Roads are of many kinds, from cart tracks to superhighways. The importance of the simpler types is often overlooked. They are essential in their own places, and they show principles that are basic to the more elaborate highways.

Pioneer Roads. Pioneer roads are access roads built along the route of a highway, pipeline, or other heavy construction project to allow the movement of equipment to and between different sections of the job. If such a road is required, it should be the first work undertaken; and any delays in cutting it through will slow the starting of the job and may keep workers and equipment idle.

It is best to locate it sufficiently to the side that it will not be blocked or cut off by the main work, and if it must cross the construction strip, it should do so where it is close to subgrade.

The importance of the pioneer road decreases as sections of the main road become passable for trucks, but it often retains at least emergency or detour value until the job is finished.

If it is to be used only for moving in equipment, it may be narrow, crooked, and steep for the sake of economy or haste. Specifications written, and the route surveyed or walked through for it, serve as guides rather than instructions, and the job supervisors are usually given wide latitude in altering them for the sake of speed or economy.

Pioneer roads are most often needed in mountainous and timber country where severe obstacles hinder cross-country travel. Where fill is available, trees are cut flush and the stumps buried; otherwise they are uprooted and the holes graded in. Topsoil is handled as fill.

Rock is avoided as much as possible in the layout of the road, and when found is often buried instead of blasted. If an excessive amount of rock must be moved, it may be economical to place the pioneer road in the route of the highway, as the cost of the separate blasting may outweigh the advantage of the independent road.

Grades follow the land contour as closely as possible. The maximum grade will depend on the use. Shovels, tractors, and lightly loaded trucks should be able to negotiate grades up to 30 percent, but serious delays can be caused by stalling of weak units, or as a result of skidding. Ten to 15 percent grades are more practical.

Curves should be wide enough to enable the longest units to get around them somehow, and the machines in steady use should be able to make them without backing. Attention should be paid to the lane width needed, so that inside rear wheels will not run off the road. Width requirement increases with length of wheelbase and sharpness of turn.

The road width is determined by its intended traffic, construction problems, and haste. It is desirable that it be two lanes wide, but often this is not practical. On steep slopes, two one-way roads may be constructed, one above the other.

Two-way traffic on one lane will require turnouts at 100- to 500-foot (30- to 150-m) intervals. It is best to make these of two-lane roads the length of two vehicles, but deadend turnoffs may be easier to build and will serve the same purpose. A vehicle may turn into one, and back out on the road again when opposing traffic has passed.

Small streams are best bridged with corrugated metal culvert pipe and fill. Occasionally, bottoms may be hard enough to permit easy fording.

Fords are the most economical means of crossing larger streams. A soft bottom can sometimes be made safe by a rock fill. Its downstream edge should contain heavy boulders. Its surface can be crushed rock or clean gravel. It may be placed over a culvert pipe that will handle normal stream flow but not high water.

If a ford is not practical, multiple-culvert pipe, log or timber bridges or trestles, or prefabricated steel bridges may be used.

Roads built for use in a dry season may be so constructed that they will be washed out when the rains come, if the contractor believes they will have served their purpose by then.

The bulldozer, or angle dozer, is usually the primary tool for cutting a pioneer road. Methods are described in a later section.

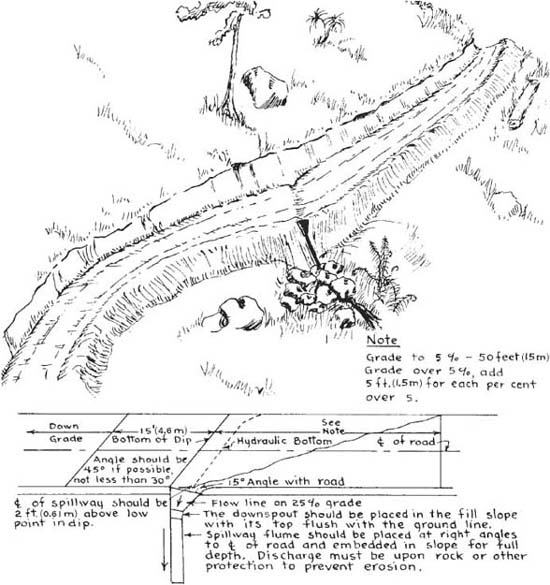

In sidehill cuts, the road surface should slope down to the bank or inner side, and may have a berm (ridge) along the outer edge. This shape allows for fill settlement, reduces washing of the fill slope, and decreases danger of sliding off the road.

Drainage from the road surface and the hill slope is carried along the inside bank to culverts, or to outward-dipping sections of road reinforced with rock or blacktop. Overhangs or sluices must be provided to carry the water across the fill.

One of the constructions used by the U.S. Forest Service is shown in Fig. 8.1.

Access and Farm Roads. A pioneer road is an access road for each otherwise isolated piece of the job it services. However, the term access road usually means a road by which a whole job is connected to a highway system, and is generally used in connection with pits and dams.

The quality of construction is variable. If the project is small, or to be quickly finished, and no substantial amount of raw material is to be trucked in or products taken out, rough pioneer construction may suffice. More often, it must be built as a haul road. Occasionally, a first-class highway will be required.

Farm roads are usually graded native soil, two lanes wide, with gravel, dirt, or other low-cost surfacing.

Haul and Logging Roads. There is no sharp distinction between these two types. Both must carry heavily loaded trucks at a good speed, and are ordinarily located according to a favorable terrain, rather than property lines. The logging road is likely to be longer, to climb to much greater elevations, and, under modern lumbering practice, to be permanent. The haul road will carry a much greater traffic for a limited time, and then often will be abandoned.

As compared with the pioneer and access types, these roads differ in that grades are limited. Ten percent is the usual maximum for the logging road, and in haul roads grade is sometimes kept as low as 3 percent of climb in the direction of load movement. Culverts and bridge capacities are designed according to the period of use, and the comparative expense of large openings, or repairing washouts over smaller ones.

The long climbs needed on log roads in mountainous country are best ascended at even grades, which can only be attained by careful survey of possible routes. Where the direct distance along a valley wall is too short to provide the ascent at the required grade, the road may be run back into spur valleys instead of crossing them on trestles, or may ascend the slope in a series of switchbacks, or hairpin turns. The turns require a wide space, which, for economy, should be placed where the grade is flatter than ordinary, or where excavation will require minimum blasting.

These factors limit the route rather closely to that originally surveyed, although occasionally, if the contractor runs into unexpected difficulties, he or she can have the road shifted to avoid them.

The haul road seldom has long ascents and descents, but switchbacks and side wanders must often be used to get them out of a deep pit or over a massive ridge.

Logging roads are surfaced with local material where possible, from cuts or borrow pits along the road. Any fairly hard and porous material, such as gravel, disintegrated granite, or broken shale can be used, as traffic is ordinarily not long sustained. Haul roads may be oiled to control dust and speed traffic.

FIGURE 8.1 Hillside roadway. (Courtesy of U.S. Forest Service.)

Trouble with snow or ice is minimized by locating on the north or east slopes of valleys, in the northern hemisphere.

Development Roads. Roads built for real estate subdivision vary in quality from the crudest pioneer type to city streets. Differences depend on the type of development, local regulations, value of land, capital available for improvement, terrain, and other factors.

Rural subdivisions are seldom regulated, but those in and near cities may have to have roads built to high standards. However, the developer may be allowed latitude in locating roads, or shifting them to avoid obstacles, to run cuts through banks of desirable fill or gravel, to change lot lines, or to obtain a more attractive appearance.

Subdivision roads may be financed partly by sale of topsoil, gravel, fill, and other surplus material. Construction costs may be reduced and swampland “reclaimed,” except where area must be kept as a wetland, by using such areas as dumps for quarry waste or other clean, solid fill.

Fills made over swamps are subject to severe settlement. For a good-quality road, mud should be removed for use in landscaping lots, so that road fill may rest on a firm bottom. Or geotextile blankets can be used as described in Chap. 3 and depicted in Fig. 3.11.

City Streets. City streets are built to exact specifications, often under circumstances which do not allow maximum output from either machines or workers.

All operations are likely to be impeded by traffic, which will probably require working the job in sections limited to a few blocks, and frequently to half the street width. Provisions must often be made to pass traffic on intersecting streets through the work. In addition to direct interference with work schedules, congestion will probably delay trucks and machines entering and leaving the job.

Removal of old pavement is usually the first construction step. Asphalt paving, on a gravel or crushed-rock base, can be dug by most front loaders, or backhoes. Occasionally it is hard enough to require preliminary breaking with a ripper or scarifier, or direct loading with a large excavator.

