19

Outline of Wine Production

19.1 Introduction

Wine production (winemaking) encompasses the techniques and technologies used in the transformation of grapes into wines of a target style, of which there are many. This primarily involves vinification (alcoholic fermentation) – the conversion of grape sugars into alcohol by yeast – but is accompanied by a variety of other important changes due to extraction and microbial metabolism of a multitude of other grape components. A secondary, malolactic fermentation (MLF), which can occur simultaneously with primary fermentation or sequentially, is also promoted for some wine styles. Furthermore, production techniques differ depending on whether white or red grapes are used and the type of wine being produced (Table 19.1).

Table 19.1 Classification of major wine styles found throughout the world. Adapted from Reference [1]

| Description | Color | Residual sugar (g/L) | Alcohol (% v/v) | Examples | |

| White wines | |||||

| Still | Dry | Pale straw to gold | <9 | 8 to 14.5 | Riesling, Chardonnay, Semillon, Sauvignon Blanc, Colombard, Grüner Veltliner, Trebbiano, Chenin Blanc |

| Sweet | Light yellow to gold | 9 to 30 (semi‐sweet) | Riesling, Gerwurztraminer, Semillon | ||

| 30 to 200 (sweet) | Riesling, Ice wines, Sauternes, Tokay | ||||

| Sparkling | Dry to semi‐sweet | Pale straw to amber (pink to light red for rosé wines) | 0 to 50 | Champagne, Chardonnay/Pinot Noir/Pinot Meuniera, Riesling, Sauvignon Blanc, Cava, Prosecco | |

| Fortified | Dry | Pale straw to amber | 0 to 30 | 15 to 20.5 | Fino and Amontillado Sherries |

| Sweet | 100 to 300 | Oloroso and Pedro Ximénezb Sherries, Topaque | |||

| Red wines | |||||

| Still | Dry | Dark red to red/brown | <7.5 | 8 to 14.5 | Grenache, Merlot, Cabernet Sauvignon, Tempranillo, Zinfandel, Sangiovese, Malbec, Pinot Noir, Shiraz |

| Sparkling | Semi‐sweet | 7.5 to 30 | Pinot Noir, Shiraz, Cabernet Sauvignon | ||

| Fortified | Sweet | Red/gold to deep brown | 100 to 300 | 18 to 22 | Ruby, Tawny and Vintage Ports, Brown Muscat |

a Of these classic Champagne grape varieties, the first two tend to be used more frequently in sparkling wines.

b Pedro Ximénez (PX) can be very sweet and may contain up to 450 g/L of residual sugar.

Certain specialty wine styles with unique production steps exist. Notably, sparkling wine involves a secondary alcoholic fermentation stage, or the addition of CO2 under pressure, to introduce the carbonation (fizz) associated with this category of wine. Other common specialty wines are the fortified wines, which have grape‐derived ethanol added either during the primary fermentation phase (which arrests fermentation) or once dry, thereby enhancing the final alcohol content.

Finally, winemaking does not end after fermentation – a range of operations are used to clarify, stabilize, mature, age, and package the wine. This chapter offers an overview of wine production and links to later chapters, which detail the processes and chemical changes that occur at various stages during winemaking.

