Graham G. Stewart

CONTENTS

6.11 Priming Sugars and Carbohydrates

6.12 Malted Cereals Other Than Barley

6.12.1 Wheat, Rye, and Sorghum Malt

6.1 INTRODUCTION

There are raw materials (ingredients) that are essential in conventional brewing procedures for beer production (details in Chapters 4, 5, 7, 8, and 10). In many countries, their use is dictated by appropriate brewing production regulations such as the German Purity Law (Reinheitsgebot)—details later. These ingredients are: malted cereals, water, hops, and yeast.1 There are materials, collectively called adjuncts that are employed for brewing but are not essential for beer production. However, with certain exceptions (details later), most countries employ adjuncts.2 Adjuncts are unmalted cereals and sugars that are used as a replacement (usually in part) for malted barley (or other malted cereals such as wheat, sorghum, oats, etc.).

Adjuncts are not just starch (or sucrose) and, over time, their quality has improved quite significantly. However, until the second half of the twentieth century, brewing adjuncts were of questionable quality. One parameter that has contributed to the enhancement of adjunct quality is the advent of a number of sophisticated novel analytical instruments (on- and off-line).3 Notable instruments in this context are:

HPLC is very important with regard to the use of brewing adjuncts. This analytical technique is employed to measure fermentable sugars, such as glucose, fructose, maltose, and maltotriose, nonfermentable carbohydrates (dextrins), and amino acids.

The standard definition of an adjunct is: “something joined or added to another thing but not essentially a part of it.”8 In the context of beer and brewing, it is important to note what is essential for the process—water, malt, hops, and yeast—and everything else that finds its way into the process is an adjunct. In the context of brewing (applications in whiskey production will be discussed in Chapter 9), adjuncts are alternative sources of fermentable extract and are used to replace a portion of the barley malt, which is usually more expensive (Table 6.1). Adjuncts will typically be used as a less expensive source of extract. Also, adjuncts can be used to impart elements of beer characteristics and quality such as color, flavor, foam, and drinkability. In addition, adjuncts are important if there are taxation considerations that make reduced malt use, and the concomitant increased use of brewing adjuncts, financially advantageous. For example, Japanese legislation states that there should be taxation on malt usage. This has permitted the development of Happoshu (a beer type that is produced containing 25% or less malt) and “Third Category” beers that do not contain any malt.

Table 6.1 Sugar Spectra (%) of Brewing Syrups Compared to an All-Malt Wort25

|

Acid |

Acid/Enzyme |

Enzyme/Enzyme MS |

Enzyme/Enzyme VHMS |

All-Malt Worts |

|---|---|---|---|---|---|

Glucose |

65 |

40 |

15 |

5 |

8 |

Maltose |

10 |

28 |

55 |

70 |

54 |

Maltotriose |

5 |

12 |

10 |

10 |

15 |

Dextrins |

20 |

20 |

20 |

15 |

23 |

Note: MS, maltose syrup; VHMS, very high maltose syrup.

Adjunct use is permitted in most countries. However, there are a few countries that do not allow the use of nonmalted carbohydrate sources (adjuncts) in brewing. It has already been discussed that Germany is the preeminent country that strictly controls beer production. The German Purity Law (Reinheitsgebot) was established more than 500 years ago (1516).9, 10 It states that only barley malt, hops, and water (yeast was listed later after its description by Antonie van Leeuwenhoek in 1680) can be employed in the brewing process and the use of adjuncts is forbidden. The similarities between the Purity Law and the Scotch Whisky Regulations, which date from 1909 and were last revised in 2009,11 will be discussed in Chapter 9.

As well as Germany, two other European countries have adopted the basis of the German Purity Law—Norway and Greece. The adoption of the Purity Law in Norwegian brewing dates from the first decade of the twentieth century. Norway separated from Sweden on June 7, 1905. Prince Carl of Denmark was offered the Norwegian throne, and he took the title of King Haakon VII. He had a great affection for German beer and insisted that his new kingdom adopt the German Purity Law. Consequently, the use of adjuncts was not permitted and, as a result, Norwegian beers are all-malt to this day.

The precise definition of brewing adjuncts varies from country to country. The narrow definition of the United Kingdom’s Food Standards Committee has been adopted in this chapter, and it is “any carbohydrate source other than malted barley, which contributes sugars to a brewer’s wort.”

The use of brewing adjuncts falls within three areas of the brewing process, although there are other areas that will not be discussed here:

Typically, adjuncts (which include exceptions—details later), other than nonbarley malted cereals, only contribute starch—no enzyme activity and little or no soluble nitrogen and are usually less expensive than barley malt. Also, many adjuncts (not all) do not contribute flavor to the finished product. However, this is not always the case. Unmalted barley tends to give beer a stronger harsher character, particularly stouts.12 Corn gives beer a full clean flavor, and wheat imparts beer with a dryness character. In addition, both wheat and barley adjuncts improve beer head retention (foam stability). Although rice does not enhance beer foam stability, it gives lager beers a characteristic light flavor with improved drinkability. It should always be borne in mind that beer is usually not sipped, it is drunk! Also included in this chapter is a discussion of malted cereals other than barley. Barley malt is considered extensively in Chapter 5.

The overall brewing value of an adjunct can be expressed by the following equation:

Brewing value = Extract + Contribution to beer quality − Brewing costs

It must be emphasized that this is an empirical equation because the contribution to beer quality cannot be quantitatively defined.