A backhoe can dig close to manholes, but care should be taken not to hook into them, or into a widened masonry base, as these are easily broken or crushed. Pavement chunks sliding up on the manhole cover may be thrown into the bucket by hand.

Concrete pavements and bases are tough, particularly if reinforced. They may be bonded to the manholes or their bases so as to require breaking away by air hammers, ahead of backhoe digging. They break out in big slabs which are difficult to pick up in the bucket, and to dump out of a small or medium truck.

Soil beneath the pavement is removed with it to required depth. It may be native soil, or rock, dirt, or even garbage fill. It may be honeycombed with pipes and conduits that may belong to the city, or to various utility companies.

If the grade is to be lowered, some of the pipes may have to be dug in more deeply. In any case, extensive repairs, enlargements, or relocations of piping are liable to be done between the removal of the old pavement and the laying of the new. This will involve a lot of ditching and probably considerable delay.

The subgrade is graded and compacted according to specifications. Because of interference with manholes, and the need for working in short sections, a large amount of handwork will probably be required.

Highways. Highways make up the bulk of the excavating contractors’ road work. Modern standards of width, grade, and alignment require heavy cuts and fills in rough or rolling land, and grading and compaction of subgrades involve heavy work on any terrain.

Contracts may be let on a basis of a fixed price for a job; a fixed price plus specified extras, such as allowance for overhaul, rock blasting, slides, or other difficulties whose extent cannot be conveniently estimated in advance; or on a price-per-yard basis. Less frequently, they are constructed on a cost-plus or equipment rental arrangement.

Highway earthwork jobs may involve widening and straightening of roads, building a new road in the approximate location of the present one, building a new road which will run along or cross the old one only occasionally, or building a totally new road crossing undeveloped country. There are of course no definite lines of distinction among these types.

A requirement of most highway construction is to provide for continuance of traffic along any roads running along or crossing the job. This may be a controlling factor in job sequence.

Airports. An airport runway is essentially a very wide, short, straight road. It is usually located on the flattest land available, but deep fills are often required.

Banks of cuts must be graded back to very gentle slopes to avoid choppy air currents. Borrow is frequently obtained from the glide areas at the ends of the runway. It is standard practice to cut away any ridges which might be hit by a plane climbing slowly off either end of the runway.

The runway may have a level centerline, crowned up from the sides slightly for drainage, or have a flat cross section and a longitudinal slope. In either case drainage slopes are very slight, and the surface must be exactly on grade to avoid puddles.

Taxiways and plane parking areas are roads surfaced to an ample width to carry the wheels of a plane running on the ground. Additional areas on each side must be cleared and lowered to allow clearance for the wings.

Airport subgrades and pavement may have to exceed standards for heavy truck highways if maximum size planes are to be carried.

Road Markers. A construction or mining road should be plainly marked as such, to prevent accidental entrance by motorists. Cars and big machinery do not mix well, and also drivers who are lost or confused may get in the way of a blast or run off a cliff.

Warning signs should be placed on highways at least 400 feet (122 m) on each side of a haul road crossing. If either road is a busy one, the intersection should be protected by a flagman or a traffic light.

One-way haul roads should be marked plainly and frequently with direction signs. There should be a sign wherever any vehicle could enter, and additional signs along the roadways to warn drivers going the wrong way. If the road is paved, arrows should be painted on the pavement, pointing in the direction of travel. A conventional dashed stripe line down the center could have arrowheads painted on some of the dashed lines.

Signs at entrances to one-way sections are not enough, as they may be destroyed by accident or vandalism, or obscured.

Failure to provide sufficient notice and warning of traffic direction is the cause of many head-on crashes on divided state and federal highways. There the blame is put on the wrong-way driver, but in a private construction road the contractor is likely to be held responsible.

Roadways are planned and staked out with consideration for horizontal alignment, vertical alignment, and cross section.

Horizontal Alignment. Horizontal alignment is the route as it would appear on a map, with detail enough to enable field engineers and contractors to lay out and build the road exactly as it was planned. It is figured in terms of the location of the centerline.

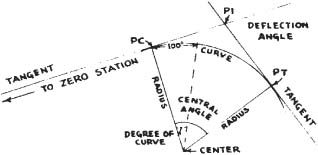

Curves. Curves are laid out as arcs of circles. Each point on such an arc is equally distant from the center of the circle that would be formed by continuing the arc on the same curve. See Fig. 8.2.

A curve is described or defined by its degree of curve or by the length of its radius. Its degree of curve is the number of degrees in the angle at the center that is made by drawing lines from the center to points on the curve that are 100 feet (30.5 m) apart. A sharp curve will have a higher degree of curve than a gradual one.

FIGURE 8.2 Curve and tangents.

Curves may also be defined according to the length of the radius, that is, the distance from any point on the curve to the center. The radius of a 1° curve is 5,730 feet (1,747 m). A 2° curve will have half that radius, or 2,865 feet (873 m). A short radius means a sharp curve.

Either measurement may be converted into the other by using one of the formulas

If someone were in a hurry, or trying to work the problem out in his or her head, the person could change the 5,730 to 6,000 feet (1,747 to 1,800 m) and be less than 5 percent off.

A highway curve may be compound. A compound curve includes two or more arcs having different degrees of curve, and may include some short straight lines also.

Tangents. In highway work and in many other surveys, straight lines are called tangents. This is because they are tangent to the connecting curves. This one word makes clear that a straight line forms a smooth continuation of an adjoining curve.

Tangents vary in length from a few inches (cm) up to many miles (km).

Whenever two tangents are joined by a curve, lines are drawn on the plan continuing them until they cross each other outside the curve. The point where they meet is called the point of intersection, or PI for short. The tangent distance is measured between the point where the tangent meets the curve (called PC at the beginning of the curve, or PT at its end) to the PI. The side or deflection (def.) angle formed by the intersection of the extended tangents equals the central angle of the simple curve between the tangents.

Baseline. In making a road survey, the engineers first lay out a baseline that follows the general route of the road, but that may be partly or wholly outside of the right of way. This line is often made before the exact location of the highway has been decided.

The baseline is very carefully surveyed and marked. Some points on it, called hubs, are more important to the engineers than any of the road line stakes. They may be conspicuously marked, or concealed with leaves or rocks.

No contractor or employee should ever destroy, move, or otherwise interfere with any stake or marker on the job, regardless of whether it seems to fit in with the markers he or she recognizes.

Centerline. The centerline is the basic location reference for the highway itself. It is the center of the pavement in a single road, or the center of the median division of a dual highway whose two roadways are a fixed distance from each other.

The engineers set the centerline according to angles and distances from baseline points. Measurements are made along it with a steel tape (an operation often called chaining), and stakes are set at 100-foot intervals.

All distances are measured along the centerline, and structures and stakes are located in reference to it. It is also the basis for grade calculations for single roadways.

There are a number of construction lines that run parallel or almost parallel to the centerline. These include pavement, shoulder, gutter, and slope edges. They are usually measured off from the centerline, at right angles to it on straight stretches, and along radial lines on curves.

Profile. The profile of a road is the vertical alignment of the centerline or of a theoretical grade line. It is a representation of its rise and fall, without indication of whether its route is straight or curved.

Two profiles are prepared, one of the existing ground surface, the other of the proposed pavement surface. Both of these are drawn on one sheet or roll of cross-section paper marked off in squares of  inch (2.54 mm), with inch squares indicated by heavier lines.

inch (2.54 mm), with inch squares indicated by heavier lines.

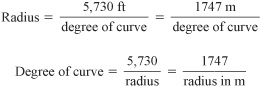

FIGURE 8.3 Typical cross section [Multiply all feet (′) by 0.305 to get meters and inches (″) by 25.4 to get millimeters].

The usual scale is 100 feet to 1 inch (30.5 m to 25.4 mm) horizontally and 10 feet to 1 inch (3.05 m to 25.4 mm) vertically. The exaggeration of the vertical scale is necessary because the ups and downs are usually quite small compared to the horizontal distances, and would be hard to measure accurately on a small scale.

The road profile is made of a series of straight lines or grades connected by curves. These vertical curves are usually arcs of parabolas, not circles. Plus grades go up as they go away from zero station, and minus grades go down.

The ground profile is prepared from topographic maps, often made by stereoscopic photography from the air. Profiles may be prepared for several possible routes, and highway profiles sketched along them. A ground survey is made along the selected route to serve as the basis for final plans.

A rough estimate of the volume of cuts and fills can be made from the profile, but accurate determination usually requires cross sections showing side slope of the ground, slopes proposed for highway cuts and fills, and other details.