19.2 Basic workflow

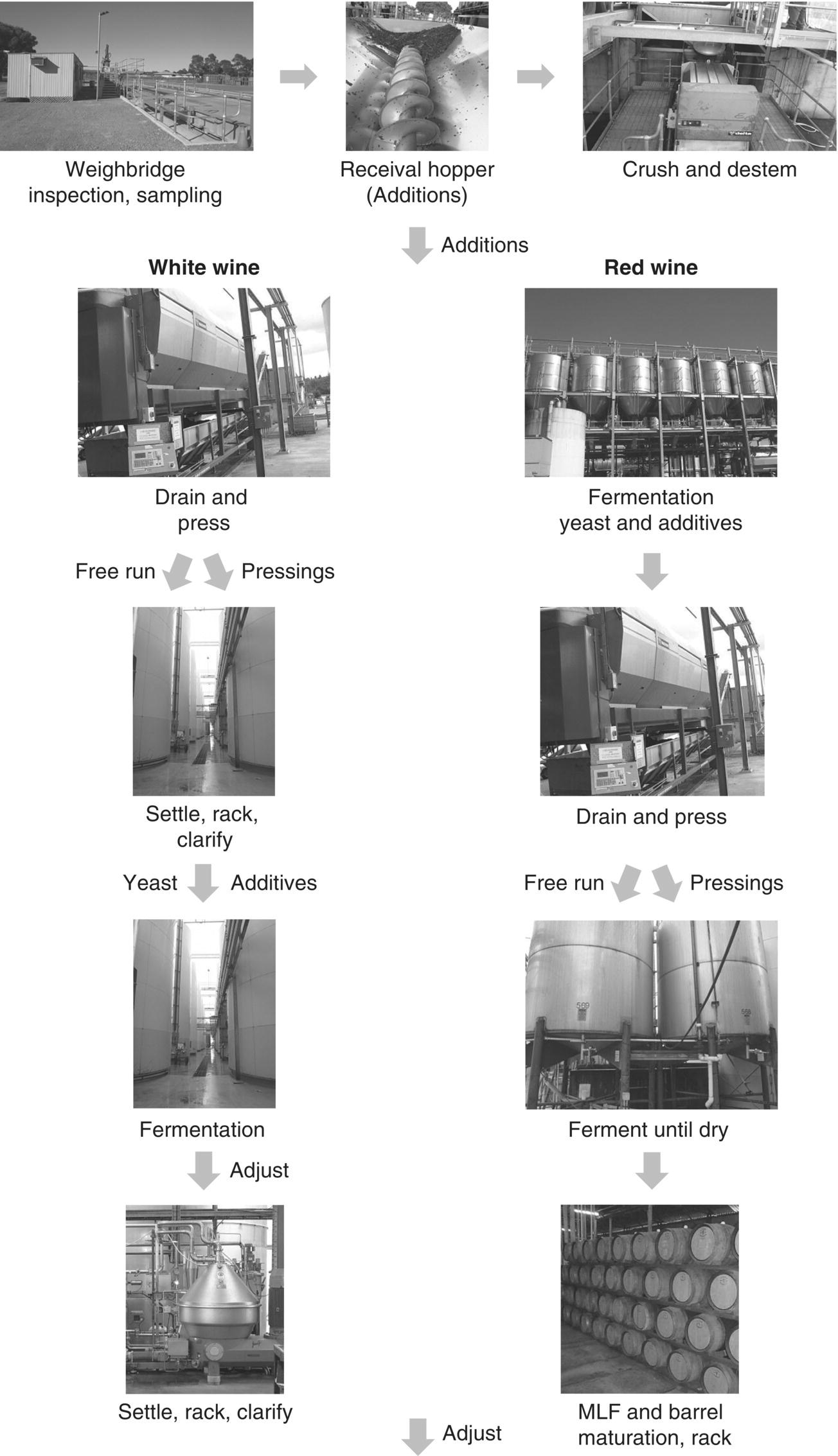

The basic steps for winemaking are outlined in Figures 19.1 and 19.2 for white and red wines. The fundamental differences between the typical production of white and red wines can be briefly summarized as follows:

- White grapes are crushed/destemmed and pressed to juice and do not typically spend much time in contact with grape solids (i.e., there is no maceration step).

- Red grapes are crushed/destemmed and the must (juice and grape solids) undergoes maceration and fermentation in the presence of skins, seeds and juice (Chapter 21).

- As a result of the above, extraction of polyphenols is mostly avoided with white wines and encouraged in red wine production.

- Cooler temperatures are used for white fermentations to control aroma characteristics and warmer temperatures enhance extraction of solids in reds.

- White fermentations mostly exclude oxygen, whereas some aeration is encouraged during red winemaking through the maceration techniques employed.

- The majority of red wines undergo malolactic fermentation (MLF) and incorporation of oak in contrast to white wines, where only certain styles experience these treatments.

- Red wines undergo a period of maturation in tanks or oak barrels to promote stabilization of color and modification of mouthfeel.

