Lean Manufacturing Including High Gravity Brewing

Graham G. Stewart

CONTENTS

9.3 Yeast Morphological Changes Induced by High Gravity Worts

9.4 Effect of Proteinase a Secretion and Wort Gravity on Beer Foam Stability

9.5 Influence of Wort Sugar Spectrum and Gravity on Ester Formation

9.6 The Influence of High Gravity Wort (Wash) During Production of Grain Whisky

9.1 LEAN MANUFACTURING

Lean manufacturing or lean production is a management philosophy developed by Toyota.1 This philosophy is renowned for its focus on improving overall customer value and satisfaction. Lean manufacturing ensures that the right improvement is chosen for the relevant reasons without effects on product quality and integrity.2

Lean is a systematic method for the elimination of waste within a manufacturing system. It also takes into account waste created through uneven workloads. The Toyota Production System (TPS) (hence the term Toyotism) was only identified as “lean” in the 1990s.3 TPS is renowned for its focus on reduction of the original seven wastes to improve overall customer value. The steady growth of Toyota from a small company to the world’s largest automaker3 has focused attention on how it has achieved this success.

Toyota’s development of ideas, which later became lean, started at the turn of the twentieth century with Sakichi Toyoda in a textile factory with looms that stopped themselves when a thread broke. This became the seed of automation and Jidoka (providing machines and operatives with the ability to detect when an abnormal condition occurs and to immediately stop work). Toyoda founded the Toyota Motor Corporation, directed the engine casting work, and discovered many problems with the manufacturing. He stopped poor quality repairs by an intense study of each stage in the process. In 1936, Toyota won its first truck contract with the Japanese government and developed the Kaizen continuous improvement process (“change for better”).

Compared to engineering manufacturing industries (such as the automotive industry), these techniques have not been directly applied to the food and beverage industries2 but are currently being actively considered.4 Although they have not been specifically applied to the food and beverage industry, many lean technology concepts are based on achieving improvement with minimal increases in cost. Indeed, the use of such techniques can be applied by any brewing (or distilling) operation no matter what the prevailing financial situation. Many of the concepts have been employed to transform breweries that have been in decline or that might even face closure to intensify operations that require considerable investment.

Lean manufacturing provides a sustainable competitive advantage that will allow a brewery (or distillery) to outperform its competitors. The focus of lean manufacturing is the implementation of continuous improvement systems that can be employed to achieve several goals:1

Beer (and spirit) production has two overlapping primary objectives—to brew quality beer that meets consumer expectations and to produce beer in the most efficient and cost-effective manner. Most stages of brewing, from raw material development to the characteristics of packaging (bottling, canning, and kegging), have evolved into a more efficient and rapid process, and most aspects have resulted in cost savings—directly or indirectly.

The influence of raw materials (including cereals, hops, and water together with processing aids and additives) is considered elsewhere in this volume (Chapters 4, 5, 6, 7, and 10, respectively). For more than 30 years, process optimization and increased efficiencies have been priorities for many brewing and distilling companies.5 Process intensification6 has become part of this endeavor and has focused on increased rates of fermentation and final attenuation, high yeast viability and vitality,7 decreased maturation times, more efficient stabilization and filtration,8 enhanced beer quality and stability,9 and high gravity brewing and distilling, as well as on reduced capital expenditures.10

The overall economic structure of the brewing industry has been under threat for some time.11 This threat has been exacerbated not only by direct inflation related to the brewing process itself, but by the costs associated with the brewing business as a whole (further details appear in Chapter 11). Many of these expenses have increased beyond basic inflation and the cost of financing developments. They have also introduced financial complexities to today’s industry as a whole.

It is beyond the scope of this chapter to discuss and itemize every financial issue that confronts the industry. However, financial pressures and opportunities related to the industry include:

All of the increased costs must be funded from somewhere! A major source of savings to fund the additional commitments detailed here is improved efficiency during the actual brewing process. For many years, lager beer production time has been approximately three to four weeks and longer from grist milling/mashing to packaging. Not counting raw material production times, typically brewing, this includes less than one day for wort production, one week for fermentation, two to three weeks for maturation (aging/lagering/conditioning), and finally, approximately one to three days for stabilization/filtration and packaging. This basic process time model assumes brewing at sales gravity. However, in many brewing operations, this is not the case because concentrated brewing has become increasingly commonplace. High gravity brewing means that the wort is brewed concentrated and is usually fermented and matured at this concentration and then diluted with deoxygenated water to sales gravity (details later).10, 12 This is one example of brewing intensification. There are a number of other examples during brewing that attempt to intensify the process, which are considered in subsequent chapters of this book.

