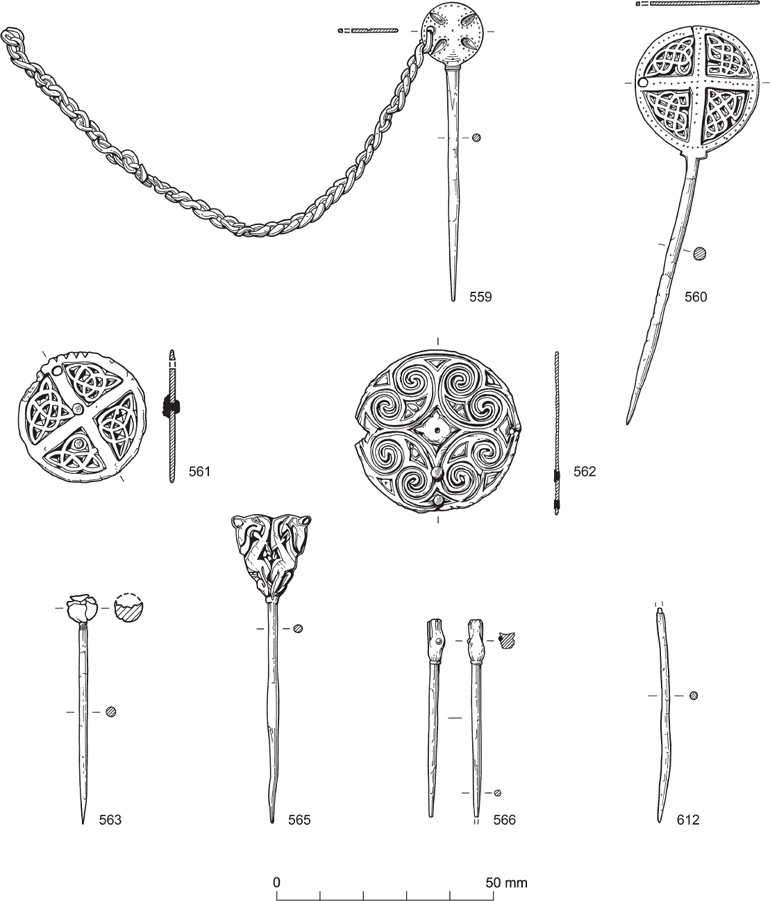

FIG. 1.26. Copper alloy pins of Types 5, 6, 7, 8, 9 and LIN1. Scale 1:1.

Complete, spiral head, shank section unvaried 401 |

|

451 |

Incomplete spiral-headed, one spiral and tip of shank broken off, shank section unvaried 401 |

452 |

Complete, slightly bent over spiral head, three incised grooves below head, shank section unvaried 401 |

453 |

Complete, well made spiral head, shank section unvaried 401 |

454 |

Complete, well made spiral head, shank section unvaried 401 |

TYPE 402 SPIRAL-HEADED, SHANK SWOLLEN (FIG. 1.25) |

|

455 |

Complete, spiral-headed, irregularly shaped, shank bent up, slightly swollen 402 |

456 |

Complete apart from tip of shank which has broken away, spiral head, one spiral incompletely joined to side, shank swollen towards tip 402 |

457 |

Incomplete, spiral-headed, one spiral broken off, shank swollen 402 |

TYPE 411 SPIRAL-HEADED, SHANK SECTION UNVARIED, DECORATION (FIG. 1.25) |

|

458 |

Incomplete, spiral-headed, one spiral broken off, decorative grooves on shank just below base of spiral head, shank section unvaried 411 |

Type 5 pins – headless (FIG. 1.26) |

|

TYPE 501 HEADLESS, SHANK SECTION UNVARIED (FIG. 1.26) |

|

459 |

Complete, headless, shank section unvaried (501) |

460 |

Complete, headless, shank section unvaried. Analysis: grey deposit around upper end of shank – XRF indicated solder or preferential corrosion (501) |

461 |

Complete, headless, shank section unvaried. Analysis: greyish deposits around upper end – XRF indicated possible preferential corrosion or solder (501) |

462 |

Complete but in two fragments, top appears headless though corrosion makes top unclear, shank section unvaried (501) |

463 |

Complete, headless, shank section unvaried (501) |

464 |

Complete but in two fragments, headless, shank section unvaried (501) |

465 |

Complete, headless, shank section unvaried (501) |

466 |

Complete, headless, shank section unvaried (501) |

467 |

Complete, headless, shank section unvaried (501) |

468 |

Complete, headless, shank section unvaried. Analysis: greyish deposits around upper end – XRF indicated possible preferential corrosion or solder (501) |

469 |

Complete, headless, shank section unvaried (501) |

470 |

Complete, headless, shank section unvaried (501) |

471 |

Complete, headless, shank section unvaried (501) |

472 |

Complete, headless, shank section unvaried. Analysis: greyish deposits around upper end – XRF indicated possible preferential corrosion or solder (501) |

473 |

Complete, headless, shank narrowing slightly at top. Analysis: grey deposits around upper end – XRF did not confirm solder (501) |

474 |

Complete, headless, shank section unvaried. Analysis: deposits around upper end, XRF did not confirm solder (501) |

475 |

Complete, headless, top pointed, shank section unvaried. Analysis: white-metal patches at upper end – XRF did not indicate solder or plating (501) |

476 |

Headless, upper end slightly pointed, shank tip faceted and slightly narrowed. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (501) |

TYPE 502 HEADLESS, SHANK SWOLLEN |

|

477 |

Complete, headless, shank swollen towards tip (502) |

478 |

Complete, headless, shank slightly swollen towards tip (502) |

479 |

Incomplete, headless, shank appears swollen towards tip. Analysis: white-metal patches at upper end – XRF did not indicate solder or plating (502) |

480 |

Complete, headless, with triangular notch cut into side of shank just below head, swollen shank. Analysis: white metal around upper end, XRF did not confirm solder (502) |

481 |

Complete, headless, possible traces of solder around top, shank swollen towards tip. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (502) |

TYPE 503 HEADLESS, SHANK HIPP ED/SQUARE AT TIP |

|

482 |

Complete, headless, shank hipped towards tip. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (503) |

TYPE 510 HEADLESS, SHANK FO RM UNKNOWN, GROO VES |

|

483 |

Incomplete, lower end of shank broken away, headless, groove just below top (510) |

484 |

Incomplete, lower part of shank broken off, headless, faint traces of grooves just below top (510) |

TYPE 511 HEADLESS, SHANK SECTION UNVARIED, GROO VES (FIG. 1.26) |

|

485 |

Complete, headless, three grooves just below top, shank section unvaried. Analysis: white metal around upper end – XRF unable to identify solder or plating (511) |

486 |

Complete, headless, top corroded but traces of groove just below top, shank section unvaried (511) |

487 |

Complete, headless, two deep grooves, shank section unvaried (511) |

488 |

Headless, four grooves just below top, shank section unvaried. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

489 |

Complete, headless, eight grooves just below top, shank section unvaried (511) |

490 |

Incomplete, part of separate (?) lead alloy head (not analysed) and headless shank with three grooves just below top, shank section unvaried (511a) |

491 |

Complete, headless, two grooves just below top, shank section unvaried (511) |

492 |

Complete, headless, two grooves just below top, shank section unvaried (511) |

493 |

Complete, three grooves around shank just below top, shank section unvaried. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

494 |

Complete, headless, two grooves below top, shank section unvaried (511) |

495 |

Complete, tall narrow conical head, top appears flat but attached bone fragment obscures, two grooves well spaced, shank section unvaried (511) |

496 |

Complete, tall narrow conical head, top flat, two grooves, shank section unvaried. Analysis: grey deposits around upper end – XRF indicated possible preferential corrosion or solder (511) |

497 |

Complete, headless, three deep grooves just below top, shank section unvaried. Analysis: at upper end: XRF indicated possible preferential corrosion or solder (511) |

498 |

Complete, headless, pointed top, groove just below top, shank section unvaried (511) |

499 |

Complete, headless, two grooves below top, shank section unvaried (511) |

500 |

Complete, headless, three grooves just below top, shank section unvaried (511) |

501 |

Headless but top incomplete, two grooves just below top, shank section unvaried (511) |

502 |

Complete, headless, three grooves just below top, shank section unvaried (511) |

503 |

Complete, headless, two incised grooves just below top, shank section unvaried. Analysis: metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

504 |

Complete, headless, traces of material at top, two grooves just below top, shank section unvaried. Analysis: metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

505 |

Complete, headless, two grooves just below top, shank straight. Analysis – XRF indicated no solder or gilding (511) |

506 |

Headless, two grooves, shank section unvaried (511) |

507 |

Complete, headless, six lightly incised grooves just below top, shank section unvaried. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

508 |

Complete, headless, groove just below top, shank section unvaried (511) |

509 |

Complete apart from extreme tip, headless, two deep grooves on shank just below top, shank section unvaried. Analysis: white metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

510 |

Complete apart from extreme tip, headless, three grooves just below top, shank section unvaried. Analysis: grey deposits and white metal around upper end – XRF indicated possible preferential corrosion or solder (511) |

511 |

Complete, headless, two deep grooves just below top, shank section unvaried (511) |

512 |

Incomplete, top broken off, two grooves just below indicate originally headless, shank section unvaried (511) |

513 |

Complete, headless, with two grooves just below top, shank section unvaried (511) |

514 |

Complete, headless, two grooves below top, shank section unvaried. Analysis: white metal around upper end – XRF indicated pin made of high tin alloy (511) |

515 |

Complete, headless, three grooves below top, shank section unvaried (511) |

516 |

Complete, headless with three grooves just below top, shank straight (511) |

517 |

Complete, headless, shank section unvaried, three grooves just below squared upper end (511) |

518 |

Complete, headless, three grooves below top, shank section unvaried (511) |

519 |

Complete apart from extreme tip which has broken off, headless, three grooves below top, shank section unvaried (511) |

520 |

Complete, headless, six lightly incised grooves just below top, shank straight. Analysis: white metal around upper end, XRF did not confirm solder (511) |

521 |

Complete, headless, three grooves just below top, shank section unvaried (511) |

FIG. 1.26. Copper alloy pins of Types 5, 6, 7, 8, 9 and LIN1. Scale 1:1.