- White wines can be released much earlier than red wines due to typically greater need for maturation with reds.

Figure 19.1 Indicative flowchart for commercial winery fermentation operations. Additions may include tartaric acid, tannin, sugar, SO2, and enzymes. Additives mostly include nutrients in the form of diammoniun phosphate, and adjustments mainly involve the use of tartaric acid, carbonate salts, and SO2. Additional clarification steps beyond those shown are likely, and incorporation of oak (and MLF in some white wines) can occur in a number of ways and at different stages of the process. The remainder of the operations is outlined in Figure 19.2

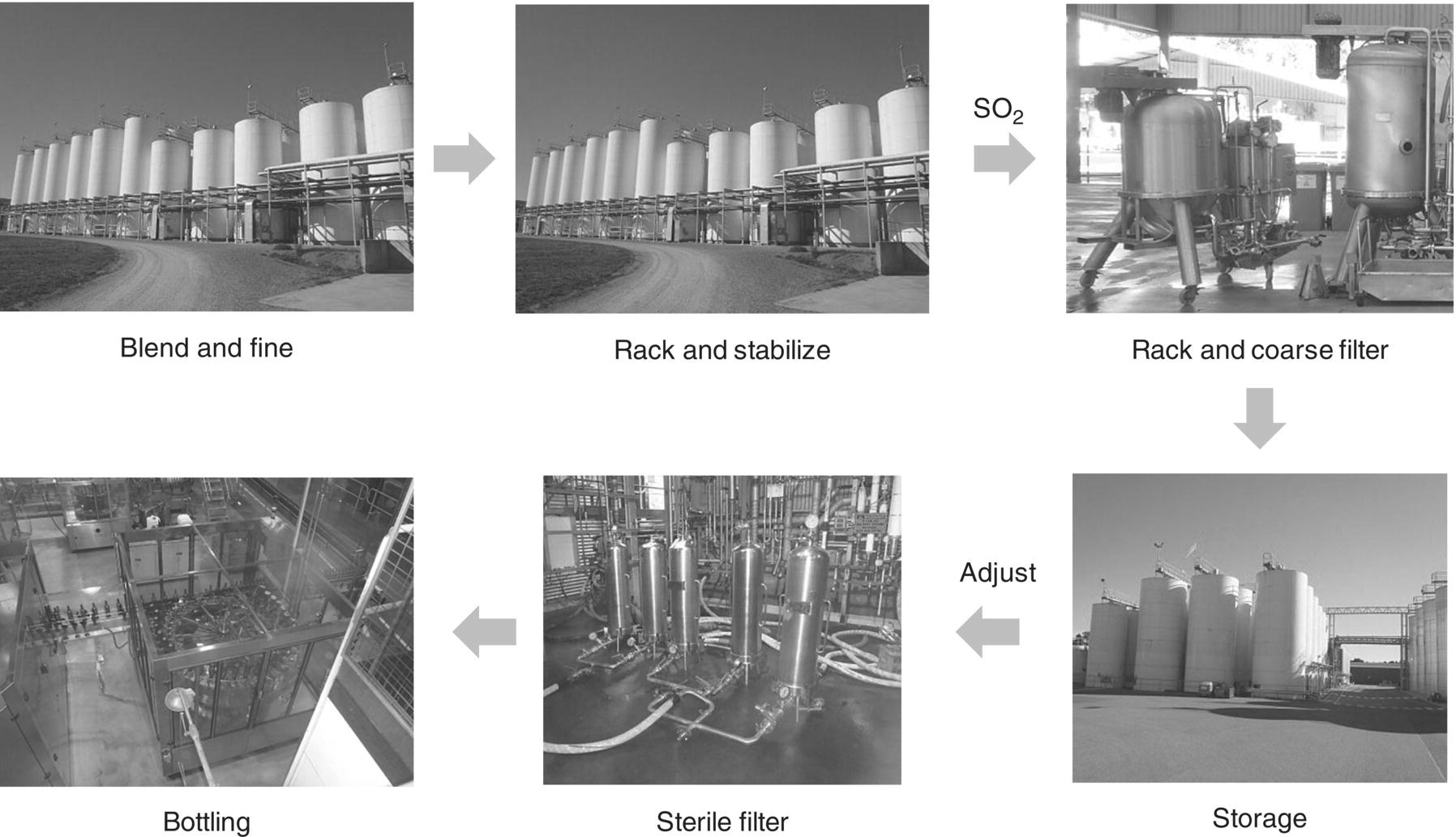

Figure 19.2 Indicative flowchart for commercial winery operations after fermentation is complete. Adjustments primarily involve the use of tartaric acid, carbonate salts, and SO2