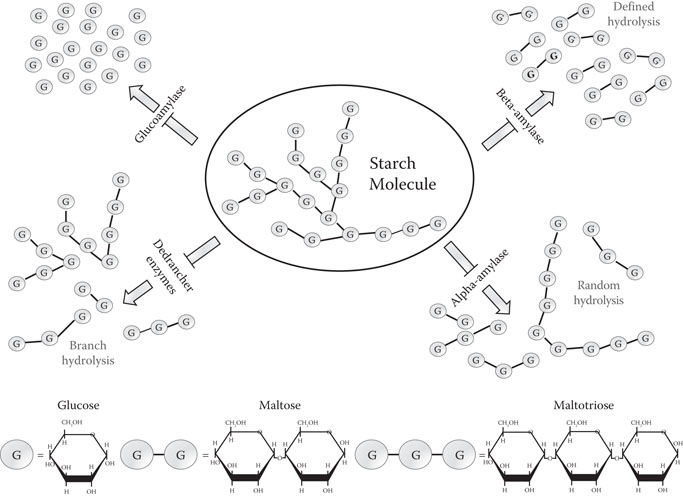

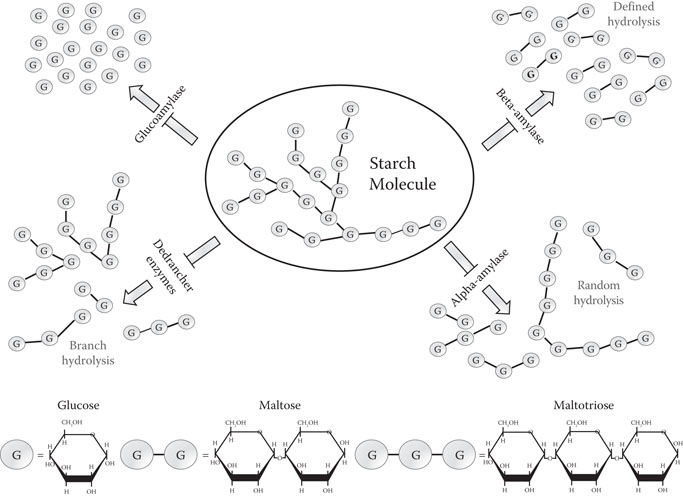

Adjunct starch consists of two types of polymer molecule—linear amylose and branched amylopectin (Figure 6.1). Depending on its source, starch amylose and amylopectin are inherently incompatible molecules, with amylose having a lower molecular weight with a relatively extended shape, whereas amylopectin comprises larger, but more compact, molecules.13 Amylose molecules consist of largely single unbranched chains with 500 to 20,000 α-(1→4)-D-glucose units, depending on the plant source of the starch. (Very few α-1-6 branches may be found, and they will have little influence on the molecules’ overall characteristics.) Amylopectin is formed by nonrandom α-1→6 branching of the amylose-type α-(1→4)-D-glucose structure. The branching is determined by branching enzymes that leave each chain with up to 30 glucose residues. Amylopectin and glycogen (an intracellular energy storage molecule for mammals, insects, and fungi, including yeast—details in Chapter 8) have a similar structure, but the amylopectin molecular structure has about one branch point per 10 1,4-α bonds compared to approximately 30 in glycogen. The amylopectin molecule contains a million or so glucose residues, about 5% of which form the branch points.

Figure 6.1 The enzymatic hydrolysis of starch.

The current use of brewing unmalted adjuncts in the United States averages about 38% of the total brewing materials employed in the industry. Excluding hops, corn (maize) (46% of total adjunct), rice (31%), barley (1%), and sugars and syrups (22%) are the most commonly used adjunct materials. The listing of unmalted brewer’s adjuncts is quite extensive: yellow corn grits, refined corn starch, rice, sorghum, barley, wheat, wheat starch, cane and beet sugar (sucrose), rye, oats, potatoes, cassava (tapioca), triticale, and even pea starch (which is not green!). There are also a number of processed adjuncts employed in brewing, which include: corn, wheat and barley syrups, torrified cereals, cereal flakes, and micronized cereals (details later in this chapter).

6.2 USE OF SOLID ADJUNCTS

The processing of solid adjuncts is similar in a typical brewhouse. The objective is to hydrolyze the starch into fermentable sugars, mainly glucose, maltose, and maltotriose (together with unfermentable dextrins). Processing usually occurs separately from mashing (though not always), with the adjunct processed in a cereal cooker and mashing occurring in a mash mixer. The hydrolysis of adjunct starch usually occurs by malt enzymes, which are transferred from the mash mixer into the cereal cooker (usually 10% to 15% of the total malt grist; details of malt barley mashing are in Chapters 3 and 5). Exogenous amylases (usually of either bacterial and/or fungal origin) can be added to the adjunct slurry in the cereal cooker. The saccharification temperature profile depends upon the starch source and the enzymes employed (further details later). Sixty minutes at incubation temperature is the usual period, and then the temperature is raised to 100°C for 5 to 10 min. Following this incubation regime (cereal cooking and mashing), the grist containing converted (hydrolyzed) malt and adjunct starch is discharged into the mash tun or the mash filter, and the sweet (unhopped) wort is separated from the spent grains (details in Chapters 3 and 11). The sweet wort flows into the kettle, where it is boiled and hops (as leaf, pellet, or extract—details in Chapters 3, 7, and 11) are added together with processing aids and additions (details in Chapter 10).

6.3 CORN GRITS

It has already been discussed that corn grits are the most widely used adjuncts in the United States and Canada. They are produced by the dry milling of yellow corn. The hull and the endosperm’s outer layers, along with the oil-rich germ, are removed during the milling process, which leaves behind almost 100% endosperm fragments. These fragments are milled further and classified according to the brewer’s specifications. Corn grits produce a slightly lower extract than other unprocessed adjuncts, such as rice, because of less unfermentable dextrin material in the wort after mashing and also the presence of protein and fat. The gelatinization temperature range for corn grit starch is 62°C to 74°C, whereas for rice starch grit it is 64°C to 78°C. Flaked grits, flaked micronized grits, and corn grits have been compared with untreated corn grits, and they compare favorably with flaked and micronized barley and wheat adjuncts regarding extract yield, fermentability, α-amino nitrogen, and wort viscosity.14 Wort protein, peptides, free amino acids, and nucleic acid derivatives decline in proportion to the adjunct level in the grist, as would be suggested. The wort amino acid profile was not affected by a particular adjunct but was affected by its level in the mash compared to the level of malting barley in studies by Lekkas et al.15

6.4 RICE

Currently, the second most widely used adjunct material in the United States is rice.16 On an extract basis, it is approximately 25% more expensive than corn grits. Brewer’s rice is a by-product of the edible rice-milling industry.15 The hulls are removed from paddy rice, and this rice is dry milled in order to remove the bran, aleurone layers, and germ. Rice milling’s objective is to completely remove these fractions and to inflict minimal damage to the starchy endosperm, resulting in whole kernels for domestic consumption. Nevertheless, up to 30% of the kernels are fractured during the milling process. These broken pieces (“brokens”) are regarded as aesthetically undesirable for domestic use and are marketed to brewers at a considerably reduced price compared to whole kernels or the mill run rice price. Rice is preferred by some brewers for a number of reasons such as its lower oil content, neutral aroma, and flavor, and when properly converted in the brewhouse, it results in a light, clean-tasting drinkable beer.