9.2 HIGH GRAVITY BREWING

What is high gravity brewing? It is a procedure that employs wort at a higher than normal concentration and, consequently, requires dilution with water (usually deoxygenated) at a later stage in processing. With this brewing method, increased production demands can be met without expanding the existing brewing, fermenting, maturation, and storage facilities.12

High gravity techniques in both brewing and distilling include a diverse series of processes and exhibit a number of advantages and disadvantages. The advantages are numerous. e.g., highly concentrated wort produced from this process can be diluted to produce an array of products with different gravities, bitterness units, residual extracts, and color or sweetness. There can be greater use of adjuncts13 and, consequently, a reduction in raw material costs due to less use of malt14 (further details later in this chapter and in Chapters 5 and 6). Although widely debated,12 there is also an improvement in the physical and flavor stability of beer and in overall quality. Perhaps the most important aspect is the significant increase in overall productivity that can be attained without significant capital expenditure on existing facilities.10 High gravity brewing can also reduce the water and energy required in a brewhouse per unit of sales-gravity beer produced—areas that are very important in an era of sustainable development.12 In addition, high gravity procedures can result in reductions in labor, cleaning, and effluent costs. Finally, high gravity wort conditions increase alcohol production per unit of fermentable extract as a result of reduced yeast growth because of increased osmotic pressure in the high gravity wort and, consequently, the conversion of more wort sugars to alcohol.10

Although the high gravity process has a number of advantages, inevitably, there are disadvantages. Due to the more concentrated mash (increased ratio of carbohydrate to water), there is a decrease in brewhouse material efficiency (BME). This problem can be overcome by the use of modern mash filters (details in Chapter 11) or kettle syrups (details later in this chapter and in Chapter 6). Also, the more concentrated wort during boiling results in reduced kettle hop utilization. This process challenge can be alleviated by the use of kettle and post-fermentation hop extracts (details in Chapter 7).

One of the major disadvantages of the high gravity brewing process is reduced foam stability (head retention) in the final diluted beer.12 The major reason for this is the greater losses of hydrophobic polypeptides encountered during the brewing process. This problem can be partially overcome by the use of hop extracts, wheat malt, and increased sparging of the mash by either employing a lauter tun or mash filter.15

In addition, when using high gravity techniques, there are difficulties in achieving beer flavor matches with lower gravity beers. This is due (in part) to elevated ester formation (especially ethyl acetate and isoamyl acetate) during the fermentation of high wort16 (Table 9.1). Yeast performance is profoundly influenced by high gravity worts, with specific effects on fermentation, flocculation, and the number of yeast generation cycles during recycling. Further, high gravity worts require greater dissolved oxygen levels at the beginning of fermentation, together with an increased yeast pitching concentration. Finally, specially treated dilution water (low dissolved oxygen and other factors) is required (details in Chapter 4). Beer with low levels of dissolved oxygen is required in order to prevent staling reactions (details in Chapter 20).

Table 9.1 Influence of Wort Gravity on Beer Ester Levels

|

12°Plato |

20°Plato |

|---|---|---|

Ethanol % (v/v) |

5.1 |

5.0 |

Ethyl acetate (mg/L) |

14.2 |

21.2 |

Isoamyl acetate (mg/L) |

0.5 |

0.7 |

Four specific areas related to aspects of high gravity brewing and distilling are worthy of discussion.

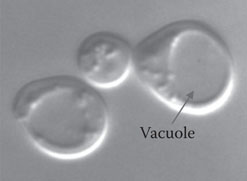

9.3 YEAST MORPHOLOGICAL CHANGES INDUCED BY HIGH GRAVITY WORTS

The vacuole plays an important role in the ability of yeast cells to successfully ferment high gravity worts. The reduction in vacuolar volume at 24 h during normal and high gravity (12 and 20°Plato, respectively) fermentation was consistent with accepted theories of stress effects on vacuolar volume17 and confirmed that a relationship exists between vacuole integrity and yeast viability. The findings also confirmed that wort gravity has a significant negative effect on the yeast cell vacuolar volume of both lager and ale strains during fermentation (Figure 9.1).18

Figure 9.1 The yeast vacuole—the most prominent organelle in a yeast cell.