Additional variations to the basic process occur for mainstream production of rosé, sparkling, and fortified wines, as detailed below and elsewhere (for example, see References [2], [3], and [4]). More specific details of techniques employed for red winemaking are outlined in Chapter 21.

In most wineries, a range of parameters are monitored during winemaking to ensure a level of quality control over the production process. The main measurements relate to temperature, pH, titratable acidity, residual sugars, fermentation kinetics, assimilable nitrogen, alcohol, free and bound SO2, malic acid, and volatile acidity. Comprehensive information on these tests and many others is provided in a variety of separate sources (for example, see References [5] to [9]).

19.3 Processes involved

Once grapes are harvested and transported to the winery, various processes are set in motion to transform those grapes into wine. The processes involve an array of equipment as depicted in Figures 19.1 and 19.2; the general equipment is further outlined in Table 19.2. Because a range of tanks and fermentation vessels are used in the production of different wines throughout the world, these are described in more detail in Section 19.4.

Table 19.2 Winemaking processes, description of objectives being achieved, and the equipment required for each processing stage

| Process | Objectives | Typical Equipment |

| Grape weighing, inspection and sampling | Weigh and assess grapes (e.g. examine for disease or matter other than grapes), determine basic compositional parameters (e.g. pH, TA, TSS, color) and stream fruit for a specific wine style/quality grade | Weighbridge, automated grape sampler/analyzer (e.g. Maselli Misure) or basic lab equipment (e.g., refractometer, pH meter, autotitrator, spectrophotometer, thermometer) |

| Grapes tipped into hopper | Transfer grapes from picking bins so processing can begin | Crane or forklift, receival hopper with auger to move grapes to next stage |

| Crushing and destemming grapesa | Remove grapes from stems and crush to provide must (i.e., grape juice and solids) | Crusher/destemmer, dosing pump to include additives, heat exchanger to alter temperature of must |

| Pressing to produce free run and pressed fractionsb | Extract and separate liquid (juice or wine) from grape solids (marc) | Screens or drainers, press (different kinds available) |

| Clarifying white juice | Promote precipitation and eliminate the majority of suspended solids (e.g., proteins, polysaccharides, grape debris, microflora, fatty acids) from the juice | Tanks (for cold settling) and clarification equipment (e.g., centrifuge, filter units) |

| Fermentationb | Conversion of grape sugars to alcohol (or malic to lactic acid for MLF) | Fermentation vessels |

| Maturation of red wine | Stabilize color and promote changes to mouthfeel | Tanks or barrels, possibly a microoxygenation system |

| Settling and racking | Remove yeast lees and other precipitated matter (e.g. phosphates, tartrates, colloids) | Tanks and clarification equipment (e.g., centrifuge, filter units)c |

| Blending and fining | Produce a desired wine style from different components and moderate sensory properties (e.g. removal of phenolics) | Tanks and clarification equipment |

| Stabilization | Achieve heat and cold stability of wine | Tanks or specialized equipment for tartrate stabilization (e.g., to perform electrodialysis, ion exchange, continuous processes) |

| Coarse filtration | Decrease turbidity of wine | Filter units |

| Storage | Maintain wine in good condition prior to bottling | Tanks |

| Sterile filteration and bottling | Produce a clear and microbiologically stable product in its package | Filter units, bottling line |

a Grapes may be “whole bunch” pressed for some wine styles, eliminating this step.

b The order of these processes depends on whether red or white wine is being produced. The order presented here (i.e., pressing before fermentation) is for white wine production; fermentation would precede pressing for red wine production.

c This stage may include further clarification operations beyond settling in tanks, especially for white wine.