Brewer’s rice quality can be judged by several factors: cleanliness, gelatinization temperature, mash viscosity, mash aroma, moisture, oil, ash, and protein content. The rice should be free of seeds and foreign matter. Insect and mold damage cannot be tolerated because these indicate improper storage and/or handling conditions. Although rancid rice oil can be a problem, modern storage techniques render this potential problem negligible. Nevertheless, laboratory rice mash samples should be conducted regularly. Such mashes should gelatinize and liquefy in a standard manner and be clean and free from undesirable odors and tastes.

Some rice varieties are unacceptable for brewing. It has already been mentioned that compared to corn, and other starch sources such as potatoes, rice possesses a relatively high gelatinization temperature13 and is extremely viscous prior to liquefaction in a cereal cooker. Many rice varieties, such as Nato, will not liquefy properly and are difficult to pump from the cooker to the mash mixer. Other acceptable rice varieties, such as short-grain Californian Pearl, Mochi Somi, and Cahose,12, 16, 17 liquefy well in the cooker during a 15-min boil. The amylose and liquid content of rice varies with variety and cultivation conditions. Consequently, suitable rice grades are important. The finer the particle grist, the easier the rice liquefaction process, with particles less than 2 mm in size considered adequate. Rice handling is relatively easy because “brokens” contain minimal dust and flow easily through standard hopper bottoms and conveying equipment. Rice is milled in fixed roller mills, and there is minimal difficulty in developing a rice slurry at 64°C to 76°C. However, it is common practice to mash and hold the slurry initially at 36°C to 42°C, as a form of “protein rest” (further details in Chapter 11). As with all cereal cooking operations, whatever the starch source, 10% to 15% of the malt grist is added to the cereal cooker because the malt enzymes (primarily amylases and proteases) are essential in order for partial liquefaction to occur so that the cereal cooker fluid can be pumped. Atmospheric boiling of the adjunct mash is necessary for gelatinization, although some breweries pressure cook at 112°C. If conversion in the cooker occurs to specification, runoff problems will not occur. Rice extract is slightly lower in soluble nitrogen than a similar extract from corn grits.

6.5 UNMALTED BARLEY

An obvious brewing adjunct is unmalted barley. This adjunct is abrasive and difficult to mill, yielding a high percentage of fine materials resulting in lautering problems.12 As a consequence of this, many brewing operations that include unmalted barley in their grist have installed hammer mills and mash filters in order to overcome runoff problems.18 Runoff problems (details in Chapter 11) can also be overcome by conditioning the grain to 18% to 20% moisture prior to milling. This process has not been widely employed in brewing.

Barley has normally been partially gelatinized prior to use, often in a location outside a brewery. Gelatinization occurs either by mild pressure cooking or by steaming at atmospheric pressure, followed by the passage of the hot grits through rollers held at approximately 85°C. The moisture content of the flakes is reduced to 8% to 10%. This process of pregelatinization can also be applied to corn. Barley that has been pregelatinized enhances the ease of β-glucan extraction during mashing and therefore the β-glucan wort content. Prolonged steaming prior to barley rolling develops a raw material that produces sweet worts with a higher viscosity. Wort viscosity can be managed by measuring the viscosity of the flaked barley in a cold water extract, which is a good indication of the extent of the steaming process. Barley starch is more readily hydrolyzed than corn or rice starch because of its lower gelatinization temperature. In order to increase extract yields, barley may be dehusked before use. However, this may lead to runoff difficulties because the husk provides filter bed formation material (another reason for the use of a mash filter instead of a lauter tun). A malt with sufficient enzyme activity is required if significant proportions of barley are to be used in the grist and subsequently the mash. The use of unmalted barley as an adjunct leads to a reduction in the wort nitrogen content together with decreased wort and beer color. Difficulties have not been reported during the fermentation of wort containing barley adjunct. In addition, beer foam stability is usually improved because the foam-enhancing peptides from the barley are not hydrolyzed due to lower levels of proteolysis. It should be emphasized that a major difficulty associated with employing high proportions of unmalted barley can be increases in wort viscosity and runoff times resulting from the incomplete degradation of β-glucans and arabinoxylans. Mashing at 65°C rapidly deactivates malt β-glucanase activity. These problems can be alleviated by the pretreatment of the barley with β-glucanase—also, the use of a temperature-stable β-glucanase in the mash. Although a cereal cooker in the brewhouse is necessary, pregelatinized barley can be added directly to the mash mixer, circumventing the use of a cereal cooker.

Raw (feed) barley can be employed at a level of as much as 50% of the grist. This has been the case in an Australian brewery. Pregelatinized barley is used as a raw material in some well-known stouts at 18% to 20% of the grist. Conventional roller mills (as already discussed) cannot be employed, and hammer mills are necessary.19 Use of a high level of malt replacement by unmalted barley usually results in the mash containing insufficient malt enzymes for the necessary hydrolysis of the available starch, proteins, and β-glucans. For this purpose, a malt replacement enzyme system is required to compensate for the reduced concentration of malt enzymes.20 Enzyme mixtures of β-amylase, protease, and β-glucanase (and sometimes α-amylase) have been developed. These enzymes are obtained from microbial sources such as Bacillus subtilis. Limitations due to the use of raw materials have been largely overcome by the use of these exogenous enzymes. Although traditionally high proportions of well-modified malt barley are required in brewing formulations to achieve sufficient extract, efficiency, and quality in a brewhouse, exogenous enzymes with cereal-specific, relevant pH, and temperature specifications are now available. As a consequence of this development, processing up to 100% under-modified malt, barley, or sorghum, as well as more than 60% wheat, rice, and corn, are currently well-established procedures. Raw material optimization is not just about the use of more unmalted cereal in formulations, but it is also to achieve consistency and efficiency without compromising quality. A number of enzyme suppliers have addressed customer needs to enable brewers to enhance raw material usage, efficiency, and flexibility.