9.4 EFFECT OF PROTEINASE A SECRETION AND WORT GRAVITY ON BEER FOAM STABILITY

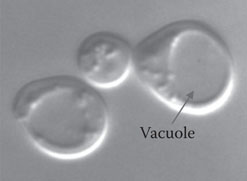

Beer brewed at higher gravities, followed by dilution, has poorer stability compared with similar beers brewed at lower wort gravities.19 Specific hydrophobic polypeptides play an important role in foam formation and stability.20 Iso-α-acids, metal ions, and melanoidins are also important for foam formation and stability.21 The level of hydrophobic polypeptides has been determined throughout the brewing and fermentation of high and low gravity worts (20 and 10°Plato, respectively) using the liquid chromatography method developed by Bamforth20 employing phenyl sepharose. During the brewing process, there was a proportionately greater loss of hydrophobic polypeptides from the 20°Plato than from its 10°Plato counterpart (Figure 9.2). When the high gravity fermented beer was diluted to the 4.5% (v/v) alcohol, equivalent to an undiluted low gravity beer, it contained a level of hydrophobic polypeptides that was less than 50% of the level produced in a low gravity beer (Figure 9.2).

Figure 9.2 Changes in hydrophobic polypeptide levels during the brewing and fermentation of low (10°Plato) and high (20°Plato) worts. Final beer diluted to 4.5% (v/v) alcohol.

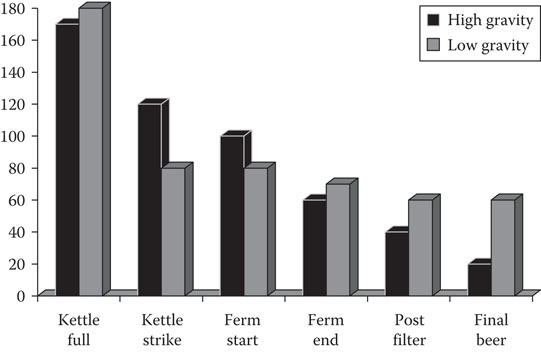

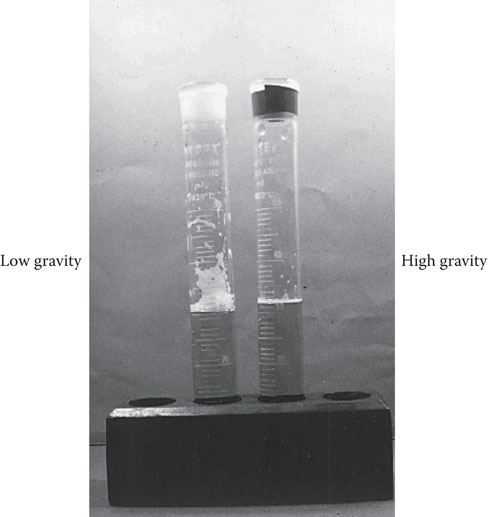

The head retention of the diluted high gravity brewed beer was less than that of the low gravity brewed beer.22 The difference was apparent when both beers were poured into 100 ml measuring cylinders and the time for foam collapse determined. Two minutes after pouring, there was very little foam or cling on the diluted high gravity beer sample, but substantial foam and cling remained on the low gravity sample (Figure 9.3). Four minutes after pouring, differences in the foam stability of the two beer types were even more striking (Figure 9.4).

Figure 9.3 Beer foam collapse characteristics 2 min after pouring—beers produced with low (10°Plato) and high (20°Plato) gravity worts.

Figure 9.4 Beer foam collapse characteristics 4 min after pouring—beers produced with low (10°Plato) and high (20°Plato) gravity worts.