In contrast to red wines, most white wines and rosé wines are fermented in the absence of grape solids (skins, seeds). Prior to fermentation, the juice is pressed and separated from the rest of the grape material. Immediately following pressing, the juice is turbid due to the presence of pulp, pieces of skin, and other suspended insoluble materials. Production of high‐quality white wine requires the juice to be clarified prior to fermentation – clarified juices produce wines with higher concentrations of “fruity” esters and lower concentrations of higher alcohols and low molecular weight sulfur compounds, among other effects (Chapters 22.2 to 22.4). However, excessive clarification will result in sluggish or stuck fermentations, and winemakers will typically target a small proportion of suspended solids (e.g., 0.5% by volume) to ensure a good balance of fermentation characteristics. Clarification can be achieved through several means:

- Most commonly, clarification is achieved through cold settling, where juice is held cold (e.g., 5 °C) in a tank for a period of time. This process is simple and relies on the greater density of most insoluble solids (polysaccharides, proteins, polyphenols) as compared to the juice. Once a sufficient degree of clarification occurs, the juice can be racked to a separate tank. This process can be enhanced through the use of pectic enzymes, which break down cell wall polysaccharides and increase their settling rate (Chapter 21).

- Centrifugation achieves similar results to cold settling but in far less time, although it requires more equipment.

- Flotation involves addition of gelatin (Chapter 26.2) to turbid juice to flocculate with the polysaccharide and polyphenolic constituents. The gelatin‐containing precipitate is then floated to the surface after addition of gas and slowly allowing the pressure to release in a tank – a result similar to the formation of a proteinaceous “scum” on the surface of a soup pot when making stock. The clear juice can then be racked from the bottom of the tank.

- Filtration may also be employed, typically using high capacity DE‐based depth filters (Chapter 26.3).

- Following cold settling, juice may also be recovered from tank bottoms by applying similar clarification treatments, but this juice is often of lower quality.

19.4 Tanks and fermenters

Tank sizes and the types of fermenters used for wine production vary depending on the size of the winery (i.e., tonnages crushed) and styles of wine being produced (e.g., red, white, or sparkling wine). Tanks in modern wineries are typically made of stainless steel and are used to store juice or wine for purposes such as cold settling, stabilizing, maturing, blending, and while awaiting bottling. Tanks vary in their capacity and range from several hundred liters (including variable volume designs) to hundreds of kiloliters; some very large wineries have tanks that can hold a million liters or more. Smaller tanks may be housed indoors but bigger wineries will have large outdoor “tank farms” (e.g., see images in Figure 19.2) consisting of insulated and refrigerated tanks to maintain temperatures. Different size tanks are used not only to separate different batches of wine but also so they can be kept full to minimize ullage (i.e., the headspace above the liquid) and limit contact with air, which decreases the incidence of oxidation or spoilage issues (Chapters 22.5 and 24). Inert gas coverage (commonly CO2 or N2, or their combinations3) is used to exclude air when transferring wine and during storage, and solid CO2 (dry ice) powder may be employed to displace air in the headspace after opening the lid of a tank.

Oak barrels and vats, being the traditional forms of a “tank”, are still commonly used for storage during maturation, primarily to incorporate oak flavor components (Chapters 12 and 25), but also to allow a slow ingress of oxygen that facilitates the maturation and stabilization process for red wines (Chapters 24 and 25). In contrast to seeking a flavor contribution from oak, certain spirits and most fortified wines are aged in old oak vessels for many years to allow for concentration of components and slow chemical reactions, and the promotion of oxidative changes in some cases. In recent years, food‐grade polyethylene has been used in the construction of smaller tanks for storage or maturation; the plastic allows for a slow ingress of air in order to emulate the effect obtained with oak barrels. Desirable oak components can be incorporated to an extent with the use of oak alternatives such as chips, staves, and powders (Chapter 27), and considering the cost of purchasing and maintaining oak barrels, this approach may be more suitable for some wineries.

