The circular industrial economy manages the stocks of manufactured objects after the point of sale, which are controlled by the owner-users (called the era of ‘R’), and the stocks of manufactured materials, controlled by economic actors recovering resources (called the era of ‘D’). A mature circular industrial economy will integrate the two domains and the linear industrial economy into one single loop, with the use value replacing the exchange value as the central economic value. A shift to such a mature circular industrial economy would substantially reduce greenhouse gas (GHG) emissions and increase the number of jobs.

3.1 Shifting from a circular society to a circular industrial economy

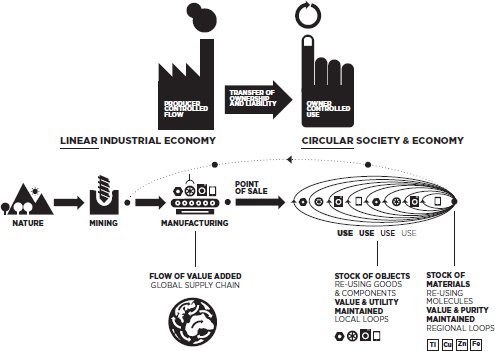

Early man lived in a circular society of scarcity driven by necessity, which still exists in industrially less developed regions of the world. A circular economy manages stocks of assets with the objective of maintaining their value in both qualitative and quantitative terms for as long as possible in a monetarised world. Owner-users of objects and resources are in control in the circular society and economy (Figure 3.1).

Figure 3.1 The characteristics of the linear industrial economy and the circular society and economy

Clashes between circular and linear systems are frequent, for example when indigenous people living in and from natural habitats – a high-value long-term capital or stock – are confronted with logging companies and geologists searching for oil or mineral deposits that can be rapidly industrially exploited. The latter will produce monetarised revenue only for a limited period of time, for these high-value producer-controlled flow processes will deplete the natural and cultural capital, destroying the (non-monetarised) stocks.

The circular economy is thus about maximising the use value of stocks within the vision of a sustainable society, encompassing stocks (assets, capitals) of natural, human (work and acquired skills), cultural (material and immaterial), financial and manufactured nature – objects and materials – through an economic lens. The latter is key as it focuses on economic value, which in turn introduces ownership and liability – notions which do not exist in the circularity of nature.

The circular industrial economy focuses primarily on the stocks of manufactured objects after the point of sale controlled by the owner-user, and second on the stocks of manufactured materials. Today, the circular industrial economy is complementary to the linear industrial economy, which produces the objects that form the stocks of the circular industrial economy. In a mature circular industrial economy, production becomes an integrated part of it (Figure 3.3). Mining industries may feel left out in a circular industrial economy, yet could occupy the driver’s seat if they shift to renting molecules in a Performance Economy (see Chapter 8) instead of selling materials.

In a 2018 report entitled ‘From waste to resource productivity, evidence and case studies’, the UK Government Chief Scientific Advisers state that: ‘waste is actually an enormous opportunity. Much of it is a potential resource that can be recovered and reused in a huge number of ways’ (UK OGL 2017).

3.2 Analysing the circular industrial economy

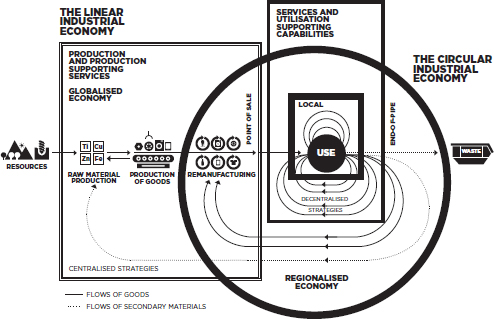

The circular industrial economy manages stocks of manufactured objects with the objective to maintain their value and utility as high as possible for as long as possible; and stocks of molecules with the objective to maintain their highest purity and value for as long as possible. The probably first graphic presentation of the circular industrial economy dates from 1991 (Stahel 1991) and is reproduced schematically in Figure 3.2.

This early diagram already clearly distinguishes three key domains of the circular industrial economy:

- in the circle, the loops of managing the utilisation or use phase of stocks of manufactured objects and their components, by maintaining the value and quality of infrastructure, buildings, investment goods, equipment and durable consumer goods in a local or regional economy;

- in the small square, the local use-focused Performance Economy;

- the hatched line of flows of used materials returning to the raw material producer to recover molecules and atoms in a globalised economy.