TYPE 512 HEADLESS, SHANK SWOLLEN, GROO VES |

|

522 |

Complete, headless, decorated with three grooves just below top, very slightly swollen shank (512) |

523 |

Complete, headless, three grooves just below top, shank slightly swollen (512) |

TYPE 513 HEADLESS, SHANK HIPP ED/SQUARE AT TIP, GROO VES (FIG. 1.26) |

|

524 |

Complete, headless, four grooves on shank just below top, below grooves shank changes to square section (513) |

525 |

Incomplete, headless, upper end squared off, lower end of shank of square section and broken away, with four incised grooves where shank changes section (513) |

Type 6 pins – disc-headed (FIG. 1.34) |

|

TYPE 600 DISC-HEADED, SHANK FO RM UNKNOWN |

|

526 |

Incomplete disc-headed, with stamped ring-and-dot decoration, dots perforate head, upper end of head broken across perforation, shank incomplete (600) |

Incomplete, part of sub-discoidal head only, decorated with perforating ring-and-dot motifs, one face with three ring-and-dot, the other with two, the third perforation undecorated (600) |

|

TYPE 602 DISC-HEADED, SHANK SWOLLEN (FIG. 1.28) |

|

528 |

Incomplete, part of shank broken off, sub-discoidal head, three ring-and-dot motifs, two perforated, third possibly perforated originally, slight swelling on shank towards break (602) |

Type 7 pins – Flat triangular/trapezoidal head (FIG. 1.26) |

|

TYPE 700 FLAT TRIANGULAR/TRAPEZOIDAL HEAD, SHANK FO RM UNKNOWN |

|

529 |

Incomplete, part of head only, flat trapezoidal, with perforated ring-and-dot decoration (700) |

530 |

Incomplete, most of shank broken off, flat sub-trapezoidal head, upper edge with triangular cut-outs, three ring-and-dot motifs, two of which are perforating (700) |

TYPE 701 FLAT, TRIANGULAR/TRAPEZOIDAL HEAD, SHANK SECTION UNVARIED (FIG. 1.26) |

|

531 |

Complete, flat rounded triangular head with three perforating ring-and-dot motifs, shank of squarish section just below head, remainder of circular section and unvaried (701) |

532 |

Incomplete, most of head and tip of shank broken away, but head flat, incised grooves on shank just below head, shank section unvaried (701) |

533 |

Incomplete flat head with angular sides but original shape uncertain, decorated with perforating ring-and-dot, shank of squarish section (701) |

534 |

Complete, flat trapezoidal head, decorated with stamped dots on both faces, shank section unvaried (701) |

535 |

Complete, flat rounded triangular head, decorated on one face only with stamped dots around edge and in cross-shape inside this decorative edging, shank slightly flattened below head, remainder of circular section and unvaried (701) |

TYPE 702 FLAT TRIANGULAR/TRAPEZOIDAL HEAD, SHANK SWOLLEN (FIG. 1.26) |

|

536 |

Complete, flat rounded triangular head, decorated with three perforating ring-and-dot motifs, shank swollen towards tip (702) |

537 |

Complete, flat sub-triangular head with rounded corners, decorated with three perforating ring-and-dot, shank centrally swollen before tapering markedly to tip (702) |

538 |

Complete apart from extreme tip, flat trapezoidal head decorated on both faces with two stamped ring-and-dot, shank swollen towards tip (702) |

539 |

Complete, flat trapezoidal head, decorated with two perforating ring-and-dot motifs, shank swollen towards tip (702) |

540 |

Complete, flat trapezoidal head, with two perforating ring-and-dot motifs, shank swollen towards tip (702) |

541 |

Complete apart from one corner of sub-triangular head which has broken off, swollen shank, head decorated on both faces with stamped ring-and-dot close to one edge (702) |

TYPE 703 FLAT, TRIANGULAR/TRAPEZOIDAL HEAD, SHANK HIPP ED/SQUARE AT TIP |

|

542 |

Complete, flat trapezoidal head, with two stamped ring-and-dot on each face, shank hipped towards tip (703) |

TYPE 713 FLAT, TRIANGULAR/TRAPEZOIDAL HEAD, COLLAR, SHANK HIPP ED/SQUARE AT TIP |

|

543 |

Complete, flattened sub-triangular head, sides convex, ring collar, shank swollen towards tip (713) |

Type 8 pins – inverted conical heads (FIG. 1.34) |

|

TYPE 803 INVERTED CONICAL HEAD, SHANK HIPP ED/SQUARE AT TIP |

|

544 |

Complete, inverted conical head, shank section changes to square towards tip (803) |

TYPE 811 INVERTED CONICAL HEAD, COLLAR, SHANK SECTION UNVARIED |

|

545 |

Complete, inverted conical head, ring collar, shank section unvaried (811) |

546 |

Incomplete, lower end of shank broken off, inverted conical head, top rounded, double ring collar, shank section unvaried, whole gilded. Analysis: XRF – gilded pin, base metal alloy of silver/copper. (811) |

547 |

Complete apart from extreme tip which has broken off, inverted conical head, top rounded, ring collar, shank section unvaried with incised grooves just above break (811a) |

TYPE 832 INVERTED CONICAL HEAD, COLLAR, SHANK SWOLLEN, DECORATION ON HEAD (FIG. 1.26) |

|

548 |

Complete, inverted conical head, top rounded, wrythen decoration, ring collar, shank swollen towards tip (832) |

549 |

Complete, inverted conical head, decorated with incised cross-hatching, ring collar, shank swollen towards tip (832) |

Type 9 Faceted dome-shaped head (FIG. 1.26) |

|

TYPE 902 FACETED DO ME-SHAPED HEAD, SHANK SWOLLEN TOWARDS TIP (FIG. 1.26) |

|

550 |

Complete, dome-shaped head, top flattened, sides faceted, shank swollen before narrowing markedly to tip (902) |

551 |

Complete, faceted dome-shaped head, slight swelling on shank towards tip (902) |

TYPE LIN 1 – SMALL FLAT TRAPEZOIDAL OR SUB-CIRCULAR HEADS (FIG. 1.26) |

|

552 |

Complete pin, flattened sub-circular head, perforation containing length of chain, triple collar below, shank section unvaried (LIN1) |

553 |

Pin complete apart from extreme tip, in two adjoining fragments, flattened sub-trapezoidal head, top edge rounded, perforation below containing fragment of chain link, shank section unvaried (LIN1) |

554 |

Complete pin, flattened sub-circular head, perforation containing length of chain, triangular projections to each side of shank just below head, shank section unvaried (LIN1) |

555 |

Complete pin, flattened sub-trapezoidal head, top edge rounded, perforated and containing chain link, shank section unvaried. Also separate length of chain (LIN1) |

556 |

Pair of pins, identical in size, both with flattened trapezoidal heads, one with two grooves below head, other with three, both perforated and containing length of chain, shanks section unvaried. Also two separate lengths of chain and four separate chain links (LIN1) |

557 |

Complete, flattened sub-trapezoidal head, upper edge rounded, perforation below containing length of chain, shank section unvaried. Also separate length of chain (LIN1) |

558 |

Complete pin, flattened trapezoidal head, upper edge rounded, perforation below containing length of chain, shank of circular section, hipped towards tip (LIN1) |

559 |

Complete, disc-headed decorated in the form of a cross with expanded terminals, defined by four leaf-shaped indentations, two partially perforated, and outlined with punched dots. There is a large perforation for the chain in the left arm of the cross, and two grooves at the top of the shank which has a swelling towards the tip. When found, the chain was attached but is now separate (LIN2) |

560 |

Complete, discoidal head, decorated on one face only with central cross, and chip-carved interlace filling the quadrants between the arms. The cross and a band around the edge are decorated with small punched dots, and a perforation for a chain is right on the edge on the left arm of the cross. The interlace and dots are mercury-gilded. There is a small collar below the head and the shank has a long tapering tip. Analysis: XRF – alloy is bronze with some lead, head has been mercury-gilded. (LIN2) |

561 |

Discoidal head only, with narrow plain border, and plain central equal-armed cross, the quadrants between the arms filled with gilded (not analysed) chip-carved interlace. At the end of one arm of the cross there is a perforation for a chain, and close to this the edge of the disc has a series of V-shaped notches cut in, and in the same area part of one quadrant has been damaged. Two rivet-heads for attachment of the shank survive, one approximately in the centre of the cross, the second inside the interlace in one quadrant; the perforation for the chain would have had a north-west orientation to the shank (LIN2) |