Cross Sections. There are two types of highway cross section. The plans usually include a set of “typical road sections” that show the details of pavement width and thickness, shoulder and gutter width, crown or side slope, and other construction information. These typical sections serve as guides in staking out and building the road. See Fig. 8.3. The cross section for the roadway can be achieved without numerous stakes by using the TS5 instruments, described in Chap. 2, to enable the operator on the grader to get the required shape.

An ordinary cross section is a profile taken at right angles to the centerline. It is at least long enough to include the full width that will be graded. It is usually taken with a transit, but for rough calculations a hand level may be satisfactory.

The number of cross sections taken depends chiefly on the irregularity of the ground. In hilly country they are taken at each 100-foot (30.5-m) station, and at additional points where the ground surface changes. On perfectly flat land only one or two might be taken on a whole project.

The cross section of the ground is drawn on cross-section paper with the vertical and horizontal scales the same, or the vertical scale exaggerated. Then the proper typical road section is selected and its subgrade line is drawn in, on the same scale and in proper location. Wherever present grade is above proposed subgrade, material must be “cut” or dug and removed. Where present grade is lower than subgrade, material must be added or filled in.

Such cross sections provide data to figure the cut and fill for the road.

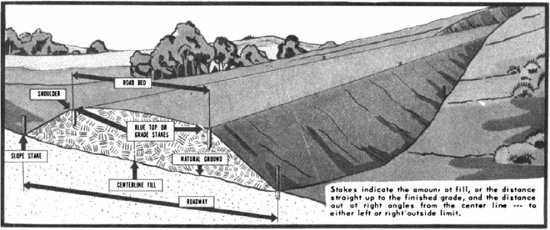

Stakes are used to guide the contractor and employees in following the engineer’s plans. They also assist inspectors in checking up on the contractor’s performance. (See Fig. 8.4.)

The first working stakes on the job may be the centerline, showing depth of cut and height of fill, and slope stakes that show the outer limits of the area to be cleared, grubbed, and graded, and usually the cut and fill information also. Some of these stakes would not be necessary if the TS5, mentioned above, is to be used.

When heavy cuts and fills are required, most of the work may be done with guidance of only slope stakes, both the originals and others that are set up or down the slopes as work progresses. (See Fig. 8.5.)

When the working levels approach the subgrade, additional stakes are needed. Centerline stakes will be restored, and lines of shoulders and gutters may be staked.

Finishing may be done with blue tops, which are stakes driven until the tops are at the grade desired, usually subgrade, and/or string on shoulder stakes.

Centerline. The centerline is usually staked at 100-foot (30.5 m) intervals in preliminary work, and sometimes as closely as every 25 feet (7.6 m) in narrow, winding roads or in finishing operations.

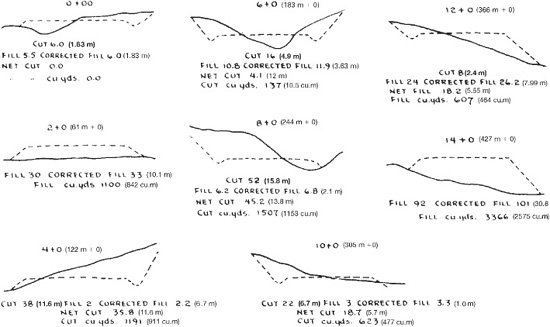

These stakes are called stations. The first one, the zero station, is at the beginning of the road or other project. The distance in feet from zero is marked as a double figure.

Stakes at 100-foot (30.5-m) intervals are called full stations, others are called plus stations. Station numbers are made up of the distance from zero, with the hundreds divided from the last two figures by a plus sign. For example, a full station 500 feet (152 m) from zero is 5 + 00 (1.52 + 00), and the part or plus station at 545 feet (166 m) is 5 + 45 (1.52 + 14.12).

If changes in plan should cause the project to be extended to the other side of the zero point, minus stations would be used. A stake 180 feet (54.9 m) beyond zero would be station - 1 + 80 (- 1.52 + 97.1).

Location measurements refer to distances on a horizontal plane, unless specified otherwise. As a result, 100-foot (30.5-m) stations will appear to be more than 100 feet (30.5 m) apart if measurement is made along steeply sloping ground. On a 1-on-3 slope (33⅓ percent grade) the surface distance would be about 105.4 feet (32.1 m). But if the stakes were extended upward or downward, any horizontal line between them would be 100 feet (30.5 m) long.

Centerline stakes are in the middle of a single roadway, and usually in the median of a double one. They are marked L, C, or /c. They show depth of cut or height of fill needed, and usually carry information about location of culverts, structures, and other features.

Slope. Slope stakes are set where the outer slopes of the cuts or fills meet the original grade, usually at 100-foot (30.5-m) intervals along the roadway, and also at other points where ground slope changes or special structures affect the slope. They are always at points of no cut and no fill.

Slope stakes are usually set with a transit or dumpy level and a 100-foot (30.5-m) steel tape. They provide the first markers the work crews need, as they show the outer limits of the area to be cleared.

Each stake should show the cut or fill necessary to make the ground level with the centerline at that point, and the distance to the centerline. It should also show the steepness of the slope, but it often does not. If this is the same for the whole job, the grading supervisor can carry the information in her or his head.

Slope and other side stakes are usually marked with the station number, the distance from the centerline, and the direction of the centerline. Direction is indicated by the letter R for right or L for left. Such directions for plus stations are read looking from the zero stake. In some localities 25-R means 25 feet (7.6 m) right of the centerline, in others that the centerline is 25 feet (7.6 m) to the right of the stake.

A slope that is not known can be figured by subtracting one-half the width of the road (including a gutter, if there is one) from the distance from slope stake to center, and dividing the remainder by the cut or fill measurement.

For example, if the distance from slope stake to center were 28 feet (8.5 m) and the half width of the road were 24 feet (7.3 m), the width of the slope would be 4 feet (1.22 m). If its height were 2 feet (0.61 m), the slope would be 1 on 2.

As a cut deepens or a fill is built, it is usually necessary to check the slope with new stakes. These may be set from the original with a string or carpenters’ level, a rule, and a plumb bob. (See Fig. 8.6.)

Reference (Offset). Stakes on areas to be cut will be dug away, and those inside fill lines will be buried. In shallow cuts, stakes can be left temporarily in islands; and in shallow fills, long stakes may be used which will project from the top unless they are knocked over. Slope stakes are liable to be undercut or buried. Any stakes are apt to be moved by accidents, particularly if the ground is stony or frozen.

It is therefore desirable to set reference stakes well outside the work lines to simplify resetting of the work stakes.

Such stakes may be set on one side or on both sides. They are marked with the station and the distance from the centerline, and may be identified by lettering such as OFF or REF.

If the road strip is narrow or of moderate length, reference stakes on both sides will permit replacement of the working stakes simply by measuring between the offsets.

Where trees or heavy rocks are near the road, nails may be driven into trees, or marks chiseled on rocks, on opposite sides of the road, and a tape stretched between them. The reading at the centerline and ends and the station are noted. With these notes it should be possible to find the center again quickly and accurately.

When a few centerline points can be found from side references, it is often possible to sight in the rest of the missing stakes by eye with reasonable accuracy.

Grades may be marked on offset stakes, or a separate system of benchmarks may be used.

Surveyors often set a line of offset stakes instead of a centerline, leaving the center and other stakes to the contractor’s crew.

Grade. Grade stakes show the distance that the ground surface is above or below a desired elevation or grade. Vertical distances to grade are marked on the stakes in feet, inches, (meters, centimeters) and eighths of inches (centimeters), or in feet (meters), tenths, and hundredths of feet (meters). Figures are preceded by the letter C, for cut, if the ground is high and must be cut or dug away, or by F if it is low and must be filled.

Cuts and fills may be figured from the base of the stake (ground level), from its top, or a line drawn on it. Any basis except ground level is confusing to operators and may cause serious mistakes. However, ground level should be marked in case soil falls away or is added without disturbing the stake.

If the fill is less than the height of the stake, the grade may be marked directly on it with crayon. It is an excellent practice to tie a rag around the mark to make it readily visible to the operator.

Shallow cuts may be marked temporarily with rags a specified distance, such as 1 or 2 feet (0.3 or 0.6 m), above grade, so that operators will not have to dismount to read the figures.

A great number of rags can be made of one old sheet by tearing it in narrow strips. If none is available, unsterilized 1-inch bandage can be bought quite cheaply for the purpose. These cloths are easily dyed.

Original centerline stakes are usually marked to show finish grade, that is, the surface of the pavement, since it is the line that forms the basis for engineers’ calculations. The letter G indicates that reference is to finish grade.