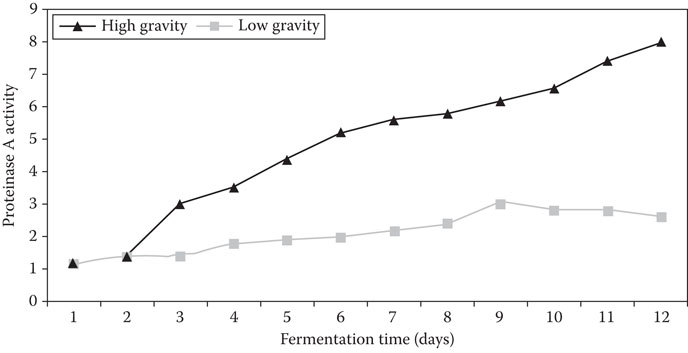

Due to the increasing polyphenol levels in high gravity worts, a disproportionately greater amount of hydrophobic polypeptides is lost in high gravity worts due to hot and cold break precipitation compared with lower gravity wort. At least two factors account for the loss of hydrophobic polypeptides during fermentation.23 First, losses occur due to fermenter foaming. A higher gradient of hydrophobic polypeptides occurs toward the surface. This enhances adhesion of foam-active compounds to the side of the fermenter vessel during transfer into the conditioning vessel. Second, yeast “secretes” proteolytic enzymes into the fermenting wort,24 and these enzymes appear to have a negative effect on the foam stability of the finished diluted beer due to the polypeptide hydrolysis that occurs during fermentation and storage. Proteinase A (PrA) has been shown to increase throughout fermentation (Figure 9.5). Higher amounts of PrA were released during a 20°Plato wort fermentation compared with 10°Plato fermentations. During high gravity wort fermentations, increased stress on the yeast, in the form of elevated osmotic pressure and ethanol concentration, appeared to stimulate PrA secretion into the wort during fermentation,25 A number of other stress factors can promote the release of PrA in brewer’s yeast cultures. The effect of gene deletion that encodes for PrA PEP4 in a lager yeast strain has been studied.26 PrA activity in wort fermented with this mutant was significantly lower than that of the parent strain and, as a consequence, the resulting beer exhibited improved foam stability.

Figure 9.5 The effect of wort gravity on proteinase A release during fermentation of low (12°Plato) and high (20°Plato) gravity worts.

9.5 INFLUENCE OF WORT SUGAR SPECTRUM AND GRAVITY ON ESTER FORMATION

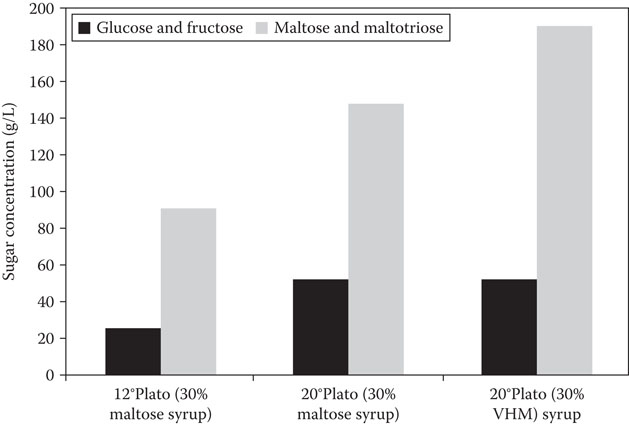

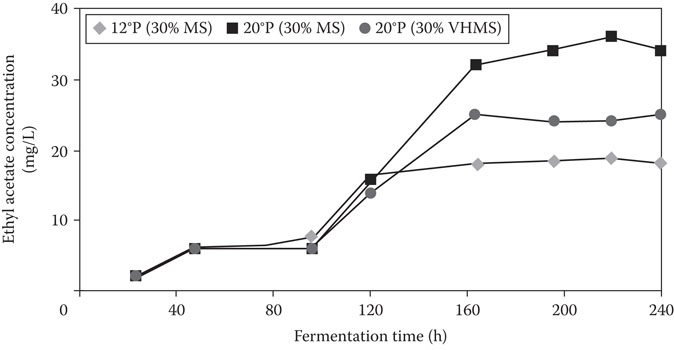

It has already been discussed that one of the disadvantages of high gravity brewing is that fermentation of high gravity worts induces the production of disproportionately higher levels of esters (Table 9.1).16, 28 Varying the wort sugar source has been shown28 to modify the levels of many metabolites, including esters, although the reasons for these differences are unclear. Details of the uptake of wort sugars are discussed in Chapters 8 and 14.