The ultimate high adjunct brewing in the absence of any barley malt being used is barley brewing. This process offers considerable economic advantages, but there are beer quality problems. In the late 1980s, there was an embargo on the importation of barley malt into Nigeria in order to conserve valuable foreign currency. Little local barley malt was available at the time. As a consequence, Nigerian brewers were compelled to develop methods to brew lager beer entirely from locally grown raw materials including sorghum, corn, and surplus barley.

In barley brewing, it is possible to approximate the hydrolysis profile of a typical brewhouse starch, the degree of fermentability, and the sugar profile (particularly glucose, fructose, sucrose, maltose, and maltotriose) of 100% malt worts. This objective is possible by substituting malt with 50% (on an extract basis) and by control of the main mash schedule (enzyme concentration, time, and temperature). Barley worts have been found to contain less fructose, sucrose, glucose, and maltotriose but more maltose than typical all-malt worts. No atypical cycles of fermentation, maturation, and beer flavor and stability have been reported. In addition, the astringency and harshness of barley beer can be mitigated by reducing the wort pH to 4.9 prior to boiling.12

6.6 SORGHUM (MILLET)

Although the use of sorghum as a brewing adjunct is more than 50 years old, it is only during the last 25 years that real brewing interest has been exhibited in this cereal. Sorghum is currently the fifth most widely grown cereal crop globally. Only wheat, corn, rice, and barley are produced in greater quantities.17 The major sources of sorghum are Africa and Central America. Nevertheless, the “seed industry” has conducted limited research into a wide range of sorghum genotypes that may be suitable for brewing. The development and use of sorghum malt, as well as wheat malt, will be discussed later in this chapter.

Sorghum is a traditional raw material in Africa for the production of local top-fermenting beers that are known by various names such as Bantu beer in South Africa, dolo in Burkina Faso, and billi billi in Chad. These beers are relatively low in alcohol concentration (approximately 2.5% [v/v]) and are hop-less. They are slightly sour in taste and are drunk unfiltered (they contain “bits”), mainly in rural regions.21

The U.S. brewing industry employed sorghum as an adjunct during World War II because of the scarcity of other brewing raw materials. The sorghum was of poor quality. It was cracked and only partially dehulled and degerminated. As a consequence, brewers obtained poor yields and bitter-tasting beers that lacked drinkability. Modern milling techniques and better purification methods have changed the situation, and sorghum brewer’s grits are considered to be of comparable quality to corn and rice grits.22 In the United States, because of the bad experiences during 1939 to 1945, sorghum brewer’s grits are almost never used today. However, Africa, Mexico, and other parts of Central America are currently using an appreciable, and increasing, percentage of brewer’s grits and are producing very acceptable beer quality.

Agronomically, the advantage of sorghum is its ability to survive under extreme conditions of water stress. Sorghum is ideally suited for cultivation in tropical areas including Africa and Central America. The current yield, without fertilization, is 2 to 3.8 tons of grain per acre. With the adoption of appropriate enhanced agronomic conditions, this yield can be further increased.

Typically, the dried sorghum is screened to remove extraneous material (as is the case in the malting of barley). The whole grain is then fed into a series of dehullers that produce two product streams. One stream, the husks and embryonic material, which constitutes approximately 48% of the original grain, is removed. This fraction, together with the initial screenings, is sold as a by-product. The second stream consists of peeled sorghum together with a small amount of husk. This stream is then passed through an aspirator, in which the husk is removed. The purified peeled sorghum, now representing 47% of the original processed cereal, is milled to give 12% of the original material as flour and 35% as sorghum grits. Both of those fractions are used as brewing adjuncts and can contribute up to 45% of the total wort extract.

Sorghum and corn grains have a similar composition. The starch in both grain types consists of 75% amylopectin and 25% amylose, with the grains uniform and similar in range, shape, and size. Sorghum granules are slightly larger (15 µm) than corn (10 µm). Sorghum starch has a higher gelatinization temperature (68°C to 76°C) than corn starch (62°C to 68°C). Sorghum brewer’s grits perform in a typical brewhouse and do not require special handling or cooking procedures. Only 5% barley malt is required in the cereal cooker to provide the necessary amylolytic and proteolytic enzymes. Conversion of starch occurs within the allowed mashing time. The beers produced with sorghum starch adjuncts are equivalent in chemical analysis, flavor, and stability to beers produced with other solid adjuncts such as corn starch. Also, in many parts of Africa and Central America, sorghum offers the lowest-cost source of available fermentable sugar.23

6.7 REFINED CORN STARCH

The purest starch available to brewers is refined corn starch.24 It is a product of the wet-milling industry. Its use in the brewing industry is not widespread because the price is higher relative to corn grits and brewer’s rice. It is also difficult to handle because the powder is extremely fine! It must be contained in well-grounded lines and tanks to prevent explosions that can result from static electricity sparks produced during conveying. This refined starch easily becomes viscous, and it is nearly impossible to make it flow from tanks unless they have fluidizing bottoms.

Refined starch can be delivered to a brewery in bags (usually 50, 75, or 100 kg) or in bulk, which is necessary to reduce starch and labor costs. The starch is removed from a railcar or tanker truck by vacuum and is then blown through an air conveyor to a drop out cyclone above a bulk storage bin. Dust collection is essential for the air conveyor because it can result in explosions and brewery operator lung contamination. This can result in labor relations problems.

Refined corn starch can be used as the total adjunct or can be mixed with rice and/or corn grits at the option of the brewer. Gelatinization and liquefaction of the starch proceeds at a lower temperature than rice or corn grits, but it is not sufficiently different to preclude use of a blend with either. During use of refined corn starch as a total adjunct, care must be taken to prevent sticking on the bottom of the cereal cooker. Refined starch can be easily liquefied by a process similar to that of rice. With the exception of trained beer tasters, the resulting beers cannot be organoleptically (or chemically) differentiated from an all-adjunct rice extract. Brewhouse yields can be increased 1% to 2% by the use of refined corn starch compared to rice. As long as there is an appropriate supply of barley malt, there are no runoff problems when using refined corn starch as an adjunct. Also, beer flavor is unaffected, except that the beer might be slightly thinner due to enhanced wort attenuation limits.