Subgrade is the surface of the native soil after cutting, filling, grading, and compaction. See Fig. 8.7. It is lower than finish grade by the thickness of the pavement and any pavement-base and/or subbase that may be required. The combined thickness of these layers may be almost nothing, if the surfacing is to be oil or cement stabilization of native soil; or 3 or more feet (0.9 or more meters) for very heavy construction.

Since the cut and fill operations are directed toward reaching subgrade, much confusion will be avoided by making all such stake markings refer to subgrade, using the symbol SG.

A misunderstanding as to whether figures on grade stakes are for grade or subgrade can be very expensive.

Centerline stakes are quickly lost in most heavy grading, and the work is checked mostly by slope stakes. However, as sections are brought near the correct subgrade, the center stakes are replaced, and additional lines of markers are used to show the crown or cross slope of the road, and shoulders and gutters.

Stakes at the edge of any grading area should be set back about 6 inches to 1 foot, so that they can serve as a guide without interfering with the work.

It is frequently necessary to remove spilled dirt or level around a stake by hand, so that the operator can read it and see whether the grade is high or low in reference to it.

Blue Tops. The final or fine grading operation is often guided by blue tops. These are usually 2 × 2 inches (5.1 × 5.1 cm) grade stakes driven down until tops are at subgrade. The tops are often colored with blue crayon to make them more visible. Any that are driven below the surface are marked by a light stake alongside.

An expert grader operator can work over blue tops without disturbing them. However, it is necessary for a person on the ground to remove spill piles that hide them, and to expose them if they become buried. Even with this precaution, varying numbers of these stakes are caught by the blade, or rolled over by tires, so that they have to be reset.

To set blue tops, a telescopic level of any type is set up, and its height (HI) figured from a benchmark. The correct rod reading for grade is figured for each stake location from the center or the theoretical grade profile, with allowance for crown or banking where necessary. The rod worker starts the stake and holds the rod on top of it, and is told by the instrument operator how high it is. The rod worker drives the stake the approximate distance, another reading is taken, and the process is repeated until the top is within a few hundredths of feet of grade.

It is common practice to set blue tops 50 feet (15.2 m) apart along the length of the roadway, and at 12- to 15-foot (3.7- to 4.6-m) spacing across it. The 50-foot (15.2-m) spacing sometimes produces a low, wavelike effect, as a grader operator may get the grade perfectly at the stakes but have a tendency to run consistently high or low between them. This may be prevented by reducing spacing to 25 feet (7.6 m).

A grader equipped with automatic blade control can grade widths up to 40 feet (12.2 m) from a single line of blue tops, resulting in substantial savings in grading and staking time.

Care. Operators should be very careful when working around stakes as they are valuable, both as guides to correct work and in relation to replacement cost. In general, an occasional stake can be replaced readily, sometimes without instruments, but a group of them may involve considerable work for surveyors.

Errors. A new set of stakes may not agree in grade or location with the missing ones. This difficulty could arise from an error in the original settings or in replacing them. A satisfactory road can often be built according to an error, but seldom when right and wrong markings are mixed together.

Stakes are accepted as correct until discrepancies are noted. If any stake appears to be out of line, or badly off grade, it may have been moved or disturbed; it may be a baseline or other marker; or a mistake may have been made in placing or marking it.

When possible, the surveying crew should be recalled to check it. If this is not practical, the supervisor may be called upon to use his or her judgment as to whether it should be remeasured. It should not be disturbed, however, unless absolutely necessary, as the suspected stake may be right and others wrong.

Surfaces of bank gravel and other low-cost materials are so frequently required for haul, access, and other work roads that a brief discussion of them is in order.

Bank Gravel. Bank gravel is a natural mixture of pebbles and sand. For road-building purposes, it should contain some fines that will act as a binder. Most deposits contain cobblestones and boulders.

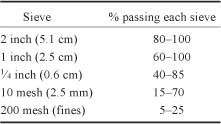

Specifications for road gravel vary greatly. The following spread includes most of them:

In general, gravels with over 10 percent fines are not suitable for roads that will be subjected to freezing. Less than 5 percent may lead to loosening up in hot, dry weather. However, an increase in the percentage of coarse particles will lessen the softness caused by too much binder. Variations in particle shape and material will also affect results considerably. Increase of depth may make up for weakness.

There is no consistent difference between the parts of gravel banks which are above and below the water table. Water levels usually are different at the times when the material is deposited. However, there is very often a difference in color due to above-water oxidation of certain pigments.

Engineers frequently write ideal specifications for gravel that is not obtainable, and contracts are let to use practical grades on a price or availability basis.

Screened Gravel. Specifications may call for screening gravel to be used in the top course or in the full road depth. Maximum size stones may be limited to 1-, 2-, or 4-inch (2.5-, 5.1-, or 10.2-cm) diameters.

Screening is desirable to obtain a smooth, easily worked surface, but it often involves wasting of an excessive amount of stone which could be worked into the road. The resulting loss of strength may affect the road stability, particularly in crossing soft or wet ground.

In general, most oversize stone can be eliminated during the spreading and grading processes at less expense than pit screening, except in patching work.

Crusher Gravel. Bank gravel which is short of pebbles and long on stones may be run through a crusher to reduce the oversize to pebbles. The result may be superior to run of bank of similar size distribution because of the angular shape of the crushed pieces.

Blasted rock which is run through a crusher, without separation of the product, will often produce a material similar in size, distribution, and performance to the best of bank gravels.

Crusher gravel is usually more expensive than run of bank because of the extra processing.

Similar Materials. Any hard material which is broken into particles of the gravel size range may be used in its place. The breakage may be from blasting, rooting or digging, burning, or the effect of heat and cold. Such materials include shale, soft limestone, fine blasted rock of any kind, scoria, red dog, slag, disintegrated granite, cinders, and shell.

Exposures of shale rock are frequently soft enough to be dug by a small shovel without blasting. The broken shale has the appearance of excellent road material, but breaks down readily into mud. Some very expensive road failures have been caused by allowing traffic to use a shale subgrade, then putting a concrete pavement over it after its usefulness had been destroyed.

Soft limestone is the “coral” of the island military bases. It is often dug from the solid by loosening with heavy rippers, or hydraulic dozer blades fitted with teeth. It is easy to drill, but blasting may require as heavy loading as hard rock.

Such limestone is used as it comes from the pit. It should be rolled promptly after placing, as rain can make a soggy mess of it when loose. After compaction, wetting sets it into a hard surface that requires less maintenance than gravel.

Rock from tunnels (muck) is well suited for road fills, as the tight, heavily loaded shots cause fine fragmentation.

Scoria comes from clay beds that have been cooked by the underground burning of adjacent coal seams. It resembles broken brick. Red dog is a similar material that is produced by the burning of piles of waste bituminous coal with a high clay content. Both of these substances may break down into mud under traffic unless protected by some other surfacing.

Disintegrated granite is the standard low-cost road material in many parts of the southwest. It is a rough, coarse sand with excellent compaction and drainage characteristics.

Slag is a by-product of hot refining of metals, which may be poured molten onto dumps where it hardens into rock, or may be cooled and broken up by a water spray.

Cinders are of two kinds—refuse from steam power plants burning lump coal, and aerated rock blown from volcanoes.

Those from power plants are light, easily worked, and free-draining. However, they pound into mud quickly under traffic, and are useful for light-duty footings and emergency surfaces only. They are becoming rare because of power plants changing over to powdered coal and other fuels.

The use of fly ash mixed with lime makes an economical slurry to stabilize a wet base. The fly ash is a by-product of coal-fired power plants. The slurry might have a mix of 4 parts of fly ash with 1 part of lime. It is injected into a depth of up to 4 feet (1.2 m) of base. The fly ash drives out the moisture by filling the voids in the subgrade, and the lime locks the fine-grained soils into a firm, stabilized mass.

Weight of volcanic cinders and ash ranges from 60 to 120 pounds per cubic foot (962 to 1,924 kg/cu.m), compacted. The difference is chiefly in entrained air, the lighter qualities being so full of bubbles that they have little strength.

Most volcanic cinders from 90 pounds (40.9 kg) up make good road material, but care may be needed in selecting them in the pit. They are too resilient for use under rigid pavements, but have good frost resistance because of their air content.

Shells are dredged in enormous quantities from bars along the Gulf of Mexico, and serve locally for the principal low-cost road base and surface.

Preparing Subgrade. The subgrade should be finished as accurately as possible. Ridges or hummocks of subsoil which extend up into the gravel weaken it. If the subgrade is clay or silt, it is good practice to place a blanket of clean, coarse sand to interrupt capillary flow and add to road stability.

The subgrade should be compacted if it is practical to do so. However, temporary gravel roads are often put across wet spots that are not workable. Rock fill or extra depth of gravel is used to make up for lack of subgrade preparation.