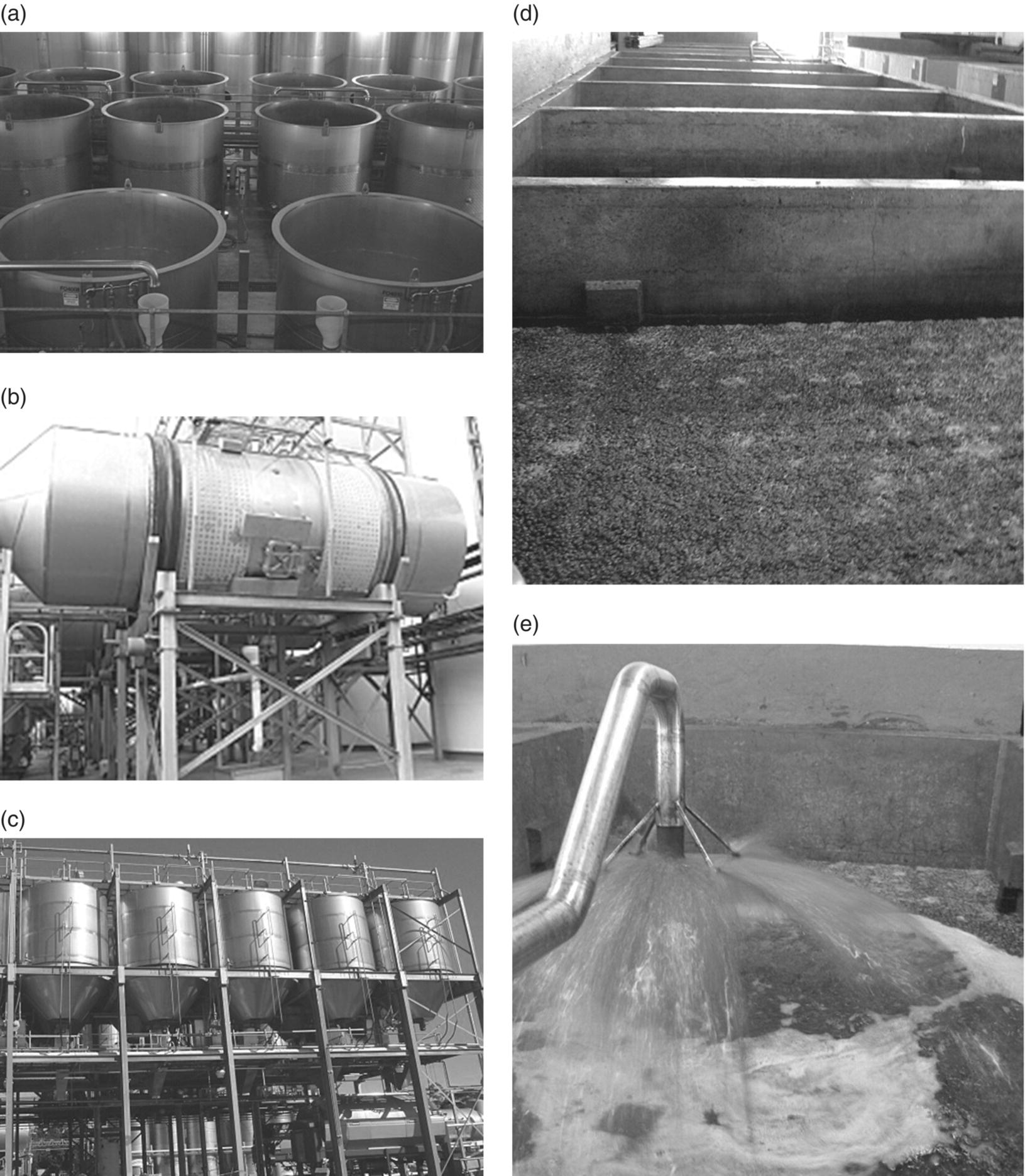

Fermentation vessels may be the same as the tanks used for storage, especially with white table wine production, or may be more specific, as is the case for tanks used for maceration during red winemaking (Figure 19.3). In this case, there is a need to promote extraction of color and tannins from the cap (the grape skins that rise to the top during fermentation) through different vessel designs. This can be achieved in open (e.g., Figure 19.3a and d) or rotary (e.g., Figure 19.3b) fermenters, where the cap can be submerged and macerated through periodic mechanical action. Alternatively, closed static fermenters (e.g., Figure 19.3c) are used to obtain a similar effect, as these allow for wetting of the cap via mechanisms that pump fermenting juice over the top (i.e., pump over as depicted for an open fermenter in Figure 19.3e) at certain intervals to facilitate extraction. In most cases the operations can be automated and winemakers may use a combination of cap management techniques depending on the fermenter in use. With red wine production there is also a need to remove the grape solids (marc or pomace) once the maceration stage is complete and the tank is drained, and design features assist with this (e.g., large door at base, sweeping arm, open top, ability to tilt or lift fermenter). Additionally, it is necessary to control fermentation temperatures by applying heating or cooling, either to the building, directly to the tank, or via a heat exchanger.

Figure 19.3 Examples of red wine fermentation showing (a) 5 tonne open fermenters, which can be lifted by a crane and taken to a press, (b) 60 tonne rotary fermenter, (c) 50 tonne closed static sweeping arm Potter (SWAP) fermenters, (d) 6 tonne concrete open fermenters with cap submerged using “heading down” boards, and (e) a “pump over” to wet the cap in an open fermenter

Fermenters as described above are often made from stainless steel and can be quite large (e.g., capable of holding 50 t/50 kL or more), but oak is still very commonly used in the construction of (smaller) vessels for fermentation, and other materials such as concrete or stone (e.g., a square open fermenter usually sealed with wax or lined in some way, or other fermenters such as egg‐ or oblong‐shaped), plastic (e.g., cube or egg‐shaped polyethylene as mentioned above), or terracotta (e.g., amphora often lined with beeswax) also feature in some wineries, but are necessarily much smaller than stainless steel tanks. Furthermore, certain types of sparkling wine production call for the use of pressure vessels after alcoholic fermentation to incorporate or maintain a high level of CO2 in the product, whereas in other cases the bottle acts as the vessel for the fermentation stage, which imparts the carbonation (see Section 19.6 below).