The future use of refined starch as a brewing adjunct depends largely on relative pricing. It is unlikely that refined starch will assume any real market from dry-milled corn grits. However, a wet-milling starch plant in close proximity to a brewery could provide a starch slurry as an adjunct at a competitive price. In addition, the effect of the high fructose syrup (HFS) market (details later) and the use of starch slurry in the paper industry could adversely affect starch availability and its price.

6.8 REFINED WHEAT STARCH

This product is not currently attractive to most breweries worldwide, particularly in the United States, because of its high price. In the past, a wheat starch surplus has been employed by Canadian brewers. (This was also true of pea starch—which enjoyed a brief period of popularity in the 1970s.) Chemically, wheat starch is similar to corn starch, and its gelatinization temperature is similar during mashing. Consequently, it can be added to the malt mash. However, 10% higher brewhouse yields can be obtained by cooking the wheat starch separately in a conventional adjunct cereal cooker.

Wheat starch has conveying and handling problems similar to refined corn starch. Slurrying should take place below 52ºC to prevent lumping. The cooker temperature should not exceed 98ºC because the starch foams excessively upon boiling. Wheat starch is higher in β-glucans, and it is suggested that the cooker mash, with 10% of malt added, should stand at 48ºC for 30 min, prior to the 98ºC rise, to give the β-glucanase time to break down the β-glucans at optimal temperature. This procedure will result in little or no runoff problems. The resulting beer is comparable to beer brewed with corn grits in analysis, flavor, and drinkability. If wheat starch is available at prices competitive to other adjuncts, it would be a suitable adjunct.

6.9 CEREAL TORRIFICATION

Torrification of cereals25 is a process by which cereal grains are subjected to heat at 260ºC and expanded or “popped” (popcorn process). This process renders the starch pregelatinized and thereby eliminates the brewhouse cooking step. Torrification also denatures a major portion of the protein in the kernel, with the result that the water-soluble protein is only 10% of the total. Barley and wheat are potential candidates for torrification as is their use as torrified adjuncts. The chemical analyses are quite similar for each. They both contain approximately 1.4% wort-soluble protein and, as a consequence, could permit the use of lower-protein malts or high adjunct levels and still maintain soluble protein levels similar to worts produced with lower soluble protein adjuncts.

There are no handling or dust problems associated with the use of torrified cereals. It is possible to blend these torrified products with malt. They can then be ground simultaneously and mashed-in together. However, if they are used and the torrified product is cooked at 71ºC to 77ºC prior to addition to malt, higher yields will result. Torrified cereals lead to increased lauter grain bed depth and to slight runoff penalties. Particle size and mill settings are critical, with large particle size leading to poor yield and with too fine a grind resulting in runoff problems. The beer flavor produced with torrified cereals is reported25 to be unchanged; if torrified cereals became economically competitive with other adjuncts, they could become employed as an alternative source.

6.10 LIQUID ADJUNCTS

As already briefly discussed, liquid adjuncts are usually added to the brew at the wort boiling stage. The major sugars are glucose syrups, cane sugar syrups, and invert syrups. Although these syrups differ in detail, the essential similarity is that they are all largely concentrated fermentable solutions of carbohydrates. The term glucose can be misleading. Although glucose is the commonly used name for dextrose glucose syrups used in brewing, they are solutions of a large range of sugars and will contain, in varying proportions, depending upon the hydrolysis method employed, glucose (dextrose), maltose, maltotriose, maltotetraose, and larger dextrins.26

Cane sugar syrups contain sucrose derived from sugarcane and sugar beet and sometimes, depending upon the grade, small quantities of invert sugar. Invert syrups, as the name suggests, are solutions of invert sugar—a mixture of glucose and fructose. Invert sugar is produced in nature and commercially, by the hydrolysis of sucrose, which together with glucose and fructose, occurs abundantly in nature. Commercially, sucrose is extracted from sugarcane or sugar beet, while glucose syrups are usually manufactured from starch, which is usually derived from corn and wheat grains.

Glucose syrups have been commercially available since the mid-1950s. They were originally produced by direct acid conversion of starch to a 64–48 dextrose equivalent range. The degree of starch conversion is usually expressed as dextrose equivalents or DEs. This is a measure of the reducing power of the solution, expressed as dextrose in dry solids. For example, pure starch would have a DE of 0 and pure dextrose (as a solid) would have a DE of 100. In the mid-1960s, new developments in enzyme technology, in addition to the poor quality of straight and converted syrup, led to acid conversion technology resulting in a 42 DE product, followed by a 64 DE product with enzyme conversion. All syrups were refined using activated carbon filtration. Table 6.1 shows the sugar profile of these syrups in comparison to a typical all-malt wort. It can be seen that the only similarity is the content of the higher saccharides or nonfermentables. At the time of this development, a brewery’s main concern was that the apparent extract of the finished beer did not change with the addition of the liquid adjunct—the syrup had to be approximately 22% nonfermentable.27

The use of liquid adjuncts continued in the 1980s, and it became apparent that they had shortfalls. The high level of glucose in these syrups became a particular concern.28 Conversion of starch with the aid of a mineral acid produces predominantly glucose as the hydrolysis product. When brewer’s yeast is exposed to high concentrations of glucose, a phenomenon referred to as the “glucose effect” may be experienced with poor quality yeast, which can result in sluggish and “hung” wort fermentations.29