The first two domains, focused on the utilisation phase of manufactured objects, open a number of new industrial opportunities and strategies, which are of less interest to the linear industrial economy as they are service activities, which are considered non-productive.1

The opportunities include for the:

- first domain: service-life extension of goods, through reuse, repair, remanufacture and technological upgrading of goods and components (in the following called era of ‘R’);

- second domain: long-life goods, multifunctional goods, and such systems solutions as selling goods as a service (rental, leasing), shared, common and multiple use, selling quality monitoring instead of replacement products (in the following called Performance Economy);

- third domain: recovery of molecules and atoms, in the 1991 report this domain was structured under recycling of clean production scrap, pure material ‘end-of-pipe’ waste and mixed end-of-pipe waste (in the following called era of ‘D’).

The shift from an artisanal local to an industrial regional circular economy started in the second half of the twentieth century with the remanufacture of one-off objects to ‘as good as new’ condition by Small and Medium Sized (SME) workshops, as a service for owners of the objects. Then independent service companies specialised in remanufacturing mass-produced equipment, such as automotive components and vending machines, appeared, followed by fleet managers – owner-users of large stocks of equipment, such as armed forces, railways and airlines – who developed their own maintenance, repair and remanufacture activities, including technologies, tools and methods to improve remanufacture and enable technological upgrading to ‘better than new’ quality.

In the last decade of the twentieth century, Original Equipment Manufacturers (OEM) of photocopiers (Xerox Corp.), truck engines (Caterpillar) and car engines and gearboxes (Volkswagen) pioneered remanufacture with technological upgrading as new industrial strategy, combined with buying back the broken and reselling the remanufactured objects (Caterpillar, Volkswagen), or by selling goods as a service (Xerox selling customer satisfaction).

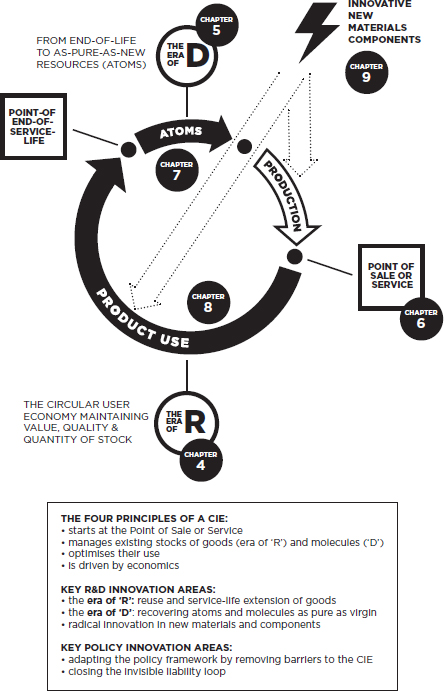

In a mature circular industrial economy, the domains of objects and materials become integrated into one single loop, which also integrates the linear industrial economy supplying innovative new materials and components. Figure 3.3 shows this mature circular industrial economy by using a backcasting approach. ‘Backcasting’ is the opposite of forecasting; the observer defines the result that he wants to achieve, puts himself in this future position and then analyses opportunities and risks looking back. For ease of reading, links to the following chapters are added. Such a circular industrial economy has the potential to become the industrial default option of a sustainable society.

The macro-economic impact of such a mature circular industrial economy has been researched pertaining to the Czech Republic, Finland, France, the Netherlands, Poland, Spain and Sweden by Anders Wijkman and Kristian Skanberg. In their 2016 study, they have calculated that a nation-wide shift to a circular industrial economy would reduce greenhouse gas (GHG) emissions by 66 per cent and increase the number of jobs at national level by more than 4 per cent (Wijkman and Skanberg 2016). This reduction of 66 per cent is way above any figures discussed in the political agenda of slowing global warming, such as the COP 21 conference in Paris. Conference of Parties (COP) meetings are organised under the leadership of the UN with the aim to find political solutions to stop global warming. COP 24 took place in Katowice in December 2018.

A mature circular industrial economy is intertwined with the linear industrial economy in two ways, the latter serving to:

- upgrade existing stocks by introducing innovative materials and components; and

- replace stocks that have become technically or fashion-wise obsolete or have been destroyed.

In fact, the linear industrial economy becomes one of the segments of the big loop of a mature circular industrial economy.

3.3 Some principles underlying the circular industrial economy

The circular economy is a better economy because it uses resources more efficiently. Maintaining the value and utility of stocks for the longest period of time, the key feature that distinguishes the circular industrial economy from the linear industrial economy introduces the ‘Factor Time’ – no limits – into economics, ultimately also with regard to liability (see Figure 8.5).

By extending the service-life of objects and materials, the circular economy reduces the speed of resource flows through the economy and directly impacts the production volumes and end-of-pipe waste volumes of the linear industrial economy: in the saturated markets of industrialised countries, doubling the service life of goods halves both production and waste volumes.