562 |

Discoidal head only, decorated with a cross motif with scrolled terminals, the whole gilded (not analysed). Two rivet-heads for attachment of the shank survive along one arm of the cross, and there is one perforation for a chain at right angles to the position of the shank on one edge, the other edge appears torn across a second perforation (LIN2) |

GLASS HEAD (FIG. 1.27) |

|

563 |

Complete apart from part of globular glass head which has been broken away, glass decayed so original colour unknown, two grooves around shank below head, shank section unvaried with tool-marks. Analysis: glass head, tool-marks like “chatter marks” along shank. 000 |

SEPARATELY MADE GLOBULAR HEAD, (?) OF GLASS |

|

564 |

Incomplete, part of separately made globular head (material unidentified) still attached, shank incomplete 000 |

565 |

Complete, with a flat sub-triangular head with chip-carved decoration on the front face depicting a pair of addorsed beasts with long noses and necks, projecting ears and dangling entwined tongues. There is little room for the bodies which meet at the rumps and the legs are short. There is a collar below the head, and the shank swells towards the tip. The pin is made of copper alloy, the shank and back of the head have been silvered and the front of the head and collar are mercury-gilded. File marks are visible under the gilding on the head. Analysis: XRF – high copper/silver ratio on shank – silver-plated copper alloy pin, with mercury-gilded head. 000 |

566 |

Complete apart from the extreme tip of the shank, the terminal in the form of a dog’s head, with round nostrils, and circular eyes set with blue glass, one glass eye missing. A collar separates the head from the shank which has a swelling towards the tip. The whole is gilded. Analysis: mercury gilded pin, strong iron and copper peaks, therefore might be an iron pin or a copper alloy one, blue glass eyes 000 |

Type 00 pins – head type unclear (FIG. 1.27) |

|

567 |

Head type unclear, possibly unfinished or too damaged to identify, shank slightly swollen. Analysis: XRF indicated solder or preferential corrosion around head end of shank 00 |

568 |

Head type unclear, shank swollen towards tip. Analysis: pin is made from a quaternary alloy – XRF indicated solder or preferential corrosion at head end of shank 00 |

569 |

Complete apart from tip of shank but very corroded and form unidentifiable 00 |

570 |

Complete, apparently globular head but corrosion obscures most of pin, shank section appears unvaried, whole pin gilded. Analysis: XRF – mercury-gilded copper 00 |

571 |

Fragmentary, both ends very corroded, one end possibly with attached separate head, shape uncertain, lower end of shank also broken 00 |

572 |

Incomplete, head too corroded to identify, most of shank broken off 00 |

573 |

Complete but very corroded, head appears polyhedral but uncertain, shank section unvaried 00 |

574 |

Complete but too much concretion to identify fully. It may have a globular head and shank of section unvaried 00 |

Type 09 – pin shanks only (FIG. 1.27) |

|

TYPE 090 – SHANK FO RM UNKNOWN |

|

575 |

Shank fragments (2), both broken at both ends (090) |

576 |

Shank fragments (3) (090) |

577 |

Shank fragment, both ends broken (090) |

578 |

Shank fragment, both ends broken (090) |

579 |

Shank fragment, both ends broken (090) |

580 |

Shank fragment, upper end broken off (090) |

581 |

Shank fragment, both ends broken (090) |

582 |

Shank fragment, both ends broken (090) |

583 |

Shank fragments (5), all very corroded (090) |

584 |

Shank fragment, both ends broken (090) |

585 |

Shank fragment (090) |

586 |

Shank fragment, both ends broken (090) |

587 |

Shank fragment (090) |

588 |

Shank fragment, both ends broken (090) |

589 |

Shank fragment, tip and lower end only (090) |

590 |

Shank fragment, both ends broken (090) |

591 |

Shank tip fragment (090) |

592 |

Shank fragment, both ends broken (090) |

593 |

Shank fragment (090) |

594 |

Possible shank fragment both ends broken, identification uncertain (090) |

595 |

Shank fragment, both ends broken (090) |

FIG. 1.27. Copper alloy pins of Types LIN2 and 000, and a Type 09 shank. Scale 1:1.

TYPE 091 – SHANK SECTION UNVARIED |

|

596 |

Shank fragment, one end broken, other end probably broken but obscured (091) |

597 |

Shank fragment, tapering to tip (091) |

598 |

Shank fragment, both ends broken (091) |

599 |

Shank fragment, traces of ring collar just below break, shank section unvaried. Analysis: white-metal shank – XRF detected high tin level probably accounting for appearance. (091) |

600 |

Shank fragment, section unvaried (091) |

601 |

Shank fragment, upper end broken off, shank section unvaried (091) |

602 |

Shank fragment, broken at upper end (091) |

603 |

Shank fragment, broken at upper end (091) |

604 |

Shank fragment, upper end broken off (091) |

605 |

Shank fragment, section unvaried (091) |

606 |

Shank fragment, upper end broken off, two decorative grooves run around shank (091) |

607 |

Shank fragment, broken at upper end (091) |

608 |

Shank fragment, upper end broken off, very solid (091) |

609 |

Shank fragment, both ends broken, section unvaried. Analysis: grey deposit around head end – XRF indicated solder or preferential corrosion. (091) |

610 |

Shank fragment, broken at upper end, incised grooves close to tip (091) |

611 |

Incomplete, head appears broken off, shank section unvaried. Analysis: white metal within corrosion around head end – XRF detected a much higher tin content in this region, but low lead level, possibly the result of preferential corrosion (091) |

TYPE 092 – SHANK SWOLLEN (FIG. 1.27) |

|

612 |

Incomplete, head broken off, shank slightly swollen towards tip (092) |

613 |

Incomplete, lower end of shank only, slightly swollen (092) |

614 |

Shank fragment, broken at upper end, swelling towards tip (092) |

615 |

Shank fragment, very slightly swollen towards tip. Analysis: powdery grey deposit around head end – XRF indicated may be solder or preferential corrosion, the alloy has a high tin content. (092) |

616 |

Shank fragment, upper end broken off, shank swollen towards tip (092) |

617 |

Shank fragment, broken at both ends, swelling towards one end (092) |

618 |

Shank fragment, broken at upper end, slight swelling close to tip where there are also two incised lines (092) |

TYPE 093 – SHANK HIPP ED/SQUARE AT TIP |

|

619 |

Incomplete, shank only, of square section at tip (093) |

620 |

Shank fragment, of squarish section, both ends broken (093) |

Catalogue of the bone pins (FIG. 1.28)

Bone identifications by Sonia O’Connor

TYPE B1 – MADE FROM A STRIP OF LONG-BONE COMPACT TISSUE FROM A MEDIUM-SIZED ANIMAL (FIG. 1.28) |

|

621 |

Complete, roughly shaped sub-circular head of sub-rectangular section, shank narrowing from centre to both ends, shank of circular section |

622 |

Complete, sub-inverted conical head of irregular section, shank narrowing from centre to both ends, of circular section |

623 |

Complete, well made inverted conical head of sub-square section, shank tapering to tip, shank of circular section |

624 |

Complete, roughly shaped inverted conical head of rectangular section, shank narrowing from centre to both ends, shank of sub-circular section |

625 |

Complete, well made globular head, shank tapering to tip, shank of circular section |

626 |

Incomplete, lower part of shank broken off, sub-inverted conical head of irregular section, shank of sub-circular section |

627 |

Incomplete, tip of shank broken off, irregularly shaped head, shank of sub-circular section |

628 |

Complete, sub-globular head, shank tapering to tip, of circular section |

629 |

Complete apart from extreme tip, head of irregular shape and section, shank tapering from centre to both ends, shank of circular section |

630 |

Complete apart from extreme tip, inverted conical head of sub-circular section, shank tapering to tip, shank of circular section |

631 |

Complete, sub-inverted conical head of sub-rectangular section, shank tapering to tip, of circular section |

632 |

Complete, well made sub-globular head, slight swelling just below head, shank tapering to tip, shank of circular section |

633 |

Complete, well made sub-globular head, shank centrally swollen, shank of circular section |

634 |

Complete, globular head, shank narrowing from centre to both ends, of circular section |

635 |

Complete, sub-inverted conical head of plano-convex section, shank narrowing from centre to both ends, shank of circular section |

636 |

Complete, sub-inverted conical head of sub-rectangular section, shank narrowing from centre to both ends, shank of circular section |

637 |

Complete, spatulate head of rectangular section, collar beneath, shank of circular section tapering to tip |

638 |

Complete, well made sub-globular head, shank tapering to tip, shank of circular section |

639 |

Complete apart from extreme tip, roughly shaped sub-circular head of sub-rectangular section, shank narrowing from centre to both ends, shank of sub-circular section |

640 |

Incomplete, lower part of shank broken off, head of irregular shape and section, shank of circular section |

Incomplete, lower part of shank broken off, head of irregular shape and section, shank of circular section |

|

642 |

Complete apart from extreme tip, roughly shaped inverted conical head of sub-rectangular section, shank narrowing slightly from centre to both ends, shank of sub-circular section |