The production of ethyl acetate and isoamyl acetate in maltose-grown cells28 has been shown to be lower than in glucose-grown cells. The reasons for the lower levels of ester production observed with maltose are unclear but could be due to a number of factors:

9.6 THE INFLUENCE OF HIGH GRAVITY WORT (WASH) DURING PRODUCTION OF GRAIN WHISKY

Unmalted grains, such as wheat and maize, are a form of adjunct used in the production of some Scotch and related whisk(e)ys. Scotch whisky has been defined in United Kingdom law since 1909. The current definition is contained in the Scotch Whisky Regulations of 2009 and comes under the auspices of the devolved Scottish Parliament. It replaces the 1988 Westminster Scotch Whisky Act. The regulations state: “Scotch whisky means whisky which has been produced in a distillery in Scotland employing water, malted barley, and yeast to which only unmalted whole grains of other cereals (e.g., corn and wheat) may be added.” The 2009 regulations prohibit the production in Scotland of whisky other than Scotch. Previous legislation (in 1988) had only governed the way that Scotch was produced. In addition, the Scotch Whisky Regulations 2009 have also set rules for the labeling, packaging, and advertising of Scotch whisky. Also, all single malt Scotch whisky has to be bottled in Scotland. The 2009 regulations and the accompanying European Union legislation both specify a minimum sales alcoholic strength of 40% by volume.33

Figure 9.6 Wort sugar profiles.

Figure 9.7 Ethyl acetate concentration in fermenting worts of differing gravities and sugar composition.

There are two distinct types of Scotch whisky, malt and grain, each of which has different characteristics. Malt whisky has a pronounced bouquet and taste and is made exclusively from malted barley and yeast by the pot-still method. Further discussion of malt whisky in this chapter is beyond its scope. However, grain whisky is made from unmalted maize (corn) or wheat, yeast, water, and malted barley in the average proportions of approximately 84% (w/v) maize or wheat and 16% barley malt, although this varies from one distillery to another.34

Blended grain whisky is produced by both batch and continuous fermentation processes. Unlike brewing, yeast is only used for one fermentation cycle and is purchased (in cream, cake, or dried form) usually (but not always) from a baker’s yeast supplier.35 The yeast is typically grown on a molasses-based medium. To acclimatize (liven) the yeast to a cereal-based fermentation environment, it is incubated in grain wort in a “bub” yeast vessel for 24 h. This acclimated yeast is incubated with grain wort (also called wash) in a continuous process fermenter (also termed a washback) in flow-through mode at 30°C to 32°C for approximately 36 h. When steady state has been established, the rate of wort addition is in balance with the rate at which the fermented wort leaves the fermenter into a holding tank, prior to distillation in a continuous (Coffey) process still (Figure 9.8).

Figure 9.8 Coffey still employed for the continuous distillation of grain whisky.

A Scottish grain distillery, for a number of years, successfully fermented 21°Plato grain wort that yielded 11% (v/v) alcohol in the fully fermented wort. However, without warning, problems began to arise and the alcohol yield decreased to 9.6% (v/v) due to incomplete utilization of maltose and, particularly, maltotriose. This equated to a reduction in alcohol yield from 385 to 370 l/t of grain. In an attempt to overcome this problem, the original gravity of the wort was reduced to 19°Plato (Table 9.2). This resulted in complete fermentation of the wort, with no residual maltose and maltotriose. However, as a consequence of this wort concentration decrease, the distillery’s overall alcohol yield was reduced below budgeted productivity levels. The reasons for the abrupt deterioration in yeast efficiency with regard to the uptake of maltose and maltotriose are still unclear. It would appear that 21°Plato wort exerts stress effects on the pitching yeast, with inhibitory consequences on maltose and, particularly, maltotriose uptake. Stress effects on sugar uptake, especially maltose and maltotriose, have been described previously.36, 37 The exact reasons for this inhibition are unclear, but the fact that maltose and maltotriose require energy (active transport) to be taken into the yeast cell cannot be ignored. Details of sugar uptake (both passive and active) by yeast can be found in Chapters 8 and 14.