The use of soil cement is a means for making a subgrade of granular material with some fines into a stabilized surface. The soil and cement are blended in a portable mixer and conveyed over the surface like any paving material to make the improved subgrade. More about the uses and methods for soil cement will be found in the coverage of Soil and Cement Mixtures at the end of this chapter.

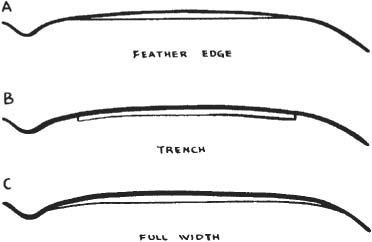

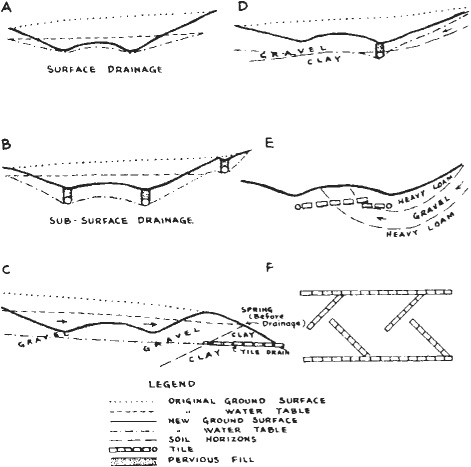

Cross Sections. Three cross sections in common use are shown in Fig. 8.8. The feather-edge construction in (A) calls for a flat subgrade. Its advantage is ease of construction. Disadvantages include poor drainage of water out of the center gravel, deficient strength at the edges, and the necessity of blading fill from gutters or shoulders into the road during maintenance.

The trench section (B) provides center drainage and strength to the outer edge of the gravel. However, frequent bleeder drains through the shoulders may be needed to prevent water from ponding in the edges, soft shoulders may be a hazard in wet weather, and maintenance work will put dirt over the gravel.

FIGURE 8.8 Cross sections of gravel roads.

The full-width surfacing in (C) is the best construction, and is to be recommended wherever the price of gravel is not a controlling factor. It saves the trouble and expense of edging, provides hard shoulders and good drainage throughout the surface, and minimizes maintenance difficulties.

Placing Gravel. On good subgrades, gravel may be very thin, but it is the best practice to use 6 to 8 inches (15.2 to 20.3 cm) compacted depth, and to spread it in two layers. On soft ground, the depth may be 12 inches (30.5 cm) or more. The greater part of deep gravel is usually in the bottom layer.

The best gravel available should be in the top layer. It should not contain many stones larger than 1 inch (2.5 cm), or at the most, 2 inches (5.1 cm) in diameter. It should be coarse enough to resist the action of tire suction, water, and wind, and should have enough binder to hold it in dry weather but not enough to make it sloppy when wet or thawing.

In the bottom, stones up to two-thirds of the layer thickness can be tolerated. Clean sand without stone may serve, if the top layer is thick and well bound enough to hold it together.

Gravel is ordinarily trucked in and spread by a dozer or grader. Occasionally, hauling and spreading can be done by scrapers.

Oversized stone may be bladed to the side, or picked out by hand. Small loose stone may also be taken off, or it may be left to be pushed back into the gravel by the roller.

Oversize stones that remain in the gravel after spreading and smoothing may be pulled out by a rake grader blade or a spike-tooth harrow.

Hand-picked stones may be thrown directly into trucks, or placed alongside the road for later removal. Second handling is easier if they are piled rather than scattered along the edge.

Compaction. Each layer should be thoroughly compacted by pneumatic tired or steel wheel rollers, or by traffic. A heavy steel wheel roller will work back into the gravel all small stone pulled out by spreading work, and it gives a well-finished appearance. See Fig. 8.9.

The edges should be rolled first, and strips should be overlapped. This preserves the crown of the road, which should be at least 4 inches (10.2 cm) for a 20-foot (6.1-m) road.

Proper compaction is impossible if the gravel is entirely dry, and difficult if it is too wet. However, dry gravel can be watered, and wet gravel will usually drain quite quickly. Full compaction on a gravel surface is not as important as in subgrades for pavements.

The use of special equipment available for “Intelligent Compaction” (IC), such as Bomag’s AM steel vibratory roller, has been introduced in North America though it has been used in Europe since the end of the 20th century. The front vibratory roller has a sensor to measure the level of compaction in the soil or surface on which it is operating. When the surface is still soft, according to the specified stiffness, the roller will deliver vertical, up-and-down, impacts on the surface, but when it is close to the specified level, the impacts will be oscillating back and forth to keep from over compaction. This removes the guesswork by the roller operator with the help of an onboard monitor. He or she can set the IC roller between 8 and 20 impacts per foot.

Use of IC rollers could save the billions of dollars cost a year caused by potholed roads, broken earth dams, and blown tires. Cost of the IC roller is probably 20% more than an equivalent non-instrumented roller, but the difference will likely be made up in the first several job uses.

Dust Control. Refer to page 1.3 for an introduction to Dust Control.

Drying out, with resultant dust nuisance and aggravation of washboarding, may be prevented by use of calcium chloride. This is spread by hand shovels or machinery on the surface, and absorbs air moisture that soaks into and dampens the surface.

Recommended application is 1½ pounds per square yard (0.81 kg/sq.m) at the beginning of the dust season, and ½ pound (0.27 kg/sq.m) a month or two later. However, satisfactory results may be obtained with much lighter applications where summers are not entirely dry.

Lignum sulfonate, a by-product of paper manufacture, is used for the same purpose. It is sold in 50 percent solution form in drums, diluted to 10 percent, and spread by watering trucks.

FIGURE 8.9 Subgrade compaction.

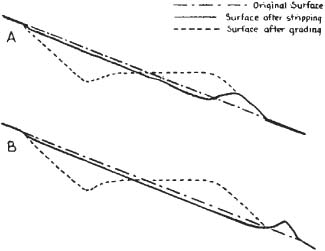

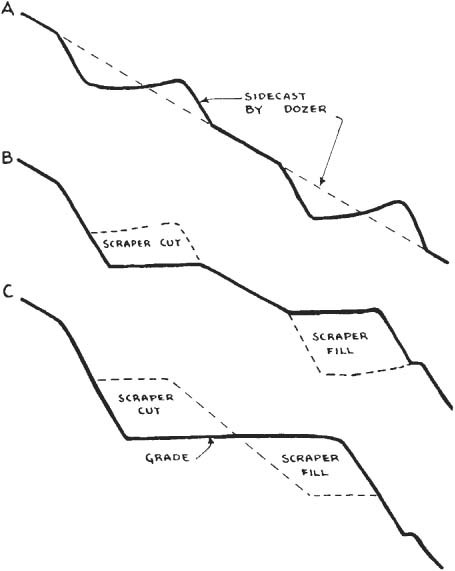

In hilly or mountainous country, roads are largely notched into slopes so that the land rises from one side of the road and dips away on the other. Such a road may be constructed by digging on the high side and using the spoil to build up the low side, as in Fig. 8.10(A); by cutting only, as in (B); or, less commonly, by building a shelf of fill as in (C).

Difficulties of design, excavation, draining, and stabilizing increase rapidly as hill slopes become steeper.

Stripping. Removal of topsoil, stumps, and logs may or may not be required. This matter will be decided by the job specifications, or by the judgment of the engineer or contractor.

In general, stripping of topsoil becomes both more difficult and less important as the slope increases, as deep cuts in steep hills increase the proportion of subsoil in the dirt moved.

When stripping is required, the topsoil can most economically be pushed straight downhill by dozers to form the toe of the fill, as in Fig. 8.11(A), or a windrow below it, as in (B). Such a windrow may be moved by scrapers to a stockpile, or left to be pushed or pulled back up the slope to cover the completed fill.

Loose stumps can be used in pioneer road fills but are unsuitable for highways. Their use in intermediate classes of roads will depend on job conditions, the estimated useful life of the road, and the rate of decay of the stumps.

FIGURE 8.10 Sidehill cut-and-fill cross sections.

Stumps left intact in steep fill areas may serve to prevent the completed fill from sliding downhill as a mass. Specifications often permit leaving them if they will be covered 2 or 3 feet (0.61 or 0.91 m) deep.

If a sidehill is cleared and stripped, the areas to be filled should be plowed or roughened across the slope to reduce the danger of slides.

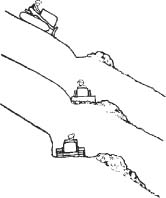

Dozer Digging. If the side slope is gentle, the road shelf may be cut by pushing downhill. Steeper slopes may be started in the same manner and finished by working along the road line, as in Fig. 8.12.