19.5 Beyond fermentation

During the winemaking process, and particularly post‐fermentation, there are a number of operations that may occur, as depicted in Figures 19.1 and 19.2, and Table 19.2. The major activities are described more thoroughly in other chapters as follows:

- Maceration: Chapter 21

- Aging: Chapter 25

- Cold stabilization: Chapter 26.1

- Fining: Chapter 26.2

- Filtration: Chapter 26.3

19.6 Specialty wines

Certain specialty wines undergo processing steps that lead to distinctive changes in final chemical composition and sensory properties. The two most common specialty wines are sparkling and fortified.

19.6.1 Sparkling wine

As the most widely consumed specialty wine, sparkling wine is produced by addition of yeast and sugar to a dry base wine (most often a blend, known as the cuvée) prior to carrying out a second fermentation in a closed container so that both the ethanol and carbon dioxide are captured and retained (e.g., in a sealed bottle or tank).4

The traditional method for sparkling wine production (méthode champenoise)5 involves the following steps [2]:

- Fruit is harvested early, 16–18 °Brix, and fermented to dryness to make the base wine.

- Base wine is blended to produce a cuvée, and added to bottles along with sugar and yeast, the tirage (liqueur de tirage) – every 4 g/L of sugar yields 1 bar of pressure, and 32 g/L is generally added to generate 8 bar following secondary fermentation.

- The second fermentation occurs in the bottles under crown seal, and there is a period of 1–4 or more years of aging on lees in the same bottle. During this period, yeast will undergo autolysis (Chapter 25).

- The yeast is dislodged from the bottle and collected in the neck of the bottle by riddling (remuage), in which the bottle is rotated in small increments at regular intervals.6

- The wine is chilled and the yeast is removed by freezing and disgorging. In addition to the yeast, a portion of CO2 (accounting for about 2 bar) will also be lost.

- A small amount of sugar is added, the dosage (liqueur d’expedition, may also contain additives such as citric/ascorbic acid, brandy, and SO2), and the bottle is resealed at a pressure of about 6 bar.