Table 9.2 Fermentation Characteristics of 19°Plato and 21°Plato Grain Worts During 2008

|

Alcohol (v/v) |

Residual Maltose (g/L) |

Residual Maltotriose (g/L) |

|---|---|---|---|

21°Plato wort a |

9.6 |

5.8 |

19.6 |

19°Plato wort |

10.2 |

4.3 |

6.5 |

a Problems with distiller’s dried grain (DDG) consistency in 2007 and 2008.

9.7 CONCLUSIONS

In addition to high gravity brewing techniques, there are a number of other brewing unit processes to which lean technology systems have been applied. These include batch and continuous fermentation systems, centrifugation, and maturation, including diacetyl management and the control of inorganic and organic sulfur compounds in beer. These processes, including applying lean manufacturing to them, have been considered in Chapters 8, 14, and 15.

REFERENCES

1. Holweg, M., The genealogy of lean production, J. Oper. Manag., 25: 420–437, 2007.

2. Krafcik, J.F., Triumph of the lean production system, Sloan Manage. Rev., 30: 41–52, 1988.

3. Bailey, D., Automotive News calls Toyota world No 1 car maker, Reuters.com. 2008.

4. Dudbridge, M., Handbook of Lean Manufacturing, Wiley, New York, 2011.

5. Stewart, G. and Murray, J., A selective history of high gravity and high alcohol beers, Tech. Q. Master Brew. Assoc. Am., 47(2): 1–6, 2010. doi:10.1094/TQ-47-2-0416-01.

6. Stewart, G.G., and Murray, J., Brewing intensification—Successes and failures. Tech. Q. Master Brew. Assoc. Am., 49: 111–120, 2012.

7. Stewart, G.G., Bryce, J.H., Cooper, D.J., Monagas M., and Younis, O., High gravity brewing: Its influence on beer and yeast quality, Proc. 7th Inst. Brew. Conv. Africa Section, pp. 100–110, 1999.

8. Leiper, K.A., Stewart, G.G., and McKeown, I.P., Beer polypeptides and silica gel, Part I. Polypeptides involved in haze formation, J. Inst. Brew., 109: 57–72, 2003.

9. Stewart, G.G., High gravity brewing and distilling—Past experiences and future prospects, J. Am. Soc. Brew. Chem., 68: 1–9, 2010.

10. Stewart, G.G. (Ed.), High-gravity brewing, in Brewing Intensification. American Society of Brewing Chemists, St. Paul, MN, pp. 13–92, 2014.

11. Stewart, G.G., Biochemistry of brewing, in Biochemistry of Foods. Eskin, N.A.M. and Shahidi, F., Eds., Elsevier, New York, pp. 291–318, 2012.

12. Murray, C.R. and Stewart, G.G., Experiences with high gravity lager brewing, Birra Malto, 44: 52–64, 1991.

13. Pfisterer, E., and Stewart, G.G., High gravity brewing, Brew. Guard., 51: 34–42, 1976.

14. Briggs, D.E. (Ed.), The principles of mashing, in Malts and Malting, Blackie Academic and Professional, London, pp. 229–244, 1998.

15. Bryce, J.H., Cooper, D., and Stewart, G.G., High gravity brewing and its negative effect on head retention, Proc. Eur. Brew. Conv. Congr., Maastricht, IRL Press, Oxford, pp. 357–365, 1997.

16. Anderson, R.G., and Kirsop, B.H., Quantitative aspects of the control of oxygenation of acetate ester concentration in beer obtained from high-gravity wort, J. Inst. Brew., 81: 286–301, 1975.

17. Pratt, P.L., Bryce, J.H., and Stewart, G.G., The yeast vacuole—Its role during high gravity wort fermentations, J. Inst. Brew., 113: 55–60, 2007.

18. Pratt, P.L., Bryce, J.H., and Stewart, G.G., The effects of osmotic pressure and ethanol in yeast viability and morphology, J. Inst. Brew., 109: 218–228, 2003.

19. Cooper, D.J., Stewart, G.G., and Bryce, J.H., Yeast proteolytic activity during high and low gravity wort fermentations and its effect on head retention, J. Inst. Brew., 106: 197–201, 2000.

