (gravity) points per kilogram per liter; R, wt./wt. water-to-grist ratio; Rv, vol./wt. water-to-grist ratio; SG, specific gravity.

Notes: Boil volume is 27 L to yield 23 L to the fermentor at the stated OG. For discussion of calculations used, refer to the section “Brew-in-a-Bag Efficiency.”