Making the circular industrial economy the default option of a sustainable society will be facilitated by behavioural shifts, such as stewardship replacing ownership, and personal bottom-up motivation – Saint-Exupéry’s longing for the sea – complementing top-down command-and-control legislation. Adapting policy frameworks to reflect the changed objectives of managing stocks instead of flows, and of maintaining the values of stocks instead of creating value added in production, may be the biggest challenge for governments and thus promises to become a driver of sustainable competitiveness between nations.

The separate silo-liabilities for take, make, sell, use, dispose and manage waste of the linear industrial economy will gradually have to give way to an overall stewardship and even liability for maintaining stocks at their highest value. A mature circular industrial economy will need a ‘stewardship value’ method to monitor changes in the quality and quantity of stocks over time, which is distinct from the ‘supply chain management’ method of the linear industrial economy, used to minimise production costs up to the point of sale. Supply chain management is the active management of supply chain activities from product development, sourcing, production and logistics to the point of sale, as well as the information systems needed to coordinate these activities.

3.4 Which external factors drive the circular industrial economy?

A number of external factors fuel the growth of the circular industrial economy. Urban regions may run out of landfill sites, for instance for construction waste, and favour the transformation of buildings instead of their demolition; or policymakers may push for lower dependency on resource imports or waste exports for political reasons, and as a result promote or legislate longer service-lives of objects. Individuals may develop increased attitudes of caring for objects for sentimental or status reasons – witness the rapidly growing number of vintage vehicles – or nations could emphasise the role of cultural heritage to maintain political stability.

The result will be increasing business volumes of reuse, repair and remanufacture, outpacing the capacity of local SMEs, enabling economies of scale and leading to regional circular industrial economies with more industrialised processes – witness the textile leasing sector – and to manufacturers entering the market for circular industrial economy services. These newcomers could learn from existing fleet managers, such as railways and airlines, which is also an obvious learning pool for business schools (Scott and Stahel 2013).

An emerging external factor is ‘government liability’ claims by groups of citizens, attacking the fact that governments are not taking actions to fulfil their promises made under the COP 21 agreement to limit global warming to 2°C in the near future. Activities of the circular industrial economy would qualify as CO2 compensation measures to fight off these claims in court (see Chapter 10 for details).

3.5 The value fork

Within the circular industrial economy, there are differences in the tasks and values between the two key domains of maintaining the value and utility of stocks of manufactured objects (the era of ‘R’) and maintaining the value and quality (purity) of stocks of molecules and atoms (the era of ‘D’).

These differences need to be taken into account with regard to ownership and control. The era of ‘R’ is controlled by owner-users, both individuals and corporates; the era of ‘D’ is controlled by the economic actors in charge of end-of-service-life objects.

- The era of ‘R’ can appear as inhomogeneous because the stock of goods in use is geographically dispersed, of a high diversity and because ‘R’ activities reach from local ones for tailor-made objects, to the regional remanufacture of mass-produced goods.

- To enable the best value preservation of stocks of objects, owner-users in the era of ‘R’ should have the right to reuse and repair objects as long as they see fit. As the technical complexity of objects increases, this right is increasingly restrained by producers (OEMs), through such strategies as premature product obsolescence and technical incompatibility of new objects with existing stocks.

- The era of ‘D’ is a suitable case for material innovation and technology solutions to sort high-volume low-value end-of-service-life materials, commonly referred to as ‘waste’, and turn it into molecules ‘as good as virgin’.

- To enable the best value preservation of stocks of molecules, owners of materials embodied in end-of-service-life objects should have a duty to sort and de-link the materials in order to recover molecules of highest purity. In the case of fugitive materials, such as plastics in the oceans, objects could be commercialised through rent-a-molecule strategies instead of being sold, or producers forced to accept an Extended Producer Liability (EPL, see Chapter 6).

But at the end of a service-life of goods, who decides which of these two options should be given preference? And on which criteria should this decision be based?

The circular industrial economy is about economics; the overarching principle should therefore be economics! Environmental and social benefits will be a result, but only exceptionally the decision criteria.

A simple economic rule says that:

The use value of a product is higher than the sum of the value of the materials it is made of.

The manufacturing principle of value added is living proof of this rule, as the market value per unit of weight increases from raw material to manufactured component to finished product. In a mature circular industrial economy, solutions in the era of ‘R’ should therefore be preferred over solutions in the era of ‘D’. Product use optimisation is clearly more profitable for the product owner than selling the product for scrap to recover atoms and molecules (see Figure 5.2).