Brewer’s expect consistency and acid and acid/enzyme syrups depend upon the termination of a reaction by chemical or mechanical means when the desired endpoint is reached. It is difficult to attain proper production consistency when parameters such as temperature, time, pH, and concentration are critical. In addition, there has been concern regarding the physical properties of acid and acid/enzyme syrups. Large-volume users and breweries located long distances from the supplier experienced inconsistent syrup color when the product was stored for lengthy periods at elevated temperatures. This is the “browning reaction” (melanoidin formation) of sugars, and particularly high levels of glucose in syrup will darken (melanoidin reactions), catalyzed by the presence of metal ions and protein.30 To inhibit this reaction, wet millers add sulfites. However, sulfites have been shown to cause allergic reactions with some people and, consequently, food and drug agencies look upon their use with disfavor (further details in Chapter 24). In addition, “darkened” syrups can leave a bitter taste, stringent overtones, and characteristic “corn” flavors in the beer. Finally, there has been concern regarding the chemical composition of acid/enzyme carbon-refined syrups. The production involves exposure to low pH conditions followed by neutralizing with a sodium base. Consequently, residual compounds will form, including high levels of sodium hydroxymethylfurfural (HMF). Although this acid/enzyme carbon-refined process had disadvantages, it was acceptable until the late 1980s, when it was time for changes. At that time, many changes in the brewing and wet-milling industries were occurring, and this led to the development of a new series of liquid adjuncts. The two most important brewing production issues at that time were an increase in the adjunct levels of North American beer (up to 50% of the wort content) and increasing wort gravities as part of high gravity brewing procedures, the latter procedures being employed to ease capacity constraints and to improve brewhouse efficiencies.29, 31 Indeed, the need for capital investment has been largely alleviated by increasing output by as much as 50% through the practice of fermenting wort at gravities of 16ºPlato or higher. Further details regarding the use of liquid adjuncts during high-gravity brewing are in described in Chapter 9.

With the advent of new enzyme liquefaction technologies and downstream multistage enzyme hydrolysis, production of corn syrups with virtually any required carbohydrate (sugar) profile is now possible. This new enzyme liquefaction technology is an immobilized enzyme/enzyme system employing a number of amylase enzymes of bacterial/fungal origin.26

A major stimulator of change in the syrup manufacturing industry was the advent of HFS.32 This is a process in which glucose is isomerized, by immobilized glucose isomerase, to fructose. This reaction typically produces an HFS containing 42% fructose and 58% glucose. HFS is extensively employed in the soft drinks industry as a replacement for cane and beet sugar because fructose is 1.6 times sweeter on the human palate then sucrose, on a molecule for molecule basis. Although HFS does not have a direct application in brewing, it has been used as a sweetener in the production of “beer coolers”—a blend of beer and fruit flavors plus sweetener.

Depending on the sugar spectrum required following the hydrolysis of corn starch, the following matrix of enzymes can be employed: glucoamylase, α-amylase, β-amylase, glucose isomerase, and pullulanase (debranching enzyme). The specificity and efficiency of these processes have been enhanced by using thermotolerant enzymes, developed as a result of genetic manipulation (GM) techniques.28 As a result of the application of this technology, some—but not all—breweries are reluctant to use syrups produced with GM techniques. Table 6.1 shows the carbohydrate profile of a “new generation” high maltose corn syrup (enzyme/enzyme) (MS) compared to a typical all malt wort. The profiles are almost identical. This novel enzyme/enzyme manufacturing process for “tailor-made” syrups permits brewers to introduce liquid adjuncts at any level into the brewing process without changing the carbohydrate profile of the wort. Brewing with these syrups as adjuncts is now routine, and no difficulties in either the brewhouse or fermentation cellar have been reported. (The author can confirm these findings from his own experience.) In addition, syrup (and consequently beer) sodium levels decreased by as much as 60% (with no need to employ sodium hydroxide [or sodium carbonate] to neutralize the starch hydrolysate), in comparison to beer produced with acid/enzyme syrups as an adjunct. This development has been looked upon with favor by the U.S. Food and Drug Administration (FDA) and similar agencies from other countries.

Although these newer generation syrups fulfilled the ongoing needs of the brewing industry, demands were made for syrups with higher fermentabilities, lower glucose, and higher maltose (and maltotriose) concentrations. Studies have led to the production of syrups containing higher levels of fructose (HFS),32 very high levels of maltose (VHMS), and syrups containing a spectrum of different molecular weight dextrins33 (Table 6.1). The use of liquid adjuncts during High Gravity Brewing (HGB) is discussed in more detail in Chapter 9.

6.11 PRIMING SUGARS AND CARBOHYDRATES

These sugars and carbohydrates are used as wort supplements, and syrups are used as priming sugars. A priming sugar (or sugars) is any sugar added to a fermented beer with the principal purpose being to start a secondary fermentation in a tank, cask, bottle, or—more rarely—a keg. The end result is natural carbonation and, usually, flavor development.34 The sugar may be added as a solid but is more often added in liquid (syrup) form just prior to racking the beer into a conditioning tank or final container.

Yeast, which may be added at the same time as the priming sugar(s), takes up these sugars and produces carbon dioxide. This carbonates the beer in the tank, keg, or package. Priming sugars are usually highly fermentable, with the most common being sucrose, glucose, fructose, maltose (rarely), and dextrins (unfermentable). Dextrins are usually added to give a beer body and are often added to low-alcohol products.

6.12 MALTED CEREALS OTHER THAN BARLEY

These cereals are classed by many jurisdictions as adjuncts. They are produced in relatively small amounts. Some are used in brewing European-style beers; others are used in the manufacture of opaque beers, distilled products, foodstuffs, and confectionary. These malts are made from temperate-zone cereals (wheat, rye, triticale, and oats) and also from tropical cereals (sorghum, corn [maize] and rice). Only barley and oat grains in the temperate-zone cereals are husked. Wheat, rye, and triticale are huskless, and this can give rise to malt house problems. Only wheat, rye, and sorghum malts will be discussed in detail here.

6.12.1 Wheat, Rye, and Sorghum Malt

These malts have been prepared on an industrial scale for many years. Most wheat malts used in brewing are pale and lightly kilned. In the United Kingdom, wheat malts may be used in the grist for beers and stouts (at a rate of 3% to 10%) to improve beer head formation and head retention and possibly to enhance the diastatic activity of the grist and the supply of yeast nutrients. Wheat malt is also being used by many brewers in the United States to produce wheat beers, which are part of the craft brewing sector (details in Chapter 22). Wheat malt lacks husks, and this contributes to the way that it is prepared in the grist and how the wort is separated in the brewhouse. In contrast to barley malts, wheat malts contain very little tannin material. In Europe, much larger proportions of wheat malt are used in particular beers. For example, in traditional German and Belgian wheat beers (Weizenbier or Weissbier [white beers]), 75% to 80% of the grist may be wheat malt.35 Although, unlike barley, wheats are not widely developed and selected by breeders for their malting qualities, regular reports appear on the comparative malting characteristics of German wheats.36

The physical and chemical differences between wheat and barley, already discussed, render the malting of wheat a different challenge than barley. The lack of a husk means that it absorbs water more quickly than barley. Consequently, steeping times will be shorter. Also, the wheat grain achieves modification more rapidly than barley, but wheat malt is relatively less well-modified than barley malt. Kilning is conducted at a lower temperature (35ºC to 40ºC air temperature compared to a 70ºC to 80ºC air temperature for pale barley malt). Because wheat contains a higher protein content than typical malting barley, this results in a slightly darker color, even in the palest wheat malt.