643 |

Complete apart from part of head broken off, roughly shaped inverted conical head of sub-rectangular section, shank narrowing from centre to both ends, shank of sub-circular section |

644 |

Complete apart from extreme tip, roughly shaped inverted conical head of sub-rectangular section, shank narrowing slightly from centre to both ends, shank of sub-circular section. |

645 |

Complete, roughly shaped inverted conical head of sub-rectangular section, shank narrowing from centre to both ends, shank of sub-circular section |

646 |

Complete, irregularly shaped head of irregular section, shank tapering slightly from centre to both ends, of sub-circular section |

647 |

Complete, sub-globular head, shank tapering to both ends, of circular section |

648 |

Complete, head of irregular shape and section, shank tapering to both ends, of sub-circular section |

649 |

Complete, sub-globular head, shank tapering to both ends, of sub-circular section |

TYPE B1 SHANKS |

|

650 |

Shank fragment, broken at both ends, of circular section |

651 |

Shank fragment, broken at both ends, of circular section |

652 |

Incomplete, shank fragment, head and upper end broken off, shank of circular section |

653 |

Incomplete, lower part of shank only, of sub-oval section |

TYPE B2 – MADE FROM PIG FIBULAE (FIG. 1.28) |

|

654 |

Complete, but in two fragments, expanded head, top edge rounded, perforation, shank of circular section |

655 |

Incomplete, lower part of shank broken off, slightly modified expanded head, perforated, shank of sub-oval section |

656 |

Complete, expanded head, one corner trimmed, perforated, shank of sub-oval section |

657 |

Complete, expanded head unmodified apart from perforation, shank of sub-plano-convex section |

658 |

Complete apart from shank tip, expanded head unmodified apart from a perforation, shank of sub-oval section |

659 |

Complete, expanded head, unmodified apart from perforation, shank of sub-oval section |

66 |

Complete, well made sub-discoidal expanded head, perforated, shank of oval section, tapering to tip |

TYPE B2 SHANK |

|

661 |

Shank fragments (2), adjoining, head end broken off, shank of circular section L. (together) 51 Shank section D.4mm |

Catalogue of the silver pins (FIG. 1.29)

NB All shanks are of circular section unless otherwise stated

Type 1 – Globular head (FIG. 1.29) |

|

TYPE 101 GLOBULAR HEAD, NO COLLAR, SHANK SECTION UNVARIED |

|

662 |

Complete, small, globular head, shank waisted just below head, below this shank section unvaried (101) |

TYPE 102 GLOBULAR HEAD, NO COLLAR, SHANK SWOLLEN |

|

663 |

Complete, sub-globular head, shank swollen towards tip (102) |

TYPE 111 GLOBULAR HEAD, COLLAR, SHANK SECTION UNVARIED |

|

664 |

Complete, globular head, ring collar, shank section unvaried (111) |

TYPE 112 GLOBULAR HEAD, COLLAR, SHANK SWOLLEN (FIG. 1.29) |

|

665 |

Complete, globular head, ring collar, shank swelling towards tip. Analysis: silver pin, mercury-gilded – slight trace of copper detected (112) |

666 |

Complete, globular head, ring collar, shank swells towards tip (112) |

667 |

Complete apart from extreme tip, globular head, ring collar, shank swells towards tip. Analysis: debased silver, mercury-gilded 112 |

668 |

Complete apart from extreme tip, in two adjoining fragments, globular head, ring collar, shank swells towards broken end (112) |

669 |

Complete, sub-globular head, broad ring collar, shank swells towards tip (112) |

670 |

Complete, globular head, large ring collar, shank swells towards tip (112) |

TYPE 132 GLOBULAR HEAD, COLLAR, SHANK SWOLLEN, DECORATION ON HEAD (FIG. 1.29) |

|

671 |

Complete, globular head with wrythen decoration, collar, shank swells towards tip (132) |

Type 2 – polyhedral head |

|

TYPE 212 POLYHEDRAL HEAD, COLLAR, SHANK SWOLLEN |

|

672 |

Complete, polyhedral head of square section, lozenge-shaped facets on top and sides, triangular corner facets, triple ring collar, shank swollen towards tip (212) |

Linked pin (FIG. 1.29) |

|

TYPE LIN 2 – LARGE DISCOIDAL HEAD |

|

673 |

Large disc head only, originally attached to the shank via one central rivet and a second at the junction with the shank, the second still surviving. The chip-carved decoration depicts a central narrow-armed cross, with simple interlace in the fields between the arms. There is a narrow plain band between the decoration and the disc edge, with two perforations for chains at opposing sides. |

DISCOIDAL HEAD |

|

674 |

Complete apart from the extreme tip of the shank, discoidal head formed from integral disc with a decorated disc superimposed and attached by a silver rivet at the top of the shank and possible solder on the back of the disc. The decorated disc has chip-carved simple interlace which is gilded and has almost completely split away from its backing. The shank swells slightly towards the tip. Analysis: mainly silver, trace of copper, mercury-gilded. Sheet attached to pin head by silver rivet and possible solder 000 |

675 |

Complete, with a small mercury-gilded terminal in the form of an animal head, of triangular section, thicker at the back of the head which has a deep notch between the ears, and thinning towards the gaping mouth and upturned snout. The small circular eyes are inset, and there is a collar below the head. The shank has a long tapering tip. Analysis: debased silver, mercury-gilded 000 |

676 |

Incomplete, part of head decorated on both sides with chip-carved beast, with small ear, round snout and circular eye. Part of an extended leg rests against the lower edge of the head. The upper part of both sides retains gilding which has worn off elsewhere. The head appears to have broken off at the junction with the shank. Analysis: alloy of silver and copper (silver content high), mercury-gilded 000 |

677 |

Complete apart from the extreme tip of the shank, with a head depicting a backward-looking beast on both faces. The beast has a long beak, upright ear, a collar, extended leg and a partially cross-hatched wing, the tip of which touches the beak. Gilding covers the head and the top of the shank. The shank swells towards the tip. Analysis: debased silver, mercury-gilded. |

678 |

Complete, with a flat head decorated on the front face with a pair of deeply carved confronted beasts. Each has a triangular ear, deeply punched circular eye, and wide gaping mouth which contains the tip of their companion’s tail which winds around their neck. A curving and tapering wing on each side follows the lower edges of the pinhead, and the legs of each with two long claws cross between the wings. Small triangular punched marks speckle the bodies. There is a collar below the head, and the shank swells towards the tip which is bent up. The front of the head and collar is gilded. Analysis: silver, slight trace of copper, mercury-gilded. |

679 |

Head only, shank broken off, spherical with six cylindrical settings, five containing red glass, the sixth remains of the missing shank. All the settings have beaded collars around, two having a second plain collar, and that around the shank having a spirally twisted collar below the beaded collar. The head is gilded. Analysis: remains of shank debased silver, mercury-gilded head 000 |

Other (FIG. 1.29) |

|

680 |

Incomplete, lower part of shank broken away, with sub-oval openwork terminal with chip-carved curvilinear tendrils, of sub-rectangular section, thinning out slightly to upper end, globular swelling below with ring collar, the whole is gilded. Analysis: debased silver, mercury-gilded 000 |

(?) Pin head (FIG. 1.29) |

|

681 |

Semi-quadrant shaped, riveted at lower end with two copper alloy rivets to iron shank fragment of sub-rectangular section. The head is decorated with two fields divided axially by central band and defined at edges by narrow bands, both fields decorated with chip-carved interlace of asymmetrical patterns, punched dots along all bands. Analysis: front mercury-gilded, base metal is debased silver with copper alloy. |

Catalogue of iron pins (FIG. 1.30) |

|

NB All shanks are of circular section unless otherwise stated NB non-pins = RFs11790, 2593, 9835, 9688, 9444, 7916, 7117, 7118, 1956 |

|

Type FE01 – lead heads (FIG. 1.30) |

|

TYPE FE011 – LEAD HEAD, SHANK SECTION UNVARIED (FIG. 1.30) |

|

682 |

Incomplete, lower part of shank broken off, tin/lead alloy sub-globular head, shank of sub-circular section. Analysis: tin/lead alloy head (FE011) |