20. Bamforth, C.W., The foaming properties of beer, J. Inst. Brew., 93: 370–383, 1985.

21. Roberts, T.R., and Wilson, R.J.H., Hops, in Handbook of Brewing, 2nd Ed., Priest, F.G. and Stewart, G.G., Eds., Taylor and Francis, Boca Raton, FL, pp. 177–279, 2006.

22. Cooper, D.J., Stewart, G.G., and Bryce, J.H., Hydrophobic polypeptides extraction during high gravity mashing—Experimental approaches for its improvement, J. Inst. Brew., 104: 283–287, 1998.

23. Brey, S.E., Bryce, J.H., and Stewart, G.G., The loss of hydrophobic polypeptides during fermentation and conditioning of high gravity and low gravity brewed beer, J. Inst. Brew., 108: 424–433, 2002.

24. Brey, S.E., de Costa, S., Rogers, P.L., Bryce, J.H., Morris, P.C., Mitchell, W.J., and Stewart, G.G., The effect of proteinase A on foam-active polypeptides during high and low gravity fermentation, J. Inst. Brew., 109: 194–202, 2003.

25. Brey, S.E., Bryce, J.H., Higgins, V.J., Rogers, P.J., and Stewart, G.G., Expression activities and generation of yeast proteases—Minimizing the impact on beer foam and stability, Proc. Eur. Brew. Conv. Congr., Dublin, CD Fachverlag Hans Carl, Nürenberg, paper No. 46, 2003.

26. Hao, J., Dong, J., Speers, R.A., Shen, W., Shan, L., Fan, W., Li, Q., Gu, G., and Chen, J., Construction of a single PEP 4 allele deletion in Saccharomyces carlsbergensis and a preliminary evaluation of its brewing performance, J. Inst. Brew., 114: 322–328, 2008.

27. Stewart, G.G., Hill, A.E., and Russell, I., 125th anniversary review: Developments in brewing and distilling yeasts, J. Inst. Brew., 119: 202–220, 2013.

28. Younis, O.S., and Stewart, G.G., Sugar uptake and subsequent ester and alcohol production in Saccharomyces cerevisiae, J. Inst. Brew., 104: 255–264, 1998.

29. Stewart, G.G., Recent developments in the characterization of brewery yeast strains, Tech. Q. Master Brew. Assoc. Am., 9: 183–191, 1972.

30. Thurston, P.D., Quain, D.E., and Trubb, R.S., Lipid-metabolism and the regulation of volatile ester synthesis in Saccharomyces cerevisiae, J. Inst. Brew., 88: 90–96, 1984.

31. Stewart, G.G., Lyness, C.A., and Younis, O.S., The control of ester synthesis during wort fermentation, Tech. Q. Master Brew. Assoc. Am., 36: 61–66, 1999.

32. Younis, O.S., and Stewart, G.G., The effect of malt wort, very high gravity malt wort and very high gravity adjunct wort on volatile production in Saccharomyces cerevisiae, J. Am. Soc. Brew. Chem., 52: 38–45, 1999.

33. Gray, A.S., The Scotch Whisky Industry Review, 36th ed., Sutherlands, Edinburgh, 2013.

34. Bringhurst, T., and Brosnan, J., Scotch whisky: Raw material selection and processing, in Whisky: Technology, Production and Marketing, Russell, I. and Stewart, G.G., Eds., Elsevier, Amsterdam, pp. 49–112, 2014.

35. Jenkins, D.M., Powell, C.M., and Smart, K.A., Dried yeast: Impact of dehydration and rehydration on brewing yeast DNA integrity, J. Am. Soc. Brew. Chem., 68: 132–138, 2010.

36. Younis, O., and Stewart, G.G., The effect of wort maltose content on volatile production and fermentation performance in brewing yeast, in Brewing Yeast Fermentation Performance, Smart, K., Ed., Blackwell Science Publications, Oxford, pp. 336–341, 2000.

37. Zheng, X., D’Amore, T., Russell, I., and Stewart, G.G., Factors influencing maltotriose utilization during brewery wort fermentations, J. Am. Soc. Brew. Chem., 52: 41–47, 1994.