Wheat malting is hastened and α-amylase levels are enhanced by the application of gibberellic acid to the germination. Malt extracts can be increased from 82.5% to 87.6%37 with the application of gibberellic acid. However, currently, the use of gibberellic acid during malting is not encouraged. As well as having a high extract, wheat malts are often rich in free amino nitrogen (FAN), which assists fermentation. However, when mashed, wheat malts tend to give slow wort separations, probably due to the pentosans that are present in the wort. This will often give rise to viscous worts. A wide range of malts can be made from wheat including smoked, roasted, and pale malts.

Rye grains are hull-less; consequently, malting rye has all of the problems (milling, ease of damage, etc.) and all of the advantages (rapid water uptake, high potential extract) of wheat. Rye grains are relatively small and thin. Little rye grain is malted for brewing, but rye is malted for use in the production of rye whiskey in Canada. However, even in these circumstances, rye malt is only 5% to 10% of the grist. Nevertheless, rye malts can have very high levels of starch-degrading enzymes, and this makes them attractive to distillers using mashes rich in unmalted cereals, where fermentable extract yield is critical!

Sorghum has been malted for the production of opaque Bantu beers and related products for a long time. For centuries, sorghum has been one of the third most important cereal crops grown in the United States and the fifth most important cereal crop grown in the world. Nigeria is the world’s largest producer of grain sorghum, followed by the United States and India. In developed countries, and increasingly in developing countries such as India, the predominant use of sorghum is as fodder for poultry and cattle. Leading exporters in 2010 were the United States, Australia, and Argentina; Mexico was the largest importer of sorghum.

Sorghum grains are huskless. The grains are variously pigmented, having red, white, brown, yellow, or pink coloration. The internal endogenous structure of sorghum grain is similar to maize. It comprises a single layer of aleurone cells, an outer steely area, and an inner mealy area. Like maize, the embryo of sorghum is large (approximately 10% of the grain’s dry weight), and it contains most of the lipids.

Sorghum germinates rapidly at between 20ºC and 30ºC. Unlike barley, where gibberellic acid will induce the aleurone cells to produce quantities of α-amylase, gibberellic acid in sorghum does not increase α-amylase development. Some cultivars of sorghum have moderate levels of β-amylase, while many others contain low β-amylase levels. Limit dextrinase (de-branching enzyme) (Figure 6.1) and protease activities are found mainly in the endosperm, while carboxypeptidase activities are present mainly in the embryo.

During steeping, formaldehyde (approximately 0% to 1%) was sometimes added to suppress fungal growth, but this practice is now not permitted in most jurisdictions globally38 (details of formaldehyde’s use in brewing are in Chapter 24). When the grain has been steeped at 25ºC for 24 h, it usually contains 33% to 35% moisture. Water is sprayed onto the grain during germination in order to maintain embryo growth and enzyme modification of the endosperm. During germination, extensive amylolytic digestion of starch granules can occur, especially in mealy endosperm areas.

Although starch breakdown in mealy areas of sorghum endosperm can be extensive, cell wall breakdown is limited. This contrasts greatly with cell wall breakdown in the malted barley endosperm. Beer filtration problems in the brewing of sorghum malt have been observed, and this may reflect the possibility that, during malting, localized breakdown of endosperm cell walls may expose portals through which proteases and amylases migrate. During malting, troublesome quantities of β-glucans, pentosans, and proteins may be insufficiently broken down and may be extracted into the wort. Nitrogen solubilization, starch extract development, wort separation, and beer filtration are more limited when beer is produced from sorghum malt rather than from barley malt. Despite the low levels of β-glucans found in sorghum grain, malted sorghum worts of low viscosity can contain troublesome quantities of β-glucan.

Irrespective of commercial enzyme addition, sorghum malts, mashed at 65ºC, produce low extracts. It has been suggested that increased α-amylase stability can result from calcium ion addition and enhanced extract development in sorghum mashes will occur. Although wort viscosities from sorghum malts are lower than those of barley, such low viscosities may not indicate trouble-free beer filtration or beer physical stability. In contrast to barley malt worts, sorghum worts usually contain high percentages of dextrins. The lower wort maltose concentration (approximately 15%) of some sorghum worts reflects the reduced β-amylase activity (diastatic power) and fermentation extract of some sorghum malts. Higher concentrations of high molecular weight α- and β-glucans may aggravate filtration problems with sorghum beers.

Although barley malt is the preferred cereal malt for brewing beer (see Chapter 5), other malted cereals can be employed. Sorghum malt and wheat malt beers have been marketed for use in the production of both traditional and new types of beers. The response of the customer for such products will indicate whether acceptable beers can be produced with minimal quantities of barley malt. An intensive review on the use of unmalted oats and unmalted sorghum in brewing has been published elsewhere.39

6.13 SUMMARY

The primary raw material that provides fermentable sugars for producing beer (and whiskey) is malted barley (Chapter 5). However, there are a number of other fermentable substrates that can be used in association with it. These materials are defined as adjuncts,40, 41 and they can be employed during various stages of the brewing (and distilling) process, including the brewhouse, the kettle, or the fermenter, or blended as a fermented unmalted grain “neutral base” with the fermented barley malt extract.42

REFERENCES

1. Oliver, G., The Oxford Companion to Beer, Oxford University Press, New York, 2011.

2. Goldammer, T., Hops, in The Brewers’ Handbook—The Complete Book to Brewing Beer. KPV, Clifton, VA, pp. 49–72, 2008.

3. Skoog, D.A., West, D.M., Holler, F.J. and Crouch, S.R., Fundamentals of Analytical Chemistry, Brooks/Cole Thomson Learning, Belmont, CA, 2004.