683 |

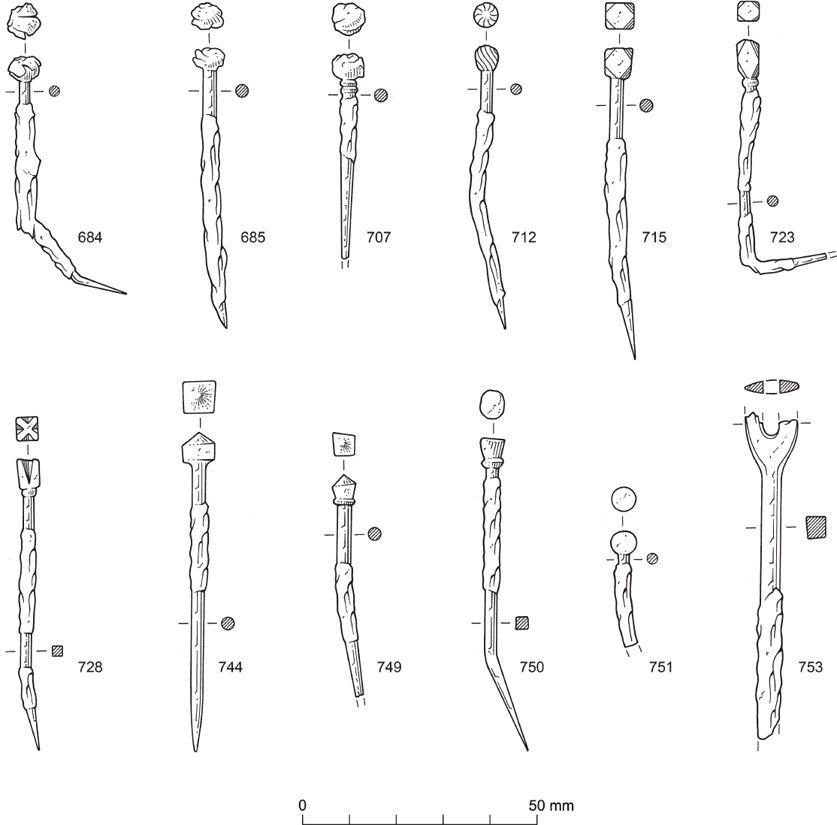

Complete, sub-globular lead/tin alloy head, shank of circular section with white-metal plating all over. Analysis: lead/tin alloy head, tin/lead plating (FE011) |

684 |

Complete, sub-globular lead/tin alloy head, shank of circular section. Analysis: lead/tin alloy head (FE011) |

Complete, sub-globular lead head, shank of circular section with white-metal plating all over. Analysis: lead head, tin/lead plating (FE011) |

|

686 |

Incomplete, lower part of shank broken off, globular lead head, shank of circular section (FE011) |

687 |

Incomplete, part of globular lead head broken off, short shank of sub-circular section. Analysis: lead head (FE011) |

688 |

Complete, sub-globular lead head, shank of circular section, white-metal plating all over. Analysis: lead head, tin/lead plating (FE011) |

Complete apart from extreme tip, globular tin/lead alloy head, shank of circular section, shank with white-metal plating. Analysis: tin/lead alloy head, tin plating on shank (FE011) |

|

690 |

Complete apart from extreme tip, sub-globular lead/tin alloy head, shank of circular section, white-metal plating on shank. Analysis: lead/tin alloy head, tin/lead plating (FE011) |

691 |

Incomplete, part of head and lower part of shank broken off, sub-globular lead alloy head, shank of sub-circular section. |

692 |

Incomplete, lower end of shank broken off, lead alloy head wrapped around top of shank which is of sub-circular section. |

693 |

Incomplete, part of head and lower part of shank broken off, traces of lead head remain, shank of circular section. |

FIG. 1.29. Silver pins of Types 1, LIN2 and 000, and a possible pin head. Scale 1:1.

Type FE1 – globular heads (FIG. 1.38) |

|

TYPE FE100 GLOBULAR HEAD, NO COLLAR, SHANK FO RM UNKNOWN |

|

694 |

Sub-globular head fragment only (FE100) |

TYPE FE101 GLOBULAR HEAD, NO COLLAR, SHANK SECTION UNVARIED |

|

695 |

Complete but in two adjoining fragments, sub-globular head, tapering shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating (FE101) |

696 |

Incomplete, lower part of shank broken away, sub-globular head, shank of circular section (FE101) |

697 |

Incomplete, lower part of shank broken off, globular head, shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE101) |

698 |

Complete, globular head, short shank of circular section (FE101) |

699 |

Incomplete, part of head and lower end of shank broken off, head type unclear but possibly globular, shank of circular section (FE101) |

700 |

Incomplete, lower part of shank broken off, sub-globular head, shank of circular section (FE101) |

701 |

Complete, globular head, shank of circular section (FE101) |

702 |

Complete, sub-globular head, groove just below head, shank of circular section (FE101) |

703 |

Complete apart from extreme tip, globular head, shank of sub-oval section (FE101) |

704 |

Incomplete, lower end of shank broken off, sub-globular head, shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE101) |

705 |

Complete, head appears globular although obscured by corrosion, shank of circular section (FE101) |

TYPE FE103 GLOBULAR HEAD, NO COLLAR, SHANK OF SQUARE SECTION |

|

706 |

Incomplete, lower part of shank broken away, globular head, shank of sub-square section (FE103) |

TYPE FE111 GLOBULAR HEAD, COLLAR, SHANK SECTION UNVARIED (FIG. 1.30) |

|

707 |

Complete apart from shank tip, globular head, double-ring collar, shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE111) |

708 |

Incomplete, lower part of shank broken off, globular head, collar, shank of sub-circular section (FE111) |

709 |

Incomplete, lower part of shank broken off, globular head, ring collar, shank of circular section (FE111) |

TYPE FE123 GLOBULAR HEAD, NO COLLAR, SHANK OF SQUARE SECTION, DECORATION ON HEAD (FIG. 1.30) |

|

710 |

Incomplete, lower part of shank broken off, globular head, wrythen decoration, two grooves around shank below head, shank of sub-square section, white-metal plating all over. Analysis: tin/lead plating (FE123) |

711 |

Complete apart from extreme tip of shank, globular head with wrythen decoration, three grooves around shank below head, shank of sub-square section, white-metal plating all over. Analysis: tin (trace of lead) plating (FE123) |

712 |

Complete, globular head with wrythen decoration, shank of sub-square section, white-metal plating on head and top of shank. Analysis: tin/lead plating (FE123) |

FIG. 1.30. Iron pins of Types FE01, FE1, FE2, FE3, FE8, and FE000. Scale 1:1.

Type FE2 – polyhedral heads (FIG. 1.30) |

|

TYPE FE201 POLYHEDRAL HEAD, NO COLLAR, SHANK SECTION UNVARIED |

|

713 |

Complete but in two fragments, polyhedral head of square section, sides obscured by corrosion, shank of circular section (FE201) |

714 |

Incomplete, lower part of shank broken away, head possibly polyhedral but heavily obscured by corrosion, shank of circular section (FE201) |

715 |

Complete, polyhedral head of square section, lozenge-shaped facets on top and sides, triangular corner facets, shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating all over (FE201) |

716 |

Complete, polyhedral head of square section, lozenge-shaped facets on top and sides, triangular corner facets, shank of sub-circular section (FE201) |

717 |

Complete apart from extreme tip, polyhedral head of square section, lozenge-shaped facets on sides and top, triangular corner facets, shank of circular section (FE201) |

718 |

Complete, head polyhedral of square section, details of top and sides obscured by corrosion, shank of sub-circular section (FE201) |

TYPE FE203 POLYHEDRAL HEAD, NO COLLAR, SHANK OF SQUARE SECTION |

|

719 |

Complete apart from tip of shank, polyhedral head, details of sides and top obscured by corrosion, shank of square section, tin plating all over. Analysis: white-metal plating (FE203) |

TYPE FE210 POLYHEDRAL HEAD, COLLAR, SHANK FO RM UNKNOWN |

|

720 |

Incomplete, most of shank broken away, remaining shank split along one side, polyhedral head, lozenge-shaped facets on top and sides, triangular corner facets, collar, shank section unclear (FE210) |

TYPE FE211 POLYHEDRAL HEAD, COLLAR, SHANK SECTION UNVARIED (FIG. 1.30) |

|

721 |

Complete apart from extreme tip, polyhedral head, detail of sides and top obscured by corrosion, collar, shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating (FE211) |

722 |

Complete, polyhedral head, of square section, lozenge-shaped facets on top and sides, triangular corner facets, collar integral with head, shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE211) |

723 |

Complete, polyhedral head of square section, sub-lozenge shaped facets on top and sides, triangular corner facets, ring collar, shank of sub-circular section, white-metal plating on head and grooves around collar. Analysis: tin/lead plating (FE211) |

724 |

Incomplete, most of shank broken off, polyhedral head, obscured by corrosion, but appears to have lozenge-shaped facets, collar, shank of circular section (FE211) |

725 |

Complete apart from extreme tip of shank, polyhedral head of square section, lozenge-shaped facet on top, sub-triangular side facets, triangular corner facets, collar, shank of circular section, appears plated all over (but not analysed) (FE211) |

TYPE FE213 POLYHEDRAL HEAD, COLLAR, SHANK OF SQUARE SECTION |

|

726 |

Incomplete, lower part of shank broken off, polyhedral head, of square section, lozenge-shaped facets on top and sides, triangular corner facets, collar integral with head, shank of square section, white-metal plating on shank. Analysis: lead/tin plating (FE213) |

727 |

Complete apart from extreme tip, polyhedral head, of square section, lozenge-shaped facets on top and sides, triangular corner facets, collar, shank of square section, white-metal plating all over. Analysis: tin with trace of lead plating (FE213) |

TYPE FE233 POLYHEDRAL HEAD, COLLAR, SHANK OF SQUARE SECTION, DECORATION ON HEAD (FIG. 1.30) |

|

728 |

Complete, polyhedral head of square section, sides trapezoidal with deep V-section notches cut in from the top, irregular collar, shank of sub-square section, white-metal plating all over. Analysis: tin/lead plating (FE233) |

729 |

Complete apart from extreme tip, polyhedral head of square section, sides trapezoidal with deep V-section notches cut in from the top, two ring collars, shank of sub-square section (FE233) |