But the end of the service-life of objects falls into a control vacuum. The new owners of used objects – ‘recyclers turned resource managers’ – act under legal and time pressure and their knowledge and business contacts are mostly in the era of ‘D’, not ‘R’. For mobile objects, the short-cuts of shredding, incineration and landfill are often the easy and quick way in waste management, but destroy the value and utility of stocks.

The disassembly of objects into components and clean fractions of materials, followed by their remarketing, is labour and knowledge intensive and for many economic actors unknown territory, ‘the road not taken’ (Frost 1916).

This problem is even more acute for immobile objects, such as infrastructure and buildings. Buildings, which no longer serve a purpose or cannot be transformed or adapted for new uses, could at least partly be dismantled and their components reused, but time pressure is often the dominating factor in demolishing built structures. They are blown up or smashed to bits, and the resulting waste used at the lowest value, for instance in road construction.

Yet about 80 percent of the material and energy resources initially spent to build a structure are embodied in the load-bearing structure. These resources are preserved in the reuse and repair options of the era of ‘R’, but mostly lost in the era of ‘D’.

Designing buildings as modular systems of standardised components, which can be reused after dismantling, is part of an emerging trend of designing building components for a multiple life in the era of ‘R’. Considering infrastructure and constructions as material banks to confront potential problems of resource supply in the future is a new trend in the era of ‘D’.

3.6 Innovation challenges in the circular industrial economy

These challenges are of a holistic nature and concern economic actors as much as policymakers.

The era of ‘R’ is the best known part of the circular industrial economy, but spreading the knowledge to boardrooms and classrooms, academia and professional training institutions and public procurement agencies is wanting.

The era of ‘D’ is a largely unexplored Research & Development domain, with no national borders. Many innovative solutions will be patentable and provide a long-term competitive advantage to its finders (Chapter 9).

Exploiting the potential of systems solution and the corresponding innovative techno-commercial business models of the Performance Economy is an opportunity ignored, or the changes of their implementation feared, by many corporate actors.

National policies to holistically exploit the social, ecologic and economic opportunities inherent in the circular industrial economy are rare, partly because policymaking is organised in silos, similarly to academia (scientific disciplines), macro-economy (industrial sectors) and micro-economy (departments in a company). But innovative sustainable solutions are mostly multi-disciplinary and multi-sectoral – and need a new policy thinking outside the box.

China released a Circular Economy Promotion Law in 2008, which was enforced in 2009 (Stahel 2009; Zhu 2016). Since then, the Party Congress of the People’s Republic of China sets new circular economy targets every year within its Five Year Plan during the annual Congress. By comparison, the EU Waste Directive of 2008, which had waste prevention through reuse and service-life extension as its priority strategy, was never transferred into national legislation by most EU Member States. The Framework Programme FP7 of the European Union, Horizon 2020, is also an effort to catch up.

In 2017, researchers at the Institute of Sustainable Development and Management at Tongji University in Shanghai, People’s Republic of China, published a working model of sustainability science, consisting of three cycles: the circulation of wastes, the circulation of products, and the circulation of services, corresponding to the era of ‘D’, the era of ‘R’ and the Performance Economy in this book (Zhu et al. 2017). Today, the People’s Republic of China may have become the leading country in pursuing the circular industrial economy on a scientific level.

References

Frost, David (1916) Mountain interval. Henry Holt, New York.

Scott, Jonathan T. and Stahel, Walter R. (2013) The sustainable business workbook: Waste elimination. Greenleaf Publishing, Sheffield.

Stahel, Walter R. (1991) Waste minimization case studies for three products. U.S. EPA, R&D Office, Washington, DC. Translated from the 1991 report ‘Langlebigkeit und Materialrecycling’ for the Ministry of the Environment Baden-Württemberg, Stuttgart.

Stahel, Walter R. (2009) Chinese translation of The performance economy, first edition 2006, published in Simplified Mandarin, translated by Dr Zhu Dajian.

UK OGL (2017) From waste to resource productivity, evidence and case studies. The UK Government Office for Science, London.

Wijkman, Anders and Skanberg, Kristian (2016) The circular economy and benefits for society,, jobs and climate clear winners in an economy based on renewable energy and resource efficiency. The Club of Rome, Winterthur. www.clubofrome.org/wp-content/uploads/2016/03/The-Circular-Economy-and-Benefits-for-Society.pdf, accessed 20 March 2019.

Zhu, Dajian (2016) Circular economy: a new economic model for China and the world. Les cahiers du Comité Asie de l’Anaj-Ihedin.

Zhu, Dajian, Han, Chuanfeng and Zhang, Chao (2017) A working model of sustainability science. Nature, vol. 544, no. 7651.