FIGURE 8.11 Topsoil stripping.

FIGURE 8.12 Starting side-hill cut with dozer.

In general, when the upper bank becomes so steep that the dozer cannot back up it without assistance, it is more economical to work from the side. However, if the line of cut is interrupted by rock ribs, which are not to be blasted until the softer parts of the road are made, a dozer with a helper cable may be used to cut benches in each section, at least long enough to permit it to start a sidecasting cut.

Pushing from above, where practical, is faster than sidecasting.

Sidecasting. The standard method of notching a steep sidehill is to sidecast with a dozer. A wide-track, close-coupled dozer with a blade that can be tilted to cut low on the uphill side is most efficient. An angling blade, set with the uphill side low and angled to cast down the hill, is useful, particularly in light soils and shallow cuts. The advanced position of the blade may make it difficult to turn with heavy loads.

Work is started near the upper slope stakes, at a spot naturally or artificially level enough to permit the dozer to work parallel with the road centerline, at the upper edge of the cut. A blade full of earth is dug along the upper cut line, then the blade is lifted and the machine turned downhill at the same time. After dumping, the dozer is backed until parallel to and touching the upper line. Another scoop is dug and swung downhill.

One or several layers may have to be dug in one spot to obtain enough fill to build out the shelf wide enough to carry the dozer. The steeper the slope, the more passes are needed.

The blade is raised sufficiently during the dump to keep the fill higher than the cut so that the notch will slope oppositely to the hill. This keeps the dozer tilted for efficient cutting, allows for compaction of the fill when it is walked on, and also provides the proper cross section for a pioneer road.

When the shelf is wide enough to hold the dozer, further procedures are varied to suit the slope, the soil, the machine, and the operator’s preference. The cut can be lengthened to the end of the slope, then cut in successive layers to grade and width, or it may be developed to full size in a single cut.

Layer cutting involves more rehandling of the dirt, as the loads dropped from the first cut are moved again as it is deepened. However, it is easier for a dozer to make shallow cuts, and the angle blade sidecasts most effectively and puts minimum strain on the tractor when the cut is light.

Deep single cuts make it difficult to trim the bank and may have to be avoided for that reason.

Rock Slopes. If the slope is composed of material that the dozer cannot dig, or that it can dig only with difficulty great enough to reduce production and increase repair costs substantially, the material should be softened ahead of the dozer.

Hard clay and soft rock on moderate slopes may be loosened with a tractor-mounted ripper. But if the rock is hard or the slope is steep, drilling and blasting will probably be necessary for the pioneer cut.

Engineering geologists say slope failures are increasingly common, particularly where heavy blasting takes place during construction, where natural fractures undermine rock face stability, or where the slope has long been exposed to weathering.

If there is a considerable amount of pioneering in rock slopes, best results may be obtained by use of light self-propelled drills on crawler mountings. They can reach and work in very difficult places, and can tow their own compressors except under extreme conditions.

After blasting, dozer sidecasting proceeds in the same manner as in naturally loose soil.

Once the pioneer bench has been established, the character of the rock will determine whether rippers or drills and explosives should be used to loosen it.

Lower levels may utilize dozer sidecasting, backhoe sidecasting, scraper hauling, or shovel and truck hauling, depending on the job plan. If the material is used elsewhere, it is of course desirable to take it away immediately, rather than sidecast it first and then redig and haul it.

Belt Loaders. Once a cut of sufficient width has been made between two areas that are wide and level enough for turning, a belt loader (see Chap. 14) is sometimes used for widening and deepening the cut by sidecasting if the soil is suitable. This machine may work in only one direction. It may be followed on each trip by a dozer grading off the spoil.

Excavator. The front shovel or backhoe can be used instead of a dozer for notching a slope. It can usually do the rough work in one trip, as in Fig. 8.13, but if the bank must be trimmed or the cut is very deep, it may be done in layers.

FIGURE 8.13 Sidehill cut with excavator.

When the width of the cut will allow it, it is good practice to keep the shovel on its floor rather than with one track on the fill. For narrow roads and deep cuts, a small backhoe with a short rear overhang is desirable. The cut should be kept sloped into the bank to keep the weight off the edge.

The fill is kept higher than the cut, particularly if used for footing. Poles or platforms can be used for extra support under both tracks, or under the outside track only.

When the ground is soft or wet, the slope is very steep, soil layers slope with the hillside, or smooth bedrock is just under the cut, the smallest backhoe which can handle the digging should be used. The weight of a large machine, together with the vibration of its work, may cause a slide.

Shovel spoil can most conveniently be sidecast, but also can be loaded into trucks backed up to it. If the road is long and narrow, trucking out all the spoil will be very slow work.

Rock exposures along the road line should be blasted, as a shovel cannot be readily moved up and down steep slopes to bypass them. Use of a shovel is indicated when soil is too soft or rocky for effective dozer work, when cuts are deep, and when spoil is to be used at a distance.

The work is ordinarily left rough to be finished off by a dozer or grader.

Side Cuts. When the notch is to be largely or entirely a cut and the spoil is to be used nearby on the job, dozer sidecasting is used only until the shelf is of ample width to hold the machinery. The material is then pushed or carried along the shelf to the fill area.

Big dozers can be used for pushes up to 200 feet (61 m) on the level, and farther downhill with fair efficiency. When the cut is too narrow to allow machines to pass each other, their production can be stepped up, at some additional cost, by using two or more dozers in relays. One, working from the back of the cut, will push a load partway to the fill and spread it a bit in dumping it. The dozer below it will back over the heap and push it to the end of its beat.

Scrapers. The possibility of using scrapers should be considered. Their use on short runs is discussed later.

Tractor scrapers are impossible to back, so in a narrow road they require an additional road to bring them back from the fill. This may have to go back to the beginning of the hillside, or enter it at some intermediate point. In either case, the scraper’s travel distances are apt to be much greater than those of the bulldozer.

If some spoil is being sidecast and some hauled away, a dozer can work on widening and serve as a pusher.

In the first stages of enlarging a notch, it may be difficult to keep the road sloping into the hill because of scrapers sinking and gouging into the loose fill. This pitch may be preserved or restored by running a grader or an angling dozer close to the wall, and casting out. As the cut widens and enters solid ground for its full width, it will become possible to keep it trimmed on the bottom by proper manipulation of the scrapers.

When a steep hill contains boulders, stumps, or ledge, sidecasting is preferred to hauling, and dozers will probably be both safer and more economical than scrapers if short or medium hauls are required.

Pioneering is done by dozers. If the cuts are in material they can handle, scrapers take over the job. In very rugged terrain, crawler tractors with standard or undersized scrapers are preferred, as they can work on the steepest grades and need minimum turn space. After grades are reduced to 20 percent, self-powered scrapers can take over, if the haul is long enough to justify their use.

For rubber-tire jobs, turnarounds should be kept nearly level, and machines should be driven directly up and directly down the grades. Overhung scrapers are in their most vulnerable position in regard to overturning when turning downhill on a side slope.

Compaction. When a wide road is notched into a hillside by cut-and-fill methods, it may be difficult or impossible to compact the fill if it is sidecast.

FIGURE 8.14 Parallel cut and fill.

If compaction is required, two pioneer notches may be made (Fig. 8.14), at the top and the bottom of the cut. Scrapers are then used to cut the top down and build the bottom up. Compaction of the fill can be handled by rollers following the scrapers, until sufficient width is obtained to permit them to pass the scrapers on the fill, after which they can operate in both directions.

Angle. The angle at which bank slopes will stand in cuts and on fills is an important factor in the cost, and sometimes in the feasibility, of sidehill construction. It is also a limiting factor in the depth of through cuts.

There are two approaches to determining how steep a cut slope may be left. One is the behavior of the same or similar material in cuts and on natural slopes, the other is soil analysis and calculations. They are frequently used in conjunction, a tentative slope being determined by field observation and then checked by engineering research.

Natural slopes are seldom steeper than those that can be used in the same material in a highway cut. The exceptions usually involve groundwater problems or the binding effect of vegetation.

However, natural slopes may not be nearly as steep as the soil qualities permit. In general, a hill whose foot is being vigorously eroded by a fast-flowing stream will approach maximum steepness, and one rising above meadows will tend to have a flatter slope.