Type FE3 – Biconical heads (FIG. 1.30) |

|

TYPE FE300 BICONICAL HEAD, CONICAL TOP, SHANK FO RM UNKNOWN |

|

730 |

Complete apart from shank tip, biconical head, conical top, possible decoration or band around medial edge, shank section unknown, pin identified from X-ray only (FE300) |

731 |

Complete apart from tip, biconical head, conical top, shank section unknown, pin identified from X-ray only (FE300) |

TYPE FE301 BICONICAL HEAD, CONICAL TOP, SHANK SECTION UNVARIED (FIG. 1.30) |

|

732 |

Complete, biconical head, conical top, shank of circular section, white-metal plating all over. Analysis: tin/lead alloy plating (FE301) |

733 |

Incomplete, lower part of shank broken away, biconical head, conical top, shank of circular section (FE301) |

734 |

Incomplete and in three fragments, lower part of shank broken off, biconical head, conical top, shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating (FE301) |

735 |

Complete, biconical head, conical top, short shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE301) |

736 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of circular section (FE301) |

737 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of circular section (FE301) |

738 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of circular section, white-metal plating all over. Analysis: lead/tin plating (FE301) |

739 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of sub-circular section (FE301) |

740 |

Complete apart from extreme tip, biconical head, conical top, groove around shank just below head, shank of circular section (FE301) |

741 |

Complete apart from extreme tip, biconical head, conical top, shank of circular section (FE301) |

742 |

Incomplete, tip of shank broken off, biconical head, conical top, shank of circular section (FE301) |

743 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of sub-circular section (FE301) |

744 |

Complete, biconical head, conical top, shank of circular section (FE301) |

745 |

Incomplete, most of shank broken off, biconical head, conical top, shank of sub-circular section (FE301) |

TYPE FE303 BICONICAL HEAD, CONICAL TOP, SHANK OF SQUARE SECTION |

|

746 |

Incomplete, lower part of shank broken off, biconical head, conical top, shank of sub-square section (FE303) |

747 |

Incomplete, most of shank broken off, irregularly biconical head, shank of sub-square section, white-metal plating on head. Analysis: tin/lead plating (FE303) |

748 |

Complete, biconical head, conical top, shank of sub-square section (FE303) |

TYPE FE311 BICONICAL HEAD, CONICAL TOP, COLLAR, SHANK SECTION UNVARIED (FIG. 1.30) |

|

749 |

Complete apart from extreme tip, biconical head, conical top, collar, shank of circular section, white-metal plating on shank. Analysis: tin/lead plating (FE311) |

Type FE8 – Inverted conical head (FIG. 1.30) |

|

TYPE FE813 INVERTED CONICAL HEAD, COLLAR, SHANK OF SQUARE SECTION |

|

750 |

Complete, inverted conical head of oval section, ring collar, shank of sub-square section, white-metal plating all over. Analysis: tin (trace of lead) plating (FE813) |

Miscellaneous pins (FIG. 1.30) |

|

GLASS HEADS |

|

751 |

Incomplete, lower end of shank broken off, globular blue glass head, shank of sub-circular section (FE000) |

752 |

Incomplete, much of shank broken off, globular pale blue-green glass head, shank of sub-square section (FE000) |

OTHERS (FIG. 1.30) |

|

753 |

Incomplete, both ends broken, shank of square section, one end flattened and appears originally oval or sub-circular with perforation, broken across perforation, other end cracked and distorted (FE000) |

754 |

Complete apart from extreme tip, narrow conical head, broad groove either side of collar just below head, shank of circular section (FE000) |

755 |

Incomplete, lower part of shank broken off, horizontal discoidal head with two collars beneath, shank of circular section, white-metal plating all over. Analysis: lead/tin plating (FE000) |

756 |

(?) Pin, complete with sub-discoidal head, tapering shank of circular section |

757 |

Pin with looped ‘shepherd’s crook’ head. L.48mm |

Type FE09 – shanks |

|

TYPE FE090 – SHANK FO RM UNKNOWN (SECTION DIMENSIONS UNMEASURABLE) |

|

758 |

Shank fragment, both ends broken off, shank split along side and section unclear (FE090) |

759 |

Shank fragment, broken at both ends and along side of shank, section unclear (FE090) |

760 |

Shank fragment, upper end broken off, shank broken up and section unclear (FE090) |

761. |

Shank fragment, broken at both ends, shank section unclear (FE090) |

TYPE FE091 – SHANK SECTION UNVARIED |

|

762 |

Shank fragment, both ends broken off, shank of sub-circular section (FE091) |

763 |

Shank fragment, both ends broken off, shank of sub-circular section (FE091) |

764 |

Shank fragment, upper end broken off, of sub-circular section (FE091) |

765 |

Shank fragment, upper end broken away, of circular section (FE091) |

766 |

Shank fragment only, both ends broken, of circular section (FE091) |

767 |

Shank fragment, upper end broken off, of circular section (FE091) |

768 |

Shank fragment, broken at both ends, of circular section (FE091) |

769 |

Shank fragment, upper end broken off, of circular section, white-metal plated all over. Analysis: tin plating (FE091) |

770 |

Shank fragment, of circular section, possibly part of no. 736, RF 7155 (FE091) |

771 |

Shank fragment, upper end broken away, of circular section (FE091) |

772 |

Shank fragment, broken at upper end, of circular section (FE091) |

773 |

Shank fragment, broken at upper end, of circular section (FE091) |

774 |

Shank fragment, upper end broken away, shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating (FE091) |

775 |

Shank fragment, upper end broken away, of sub-circular section (FE091) |

776 |

Incomplete, end of shank broken off, head type unclear, obscured by corrosion and possibly incomplete, shank of circular section (FE091) |

777 |

Shank fragment, upper end broken off, of circular section (FE091) |

778 |

Incomplete, upper end of shank broken off, shank of sub-oval section, white-metal plating all over. Analysis: tin/lead plating (FE091) |

779 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

780 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

781 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

|

783 |

Shank fragment, upper end broken off, shank of sub-oval section (FE091) |

784 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

785 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

786 |

Shank fragment, both ends broken off, shank of sub-circular section (FE091) |

787 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

788 |

Shank fragment, both ends broken off, shank of sub-circular section, white-metal plating all over. Analysis: tin/lead plating (FE091) |

789 |

Shank fragment, upper end and tip broken off, shank of sub-circular section, white-metal plating all over. Analysis: tin plating, trace of lead (FE091) |

790 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

791 |

Shank tip fragment, upper end broken off, of sub-circular section (FE091) |

792 |

Shank fragment, broken at both ends, of circular section (FE091) |

793 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

794 |

Shank fragment, upper end broken off, shank of sub-circular section (FE091) |

795 |

Shank fragment, broken at both ends, shank of circular section, white-metal plating all over. Analysis: tin/lead plating (FE091) |

TYPE FE093 – SHANK OF SQUARE SECTION |

|

796 |

Shank fragment, upper end broken away, of sub-square section (FE093) |

797 |

Incomplete, upper end broken off, shank of square section, white-metal plating all over. Analysis: tin/lead plating (FE093) |

1.9 Tool-marks and finishing details on non-ferrous, surface-coated and inlaid objects, including dress items

by Ian Panter, with contributions by Glynis Edwards† and Jacqui Watson

Copper alloy

A total of 72 objects were analysed, including a sample of the metal-detected material, to investigate and identify the presence of surface coatings and inlays, as well as technological evidence such as solder and alloy composition, although not all of the copper alloy was submitted for EDXRF analysis. The results are summarised below, and exclude the results of the study of the pins which is discussed above in section 1.8, Appendix 3 (pp.46–7).

Traces of both zinc and lead were often detected within the bronze and brass categories, although in very small quantities, as was silver, although no trace of a surface coating could be observed either visually or by EDXRF. The presence of silver, in these cases, is likely to be a contaminant, and, coupled with the range of alloy compositions observed, probably reflects the re-use and re-working of metal objects.

Of the objects analysed, thirty-one were found to have an applied decoration, and these are listed below:

Occasionally, during the course of investigation, areas of white metal were exposed which may have appeared to be either tinning or silvering. Subsequent analysis showed that the white metal patches represented elevated tin or lead levels within the alloy. Whether this was done deliberately to create a whiter alloy, or whether it has occurred as a result of differential corrosion is open to debate. Clearly, the most common method of surface coating for copper alloy objects was gilding, and the presence of mercury in the analyses suggests that the mercury-gilding method was usually employed. Silver coatings/inlays are rare, although a number of artefacts have been decorated with applied silver sheets.

In particular, two styli (cat. nos 1011 and 1012: RFs 7518 and 11568) are of note, in that they both have silver repoussé-decorated sheets applied to the broad eraser ends, similar to the iron stylus (no. 1013: RF 12268). EDXRF analysis of the grey deposits observed on the back of the silver sheets, as well as on the front surface of the eraser, indicated a much higher tin content, although the lead levels were low. Although both tin and lead were constituents of the copper alloy used to make the styli, it is likely that these deposits are solder.