Alternative methods to fermentation in the bottle exist. In the Charmat process, the secondary fermentation is conducted in a large pressurized tank prior to bottling. In the transfer process, secondary fermentation occurs in the bottle, but the individual bottles are emptied under pressure into a tank prior to rebottling.

In addition to “prickling” sensations and sour taste imparted by CO2, sparkling wines that undergo long periods of lees aging will have modified wine aroma and flavor due to yeast autolysis, such as an increase in “toasty” aromas. These effects are discussed in more detail in Chapter 25.

19.6.2 Fortified wines

Wines may also be fortified with distilled spirits during production [3] (see Chapter 26.4 for more information on distillation). The addition of spirits can halt fermentation and increases the final alcohol content of the wine (typically, 15–22% v/v at the time of fortification), thereby serving as a preservative. As such, fortified wines are at low risk of microbial spoilage (e.g., due to acetic acid bacteria, Chapter 22.5), even in the presence of oxygen. These wines were historically of great importance because of their ability to be shipped and stored for long periods of time. Fortified wines can be further classified by the timing of spirit addition, which can be:

- Prior to or soon after the beginning of fermentation (Pineau de Charentes, Moscatel de Valencia, Angelica). Early fortification leads to sweet wines with moderately high alcohol, often referred to as mistelles. There is negligible contribution of ethanol from fermentation, low extraction of grape constituents, and little or no production of fermentation‐related aroma compounds. These wines are often aged in old oak casks, as mentioned below.

- Prior to the end of fermentation (Port, Madeira). Known as mutage, this process leads to sweet wines with high alcohol. Since these wines are usually stored in partially filled old oak casks, they typically possess high concentrations of compounds associated with oxidation reactions (Chapter 24). Some styles (e.g., Madeira) will also have high concentrations of sugar degradation products due to high storage temperatures.

- At the end of fermentation (Sherry, Vin Jaune). This process is typically used to produce dry fortified wines. In production of certain styles (such as Fino Sherry) the alcohol content is increased to only ~15% v/v to permit growth of a surface (flor) yeast. This results in high concentrations of biotically formed acetaldehyde via ethanol oxidation, which may in turn react with other components to yield further characteristic compounds like sotolon (Chapter 9). Other styles with higher alcohol concentrations will be fully exposed to air and generate oxidation products abiotically (Chapter 24).

References

- 1. Iland, P., Gago, P., Caillard, A., Dry, P. (2009) A taste of the world of wine, Patrick Iland Wine Promotions, Adelaide, SA, Australia.

- 2. Howe, P. (2003) Sparkling wines, in Fermented beverage production, 2nd edn (eds Lea, A.G.H. and Piggott, J.R.), Kluwer Academic/Plenum Publishers, New York, pp. 139–155.

- 3. Reader, H.P. and Dominguez, M. (2003) Fortified wines: Sherry, Port and Madeira, in Fermented beverage production, 2nd edn (eds Lea, A.G.H. and Piggott, J.R.), Kluwer Academic/Plenum Publishers, New York, pp. 157–194.

- 4. Rankine, B.C. (2004) Winemaking procedures, in Making good wine, Pan Macmillan Australia, Sydney, NSW, Australia, pp. 44–78.

- 5. Iland, P., Bruer, N., Ewart, A., et al. (2004) Monitoring the winemaking process from grapes to wine: techniques and concepts, Patrick Iland Wine Promotions, Adelaide, SA, Australia.

- 6. Iland, P., Bruer, N., Edwards, G., et al. (2004) Chemical analysis of grapes and wine: techniques and concepts, Patrick Iland Wine Promotions, Adelaide, SA, Australia.

- 7. International Organisation of Vine and Wine (2012) Compendium of international methods of wine and must analysis, Vol. 1, OIV, Paris, France.

- 8. International Organisation of Vine and Wine (2012) Compendium of international methods of wine and must analysis, Vol. 2, OIV, Paris, France.

- 9. Zoecklein, B.W., Fugelsang, K.C., Gump, B.H., Nury, F.S. (1995) Wine analysis and production, 1st edn, Chapman and Hall, New York.