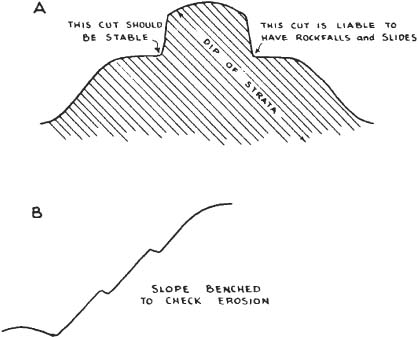

Old cuts give a much more accurate indication. However, before dependence can be placed on them, it would have to be ascertained that the material is actually the same, that it is subject to the same weather conditions (freezing and thawing loosen faces more actively on the shaded side than on the sunny side walls of canyons), to the same dip of strata, as in Fig. 8.15, and that groundwater conditions are similar.

It is desirable to cut back to entirely safe slopes, but this may not be possible. In notching along the side of a mountain, the cut wall must be substantially steeper than the natural slope to avoid excavating tremendous yardages. Also, a fill slope must be steeper than that of the sidehill on which it rests if it is to support a road.

Some soils, such as loess in the midwest and lightly cemented gravels in the southwest, will stand for long periods with almost vertical faces. In general, slopes can be steeper in arid climates than in wet ones.

There are varieties of clay that will stand steeply when first cut, but under influence of surface freezing and thawing, groundwater pressure, and vibration will slump to a 10 percent (1-on-10) grade unless stabilized by topsoiling and planting.

In general, cut slopes range from vertical or even overhanging in rock and 5 on 1 in the most stable soils down to about 1 on 6. It is the engineer’s responsibility to decide where in this wide range the requirements of stability, safety, and the roadway budget can best be compromised.

Slides. The most serious problem associated with deep roadway cuts is that of landslides. These may occur during the work, or at any time after completion. Dangers include loss of life or injury among those building or using the road; destruction of excavators, trucks, cars, and other equipment; and loss of use of the roadway for long periods.

The likelihood of slides increases with height and steepness of banks, but slides are caused by internal conditions.

In rock, the cause is usually a dip of seams or joint structure that provides an inclined slide for the cut layers, as in the right side of Fig. 8.15(A). This structure, when well lubricated by ground-water, may produce anything from a series of minor rockfalls to a 100,000-yard (76,500-cu.m) roadblock.

Much the same effect is produced in unconsolidated soils that have sloping layers of pervious and impervious material, or where a slightly pervious soil mass rests on a sloping base of clay or rock.

The existence of such a condition may be revealed by preliminary borings, or be shown by a line of springs as the top of the impervious layer is excavated. In this case a slide is most likely to occur after heavy rains, when the loose soil is heavy with water, and water movement on the base formation provides both a lubricant and pressure.

Slumping and sliding may also occur in seemingly uniform soil masses, because of water seepage or saturation zones.

The forces involved in deep-seated, large-volume slides are usually too great to be controlled by braces or anchors. However, most can be prevented by cutting to a flatter slope in danger areas, and/or diverting or draining the water that starts them moving.

The likelihood of slides may be a determining factor in selecting a route. However, there are many areas in the world where mountain roadways must be constructed for long distances along steep soil slopes, and where money is not available for engineering investigations or drainage works.

Under such conditions a pioneer road may be cut by a dozer sidecasting down slopes and pushing fills across canyons. The road is widened and improved by cutting down its floor.

When slides occur, the dozers simply cut new road shelves across them, repeating as often as necessary. When fills wash out they are replaced, cutting new slots on the slopes above the road cut where necessary.

In the course of a few years it is usually found that the larger part of the route is reasonably stable, and that other sections stabilize with repeated working. The true problem spots that remain can then receive detailed engineering investigation and corrective measures, at a fraction of the cost of similar work for the entire route.

Checking. A technique is available for testing the stability of slopes with the Seismitron, described briefly at the end of Chap. 9. The instrument’s probe or receiver may be placed on the slope surface, but results are more accurate if it is placed in a drilled hole in the bank. It picks up tiny sounds of ground movement called microseisms, and amplifies them so that they can be heard in earphones.

An increasing or high frequency, say over 25 or 30 microseisms per minute, indicates danger of a slide. A low or decreasing rate is an assurance of stability. It has been found that slopes that failed when wet had given warning of possible failure while they were dry.

Clay, mud, or fine sand may not produce warning noises that can be recognized. Most other formations do.

Stabilization. When the bank is high, it may be necessary to drill long holes into the toe to prevent water from causing the face to slump. Since this trouble usually occurs in soil that is firm enough to leave in high banks but not hard enough to resist percolating water, augers may be the preferred drilling tool. Perforated metal pipe is inserted in the holes while drilling or immediately afterward.

Long slopes may be benched, as in Fig. 8.15(B), to break the flow of surface water. Each bench has a reverse slope so that it acts as a diversion ditch, with water flowing along the back. A gentle grade spills the water toward one or both ends of the cut.

Benches may also serve to catch falling rock. Their effectiveness for this is increased by a berm of dirt along the outer edge. This construction is particularly useful in banks of cemented gravel, 1 on 1 or steeper, from which surface cobbles are released.

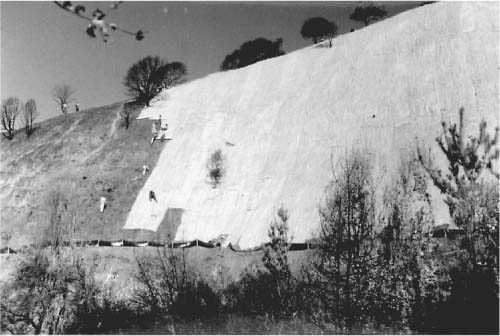

Slopes can be stabilized by growth of vegetation. Most types will provide surface protection, and types with deep or interlocking roots may hold against some internal pressure as well. To help the revegetation after fire had destroyed grass cover on a steep slope, straw and coconut-fiber blankets, as seen in Fig. 8.16, were used.

Artificial protections include supporting walls, drainage systems to intercept or remove ground-water, and fences to catch rolling pieces.

Walls may be of masonry, interlocked concrete, or metal bins. Strength of the last two constructions depends on their being filled with coarse, pervious fill. Any of these must rest on a solid footing that can resist both weight and thrust.

Logs can be used for temporary retaining walls and to catch boulders rolling during work.

Drainage. Freshly worked embankments should be protected against surface water flowing from adjoining ground. In cuts, a diversion ditch may be dug a few feet (meters) back from the upper edge. Unless its gradient is gentle, its bottom may need protection to prevent it from developing into a gully that would damage land below it and eventually break out through the bank.

FIGURE 8.16 Revegetation on a steep slope. (Courtesy of North American Green.)

Such protection may include establishment of a strong sod, construction of a series of check dams, paving with resistant materials, diversion of some of the natural drainage at higher points, or use of discharge flumes down the slope.

If the slope is threatened by softening or washing by groundwater, subdrainage may be required also. Land tile may be laid under the surface channel if its floor is impervious enough not to allow excessive surface water to enter the tile. Underdrainage may be required in the gutter at the foot of the slope, and in or behind wet spots in the slope to catch the seepage.

In areas of rapid runoff, a roadway may be protected along its entire uphill side by a system of diversion ditches that channel all drainage into culverts or access dips. For economic reasons this type of work is limited to diggable soils on slopes that are accessible to machinery.

Fills usually have less drainage across them, but because they are not as well bonded together, they are more subject to surface erosion than cuts. Water may flow onto them from the road and from slopes above the road. They can be protected by berms along the outer edge of the road shoulders, which will prevent water from going down the side of the fill, except at points protected by pipes, flumes, or pavement.

Fills which are built on sidehills have a tendency to slide along the old surface, unless it is well roughened. Leaving of stumps and boulders, roughening by plowing, and placing of subdrains to stop seepage of water along the joint are common methods of reducing this danger.

Any soil, whether original bank or fill, which rests on smooth, steep rock slopes is liable to slide. The most important step in preventing slippage is to divert groundwater moving down the surface of the rock.

Grading. Steep side slopes should be finish-graded as they are made, as it may be difficult and dangerous to work them afterward. But if it becomes necessary, a wide-track dozer may work a long slope in strips, from the top down or diagonally.

Horizontal trimming by use of graders or dozers on steep side slopes may be made safer by cabling to another machine moving parallel to it on the top of the bank. Two cables are used, attached to the front and rear of the lower machine.

It is not safe to operate unsupported heavy equipment along slopes that contain rocks, soft spots, or frozen ground.

Topsoiling. The best protection for a dirt slope is a good cover of vegetation. Grass, weeds, bushes, and trees are all effective controllers of erosion. See Fig. 8.16. The type selected will depend on the locality, soil, and season.

On most jobs, it is necessary to place a layer of topsoil over the fill or exposed earth in order to get a good growth. Occasionally plants will grow well enough on raw earth, or with the aid of some lime or fertilizer.