Silver and gold objects

All the silver objects (excluding coins – see Ch. 13) were analysed, including some of the metal-detected finds, to ascertain the quality of the silver present, that is, whether the silver had been debased by the addition of copper/copper alloys. The results are summarised in the table below:

| Alloy composition | Number of objects |

| Cu | 2 |

| Cu/Sn | 14 |

| Cu/Sn/Pb | 34 |

| Cu/Zn | 10 |

| Cu/Sn/Zn/Pb | 9 |

| Cu/Pb | 1 |

| mainly Pb | 2 |

Of these, 21 objects had been gilded, usually by the mercury process. Furthermore, it was possible to re-classify a few objects as being predominantly silver, as opposed to their original classification as copper alloy objects. Also, one pin (no. 566; RF 822) – originally thought to be iron with a gilded dog head – had high levels of copper present, and it was not possible to ascertain whether the “base” metal was a copper alloy which had become encrusted with masses of iron corrosion.

| Surface coating | Number of objects |

| Gilded/Foil | 18 |

| Silvered | 1 |

| Inlay: lead | 2 |

| Inlay: silver | 3 |

| Enamel | 7 |

A ‘finger ingot’ (no. 3289; RF 12198, unstratified) of debased silver possibly represents metal-working material.

One medieval gold brooch (no. 3367; RF 12237) was analysed and found to be predominantly gold, but with traces of silver and copper present.

Other decorative features

Alternative methods employed to decorate objects include carving/engraving, stamping, and punching, which can be observed on the iron, copper and silver objects.

Linear designs incised into the surface and often associated with plating can be seen on many buckles, strap-ends, styli and other fittings, and probably represent the most common form of adornment. One interesting item is a mount (no. 979; RF 14087) which has an incised zoomorphic design which was probably cut into the mould used to cast the object.

Stamped and punched designs are also in evidence: in particular, the styli with applied repoussé sheets which have already been discussed, and other examples can be seen in brooches, lace tags and pins.

| Alloy composition | Number of objects |

| Mainly silver | 13 |

| Debased with Cu or CuA | 25 |

One method which appears to be observed only on iron objects is the spiral or “barley twist”, whereby two rods of iron are twisted together. This feature was observed on six objects, although only one (no. 1741; RF 5732) was positively identified as a handle – the others remaining of unknown function.

Effects of fire

A small number of objects exhibited evidence for being burnt. For example, areas on a copper alloy brooch (no. 23; FX 88, R6) have a disrupted “bubbly” appearance, with loss in definition of the decorative detail.

The possible vessel fragments (RF 14014), were seriously distorted and covered in red and green “glassy” corrosion products and “slag-like” material.

Manufacturing technology

Evidence for the processes and tools used in the fabrication of objects survived in a number of cases, especially within the patinated surfaces of the copper alloys, and in particular on a great number of pins. These marks were usually exposed during the process of corrosion removal, but given the excellent state of preservation of much of the material, they were visible without the aid of any mechanical intervention. This is an important point, as the surviving tool-marks can be considered as just that, rather than something that may have occurred from the activities of mechanical intervention.

The most common tool-mark would appear to be that from a file, used either in the shaping of an object, or to roughen or key a surface ready for application of a surface coating. For example, a medieval iron belt hasp (no. 3390; RF 10990) exhibited keying marks beneath the plating, as does a looped strip of ironworking debris (no. 3002; RF 7010), whilst on a copper alloy buckle (no. 121; RF 12522), although possible keying marks were preserved on the plate, no plating could be detected either visually or by EDXRF analysis. This may be an example of an unfinished object, indicating that fabrication and plating were occurring at Flixborough. During the course of corrosion removal from the iron file (no. 3092; RF 4877), tiny flecks of copper were visible, and subsequently detected using EDXRF. Whether this file had been used during the fabrication of a number of objects from the site is open to debate. Further evidence for metal-working comes from the presence of lead splashes on four iron objects: a shoe or belt buckle (no. 3387; RF 9010), a U-shaped staple (no. 1279; RF 11155), an awl (no. 2492; RF 9654) as well as a S-shaped hook (no. 1783; 4085), where dots of lead were observed and detected.

Investigation of an iron strip (RF 8115) revealed that one end was still divided and had traces of coppering within it – perhaps the object was unfinished?

Although the majority of tool-marks appear on the copper alloys, there are a few examples preserved on the iron. For example, a knife (no. 2110, RF 3851) had faint striations running across the blade, probably from a file, although it is feasible that the marks may have been produced during the use of the blade.

Manufacturing flaws are visible within several of the copper alloy objects. A tag (no. 98; RF 6439) had a crescentic split in the back, as well as an area of white metal, as if there were impurities in the alloy, or the sheet had not been rolled out correctly. A patch of lead concentration on the eraser end of a stylus (no. 1005; RF 4762) may be indicative of a similar mishap, or may be the remains of solder, suggesting that a decorative sheet had been applied as with styli RFs 7518, 11568 and 12268 (nos 1011–13, discussed above).

The most common methods for joining two metals would appear to be the use of rivets, of solder and or welding, and one example of a possible scarf joint is visible on an iron handle (no. 1745; RF 7855). In this case, this might reflect a repair, using scarf joins to insert a new section.

Evidence for welding tends to be reflected in differential corrosion. Examination of a knife (no. 2174; RF 12303) revealed the presence of a distinct groove marking the junction of the blade and back, probably caused by a welding fault giving rise to deep-seated corrosion. A similar situation is seen in another knife (no. 2050; RF 12255), where a long split has developed from the tip, and presumably following the junction of the blade edge and back. The X-radiographic images of a number of the axes and adzes from the tool hoard also illustrate forging details.

Evidence for soldering is often notoriously difficult to confirm using techniques such as EDXRF, especially on copper alloys, as the solder constituents (tin and lead) are often components of the base metal alloy. In these instances, identification is very much dependent upon the character and position of the deposits as well as their relationship with the object. Examples from Flixborough include a domed mount (no. 975; RF 12802) and a disc-shaped mount (no. 977; RF 12803), both unstratified. Both base metals were bronze and each had a white crystalline deposit which had a lead-tin composition. Given the location and form of the material, it is likely that the deposits were solder, rather than areas of excessive corrosion.

Investigation of the copper alloy pins, especially the ones where the head was missing, revealed patches of either white metal or a dull grey/white crystalline deposit around where the head would have been. Unfortunately, because of the alloy composition, it was not possible to detect for certain the presence of a solder using EDXRF. In many cases, higher levels of both lead and tin were detected, but whether this was due to solder or simply the affects of differential corrosion, is difficult to determine. As lower levels of tin and lead were detected elsewhere on the shanks, then a plating could be ruled out. A similar situation exists with the styli described above, where crystalline deposits survived on the reverse side of the applied silver mounts and on corresponding areas of the erasers. Unfortunately, because the styli were leaded copper/tin alloys, it was impossible to differentiate between lead and tin from the solder and that from the alloy, although higher tin levels were detected in these particular zones.

Detection of solder on ironwork is less fraught, but, apart from the iron stylus (described above), only one other example was recorded.

A barrel padlock bolt (no. 1818; RF 11419) had traces of a grey/silvery deposit sandwiched between two iron “plates”.

The use of rivets, both iron and copper alloy were recorded, and examples include a bell (no. 1020; RF 138), a fitting (no. 1516; RF 181), a disc-headed pin (no. 673; RF 2068) with both iron and copper rivets, and a possible copper alloy hinge (no. 1974; RF 2597) with remains of a thin iron sheet attached using iron rivets.

Objects such as strap-ends and buckle plates that had rivets were investigated to ascertain whether organic remains such as leather and textile had been preserved by mineralisation. Glynis Edwards and Jacqui Watson comment that six buckles have traces of leather from belts, and that no. 172 (RF 9284) had clear remains of the belt loops on both sides at the back. There is not enough evidence to determine whether the buckles were lost or discarded with the complete belts, or whether parts of the belts were cut off for other use.

Appendix 4. EXDRF analysis of selected gilded copper alloy and silver objects

by Jennifer Jones

A total of forty-one copper alloy and silver objects were found to have traces of gilding. These were surface analysed using EDXRF. Twenty-five are pins (13 copper alloy and 12 silver), and 16 are non-pins (seven copper alloy and nine silver).

By the early centuries AD, the most commonly-used method of gilding was the gold amalgam method, now usually referred to as fire gilding. An amalgam of gold and mercury was formed by dropping gold leaf or fragments of gold into hot mercury, and when this mixture cooled it was spread with a brush onto the carefully cleaned object. Heating the object to a dull red heat drove off the mercury and left the gold firmly attached to the underlying alloy. The object was then ready for burnishing (Untracht 1975). This method of gilding can be applied to both silver and copper alloys, as long as the latter do not contain too much lead, and also to pure copper or silver artefacts. It can be used over the whole object surface, or just in selected areas.

EDXRF analysis of gilded objects should be able to reveal the use of fire gilding, by detecting mercury not completely driven off in the manufacturing process. Of the 41 gilded objects, mercury was detected by surface EDXRF analysis in 32 cases. It was not detected in five copper/copper alloys (three pins and two non-pins), or in four silver/silver alloys (two pins and two non-pins). The reason for this could be that where the gold layer is very thin or discontinuous, as is often the case, mercury was not detected at the exact site of analysis, or it could indicate the use of a different gilding method.

Leaf gilding and diffusion gilding techniques were also known at this time. Leaf gilding involves the attachment of gold leaf, too thin to be handled, to the object’s surface by means of an adhesive. In diffusion gilding, the gold leaf was bonded to the underlying surface (usually silver or copper) by gentle heating (Oddy 1993). Both these methods may have been less commonly used than fire gilding by this period, but where mercury has not been detected, the use of diffusion or leaf gilding should not be discounted.