4. Niessen, W.M.A., Current Practice of Gas Chromatography-Mass Spectrometry, CRC Press, Boca Raton, FL, 2001.

5. Niessen, W.M.A., Liquid Chromatography-Mass Spectrometry. 3rd ed., CRC Press, Boca Raton, FL, 2006.

6. Lewicki, J.P., Albo, R.L.F., Alviso, C.T. and Maxwell, R.S., Pyrolysis-gas chromatography/mass spectrometry for the forensic fingerprinting of silicone engineering elastomers, J. Anal. Appl. Pyrolysis, 99: 85–91, 2013.

7. Tenover, F.C., Rapid detection and identification of bacterial pathogens using novel molecular technologies: Infection control and beyond, Clin. Infect. Dis., 44: 418–423, 2007.

8. Guralnik, D.B. and Friend, J.H., Adjuncts, in Webster’s New World Dictionary of the American Language, Collins+ World, Cleveland, OH, p. 18, 1985.

9. Narziss, L., The German beer law, J. Inst. Brew., 90: 351–358, 1984.

10. Verstl, I., That mythical German thing called Reinheitsgebot, Brauwelt Int., 34: 5–9, 2016.

11. Gray, A.S., The Scotch Whisky Industry Review, 36th ed., Sutherlands, Edinburgh, 2013.

12. West, C.J., Barley, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, pp. 85–90, 2012.

13. Myers, R.R. and Smith, R.J., Inherent viscosity of alkaline starch solutions, Methods Carbohydr. Chem., 4: 124–132, 1964.

14. Stewart, G.G. and Murray, J.P., Brewing intensification—Successes and failures, Tech. Q. Master Brew. Assoc. Am., 49: 111–120, 2012.

15. Lekkas, C., Hall, A.E. and Stewart, G.G., Extraction of FAN from malting barley during malting and mashing, J. Am. Soc. Brew. Chem., 72: 6–11, 2014.

16. Holland, C., Rice, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, pp. 695–696, 2014.

17. Taylor, J.R.N., Dlamini, B.C. and Kruger, J., 125th Anniversary review: The science of the tropical cereals sorghum, maize and rice in relation to lager beer brewing, J. Inst. Brew., 119: 1–14, 2013.

18. Andrews, J., A review of progress in mash separation technology, Tech. Q. Master Brew. Assoc. Am., 42: 45–49, 2004.

19. Dornbusch, H., Wheat malt, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 839, 2012.

20. Goode D.L., Wijngaard, H.H. and Arendt, E.K., Mashing with unmalted barley—Impact of malted barley and commercial enzymes (Bacillus spp) additions, Tech. Q. Master Brew. Assoc. Am., 42: 184–198, 2005.

21. Holley-Paquette, M., Sorghum, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 743, 2012.

22. Agu, R.C., Goodfellow, V. and Bryce, J.H., Effect of mashing regime on fermentability of malted sorghum, Tech. Q. Master Brew. Assoc. Am., 48: 60–66, 2011.

23. Ogbonna, A.C., Proteolytic enzymes and protein modification in malting sorghum—A review, Tech. Q. Master Brew. Assoc. Am., 46(3), 1–6, 2009. doi:10.1094/TQ-46-3-0714-01.

24. Holliland, C., Starch, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 775, 2012.

25. Stewart, G.G., Flaked barley, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, pp. 357–358, 2012.

26. Helstad, S., Topics in brewing: Brewing adjuncts—Liquid. Tech. Q. Master Brew. Assoc. Am., 50: 99–104, 2013.

27. Dutton, I., Corn syrup brewing adjuncts—Their manufacture and use, Tech. Q. Master Brew. Assoc. Am., 33: 47–53, 1996.

28. Stewart, G.G., Biochemistry of brewing, in Biochemistry of Foods, Eskin, N.A.M. and Shahidi, F., Eds., Elsevier, Amsterdam, pp. 291–318, 2013.

29. Hardwick, B.C. and Skinner, K.E., Fermentation conditions associated with incomplete glucose and fructose utilization, Tech. Q. Master Brew. Assoc. Am., 27: 117–121, 1990.

30. Hornsey, I., Melanoidins, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 582, 2012.

31. Stewart, G.G., Brewing Intensification, American Society of Brewing Chemists, St. Paul, MN, 2014.

32. Vega, R., Fructose, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 377, 2012.

33. Helstad, S. and Friedrich, J., Flavour characteristics of liquid adjuncts derived from corn, Tech. Q. Master Brew. Assoc. Am., 39: 183–190, 2002.

34. Parkes, S., Carbonation, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, p. 221, 2012.

35. Delvaux, F., Combes, F.J. and Delvaux, R., The effect of wheat malting on the colloidal haze of white beers, Tech. Q. Master Brew. Assoc. Am., 42: 27–32, 2004.

36. Kattein, U. and Narziss, L., 35 years of malting and brewing in Germany—Experience with improvements in quality characteristics of raw materials and changes in technical in maltings and brewhouse, Tech. Q. Master Brew. Assoc. Am., 50: 93–96, 2013.

37. Agu, R.C., Effect of short steeping regime on hull-less barley and wheat malt quality, Tech. Q. Master Brew. Assoc. Am., 49: 82–86, 2012.

38. Nso, E. J., Nanadum, M. and Palmer, G.H., The effects of formaldehyde on enzyme development of sorghum malts, Tech. Q. Master Brew. Assoc. Am., 43: 177–182, 2006.

39. Schnitzenbaumer, B. and Arendt, E.K., Brewing with up to 40% unmalted oats (Avena sativa) and sorghum (Sorghum bicolor)—A review, J. Inst. Brew., 120: 315–330, 2014.

40. Bamforth, C.W., Adjuncts, in The Oxford Companion to Beer, Oliver, G., Ed., Oxford University Press, New York, pp. 11–13, 2012.

41. Hertrich, J., Topics in brewing: Brewing adjuncts, Tech. Q. Master Brew. Assoc. Am., 50: 72–81, 2013.

42. Stewart, G.G., High gravity brewing and distilling—Past experiences and future prospects, J. Am. Soc. Brew. Chem., 68: 1–9, 2010.