Deep topsoil is favorable to growth, but it may discourage plants from rooting into the subsoil, and absorb too much water so that it will slide off during rains. For this reason, and for economy, topsoiling of steep slopes is usually limited to a depth of 2 to 4 inches (5.1 to 10.2 cm).

The fill surface should be roughened so as to bond with the topsoil. A sheepsfoot or tamping roller is one of the best tools for accomplishing this. If the slope cannot be worked, the roller may be operated by a dragline at the top. The drag cable is used to pull the roller up and to let it down, and the walking of the shovel moves it along the slope.

Topsoil may be pushed up a slope from stockpiles at the bottom, pushed down it from piles trucked to the top, or distributed over the surface by a clamshell working from either top or bottom, and the resulting piles shoveled or raked out by hand.

The Gradall is an excellent tool for final shaping of the subsoil and spreading topsoil on any area it can reach.

Freshly spread topsoil gullies readily and needs protection on slopes. A thin coat of sprayed asphalt emulsion will carry off rain, and still allow grass to grow through it.

A layer of hay or straw may be mixed into topsoil by a tamping roller to hold it. The hay should be well cured, as rapid decay would make its useful life too short. It is apt to absorb so much nitrogen from the soil as to interfere with growth of seedlings. Use of barn straw that contains some manure, or adding nitrogen fertilizer, cures this difficulty.

Some hay and straw contain enough grass and weed seeds to establish a good cover. Other types are deficient and require that the ground be seeded. Seed can be mixed with water and sprayed onto slopes.

On small areas, topsoil may be held by adding straw, and holding it with chicken wire firmly pegged down. Horizontal wood slats are sometimes used. Placing and tamping cut sod in drainageways, in horizontal strips on slopes, or on the whole surface are very effective, but the cost is high.

Rock Faces. Rock cuts can be left with very steep or vertical faces, and occasionally are allowed to overhang. Such faces usually cause a hazard of rockfalls to the roadway, but the expense of cutting rock back to completely safe slopes can seldom be justified.

Some rock formations tend to break up into gravel or small stones at the face because of temperature changes, and will at times subject the road to an almost continuous bombardment. Such faces should be cut back sufficiently to permit a wall or fence to be put beside the road, with space behind to catch falling stones.

More massive cliffs may present the danger of occasional falls of larger rocks or of whole sections. These may be checked in the danger season by a worker with a bar, supported by a rope held at the top. Loose pieces can be pried out.

Long expansion bolts, similar to those used to secure tunnel roofs, can be placed to fasten a whole slope into a solid and safe unit. They are particularly efficient in shale beds parallel to the slope.

Vegetation tends to break up rock faces, so artificial planting should not be attempted.

A through cut has a high wall on each side, as shown in Fig. 8.17, so that little or no material can be excavated by sidecasting.

If it is on a sidehill, one edge will be higher than the other. The part of the cut which is above the low wall is actually a sidehill cut, and may be handled as one or as a through cut.

FIGURE 8.17 Cross section of scraper cut. (Courtesy of U.S. Army Engineers.)

Through cuts are seldom used in building pioneer roads, except where borrow is needed to cross a ravine. When roads are narrow, and the sharpness of curves is not an important consideration, sidehill work is faster and less expensive.

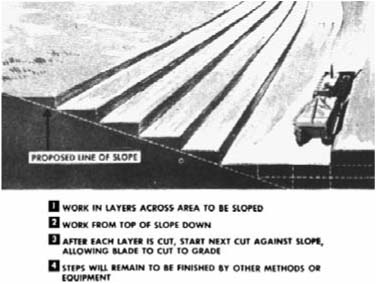

Scrapers, which are described in Chap. 17, are the standard excavator for alternating cuts and fills, where the soil is soft or fine enough for them to work, or can be made so by rippers and explosives, and where the haul is too long for dozers.

Preparation. The first requirement is to smooth over the cut and the fill areas so that scrapers can work them. This is usually a dozer job. The ground is cleared of vegetation and boulders, holes and gullies are broken in and ramped over, sharp ridges beveled off, side slopes notched, and turning places graded off.

It is not absolutely necessary to prepare the whole area in order to have the scrapers move in. Their work can start on the high part of the cut and the low part of the fill, while the dozers are clearing and smoothing the balance of the area.

If the cut has a high side, it is cut to a passable driveway by straight pushing or sidecasting. The bottom of this cut is sloped oppositely to the hill.

If the hill is high in the center of the cut, the hump is graded off sufficiently to afford good footing for scrapers.

It is sometimes economical to make small fills in areas which are to be lowered, and small cuts under future fills in order to smooth out working areas quickly.

When a dozer is not available, a scraper can smooth moderately rough ground by driving through it with the knife held low enough to cut off the bumps and high spots. If the tailgate is held near dumped position, it will act as a dozer blade.

Scraper work on side slopes is simplified by first cutting a shelf with a dozer. If no dozer is available, the scraper can be taken uphill to the start of the cut, the blade dropped, and the scraper turned to dig along the upper cut line. The turn will cause the edge to cut most deeply on the uphill side, and if done repeatedly, will level the digging area, or slope it oppositely from the hill.

Cutting Ridgetops. If the slope up from the fill is too steep for the scraper to climb, it may be broken down into a ramp by dozers, or the cut made with an excavator.

If the slope away from the fill is too steep for scrapers, the top can be lowered by the combined work of scrapers and dozers, as shown in Fig. 8.18. Full-trailer scrapers will dig across the cut as they turn, as in (A). Semitrailers can be backed up to the edge, as in (C), and if a snatch tractor is available, can be backed over it. Digging is then done straight toward the fill.

The undug lip left by the first method is pushed over the edge by a dozer, as in (B). This filling, and the cutting into the slope, will extend the floor and allow scrapers to work farther back.

Eventually the bank will be lowered sufficiently to make it practical to break it down with dozers (D), so that scrapers can go through to dump on the far side, or turn to continue hauling in the original direction.

Shaping. The outer edges of the slope should be determined before starting work so that steep banks may be cut to final grade from the first. They are taken down in a series of steps. If the slope is 1 on 3, and the scrapers are taking 6-inch (15.2-cm) slices, each new level cut should be 18 inches (45.7 cm) farther from the bank than the previous one, as shown in Fig. 8.19.

The slope should be checked frequently by engineers for correctness, and trimmed off by a grader working on the floor of the cut, as it may become very difficult to reshape when the floor has been cut too far down.

The floor of the cut should slope down toward the edges. This slope may be originally established by an angle dozer or a grader, after which it will tend to perpetuate itself, as the weight of the machine will be greater on the down side so that it will tend to cut low there. If the slope becomes too great, the upper part may be readily planed off.

FIGURE 8.18 Breaking down steep slope.

Machinery may not be available to shape the original surface, or the crown may be lost because of oppositely sloping strata or by careless operation. A scraper can cut a crown by taking advantage of the fact that the oscillating tractor part does not affect the side-to-side tilt of the knife, which is determined almost entirely by the rear axle. A gouge taken heading up a slope can be used to tilt the rear axle so that the knife can cut on the uphill side when turned along the slope. See Fig. 8.20.

FIGURE 8.19 Cutting slopes with scraper. (Courtesy of U.S. Army Engineers.)

FIGURE 8.20 Scraper pioneering a sidehill cut.

Whenever possible, the cut should be arranged for digging downhill and toward the fill. The first factor is usually more important. The grade of the cut is most important when it is or can be made steep, and when power and traction are small in proportion to the size of load desired.

To facilitate rapid movement and easy loading, it is important to keep the pit from getting too rough or ridged.

Hard Digging. Scrapers can penetrate fairly hard soils, as the cutting edge is sharp and held at an effective angle. The machine cannot be overbalanced by suction, as the knife is carried between the axles, but a plastic soil may pull the edge a few inches deeper than intended by flexing the tires or causing them to sink.

There are hardpans and rocky soils which the knife will not cut and many others which can be dug only by the expenditure of so much power in penetrating that little force is left for the loading. In such cases, the use of rippers ahead of the scrapers is advisable. Single or widely spaced teeth give best results, as coarsely broken ground is usually easier to load than that which is reduced to very fine pieces or pulverized.

In hard digging, a straddle loading se quence is often helpful. Parallel cuts are made, leaving a ridge between which is narrower than the bowl, as shown in Fig. 8.21. The ridge is then taken out on a third pass, and it will be found that the digging resistance is more nearly in proportion to the shallow cuts at each side than to the deep one under the ridge.

FIGURE 8.21 Scraper straddle loading. (Courtesy of U.S. Army Engineers.)

This method should be used with caution near the edges of cuts as it may destroy the crown.