The results of the EXDRF analysis of the great square-headed brooch (no. 23; FX 88 R6) have already been discussed (see section 1.1, p.4).

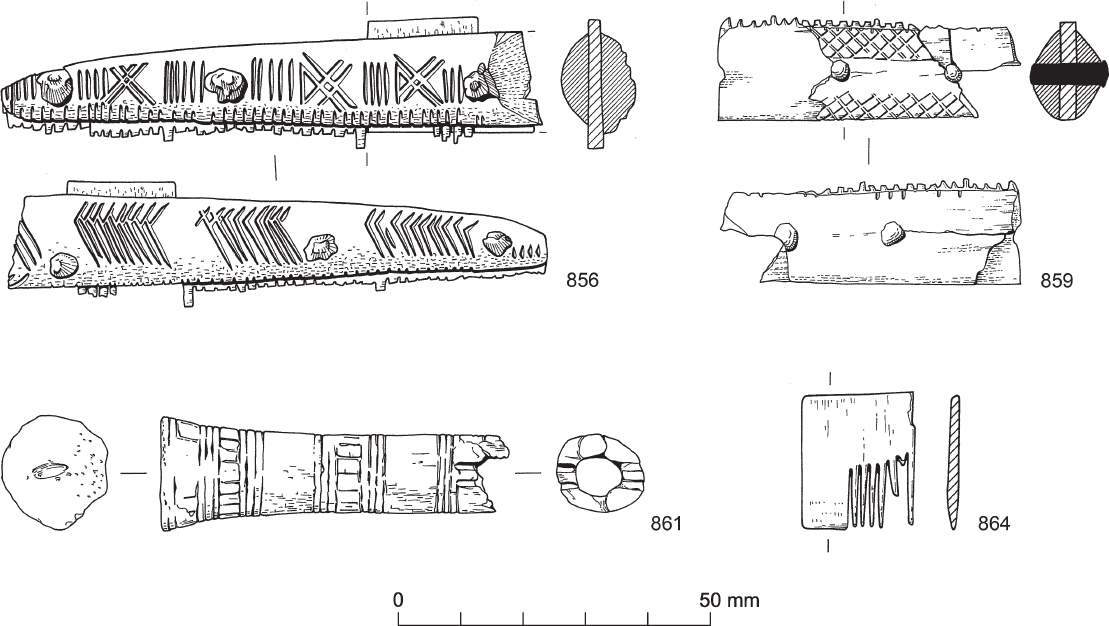

1.10 Combs

by Martin Foreman, with identifications of osseous materials by Sonia O’Connor and T. P. O’Connor

Introduction

This report considers c.80 fragments derived from approximately 70 composite combs, recovered from contexts dated to between the late 7th and mid-10th centuries. They include double-sided, single-sided and handled forms. The combs are described according to terminology set out by MacGregor (1985, 75), with tooth-spacing or value (TV) calculated following Riddler (1994). The osseous materials were identified by Sonia O’Connor, and occasionally by Terry O’Connor. Comparative study with other sites was based primarily on published material; Bob Carr, Arthur MacGregor and Ian Riddler kindly provided information about many unpublished combs to broaden the scope of review.

Double-sided combs are represented by seven disassembled fragments of limited diagnostic value; 22 similar fragments which are more informative as to the size, form or decoration of the combs; and 13 assembled comb fragments. Symmetrical single-sided combs provide nine detached comb elements; five assembled fragments, and a complete comb. Handled combs and fragments possibly derived from handled combs include five disassembled elements; three assembled fragments; and a substantially complete comb broken only at the time of its discovery. Other fragments, from either symmetrical or handled types, include seven end-plate, tooth-plate or side-plate fragments; and one small assembled fragment. Two flat mounts may be from the side-plates of composite combs of horn and bone. Another six items derive from combs of uncertain form; they include detached teeth and other small fragments.

The combs from Flixborough have previously been considered alongside those from the Anglian cemetery at Castledyke South, Barton-upon-Humber, North Lincolnshire (Foreman 1998; Foreman in prep.). The Roman affinity of Early Anglo-Saxon double-sided combs was suggested, differing from narrower and more elongated combs of later date. This development was perhaps conveyed through the introduction of single-sided forms. A regional tendency towards ‘edge-pinning’ of end-plates was identified, in contrast to common practice elsewhere (MacGregor 1985, 75). At Castledyke, double-sided combs outnumbered single-sided forms by about 3 to 1. At Flixborough, double-sided combs outnumbered single-sided forms by less than 2 to 1. Overall, this ratio resembles that reported from Middle Saxon Hamwic, Southampton. It contrasts with Middle Saxon Fishergate, York, where there were 3 single-sided combs for every 1 double-sided comb (Rogers 1993a), and more markedly still with Brandon, Suffolk (R. Carr, pers. comm.), and Thwing, East Riding of Yorkshire (T. Manby, pers. comm.): at Brandon there is only one double-sided comb, and at Thwing none. The Brandon assemblage comes as a re-deposited collection from ‘dark earths’. Combs from Thwing are considered as Middle Saxon in date, though they are comparable to material from 10th- and 11th-century contexts at Coppergate, York, where single-sided combs predominate (A. MacGregor, pers. comm.; MacGregor et al. 1999).

The absence of comb-making debris may suggest that, in so far as its excavated areas are concerned, Flixborough functioned as a centre of consumption: these combs were manufactured elsewhere. The majority of comb fragments (c.85% of which were stratified finds) come from deposits dated by pottery to between the 9th century and the mid-10th century. They accompany metalwork, the majority of which is datable to the 8th and 9th centuries on the basis of current chronologies (Webster and Backhouse 1991). It is uncertain whether the combs accompany the metalwork as part of a residual and reworked assemblage, or whether they demonstrate shifts in rubbish disposal strategies and artefact deposition. A later emphasis on organic, and – in the case of antler – specifically woodland, resources may also be detectable. Antler combs, therefore, complement the studies of the consumption of timber and other faunal resources at Flixborough, which became more conspicuous during the later occupation of the site (Loveluck 2001; Dobney Volume 4, Ch. 5; Loveluck Volume 4, Chs 3, 4 and 9). These points enhance the importance of the combs from Flixborough, to the understanding of the site and its context, as well as to the study of the artefacts themselves.

Phasing information and context interpretations were added to catalogue entries for combs. The screening out of contexts interpreted as ‘dumps’ or ‘dark soils’ left only c.25 objects to provide a starting-point for a typological review, though two more from dump contexts were so near-complete as to suggest that their deposit may have been primary. This exercise showed similar material scattered between the earliest and latest phases represented. The next stage of review, therefore, drew all stratified material from all contexts together, tracing the currency of forms, material and tooth-value. This confirmed the mixing of artefacts, with scant discernible development in construction, fineness of tooth-spacing etc. Joins between fragments were usually within the same contexts. The presence of bone comb components in earlier and later phases, and the predominance of antler in the mid-to-late-9th-century Phases 4ii–5b, may hint at the more homogeneous nature of material in 9th-century contexts, and marked residuality in 10th-century deposits.

The typological ordering of the combs was attempted with reference to stratigraphic phasing, and to phase-dates supplied by pottery. Given significant residuality, in dumps in particular, ‘spot-dates’ offered by coins were also considered, as suggesting a feasible terminus post quem for residual elements incorporated in such contexts.

Wider double-sided combs

The double-sided combs appear at first sight to form an assemblage of consistent character. They have squared end-plates, some with slightly rounded corners, others more angular, and all with generous uncut and undecorated fields. These features suggest a date-range in the Middle Saxon period (Riddler 1994, 111). The teeth on end-plates are usually graduated in length, and similarly spaced on both sides of most combs. Side-plate terminals are straight-ended. Decoration is modest, and the avoidance of ring-and-dot for all except a distinct sub-group of single-sided combs is a particular feature of the assemblage from Flixborough. The execution of linear schemes is typically fine.

The earliest double-sided combs appear to have been the widest (c.36–49mm), and their side-plates were corres-pondingly broader as well. Tooth-plates were usually 9–13mm long (along the comb), shorter than those used for most other combs. The width and length of some detached end-plates and tooth-plates from double-sided combs has prompted their speculative assignment to this group. Tooth-spacing is between 5 and 7 per cm, with tooth values of 6/6 the most common. The preferred material was antler. Decoration usually comprises vertical lines, sometimes dividing blank fields, and is typically sparse. The sparse decoration of double-sided combs towards their ends is a feature of 7th-to-8th-century Frankish material; other examples are completely undecorated (Koch 1982, Taf. 15, gr. 36; Taf. 30, gr. 25; Taf. 39, gr. 76; Taf. 40, gr. 87; Taf. 43, gr. 97). Modest linear decoration, or none at all, is a widespread characteristic of Middle Saxon combs, as from Walton, Aylesbury, Buckinghamshire (Farley 1976, figs 20, 25 and 26); from Hamwic – Cook Street – Southampton (Riddler 1992, 8); Shakenoak, Oxfordshire (Brodribb et al. 1972, figs 56–8); Sutton Courtenay, Berkshire (Leeds 1923, pls 28–9) and elsewhere.